This investigation was conducted under the Transport Safety Investigation Act 2003 (Commonwealth) by the Office of Transport Safety Investigations (NSW) on behalf of the ATSB in accordance with the Collaboration Agreement.

Executive summary

What happened

On 6 January 2022, freight train 5446, operated by Southern Shorthaul Railroad (SSR), departed from Narrabri West for Bullock Island at Newcastle, New South Wales. Due to a steep uphill gradient en route, three additional (banking) locomotives were attached to the rear of 5446 at Werris Creek.

Shortly after departure from Werris Creek, the banking locomotives separated from the rear of the train. Although the brakes automatically applied on both the lead portion of 5446 and the separated banking locomotives, the driver of the banking locomotives released this brake application. As a result, after the lead portion of 5446 had stopped, the banking locomotives collided with the rear of 5446. Significant damage to rolling stock resulted from the collision.

What the ATSB found

The cause of the train separation was highly likely due to the knuckle on the bottom operated coupler of the lead banking locomotive remaining unlocked after coupling. A stretch test, which would have identified the unlocked state of the knuckle, was not performed. It was found that the crew member who performed the shunt did not have a full understanding of automatic coupler operation. In addition, it could not be determined that the banking locomotive crew had previously demonstrated a sufficient level of competence in a stretch test procedure, either with SSR or previous operators.

After the separation event, the response taken by the banking locomotive’s driver in relation to the sudden loss of brake pipe pressure was, while inappropriate for the situation, consistent with their training and SSR’s emergency response procedures. These procedures did not differentiate between head end only and banking train operations. The appropriate response during an emergency for these differing operations can be vastly different.

Lastly, it was found that SSR’s risk assessments for this operation were mostly performed by members of the management team. While the team had varying levels of operational experience, consultation with operational staff directly affected by the operation did not occur. This had the potential for risks to be missed during the risk assessment process.

What has been done as a result

In response to the safety issues raised, SSR took safety action to:

- provide train crew with reference materials related to coupler functionality

- defined the process for a ‘stretch test’ after coupling and other shunting terms

- contextualised emergency procedures for banking operations

- further defined the need for adequate consultation during material change.

While not related to a safety issue, both Southern Cross Civil and Rail Training and Pacific National took the opportunity to review and update their training materials in shunting operations, in response to safety factors identified within the report.

Safety message

The competence of rail safety workers is critical to safe railway operations. Where competency assessments are aligned to the Australian Qualifications Framework (AQF), certain standards must be met. These include, in part, that sufficient assessment evidence be collected to ensure a reliable competency decision can be made. In the absence of an alternative and equivalent method, rail transport operators should follow these same principles when delivering enterprise‑based assessments.

Further, during assessment of risk, consultation consisting of effective and meaningful engagement with stakeholders is key to ensuring risks are identified and appropriate controls are implemented. In instances of unique operations, this engagement becomes critical in identifying novel risks which may not be immediately apparent. Particular attention should be given to procedures utilised in past operational environments, to ensure their ongoing appropriateness in these unique operational circumstances.

The occurrence

Arrival at Werris Creek

On 6 January 2022, freight train 5446, operated by Southern Shorthaul Railroad (SSR), departed from Narrabri West (565.750 km),[1] New South Wales for Bullock Island (170.298 km) at Newcastle, New South Wales. The train was powered by three diesel electric locomotives hauling 49 wagons loaded with export wheat.

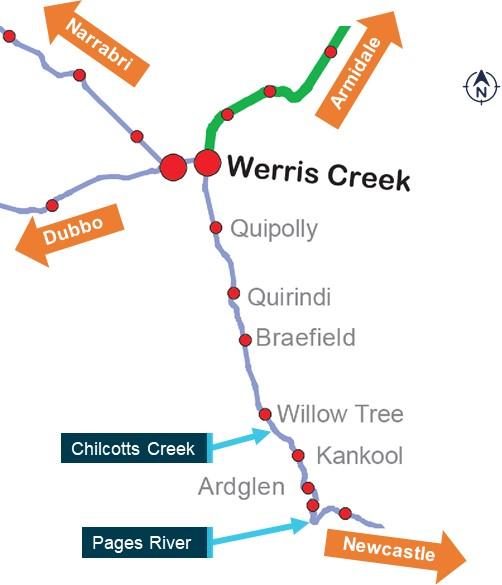

About 0620,[2] train 5446 stopped on the mainline at Werris Creek (410.800 km) clear of the station platform to allow for a crew change and the attachment of three banking locomotives,[3] based at Werris Creek. The banking locomotives were to be attached to the rear of 5446 to provide additional traction power for the heavy uphill grade from Chilcotts Creek (372.300 km) to Ardglen (363.300 km) (see Figure 1).

Source: John Holland, annotated by OTSI

The crew of the banking locomotives consisted of a trainee driver (driving) who signed on at Muswellbrook at 0315, and a mentor driver (supervising), who signed on at Werris Creek at 0445.

At 0623, the network control officer (NCO) cleared the signal to allow the awaiting banking locomotives on the Armidale side of the station platform to proceed onto the rear of 5446 and attach. The trainee driver of the banking locomotives then moved the locomotives towards the rear of 5446, stopping about 20 m short to allow the mentor driver to alight and perform the on-ground coupling duties.

The trainee driver, under radio instruction from the mentor driver, then moved the banking locomotives onto the rear of 5446 and coupled. Closed circuit television (CCTV) showed that the banking locomotives moved slightly away from the rear of 5446 after coupling, with the mentor driver briefly looking away from the train at this time. The locomotive’s data logger confirmed that the banking locomotive’s independent brake[4] was partially applied. The direction controller remained in reverse which meant a stretch test[5] of the couplers was not performed at that time. The CCTV also showed that the weather was fine, with morning daylight conditions.

The mentor driver then coupled the brake pipe hoses between the last wagon of 5446 and the lead banking locomotive (L277) for train braking purposes. The lead crew of 5446 then performed a brake pipe continuity test[6] with the banking locomotive crew, which verified the brakes were continuous and working throughout the train.

At 0640, the lead crew of 5446 was changed. The rear banking locomotive crew remained unchanged.

Departure from Werris Creek

At 0642, train 5446 departed Werris Creek with three locomotives at the front hauling the 49 loaded grain wagons, and three locomotives attached at the rear for banking purposes. The trainee driver and mentor driver were in the banking locomotive at the very rear of the train, facing the track in the opposite direction of travel. Communications between train crew en route (between the lead and banking crews) regarding signal aspects observed at the front and power requirements from the banking locomotives at the rear, was conducted using radio communications on a discrete SSR channel. The driver of the lead locomotive initiated all train braking commands.

As there was an uphill grade for almost 4 km on departure from Werris Creek, both the front and banking locomotives had power applied on departure, with full power (eight notches) selected at both the front and back of the train about one minute after departure.

After about 407.000 km, the gradient peaked in height and changed to a downhill grade, with two short sections of level/near level grade en route to Quipolly (402.000 km). As a result, at 0647 the lead locomotive commenced a reduction in traction power setting, with idle selected at about 406.500 km. The banking locomotives remained temporarily in full power before the trainee driver commenced traction power reductions, which kept the train under compression.

