Executive summary

What happened

On the morning of 21 September 2018, a train driver was using remote control equipment (RCE) to control and position TasRail train no. 604 so that it could be loaded with cement powder at a siding in Railton, Tasmania. The driver was outside the train and no-one else was on board.

Having overshot the intended location to load the last 2 wagons, the driver attempted to use the RCE transmitter to reverse the train. However, the train did not respond to their commands. The driver attempted procedures to recover the RCE from known failure modes in order to restore control, however these were unsuccessful.

As the driver began to walk towards the locomotive to attempt to reset equipment, they noticed the train start to move. They attempted several methods to command the train to stop by using the RCE transmitter, but these were unsuccessful. Instead, the train, which was on a downhill grade, continued to roll away, leaving the siding and entering the main line toward Devonport.

The driver notified TasRail network control of the runaway, and they in turn notified emergency services. Network control also organised for the points at the entrance to Devonport Yard to be set to divert the train from the main line, which continued past this location, into a dead-end siding within the yard.

The train travelled through 10 active and 3 passive public level crossings, beneath a highway overpass, and through 5 sets of points, mostly at speeds greater than the maximum track speed. It reached a maximum recorded speed of 87.5 km/h.

About 23 minutes after the train rolled away from Railton, it collided with a concrete footing and surrounding fences at the end of the silo siding in Devonport Yard. The derailment caused significant damage to the train’s locomotive and 7 wagons, as well as damage to the end of the siding and fences. Fence debris struck 2 pedestrians who had been walking in the area, resulting in minor injuries to both.

What the ATSB found

Key parameters related to the remote control equipment (RCE) were not recorded. This hindered internal and external safety investigations of events involving use of the RCE, both for this accident and previous events. However, the ATSB was able to determine that the RCE entered a spurious fault condition (involving the application of emergency braking) that was almost certainly associated with rapid movement of the RCE transmitter’s direction controller by the driver. This likely initiated an unintended interaction between a safety feature (the dual direction fault interlock) and braking systems on the locomotive, which resulted in an emergency-level brake application.

At about this time, the RCE ceased to respond to driver commands. Instead, the initial brake application was released, then 2 further emergency brake applications and releases occurred. These did not replicate any documented fault condition behaviour for the RCE. A short time later, while still unresponsive to driver commands and with the train’s brakes still released, the train started to roll away.

When a driver was operating the train from outside the train (such as during loading and unloading), there was no way for them to stop the train if the RCE ceased to respond. Also, the TasRail cement loading facility at Railton had a downhill grade to the main line, and no devices to protect against runaway.

The RCE receiver was designed to apply the train’s brakes when it was outside of radio communication range with the transmitter, but this did not occur when the train rolled away from Railton. Instead, the train proceeded to roll away with the brakes remaining released until it derailed in Devonport Yard.

When network control was notified of the runaway, TasRail staff and emergency services conducted a prompt and effective response. This included routing the train away from the main line into the yard and protecting some level crossings; actions that minimised the risk exposure of the public. However, the successful response on this occasion was not assured, as TasRail’s processes for responding to emergency situations fundamentally relied on the experience and knowledge of NCOs and did not include the provision of procedures, tools and checklists detailed enough to support the effective management of specific types of incidents that require a time-critical response.

