Safety Advisory Notice

To rolling stock operators

A recent ATSB / OTSI investigation highlights risks associated with misunderstood functionality of automatic couplers. The correct operation and verification of the locking mechanism after coupling is essential in avoiding train separation events.

What happened

The Office of Transport Safety Investigations (OTSI) has completed an investigation into an accident, on behalf of the ATSB, where 3 locomotives located at the rear of a loaded grain train separated from the lead portion of the train in transit. Shortly afterwards, the lead portion of the train stopped and the 3 now detached locomotives at the rear collided with the stationary lead portion. This resulted in significant damage to the rear wagon and a locomotive.

What increased risk

Three locomotives were coupled to the rear of the loaded grain train for the purposes of banking[1] the train later in the journey. The couplers did not lock correctly and the train separated during transit when it changed from a compressive (bunched) to a stretched state. The investigation found that a positive stretch test was not performed prior to departure. Commonly, a stretch test is performed with a low traction power setting to ensure sufficient tensile pressure is placed on the coupler knuckles to confirm they have locked after coupling.

Safety advisory notice

RO-2022-001-SAN-01: Knowledge of the design features of automatic couplers, their differences and limitations, particularly with regards to locking mechanisms, is key to understanding the importance of conducting a positive stretch test at the conclusion of a coupling manoeuvre. The ATSB advises that rolling stock operators should ensure their operational staff are advised and assessed on coupler locking design features which assist in maintaining a knuckle in an unlocked state and methods required to ensure the knuckle has again locked after coupling has occurred.

Ensure understanding of coupler operation

Understanding the purpose of a procedure is important in assisting recall of critical steps.

In automatic couplers, after being lifted by the control (uncoupling) rod the locking block rests on a set shelf.[2] This allows the knuckle to unlock and remain unlocked during coupling / uncoupling operations, enabling operational staff to release the control rod and move clear of the rolling stock profile during shunting.

To allow the knuckle to re-lock it must first be opened to dislodge the locking block from the set shelf, effectively arming the locking block to automatically drop into place and lock the knuckle again once closed.

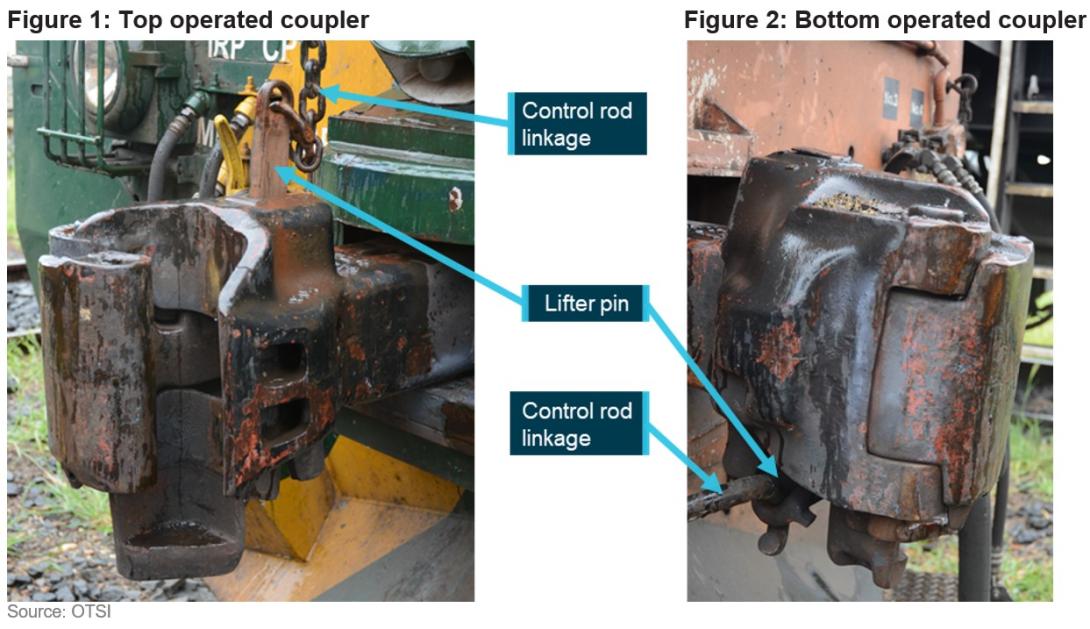

While top operated couplers provide a clear visual cue when the knuckle is unlocked, specifically, the lifter pin is significantly raised above the coupler assembly (Figure 1), the range of movement and vision of a lifter pin on a bottom operated coupler is markedly reduced (Figure 2).

Due to significant limitations in visual cues, a positive stretch test, particularly of bottom operated couplers, is essential for verifying that the knuckle is locked at the conclusion of a coupling manoeuvre.

Read more about this ATSB investigation: Collision between banking locomotives and grain train 5446, near Werris Creek, New South Wales, on 6 January 2022