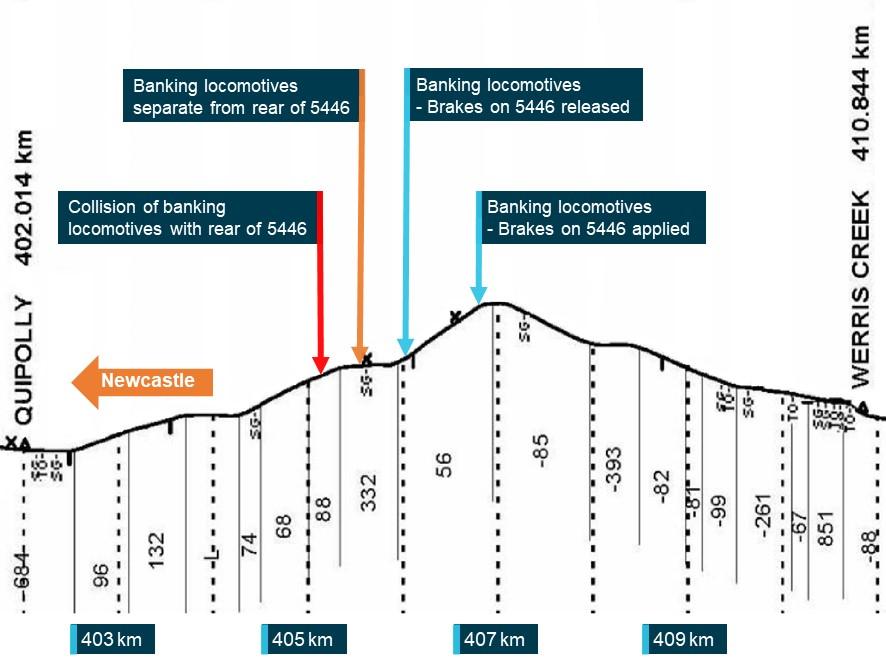

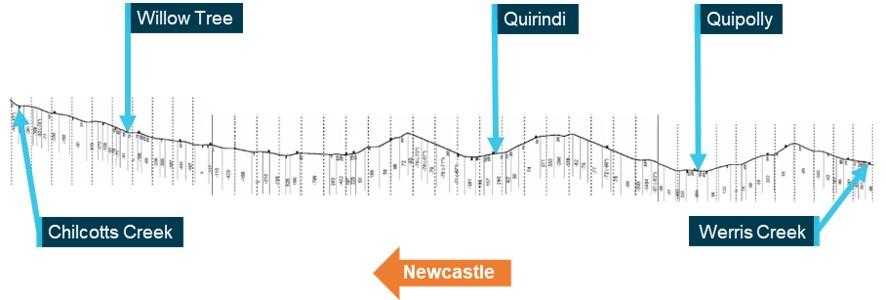

At 0648:31, with the train now on a downhill gradient, the driver of the lead locomotive engaged dynamic braking[7] and made an automatic brake application at 63 km/h. This enabled a test of the effectiveness of the train’s brakes, in preparation for the steep downhill grade from Ardglen to Pages River. This automatic brake application took effect on the banking locomotives 4 seconds later (Figure 2).[8]

Figure 2: Track profile from Werris Creek to Quipolly

Overview of the track gradients on departure from Werris Creek, and coinciding events relating to the banking locomotives on 5446.

Source: ARTC, annotated by OTSI

At 0649:09, with the train’s speed stable at 64 km/h and, coinciding with the banking locomotives tractive power being reduced to a minimum (one notch), the driver of the lead locomotive released the train’s brakes. Seven seconds later, this brake release command took effect on the banking locomotives at the rear of the train.

Separation event

Coinciding with reaching a relatively level piece of track and slowing slightly, at 0649:46 the banking locomotives separated from the rear of train 5446, 7 mins and 5 kms from departure. Most of the train was now on a downhill grade towards Quipolly.

The consequent separation of the brake pipe hose between the banking locomotives and the train resulted in a sudden loss of all brake pipe pressure on the banking locomotives, resulting in a power control switch (PCS)[9] warning light activation and the three banking locomotives’ brakes automatically applying. The trainee driver observed the PCS warning light and advised the mentor driver of the light activation, with both checking their rear-view mirrors for any issues along the length of the train. As the train was on straight track the separation event was not observed. As no issue had been identified, the trainee driver ‘bailed-off’[10] the brake application to avoid flat wheels[11] as per their training. During this time, the speed of the banking locomotives reduced from the 51 km/h at the time of train separation to 26 km/h.

Meanwhile, the driver of the leading portion of 5446 observed that the flowmeter[12] on the lead locomotive was registering an air pressure loss to the brake pipe. Although a high brake pipe pressure was maintained, the loss of some brake pipe pressure resulted in the brakes beginning to slowly apply on the wagons, and the train to gradually reduce speed. The driver of the leading portion of the train believed there had been a false activation of the vigilance penalty[13] on one of the trailing lead locomotives, a situation they had encountered with a previous rolling stock operator.[14] The driver, based on this assumption, elected to maintain dynamic braking in anticipation of 5446 coming to a stop.

At 0650:21, almost 40 seconds after the train separation event, the brakes automatically reapplied on the banking locomotives. The variation in speeds between the two portions of the train had now resulted in a separation distance of 129 m between the rear of 5446 and the banking locomotives. The trainee driver again bailed-off this brake application releasing the brakes on the banking locomotives at 23 km/h.

At 0650:39, 5446 came to a stop at 404.239 km due to the uncommanded automatic brake application. A 58 m distance now separated the rear of 5446 from the banking locomotives.

Eight seconds later, as the lead portion driver contacted the banking locomotive crew by radio to advise that 5446 had stopped due to a suspected false vigilance penalty, the banking locomotives collided with the rear of 5446 at 28 km/h. The trainee driver on the banking locomotives immediately advised the lead portion driver that they believed they had derailed. Upon inspection, the banking locomotive crew identified there had been a collision between the banking locomotives and the rear of 5446.

As a result of the collision, the mentor driver on the banking locomotives suffered a minor head injury, after being struck by an unrestrained item in the locomotive cabin. In addition, severe damage occurred to the rear grain wagon of 5446, and the lead banking locomotive.

Context

Weather and environmental information

The nearest weather observations were taken at Quirindi, about 12 km from the accident site. On the morning of the accident sunrise was at 0559, almost one hour prior to the incident. Later, at 0900, there were light winds recorded, with clear conditions and no cloud cover for the area. No rain was recorded for the day.

Weather and environmental conditions were not considered contributory to the accident.

Train crew information

Mentor driver

The mentor driver commenced in the rail industry in 1999. In 2015, after working in various depots, the driver was based at Werris Creek with another rolling stock operator (RSO). In mid‑2020, the driver joined Southern Shorthaul Railroad (SSR), operating trains on the Narrabri North, New South Wales to Sydney corridor, including over the Ardglen Bank. In December 2021, the driver became a mentor driver in preparation for becoming a driver trainer once they had completed the required training.

The mentor driver held a Certificate IV in Train Driving, which was obtained under recognition of prior learning. As this was issued prior to the mentor driver joining SSR, they undertook a driver’s practical assessment on joining SSR to ensure that they met SSR’s specific operational competency requirements. In addition, the mentor driver held all required route and safeworking qualifications.

On the day of the accident, the mentor driver started at Werris Creek at 0445 after a 4 day break, which included both rostered days off and shifts on standby. Fatigue was not considered a factor for the mentor driver on the day.

Trainee driver

The trainee driver commenced in the rail industry in 2017 as a driver’s assistant at Werris Creek, which included operations over the Ardglen Bank. In August 2020, the trainee driver joined SSR as a driver’s assistant, becoming a trainee driver two months later.[15] They were based at Muswellbrook and Ulan, New South Wales, before transferring back to Werris Creek in June 2021. Since that time, the trainee driver had mainly operated the banking engines between Werris Creek and Pages River/Murrurundi.

The trainee driver held a statement of attainment for units of competency which could apply to a driver’s assistant. As this was issued prior to the trainee driver joining SSR, they undertook a driver’s assistant practical assessment to ensure that they met SSR’s specific operational competency requirements. In addition, the trainee driver held the required safeworking qualification for the route.

On the day of the accident, the trainee driver started at Muswellbrook at 0315 after a 3 day break, which included both rostered days off and a shift on standby. Fatigue was not considered a factor for the trainee driver on the day.

Train information

General

Train no 5446 consisted of three locomotives (controlled by the lead driver) hauling 49 x BGKF wagons loaded with export wheat, weighing an estimated 4,263 t. At Werris Creek, three additional locomotives were attached at the rear of 5446 for banking purposes (controlled by the trainee driver). The train length on departure from Werris Creek was 943.60 m.

Locomotive cabin

The banking locomotives’ train crew were in locomotive C506, which was at the very rear of the train. They were facing opposite to the direction of travel. Visibility of the train was limited to that available from the rear facing side mirrors.

At the driver controls was the trainee driver, who could observe several warning light indications and pressure gauges to monitor the train consist. These included pressure changes in the train’s brake pipe and C506’s brake cylinders, and warning lights associated with C506’s PCS function and brake cylinder pressure (Figure 3).

Figure 3: Locomotive C506 control indications

Control indications on C506 as applied during banking operations.

Source: OTSI

The mentor driver, who was seated in the observer’s seat, had access to basic functions such as the locomotive horn and light switches. Although the speedometer had a side panel to enable speed monitoring by the mentor driver (Figure 3), they relied on the trainee driver to advise them of gauge and warning light indications.

Network information

General

The section of track between Werris Creek and Quipolly (the accident section), was managed by the Australian Rail Track Corporation (ARTC). Network control services were provided by ARTC’s Upper Hunter no 2 control board, based at Broadmeadow, New South Wales. The safeworking system that applied was ‘rail vehicle detection’, using track circuits to detect trains and colour light signals.