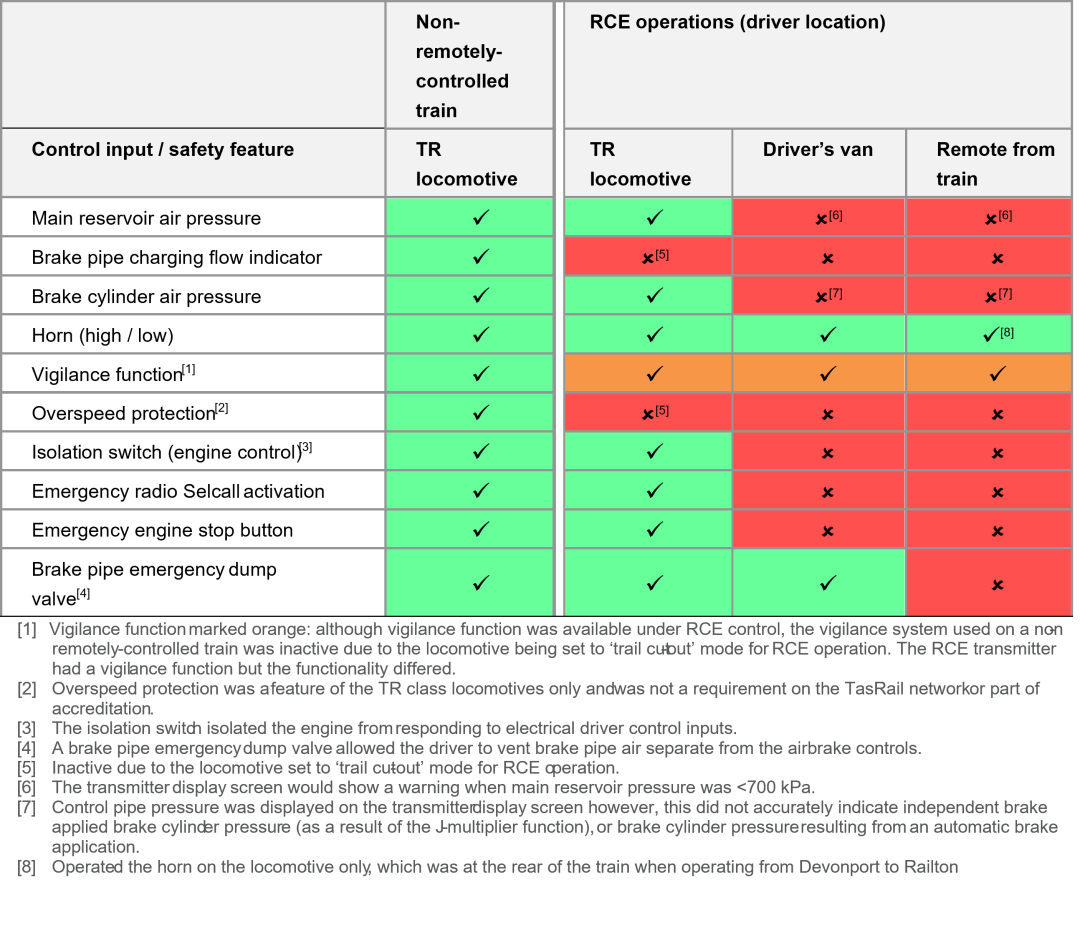

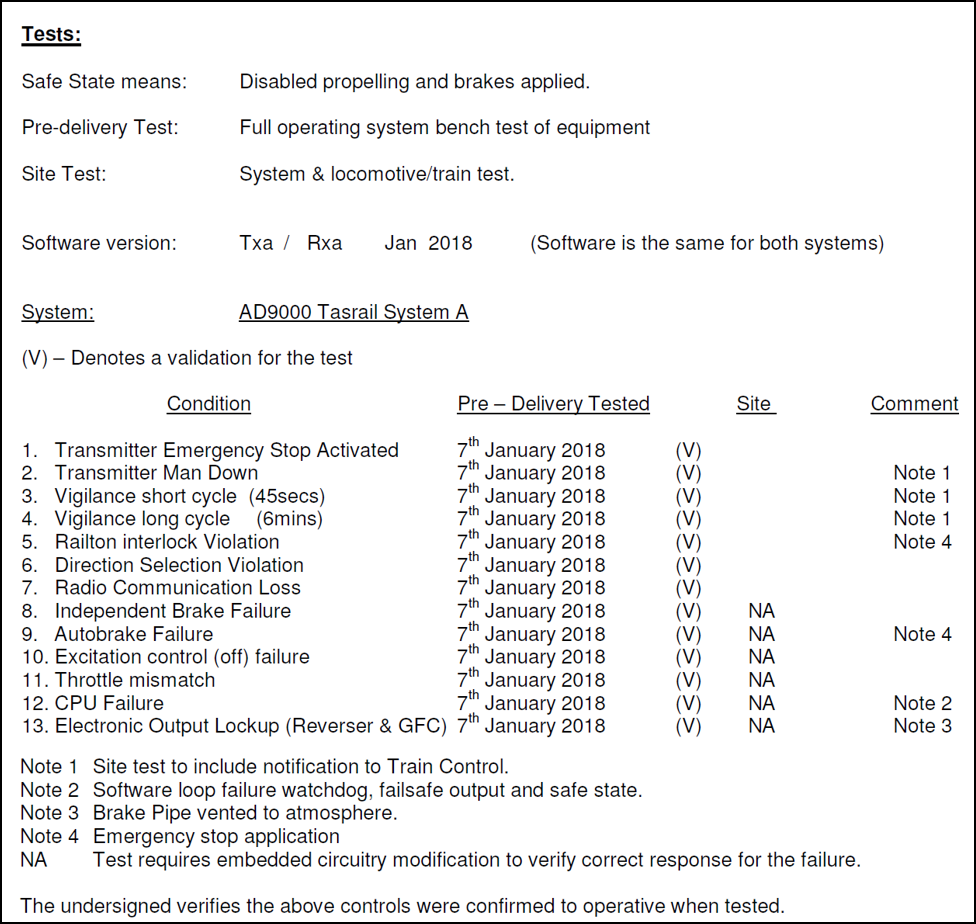

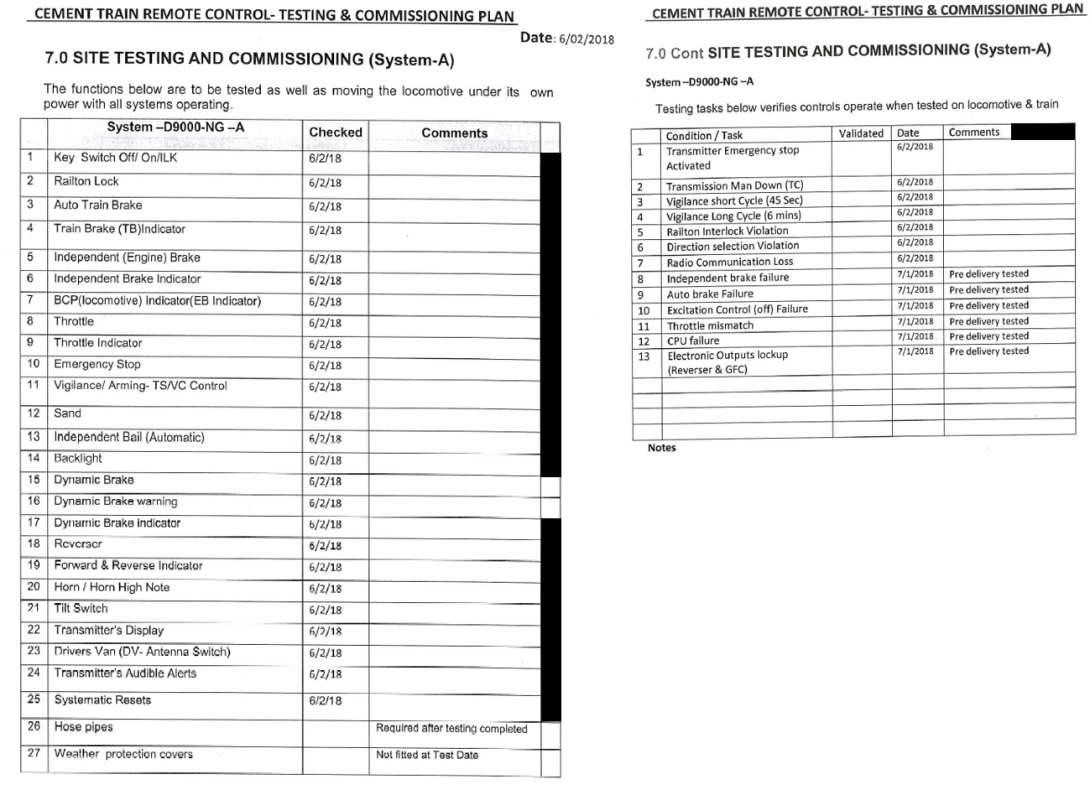

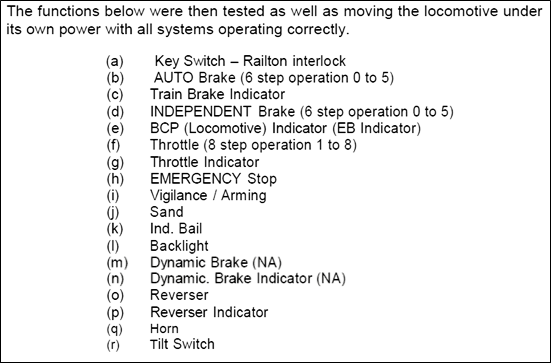

The ATSB examined a range of topics associated with the development of the RCE, and its use more broadly. At the time of the runaway, TasRail were using the third generation of RCE developed and manufactured by Air Digital Engineering (ADE) to remotely operate the cement train. The generation 3 RCE had been commissioned for use in February 2018 and incorporated several changes from the previous generation used by TasRail. However, the generation 3 RCE had several safety-related design and integration problems, including the potential for unintentional activation-and-release of emergency braking on the locomotive and opposition to externally-initiated emergency brake applications. These issues existed at the time of the accident but had not been identified during the testing and commissioning processes.