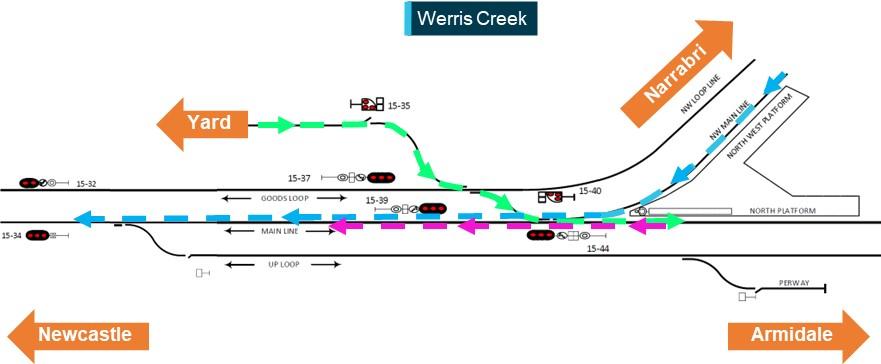

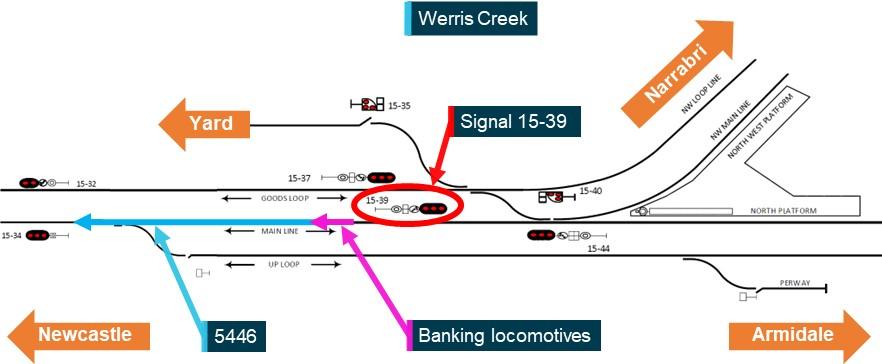

Werris Creek Yard

On most occasions and on the day of the accident, prior to the arrival of 5446 at Werris Creek, the banking locomotives exited the yard and waited at the platform on the Armidale side of the station, as depicted in Figure 4. On arrival from Narrabri, 5446 proceeded via the northwest main line onto the main line at Werris Creek, stopping at signal 15-34 and clear of signal 15-39 at the rear. Once 5446 had stopped, the banking locomotives proceeded on the authority of the shunt signal attached to signal 15-44 and coupled to the rear of 5446, clear of signal 15-39.

Figure 4: Routes taken by 5446 and banking locomotives

The route taken by the banking locomotives prior to the arrival of 5446 at Werris Creek is depicted by the light green dotted line, with the route taken by 5446 on arrival shown by the light blue dotted line. Once 5446 had stopped clear of signal 15-39, the banking locomotives attached to the rear of 5446 as depicted by the purple dotted line.

Source: ARTC, annotated by OTSI

The distance between signals 15-34 and 15-39 was 1,012 m, with the length of 5446 (including the attached banking locomotives) being about 944 m. When interviewed, the mentor driver described this as problematic. At least a ‘couple of times’ stretch tests were unable to be performed due to the proximity of the banking locomotives to signal 15-39 in the rear, after the grain train had stopped a greater distance than usual from signal 15-34 on arrival (Figure 5). This was not a factor on the day of the accident.

Figure 5: Banking locomotives’ attachment location

Source: ARTC, annotated by OTSI

Werris Creek to Murrurundi

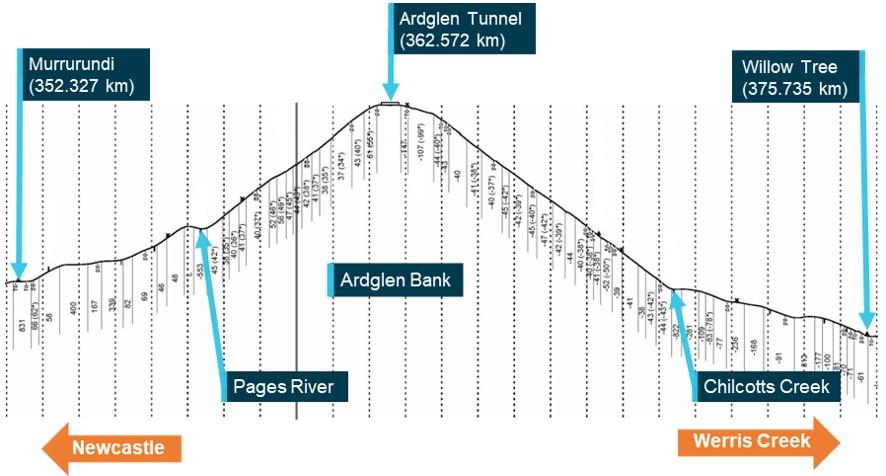

The track profile from Werris Creek (410.800 km) to Willow Tree (375.735 km) was undulating with interspersed short sections of uphill gradient. As depicted in Figure 6, from Willow Tree a moderate uphill grade was encountered to Chilcotts Creek (372.302 km), from where a steep 1:40 uphill grade[16] applied to the Ardglen Tunnel (362.572 km).

Figure 6: Track profile from Willow Tree to Murrurundi

Dotted vertical lines are in 1 km increments.

Source: ARTC, annotated by OTSI

From Ardglen Tunnel, the track commenced a steep downhill grade of about 1:45 to Pages River (354.915 km), where it reduced to a moderate downhill grade to Murrurundi (352.327 km).

The track speed was generally 115 km/h on the straight sections between Werris Creek and Chilcotts Creek, however, grain trains were limited to 80 km/h. From Chilcotts Creek to Ardglen Tunnel, banked trains were limited to a maximum of 50 km/h. As there was a steep uphill gradient on this section, grain trains operated up the grade substantially below the speed limit.

Ardglen banking operations

General

ARTC general train operation requirements were included in its train operating conditions (TOC) manual. Section 2 of the TOC manual (locomotive operations) described locomotives placed throughout a train consist as a ‘distributed power’ configuration. Where there was insufficient tractive effort available to haul the train up a steep grade, additional locomotives could be temporarily placed at the rear of the train to assist. In this instance, the configuration was considered a ‘banking’ operation. Limits on tractive power at the rear and minimum wagon mass within the consist applied to banking operation trains. These restrictions were in place to prevent excessive L/V ratio[17] in-train forces that may result in wagon lift and derailment if not observed.

For the Ardglen Bank, specific banking requirements between Chilcotts Creek and Murrurundi were contained in ARTC’s Route Access Standard (RAS) H2 (Muswellbrook–Werris Creek). As discussed further in this section, SSR’s banking operations were required to commence at Werris Creek, rather than Chilcotts Creek. To facilitate this, ARTC published supplementary instructions in TOC waiver 18060 (Operation of SSR grain trains between Newcastle and Moree & return) in April 2018, which was replaced by TOC waiver 21004 (Operation of SSR trains and light engines between Newcastle and Moree & return) in January 2021. These waivers were partly based on an independent assessment of in-train forces during banking, which was provided to ARTC in June 2017.

Chilcotts Creek based operators

In addition to SSR, two other rolling stock operators (RSOs) banked trains on the Ardglen Bank. Their banking locomotives were stowed in sidings at Chilcotts Creek provided for this purpose. As their banking locomotives were attached to the rear of their trains at the commencement of the steep uphill grade, the banked train was always in a compressed state to the Ardglen Tunnel.

Consistent with the requirements of ARTC document RAS H2, the knuckle of the automatic coupler on the banking locomotives pressed against the train to be banked was not required to be locked during coupling. Rather, an anti-locking device was placed around the top lifter pin of the banking locomotive’s coupler to prevent this from occurring (see Automatic couplers for further information). In addition, the brake pipe was not connected between the train and the banking locomotives (see Automatic brake).

When the banked train reached the summit of the Ardglen Bank on the western approach to the Ardglen Tunnel, the banking locomotives for these operators slowed to a stop, automatically separating from the rear of the train. This allowed the banked train to continue its journey without stopping.

Southern Shorthaul Railroad

SSR commenced grain train banking operations between Werris Creek and Pages River in about October 2017, ceasing about 6 months later due to drought conditions impacting loading availability. It recommenced banking operations in October 2020, and changed the location of the train crew from the lead banking locomotive to the rear banking locomotive.[18] This change altered the vision of the banking locomotive train crew from viewing the rear wagon and coupler during banking operations, to a rear view of the track, in the opposite direction of travel.

As there was no spare siding accommodation at Chilcotts Creek to store SSR’s banking locomotives between duties, the locomotives were stored and attached to the rear of SSR’s grain trains at Werris Creek. In October 2020, SSR approached ARTC to change its banking locomotive stabling location from Werris Creek to Willow Tree (see Figure 6). The change request was made to improve operational efficiency by reducing non-revenue running of the banking locomotives. ARTC did not agree to this request, and the stabling location of SSR’s banking locomotives remained at Werris Creek.

Operation

Although banking was only required between Chilcotts Creek and Ardglen, the banking locomotive crews would take the opportunity to assist loaded trains over other uphill grades on the undulating terrain between Werris Creek and Chilcotts Creek. In addition, to limit instances of slack[19] run‑out,[20] it was common practice to maintain 1–2 notches of traction power to assist in keeping the banking locomotives compressed against the rear of the train being banked.

Consistent with TOC waiver 21004, SSR required the banking locomotive’s automatic coupler to be connected and locked to the rear grain train wagon’s coupler during banking operations. This was due to the train traversing the undulating grade between Werris Creek and Chilcotts Creek (Figure 7), to ensure that the banking locomotives would not separate from the rear of the grain train en route. In addition, the brake pipe was also connected between the banking locomotives and the rear grain wagon, with all train braking and release commands on the train being initiated by the driver at the front of the train.

Figure 7: Track profile from Werris Creek to Chilcotts Creek

Source: ARTC, annotated by OTSI

Once the grain train had reached the Ardglen Tunnel, the banking locomotives would cease assisting with traction power. On arrival at Pages River, the grain train would stop, and the banking locomotives would be uncoupled to allow for their return to Werris Creek for storage in preparation for their next banking duties.

Automatic couplers

General

Couplers are fitted to both ends of most rolling stock to enable coupling to adjacent vehicles when marshalling a train. Automatic couplers are frequently fitted to freight rolling stock, automatically closing and locking the knuckle/s of open couplers when rolling stock are pushed together (Figure 8), at which point the rolling stock are ‘coupled’.

Figure 8: Open and closed automatic coupler

An open knuckle (left image) and a closed and locked knuckle (right image). The locking block keeps the knuckle from opening once closed. If adjacent rolling is coupled, the pairing knuckle of the adjacent rolling stock would lock in behind the pictured knuckle.

Source: OTSI

To couple up to other rolling stock, either one or both automatic couplers on the rolling stock to be coupled should have their knuckles fully opened prior to coupling the rolling stock together. When uncoupling, at least one of the knuckles is to be unlocked to allow this to occur.

Although automatic couplers perform the mechanical function of coupling, any air, electrical and hydraulic connections are required to be manually performed by the shunting personnel.

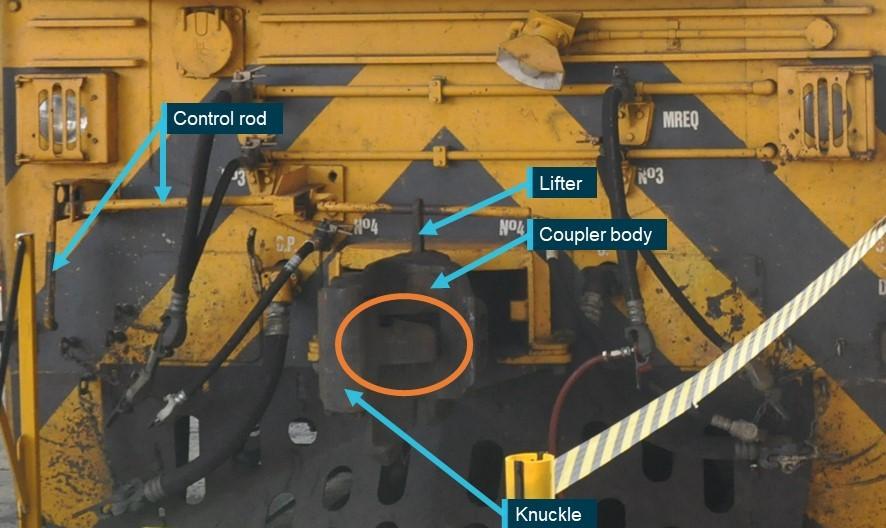

Operation

When shunting, the person conducting shunting operations on the ground operates the control rod which acts on the lifter (Figure 9). This either pulls or pushes the locking block clear of the knuckle (Figure 10), thereby unlocking it.

Figure 9: External coupler components

Main external coupler components. The area circled orange is magnified in Figure 11.

Source: ATSB

Figure 10: Locking block and lifter

Source: OTSI

Figure 11 illustrates the sequence of mechanical events internal to the coupler body when performing coupling operations, as follows:

- Image 1: As the locking block moves upward during unlocking, it contacts with and thereby engages the kicker, which assists in pushing open the unlocked knuckle. In addition, the tongue of the locking block (see also Figure 10), rests on the set shelf within the coupler, keeping the locking block raised and the knuckle in an unlocked state. This allows the shunting personnel to release the control rod without the knuckle immediately re-locking. The purpose of this safety design feature is to allow shunting personnel to:

- manually open the knuckle for coupling in instances where the kicker has not sufficiently opened the knuckle

- stand clear of the rolling stock profile while uncoupling operations occur.

- Image 2: As the knuckle opens fully, a raised contact point on the top side of the inner knuckle contacts the locking block, pulling the locking block and its tongue outwards, dislodging it from the set shelf. This effectively arms the locking block to automatically drop in front of the inner knuckle once the knuckle is closed.

- Image 3: Once the locking block drops in front of the inner knuckle, it locks it in place, preventing it from reopening (see also right-hand image in Figure 8).

Figure 11: Internal coupler mechanisms

This image shows operation of the internal mechanisms within the coupler body. Image numbers 1 and 3 have had the knuckle physically removed to allow visibility of the locking block.

Source: OTSI

Importantly, once the locking block tongue has come to rest on the set shelf, the knuckle must be fully opened to dislodge the tongue from the set shelf, thereby enabling the knuckle to be relocked. If the knuckle remains closed but unlocked, it will not lock again regardless of how much inwards pressure is exerted, as the locking block tongue will not dislodge from the set shelf. So, if both automatic couplers on adjacent rolling stock are unlocked for coupling, but only one knuckle is fully opened, only the fully opened knuckle will lock when the rolling stock are pushed together regardless of the buff (compressive) force applied. This will result in the closed but unlocked knuckle remaining in an unlocked state after coupling, and a train separation when the train is next moved with a draft (stretched) force.

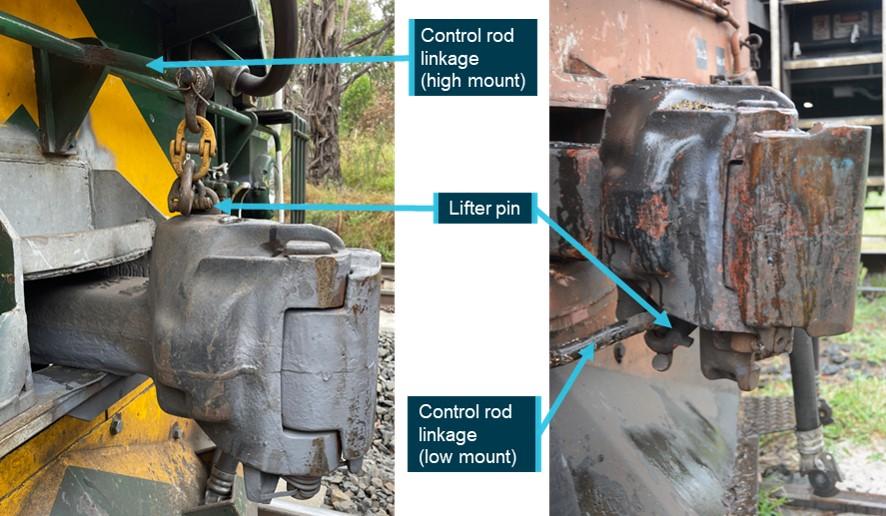

Top versus bottom operated couplers

While the operation of the automatic coupler remains the same, there is a subtle design difference in the way the locking block is lifted for a top versus a bottom lifter operation. The top lifter pulls up the locking block when operating the control rod, whereas bottom lifter pushes up the locking block. While top lifter operation is more common, the bottom lifter design allows for a lower control rod and lifter position, providing clearance from pipework (on locomotives) and reduced obstruction during loading (container wagons) (Figure 12).

Figure 12: Comparison of top lifter (left) versus bottom lifter (right) automatic couplers

Source: OTSI

As described in Operation, although the locking block can be visually observed in the locked position when uncoupled (Figure 8), this is not possible when coupled to another knuckle on adjacent rolling stock.

For top lifter operation, the lifter and control rod linkage are mounted on the top of the automatic coupler body. As shown in Figure 13Figure 13, the lifter gives a clear and reliable visual indication of the position of the locking block. Unless the locking block has fully engaged in the locked position in front of the inner knuckle, the lifter will appear in a raised position.

Figure 13: Top lifter operated automatic coupler

Visual appearance of the lifter in various operational knuckle states for a top lifter operated automatic coupler.

Source: OTSI

For bottom lifter operation, conversely the lifter and control rod linkage are mounted on the bottom of the automatic coupler body. As shown in Figure 14, the lifter provides almost no appreciable difference in indication of the position of the locking block, irrespective of whether it is in the locked or unlocked position. There is no reliable visual representation of the position of the locking block available for a bottom lifter operated automatic coupler.

Figure 14: Bottom lifter operated automatic coupler

Visual appearance of the lifter in various operational knuckle states for the bottom lifter operated automatic coupler that was fitted to locomotive L277, the accident locomotive. Note: the coupler has been bent downwards from the accident.