The RCE was used as the primary driver control interface to control the train, both when loading/unloading with the driver outside and during transit when the driver was either in the locomotive or the driver’s van. As such, the function that the RCE performed was safety critical. However, although ADE had safety as a design objective and safety elements were included in the RCE, systems safety assurance activities appropriate to its application were not conducted.

TasRail had operated the cement train service successfully using previous generations of the RCE for about 19 years without any accidents attributable to the RCE, which likely contributed to a high level of confidence in the RCE and overall operation. Nevertheless, the development and integration of new equipment is not solely the responsibility of the equipment manufacturer; the organisation using the equipment also has a duty to ensure it is safe. In this case, TasRail commissioned the manufacture of the new equipment without fully engaging with the development process or understanding the extent of design changes since the previous generation of RCE, identifying and imposing safety requirements, or verifying that the overall system met a specified level of safety.

The ATSB also found that there were problems associated with TasRail’s management of change. Most activities that were required by TasRail’s procedures for a significant change were not performed during the project to develop and implement the generation 3 RCE. Furthermore, the change management process, while detailed, had limited capability to assure that activities, approvals, and documentation that were identified as being required were completed. The process also had limited capability to reliably determine whether the change being considered had the potential to impact safety or identify what safety assurance activities were needed to manage the change.

In addition, there were broader safety issues identified relating to TasRail’s remotely-controlled train operations, separate to the implementation or use of the generation 3 RCE. TasRail had not identified or fully assessed the safety implications of remotely-controlled train operations or those of its specific implementation. TasRail also did not have a reliable process to systematically identify, track and analyse reported faults on its remotely-controlled train or to identify their potential safety implications.