Source: OTSI

Shunting requirements

As a result of the visual limitations of the status of the locking block on bottom lifter operated automatic couplers, a common industry practice for these types of couplers is to perform a stretch test after coupling. This ensures that the locking block has fallen into place in front of the inner knuckle, locking it in place. If the couplers separate during a stretch test, it indicates that one or both knuckles remained unlocked after the coupling operation. Alternatively, if the couplers remain coupled, it indicates that both knuckles have been locked correctly.

As with many rail industry procedures, how a stretch test was conducted was determined by individual rolling stock operators (RSOs), rather than detailed within an industry standard. Two of the largest rail freight RSOs in Australia required that light locomotive traction power be applied in the direction away from the coupled location to perform a stretch test. This was to provide assurance that sufficient tension had been applied to the knuckles, thereby ensuring physical train separation in the event one or both couplers had not locked.

SSR advised that it considered sufficient strain on the couplers could be provided by a ‘… gravitational “bump”’, not necessarily with the application of accompanying traction power.

SSR shunting procedures

SSR had several procedures relating to its shunting requirements, which were supported by training and assessment, including:

- WIM 63001 (Policies and general train operations work instruction manual), section 20 ‘coupling and uncoupling rolling stock’ which described shunting operations, including the requirement for stretch tests to be performed. The instruction did not detail SSR’s process for a stretch test.

- Notice 62269 (Ardglen banking procedures), which specified banking engines were to be hard coupled to the rear of banked grain trains. After coupling, the bank engines were to ‘…“ease off” to ensure that the coupler on the bank engine has become coupled’ to prevent uncoupling while the train was in transit. In this case an ‘ease off’ rather than a stretch test was referred to. The process as applied to SSR operations was not described.

For new employees without prior shunting qualifications, SSR provided training and assessment aligned to the national unit of competency TLIC4074 (shunt, couple and uncouple rail vehicles).[21] The assessments included theoretical questions regarding the purpose of a stretch test, and a practical evaluation of the tasks involved.

The training and assessment aligned to TLIC4074, the supporting instructions contained within WIM 63001 and notice 62269, did not explain details of:

- the coupler safety design feature, which required an unlocked knuckle to be fully opened to allow relocking

- visual limitations relating to the locking block position on bottom operated couplers

- SSR’s process for a stretch test/ease off.

Of note, the SSR learner’s resource material for TLIC4074 stated that locking blocks could ‘jam’, resulting in the coupler knuckle remaining unlocked. In these instances, employees were required to separate the train and investigate the cause. However, it did not detail what the possible causes were, or how these may be rectified.

Coupler inspections

The coupler on the accident end of L277 had a casting date of August 2002 and was likely fitted shortly after casting by its then owner, Rio Tinto. SSR acquired L277 in 2020, with the couplers inspected and deemed compliant during the locomotive’s previous 30-day inspection.

Both couplers on BGKF 1122F (the accident wagon) were replaced in November 2019. A major biennial ‘B service’ was conducted on the wagon 3 months before the accident, which included a full wagon lift. The couplers were inspected during this service and deemed compliant.

An inspection of the couplers after the accident by Bradken at Newcastle, New South Wales, found that the:

- Accident end coupler of L277, while worn, was within wear limits and was mechanically fully functional.

- Accident end coupler of BGKF 1122F showed minimal signs of wear, but due to significant deformity resulting from the accident was no longer functional.

Accident site

A review of evidence taken at the accident site was used to determine the mechanical state of the automatic couplers leading up to the accident. After the accident, the air brake hoses were found to be undamaged and disconnected consistent with separation having occurred between the banking locomotives and the rear of the train prior to the collision. The automatic couplers of locomotive L277 and BGKF 1122F were found to be coupled together and the knuckles locked (Figure 15), indicating that the physical structure of the couplers was sound and the knuckle locking mechanisms functional.[22] In addition, both couplers were fitted with bottom interlocking shelves, which prevented vertical disengagement of the knuckles while in transit.

Figure 15: Coupling between L277 and BGKF 1122F

Note: Both the locomotive and wagon’s brake pipe taps were closed post-accident.

Source: SSR, annotated by OTSI

All coupling components were accounted for at the accident site including the coupler, yoke pin, follower, draft pack and yoke, indicating that there had not been a catastrophic mechanical failure of the coupling mechanisms en route (Figure 16).

Figure 16: Wagon BGKF 1122F coupler components

Note: The wagon’s brake pipe tap was closed post-incident.

Source: SSR, annotated by OTSI

Finally, the bent nature of the striker, sheared-off pin carrier plate and upward bend of the coupler and yoke of BGKF 1122F, was consistent with the coupling mechanism being located within the wagon body at the time of the collision and upward lift of the wagon as it lodged into the long hood of locomotive L277.

Damage to 5446 was limited to the rear wagon of the grain train (BGKF 1122F), including a significant grain spill, and the leading banking locomotive (L277). ARTC advised that there was no track damage from the accident which required repair.

Training and assessment

Introduction of the national system in the rail environment

In 2006, the National Transport Commission (NTC) released the model Rail Safety Bill as a first step in rail safety legislation harmonisation across all the Australian states and territories. One aspect of the harmonised laws was the requirement for rail transport operators to assess rail safety worker competence[23] against available national competency units (see Australian Qualifications Framework (AQF)). This requirement was embedded in s.21 of the Rail Safety Act 2008 No 97 (NSW) that subsequently followed.

In January 2013, the Rail Safety National Law (NSW) (RSNL) came into effect and was administered by the Office of the National Rail Safety Regulator (ONRSR). For compliance with the RSNL,[24] ONRSR advised, in part, that once a position was identified as rail safety work, a rail transport operator was required to:

- Perform a task analysis to understand the competence requirements of the position, specifically, a defined list of tasks and, required technical and non-technical knowledge and skills.

- Assess the risk of the tasks to determine appropriateness and applicability of training as a risk control.

- Ascertain the extent to which competency gaps could be addressed through an AQF unit of competency.

- Utilise enterprise assessments to assess competence where an AQF competency did not exist or fully meet requirements.[25]

Australian Qualifications Framework (AQF)

The AQF provided the standards required for nationally recognised qualifications through policy and the standardisation of learning outcomes for each qualification type. This ranged from a Certificate I (level 1) to a Higher Doctoral Degree (level 10). For Vocational Education and Training (VET), AQF levels 1–8 applied for qualifications ranging from a Certificate I to a Graduate Diploma.

At the time of the accident, training packages were developed by skills service organisations in consultation with industry. Approved training packages were endorsed for use by the Council of Australian Governments Industry and Skills Council. For the rail industry, the TLI10 (transport and logistics training package) applied, which detailed available units of competency which could be packaged into a nationally recognised, portable qualification.

National recognition of VET units of competency and qualifications was the result of quality assurance by the national VET regulator, the Australian Skills Quality Authority (ASQA),[26] through:

- registration of registered training organisations to authorise delivery and assessment of VET

- monitoring of compliance to the VET standards[27]

- accreditation of nationally recognised courses, where a training package did not apply.

A VET qualification typically comprised of a minimum number of core and a mix of elective units of competency. At the time of the accident, the VET qualification TLI42621: Certificate IV in Train Driving was available for train crew. This qualification consisted of 21 units of competency, as follows:

- 12 core units.

- 5 units aligned to specialised elective groupings, which contextualised the operational environment, i.e. A) freight, B) urban electric, C) country passenger operations, D) steam locomotive and E) heritage motive power.

- 4 units from a list of 35 electives, chosen by the registered training organisation as determined by the operational requirements of the employing rail transport operator.

There was no equivalent VET qualification for the driver’s assistant position. Instead, units of competency from TLI42621 were selected by the registered training organisation to reflect the competencies required by the operator, based on the knowledge and skills necessary to perform the role specific to its operations. In this case, a Statement of Attainment was issued allowing national recognition of these individual units of competency.

In relation to competency assessment of skills and knowledge for shunting operations, the AQF provided the unit of competency TLIC4074 (shunt, couple and uncouple rail vehicles). This unit was available as a general elective within TLIC42621.

The requirements for assessment when imparting VET competencies and qualifications, including through recognition of prior learning,[28] was detailed in the Standards for registered training organisations 2015 (Cwlth).[29] These consisted of:

- Principles of assessment: where assessment was fair, flexible, valid and reliable.

- Rules of evidence: where evidence collected was valid, sufficient, authentic and current.

This ensured integrity of the competency assessment decision and judgments and, gave confidence that assessments of competence were sound, reliable and consistent across the VET sector.

To ensure these requirements were met, registered training organisations (those delivering and assessing VET)[30] were required to undertake assessment validation activities. This involved periodically reviewing a sample of assessments previously undertaken to ensure the assessment tool, process and judgements reliably met the requirements of the principles of competency assessment and rules of evidence. Registered training organisation validators were required to be independent of the training delivery and competency assessments being reviewed.

In relation to assessment judgements, sufficient assessment evidence was to be retained to enable review and validation of the competency judgement decision. The purpose was to ensure that assessment decisions would be consistent across assessors (‘reliable’), based on the evidence gathered (‘sufficient’), thereby allowing sound competency decisions to be made. Guidance for this and other requirements of registered training organisations in meeting their VET obligations was contained in ASQA’s guidebook Users’ guide to the standards for registered training organisations 2015.[31]

For theory assessments, the ASQA user’s guide suggested that model answers could be provided to assessors to enable evaluation against responses provided. For practical assessments, it was recommended that ‘practical skills are well described and include observable behaviours’, in addition to assessing the underpinning knowledge of the observed task by ‘asking the student why they are doing something’. This assured the assessor that the person being assessed was not solely mimicking a previously demonstrated task.

Enterprise attainment

VET units of competency could be used as transportable qualifications for rail safety work. However, individual rail transport operators were required to ensure that competency was assessed for all its specific knowledge and skill requirements, such as:

- the contents of the operator’s safety management system

- specific operational task risks and risk controls

- safeworking[32] for the operator’s particular operation and geographic location

- local track route knowledge

- motive power and rolling stock operations (types of locomotives and wagons in use)

- train operations (whether they be passenger or freight operations).

Further, the Rail Safety National Law (RSNL) allowed rail transport operators to assess competency through other means where complying with the AQF was not reasonably practicable,[33] for example, where:

- not all units of competency within the qualification were necessary

- a suitable VET unit of competency or qualification was not available

- the costs associated with complying with the AQF were prohibitive.

While formal requirements for assessment of VET qualifications applied to registered training organisations when issuing a VET qualification (see AQF assessment), it did not apply to enterprise-based assessments (that is, enterprise attainment) conducted by rail transport operators. Even so, ONRSR’s policy Application of the AQF to rail safety worker competence assessment did provide guidance to rail transport operators in this regard. ONRSR’s expectations in this case included that:

- training and assessment remained ‘consistent with the principles of competence-based training and assessment’

- sufficient assessment evidence to ensure ongoing consistent performance was obtained

- competence assessment was conducted by a person with a Certificate IV in training and assessment (or equivalent), who was independent of the person who conducted the training.

Competence retention

The ONRSR guideline, safety management system, outlined ONRSR’s expectation that there was periodic reassessment of rail safety worker competency. This was consistent with correcting degradation of worker knowledge, skill and competence, particularly where safety critical tasks were conducted irregularly (Vlasblom et al. 2020). These expectations applied to competencies achieved through both VET and enterprise attainment.

Of interest, VET attained qualifications and units of competency in rail safety work did not expire and were recognised across industry. Importantly however, the proven competency at time of qualification did expire – irrespective of how the initial competency in rail safety work was achieved (either through AQF based or enterprise attainment). As such, periodic reassessment of competence was to be conducted. The operator’s safety management system (SMS),[34] determined the intervals for reassessment to ensure workers remained competent to carry out rail safety work.

Credit transfer and additional training

As previously described, the Standards for registered training organisations 2015 (Cwlth) required national recognition and therefore portability of VET units of competency previously achieved.

The mentor driver of 5446 held an earlier qualification TLI42615: Certificate IV in Train Driving, which they had obtained while working for Pacific National in September 2019. While this qualification had been superseded by TLI42621 by the time of the accident, it remained an equivalent qualification. The mentor driver’s TLI42615 included the unit of competency TLIC4074 (shunting).

The trainee driver of 5446 held a Statement of Attainment, which they had obtained as a driver’s assistant through Southern Cross Civil and Rail Training (SCCRT) in September 2017. It included assessed competence in 18 units of competency which were aligned to TLI42615. Their Statement of Attainment also included assessed competence in TLIC4074 (shunting).

While a rail safety worker was required to demonstrate competency against performance criteria (defined in the unit of competency) and provide performance and knowledge evidence (defined within the assessment requirements), the VET requirements were generic in nature. This allowed registered training organisations to contextualise the training and assessment of a unit of competency to the unique operating environment within which the work was conducted.

As such, although SSR (which was both a rolling stock operator and registered training organisation), recognised the previously attained VET competencies and qualifications of both the mentor driver and trainee driver, this did not satisfy its requirements for the demonstration of competence regarding its own operations; for example, SSR policies, procedures, instructions, and its unique operating equipment and environment. SSR advised OTSI that after training in SSR’s requirements, all new employees were assessed to ensure they met and were therefore current, in all required rail safety worker competencies. These assessments were enterprise‑based rather than aligned to AQF qualifications. Where competency gaps were identified during this process, further training would occur prior to reassessment of competency.

Of note in relation to TLI42621, were the units of competency specialist elective groupings. As previously described in Australian Qualifications Framework (AQF), these five groupings contextualised the operational environment in which the qualification was originally obtained. This was important due to the specific train driving skillsets which applied to different motive power operations. For example, the method of operating a steam locomotive (specialist elective group D) was entirely different to that of an electric passenger train (specialist elective group C). Through a review of the units of competency achieved in TLI42621, a rail transport operator could determine the specific train driving skillset a driver presenting a VET qualification had previously demonstrated. During the investigation, it was identified that specialist elective groupings A (freight) and C (country passenger) were identical. This meant that a VET qualification in train driving held by a country passenger train driver, for example, a self-propelled 2-carriage diesel multiple unit, had the potential to appear identical when presented to a hiring rail transport operator as that of a heavy-haul freight train driver.

|

ATSB observation While VET qualifications were theoretically portable across industry, in practice this was of limited value due to the significant operational differences between rail transport operators. Though specialist elective groupings (including for the Certificate IV in Train Driving) gave further context, this too was problematic and was not necessarily reflective of the rail operating environment within which it was obtained. Further, reliability of the VET qualification in demonstrating competency in rail safety work quickly diminished due to the requirement to periodically reassess these initially proven competencies. Given these limitations, additional enterprise-based training and assessment was always required by rail transport operators. |

Training and assessment of shunting duties

Unit of competency TLIC4074

As previously described, the VET unit of competency TLIC4074 provided a nationally recognised shunting qualification. Within this unit of competency were several assessable requirements related to coupler operation, understanding of coupler design features and testing of a successful coupling activity (a stretch test). These were:

- coupling systems are identified and applied appropriately to couple and/or uncouple rail vehicles in accordance with manufacturer and organisational requirements [performance criteria]

- operating and adapting to differences in equipment in accordance with operating procedures [performance evidence]

- shunting, coupling, uncoupling and securing rail vehicles [performance evidence]

- principles of operation for protective devices, air and electrical couplings, handbrakes, derailers and coupling equipment [knowledge evidence].

Mentor driver

The mentor driver’s assessment of competence against TLIC4074 (within their TLI42615) was achieved through recognition of prior learning (RPL). The purpose of RPL was to assess competence which had been achieved through prior formal, non-formal or informal learning.[35] This avoided training and assessment against a unit of competency where skills and knowledge were already achieved. The RPL assessment was conducted by Pacific National in September 2019. The assessment included consideration of a prior VET qualification, prior enterprise assessments, and an RPL checklist, interview and third-party report; specifically:

- Recognition of a Statement of Attainment previously issued by Asciano (Pacific National) in March 2013 which included a Certificate III aligned unit of competency TLIC3017A (shunt rolling stock).

- In July 2016 and September 2017, Pacific National assessed the mentor driver using an enterprise-based verification of competency checklist. The mentor driver was found competent in different coupling systems and performed a stretch test on both occasions however, evidence was limited to a checkbox that this was ‘performed correctly’. There was no evidence recorded that described their understanding of these or what actions were observed.

- In July 2019, Pacific National conducted an RPL checklist, interview and third-party report which found the driver competent in shunting. As with prior assessments, evidence was limited to checkboxes that did not describe the mentor driver’s understanding of coupling systems or observed actions during a stretch test.

Pacific National advised OTSI that the RPL checklist and interview were aligned with the training materials for TLIC4074 as delivered by it in July 2019. A review of these training materials found that while coupler operation and stretch tests were referenced, it did not describe the principles of operation of a coupling safety design feature or explain how a stretch test was conducted. Pacific National did not at that time have an instruction detailing the process for conducting a stretch test.

As mentioned in Credit transfer and additional training, SSR recognised the mentor driver’s TLI42615 issued by Pacific National. However, it required the mentor driver to be practically assessed for rail safety worker competency in its own operations. It conducted this assessment in August 2020, finding the mentor driver was competent in ‘shunting the train together’ and ‘performing a train inspection’ in accordance with the requirements of WIM 63001 (see Shunting requirements). However, evidence was again limited to checkboxes that did not describe what actions were observed, or record the underpinning knowledge that was assessed.