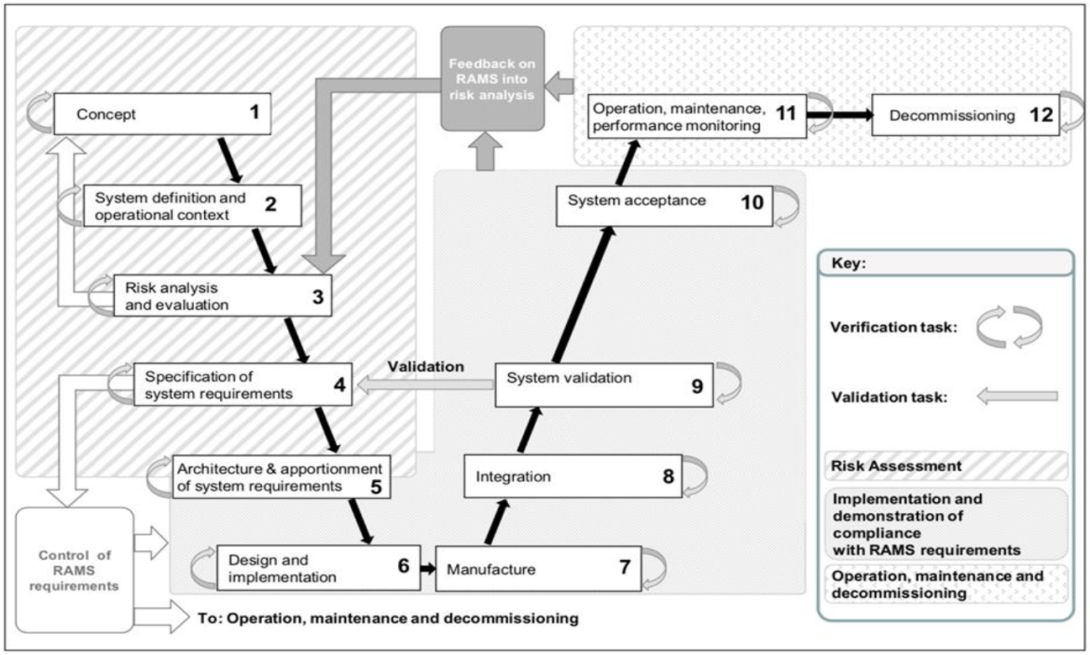

The ATSB also identified that, at the time, there was limited practical guidance specifically for the Australian rail industry for the application of system safety assurance processes to the development of complex and safety-critical rail systems. Although standards, legislative requirements, and guidance for rail safety were recognised and applied in Australia, they were of limited value in the development and operation of complex systems.

There was also no explicit regulatory requirement for developers of rail equipment to demonstrate an objective evaluation of design safety or apply system safety principles during development. If a rolling stock operator or equipment developer intended to apply system safety principles, there were numerous challenges in attaining justified confidence in its success, which were difficult even for experts to overcome. Overall, the standards and guidance for system safety available at the time of the runaway were too abstract, complex, costly and/or impractical for widespread recognition and acceptance by the Australian rail industry.