In relation to a stretch test, the mentor driver advised during interview that for the previous 20 years they had been taught that this was conducted by gravity/roll back. That is, where the newly coupled portion of a train rolled back from the rolling stock it had coupled to, and remained coupled, this indicated a successful coupling. The mentor driver advised that newer staff often used a notch of power during the stretch test for purposes of recording an action on the data logger, but no SSR procedural document required this. Since the accident, the mentor driver advised that SSR required the application of power as part of a stretch test.

In a follow-up conversation, the mentor driver advised they had been previously taught that the knuckle would only be manually opened in instances where there had been trouble in locking it. In this case the problem knuckle was to be fully opened and then closed (locked), with the other coupler’s knuckle then used to perform the coupling manoeuvre. Further, the mentor driver advised that while stretch tests had been assessed as part of their practical competency assessments, it was unclear to them what functions the assessor was observing during the test.

Trainee driver

The trainee driver was assessed as competent as a driver’s assistant against TLIC4074 by Southern Cross Civil and Rail Training (SCCRT) in September 2017, which formed part of their Statement of Attainment. The assessment consisted of both theory questions and on the job observations. A review of the theory assessment found that it did not address coupler operation, design features or the method of conducting a stretch test. The practical assessment indicated that two successful demonstrations of shunting had been observed. However, these observations did not describe the driver’s assistant’s understanding of coupling systems or, if a stretch test had been conducted, and if it had, what actions were observed.

SSR conducted a practical assessment of the trainee driver’s competence for driver’s assistant rail safety work in its operations in August 2020. On three occasions, it was recorded that the trainee driver could correctly ‘couple and uncouple rolling stock in a safe manner’ in accordance with the requirements of WIM 63001. The evidence of this was limited to nominating the yard where the actions had been observed and a checkbox of completion. The assessment did not describe what actions were observed, or the underpinning knowledge that was assessed.

Specifically, in relation to a stretch test, the trainee driver advised during interview that they understood this to be conducted by gravity. However, if the coupled rolling stock did not roll back after coupling, the trainee driver advised power would then be applied for the stretch test.

Train braking systems

General

On SSR banked grain trains, the driver of the lead portion operated the controls from within a locomotive cabin at the front of the train consist. Tractive effort to move the train was commanded from the front of the train, with the banking locomotives (at the rear of the train) providing further tractive effort (separately commanded by its driver) when uphill gradients were encountered. For train braking however, all braking commands to slow and stop the train were commanded by the driver of the lead portion only.

There were two pneumatically operated, ‘airbrake’ control systems fitted to 5446:

- automatic brake (controlled brakes on the entire train)

- independent brake (controlled brakes on the locomotive/s only).

The use of each of these two braking systems depends on the circumstance during which braking effort is required. For both airbrake systems, braking is achieved by the application of brake blocks directly to the locomotive or wagon wheels.

The following sections provide basic detail of these two braking systems and how they interact.[36]

Automatic brake

The ‘automatic brake’ controls the brakes on the entire train, including the wagons and locomotive/s. Central to this system is the brake pipe, which runs along the length of the train. Changes to air pressure within the brake pipe regulate the application and release of the train’s brakes. When fully charged (brakes released), the brake pipe pressure is about 500 kPa.

The driver regulates the pressure within the brake pipe through operation of the automatic brake handle in the driver’s cabin. To apply the brakes, the driver reduces pressure in the brake pipe. Equipment which is fitted to the locomotive/s and wagons senses this brake pipe pressure reduction and effects a corresponding air pressure increase in the locomotive and wagon brake cylinders. This pressure increase results in application of the vehicle’s brakes through the brake rigging mechanism.

It is termed the ‘automatic’ brake because the brakes will automatically apply when brake pipe air pressure is lost, such as in a major derailment or train separation where the brake pipe is broken.

Independent brake

The ‘independent brake’ applies pneumatic brakes to the locomotive/s only, independently of any trailing wagons. It is operated by the driver using the independent brake handle in the driver’s cabin. In the ‘apply’ position, air pressure is increased in the locomotive’s brake cylinders, whereas in the ‘release’ position, locomotive brake cylinder air pressure is exhausted to the atmosphere.

When pressure is reduced in the brake pipe, for example, during an automatic brake application, the locomotive’s brakes will also apply. For train handling purposes,[37] this brake cylinder pressure is usually released by the driver on hauling locomotives, without affecting the brake application on any trailing wagons. This is known as ‘bailing-off’ the automatic brake application and is achieved by the driver depressing the independent brake handle.

Dynamic brake

The electrical dynamic brake provides a supplementary means of train-speed control that complements the train’s pneumatic automatic brake. When selected by the driver, it alters the locomotive’s traction motor fields from a tractive power to a generator configuration, resulting in a retarding force. This retarding force is limited to the locomotive wheelsets only, rather than dispersed across the entire train.

Operation of the dynamic brake suppresses any locomotive brake cylinder pressure which applies during an automatic brake application. This is to prevent excessive braking effort on the locomotive wheelsets, resulting in wheel lock and slide.

Banking requirements

While all train braking commands (apply and release) were commanded by the driver on the lead portion via the brake pipe, the driver of the banking locomotives also had duties to perform in relation to the airbrake system. These were described in SSR work instruction WIM63001 (Policies and general train operations work instruction manual):

- Section 26 ‘losing the air’, in instances of sudden loss of brake pipe pressure to 0 kPa, the driver was to bail-off the automatic brake‑applied locomotive brake cylinder pressure and allow the train to stop. This procedure was generic and did not distinguish between the driver requirements for lead only consists versus banked train consists.

- Section 81 ‘3-man push pull operations’ (also banking),[38] the banking locomotive driver was to bail-off the automatic brake‑applied locomotive brake cylinder pressure en route ‘…to prevent wheel skidding on trailing locomotives’.

In interview, the trainee driver advised that they bailed off auto applications as per Section 81 and also recalled that they bailed-off the banking locomotives’ brake cylinder pressure on two occasions prior to impact in accordance with Section 26. That action was taken having observed the sudden loss of brake pipe pressure and checking the mirrors for any issues. The trainee driver advised that bailing-off banking locomotive brake cylinder pressure was common practice to prevent the brakes from applying and causing locomotive wheel lock, slide and resultant flat spots.

The trainee driver added that about a month prior to the accident, they had encountered another sudden loss of brake pipe pressure while on the banking locomotives and also bailed-off during that event. In this instance, the brake pipe had parted between the two lead locomotives, with bailing-off preventing unnecessary wheel skid on the banking locomotives.

In interview, the mentor driver advised that bailing-off banking locomotive brake cylinder pressure was accepted practice, stating ‘… all the [SSR] training is, if you get a penalty, you always bail-off because you don’t want to skid the wheels [cause flat spots]’. While a sudden loss of brake pipe air pressure and PCS light could indicate a broken brake pipe, the mentor driver had not considered that the train could have separated. The mentor driver advised that like the trainee driver, they would have bailed-off the banking locomotives’ brake cylinder pressure, given the same circumstances. However, they stated that in hindsight although this was what was trained, in this circumstance it wasn’t the right action to take.

Wheel skid events

SSR advised that locomotive wheel lock, resulting in slide and flat spots (wheel skids), was a significant operational concern. While minor flat spots could be addressed through trim blocks,[39] flat spots requiring repair by a wheel lathe could cost up to $100,000 per locomotive due to reduced wheel life.

As a result, SSR trained its drivers to ensure locomotive brake cylinder pressure was bailed-off during all automatic brake applications, including on banking locomotives. As a result, it had not had a ‘class 3’[40] or worse wheel skid event in over 10 years. The last major wheel skid event had occurred in 2011, when the driver on the rear locomotive of a push-pull consist had not consistently bailed-off the automatic brake applications.

Emergency response procedures

Several events may result in a sudden loss of brake pipe pressure[41] on a train including separated brake pipe hoses, derailment, vigilance penalty or train separation. In certain circumstances a train separation can result in an emergency event, namely a collision. This is due to the separated portions separating from each other by a distance, followed by a collision in circumstances where the front portion stops prior to the detached rear portion coming to a stop (as in this accident). To prevent this, RSOs have procedures in place to deal with train separation events.

SSR’s procedure WIM 63001 section 26 (losing the air), which related to sudden loss of brake pipe pressure stated:

If there is a sudden reduction in brake pipe pressure to zero [kPa] whilst a train is underway, bail off with the locomotive independent brake [handle] and allow the train to come to a stand. Keep the independent brake [handle] bailed off for a short period after your train comes to rest in case the rear portion of the train collides with the now stationary front portion of the train.

This process was to be followed in all cases where there was a sudden loss of brake pipe pressure. Where the cause of the pressure loss was not immediately known, drivers were to presume a derailment had occurred and take immediate protective actions. The driver’s assistant was then to walk the train to ascertain the cause of the sudden pressure loss. Both the mentor driver and trainee driver were aware of this procedure.

SSR advised that this instruction applied to all operations, with no specific instruction related to banking locomotive actions when observing a sudden loss of brake pipe pressure. However, SSR added that it had by that stage obtained extensive experience in both banking and push-pull operations. SSR advised its push-pull arrangements alone totalled more than 100 services per year since 2004. Also that this accident was the first instance of a separation between its banking/push-pull locomotives and the previously coupled train in an estimated 3,000 banking and push‑pull events.

Risk management

General

For the purposes of the Rail Safety National Law (RSNL), a Rail Transport Operator (RTO) was required to ensure the safety of its railway operations ‘so far as is reasonably practicable’.[42] The Office of the National Rail Safety Regulator’s (ONRSR’s) guideline Meaning of duty to ensure safety so far as is reasonably practicable, provided RTOs guidance on how to apply this concept to their operations. Within this guideline, ONRSR considered ISO 31000 (Risk management – guidelines) as ‘good practice’ in the management of risk, in addition to requirements of the RSNL. ISO 31000 described risk management as:

…the systematic application of policies, procedures and practices to the activities of communicating and consulting, establishing the context and assessing, treating, monitoring, reviewing, recording and reporting risk.

RTOs were required to implement a safety management system (SMS) to comply with their risk management obligations. This was to include formal processes for the identification, assessment, control, monitoring and review of risk.[43]

Communication and consultation

A key component of the risk management process was communication and consultation with internal and external stakeholders. ISO 31000 described the aims of communication and consultation as bringing together different areas of expertise and views, and to gather sufficient information during the risk management process. It was an integral part of:

- establishing the scope and context within which the risk to be managed resided

- identification, analysis and evaluation of the risk

- identification and implementation of effective risk controls.

A companion handbook HB 327:2010 (Communicating and consulting about risk) applied to ISO 31000.[44] It described the benefit of effective communication and consultation as ‘… a shared and better understanding of the risks faced and the range of treatment options.’ It further noted that consultation would help to comprehensively identify risks, increase acceptance of implemented controls and encourage feedback of effectiveness after implementation.

The importance of consultation was recognised within the RSNL, with an objective of the Act ‘to promote the effective involvement of relevant stakeholders, through consultation and cooperation, in the provision of safe railway operations.’ To achieve this, the RSNL advised that participation and consultation in establishing, reviewing or varying an RTO’s SMS (risk management), should include:

- those who may be affected by the SMS, such as rail safety workers

- health and safety representatives (where applicable)

- relevant unions

- other RTOs (where interface agreements were required)

- the public (where appropriate).

It was a requirement of the Rail Safety National Law National Regulations 2012 that an RTO’s SMS contained systems and procedures to ensure this consultation occurred.[45]

SSR risk assessments

Shunting

SSR conducted a risk assessment for train operations including shunting in February 2017, which was reviewed in March 2019. The review team consisted of an executive general manager, general manager, director and assistant general manager, most of whom had previous experience as either a driver or driver’s assistant. Stakeholders such as rail safety workers were not identified within the risk assessment.

Hazards of general shunting duties, for example, incorrectly set points, insufficiently secured rolling stock and communications failure were assessed. The hazard of incorrect / unsuccessful (unlocked knuckles) after coupling was not identified or assessed. SSR advised that the hazard of incorrect/unsuccessful coupling was addressed through:

- the shunting procedure contained in WIM 63001 (Policies and general train operations work instruction manual)

- competency of rail safety workers in shunting tasks

- experienced traincrew performing shunting tasks (addressed through assessed competency).

As discussed in Shunting requirements, WIM 63001 described the need for a ‘stretch test’ after shunting, but not how this was to be conducted.

More information relating to competency assessment of the mentor driver and trainee driver in SSR’s shunting procedures is contained in Training and assessment of shunting duties.

SSR conducted a risk assessment for its Ardglen banking operations in November 2018, with a review coinciding with recommencement of its banking operation in October 2020.[46] The review team consisted of an executive general manager, general manager, director and service manager. In addition to the review team holding either current or prior driver or driver’s assistant qualifications, in the case of the executive general manager and service manager, the former had operated over the route as a driver’s assistant in 2008, and the latter as a driver in 2018. Identified stakeholders were SSR traincrew, SSR service planners and ARTC train control.

At this time, SSR changed the location of the banking crew from being in the lead banking locomotive to the rear banking locomotive. This eliminated the requirement for the traincrew to change ends after detaching from the grain train at Pages River before returning to Werris Creek. The change was in response to a runaway event which occurred after another RSO’s crew had changed ends at Ardglen after banking operations were complete 4 months previously.[47]

In this assessment the risk of ‘separation and collision’ during banking operations was identified, with potential causes being:

- undulating terrain between Werris Creek and Ardglen, likely resulting in separation without crew awareness

- couplers not engaged correctly (knuckles unlocked) after coupling at Werris Creek

- lack of awareness of train separation en route due to both the lead train locomotive and banking locomotives having simultaneous control of the braking system.

The implemented risk controls for these hazards were, respectively:

- hard coupling with, and the brake pipe air connected between the banking locomotives and the rear of the banked train

- stretch test and confirmation of the coupler condition after coupling

- the lead locomotive on the banked train to be in full control of the braking system, with a brake pipe continuity test after coupling.

Train parting occurrences

One of the operational occurrences that RTOs were required to report to ONRSR related to instances where trains separated while in service, that is, an unintended uncoupling event. A review of these reports over the 5 year period from 2017 to 2021 inclusive, found that there were 1,261 train separation events nationally. These were attributed to:

- mechanical failure of the coupling – 44%

- the knuckle opening through various means – 27%

- track anomalies causing vertical disengagement of the knuckles – 6%

- a shunt having just been completed – 2%

- cause not determined – 21%

Of the 25 instances of train separation occurring immediately after a shunt had been completed, 7 were attributed to the locking block not having dropped fully in front of the inner knuckle after coupling, that is, the knuckle had remained unlocked.

Safety analysis

Introduction

On 6 January 2022, freight train 5446, operated by Southern Shorthaul Railroad (SSR), departed from Narrabri West for Bullock Island at Newcastle, New South Wales. The train was powered by 3 locomotives hauling 49 wagons loaded with grain.

Due to the steep uphill gradient from Chilcotts Creek (about 40 km south of Werris Creek) to the Ardglen Tunnel, extra traction power was required to assist the 3 locomotives to ascend the gradient. As such, on arrival at Werris Creek a further 3 ‘banking’ locomotives were attached to the rear of the grain train. After the banking locomotives were coupled to the rear of 5446, airbrake tests were conducted to ensure braking system continuity. Once confirmed, the train departed Werris Creek.

This safety analysis will discuss the train separation and collision which occurred shortly after departure from Werris Creek, including aspects of procedure, training and assessment of risk.

Train separation event

Separation of L277 from the rear of 5446

Although banking was only required between Chilcotts Creek and Ardglen, in practice, the banking locomotive crews would take the opportunity to assist loaded trains over other uphill grades en route. In this case, the gradient leaving Werris Creek (410.800 km) was uphill for about the first 4 km. As was common practice, on the day of the accident the trainee driver on the banking locomotives assisted 5446 with additional traction power after leaving Werris Creek. Full traction power (eight notches) was provided by the banking locomotives, in addition to full traction power at the lead of the train. Consequently, the banking locomotives were in a compressive state against the rear of 5446.

After about the 407.000 km mark, the gradient changed to a downhill grade. As a result, the lead locomotive driver commenced a reduction in traction power setting, with the trainee driver on the banking locomotives also commencing traction power reductions shortly afterwards.

At 0648:31, the driver of the lead locomotive engaged dynamic braking and made an automatic brake application at 63 km/h to test the effectiveness of the train’s brakes. At this stage, the entire train was on the downhill grade. At 0649:09, with the train’s speed stable at 64 km/h and, coinciding with the banking locomotive’s traction power being reduced to a minimum (one notch), the driver of the lead locomotive released the train’s brakes. Seven seconds later, this brake release command took effect on the banking locomotives.

The trainee driver on the banking locomotives maintained the one notch of traction power on the banking locomotives to limit any slack runouts that may have resulted as the grades changed. However, while this maintained a level of compressive force against the rear of 5446, this was insufficient when the banking locomotives reached a relatively level piece of track at about 405.700 km, allowing them to slow slightly. This slight reduction in speed resulted in the banking locomotives separating from the rear of train 5446 at 0649:46.

Release of automatically applied banking locomotive brakes

As the brake pipe was connected and continuous between 5446 and the coupled banking locomotives at Werris Creek, the separation of the banking locomotives from the rear of the train resulted in a disconnection of the brake pipe and sudden loss of air pressure as recorded on the locomotive dataloggers. At the lead of the train, the driver observed this loss of brake pipe pressure as a flow rate on the cabin flowmeter. Consistent with the SSR procedure contained in WIM63001 (policies and general train operations work instruction manual), the driver maintained dynamic braking to assist in stopping the lead portion of the train.