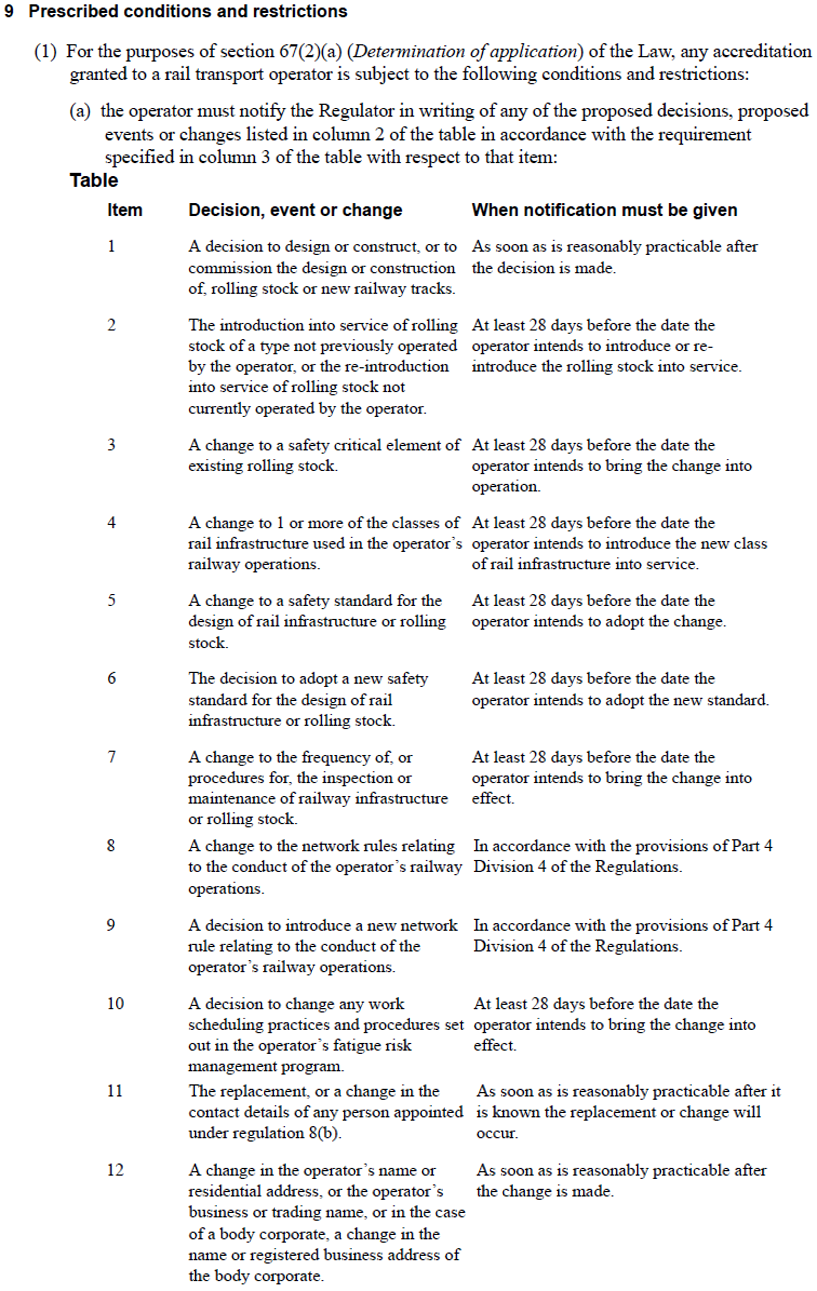

Separately, there is a requirement for rolling stock operators to notify ONRSR when they intend to make certain changes. A change to a safety critical component, such as the RCE, should be considered the type of change which should be notifiable to ONRSR, so that regulatory oversight may occur. However, TasRail did not submit a notification of change for the generation 3 RCE and this was likely because an accepted view had formed within TasRail that it was ‘like-for-like’ replacement and therefore minimal change was occurring.

Guidance material prepared by ONRSR relating to the regulatory requirements for notifying change included limited detail about the extent or type of changes that necessitated a notification. One category that was identified as requiring notification was ‘a safety critical element of rolling stock’. However, the guidance did not provide an interpretation of ‘safety critical’ or the applicability of the requirement to equipment that may not be inherently part of rolling stock (such as RCE). In this case, a notification of change had not been provided to ONRSR, but the reasons for this were not found to be related to the interpretation of the regulation.

What has been done as a result

Following the accident, TasRail immediately suspended remotely-controlled train operations. In November 2020, TasRail completed installation of a catch point at the western end of the Railton siding to prevent runaway rail vehicles from entering the main line. TasRail also:

- extensively revised its processes and guidance on change management, project management, engineering design

- enhanced processes for fault tracking and analysis

- implemented checklists to help ensure consistent and sound decisions during time-critical emergency responses.

ADE advised that it would re-evaluate the generation 3 remote control equipment under system safety design principles if it were to be used for future operations.

ONRSR advised that it planned to provide additional guidance about interpreting the conditions that describe when a notification of change to ONRSR would be required.

Other safety actions have also been taken that help address safety issues identified by the ATSB (although were not initiated as a direct result of this accident):

- In November 2018, the Rail Industry Safety and Standards Board (RISSB) finalised Australian Standard (AS) 7472 (Railway operations - management of change), to assist rail transport operators in fulfilling change management responsibilities. (This standard was in development prior to the accident.)

- ONRSR published a safety message in March 2019 titled Importance of a System Engineering Approach and 2 related fact sheets in 2020 that emphasised the need for a systems engineering approach in rail projects and drew attention to the relevant standards. The safety message stated that rail transport operators ‘should demonstrate that they use appropriate systems engineering processes and safety assurance processes… in their design and procurement approach.’

- In 2020, RISSB issued standard AS 7473 (Complex system integration in railways) to support a systems engineering approach in Australian rail projects.

- In 2021, RISSB issued standard AS 7474 (Rail industry – System safety) to ‘provide a clear standard for management of System Safety that addresses Australian legislative requirements and is readily scalable for the scope of rail projects undertaken within Australia.’

In addition to providing an overview of the relevant methods, AS 7473 and AS 7474 referred to other more detailed systems and safety engineering standards to enhance their visibility and application across the Australian rail industry.

Safety message

Rolling stock operators and equipment developers both have duties to ensure the design and modification of rolling stock and other equipment is safe for its intended use. This accident reinforces the need for such organisations to identify what systems are performing safety-critical functions and manage the risks of systems failure by ensuring the system has appropriate levels of reliability and/or by using secondary safety components that can override a failed system. This is especially true of complex systems such as those that implement software, due to the potential for these systems to fail in ways that are hard to predict.

Systems for the management of change need to reliably assure the determination of whether a change had the potential to impact safety and identify the need for relevant safety assurance activities. When a new system is implemented, or changes occur to a system, effective safety management needs to be a joint effort between the operator and the developer in order to effectively identify safety hazards and ensure that associated risks are managed. Operator involvement at this stage is important to fully account for the safety implications of the broader system.

Overall, it is important to ensure that systems have a compelling argument for their safety. Developing such an argument is not a simple task but there are numerous standards and guidelines available for a range of applications, including (more recently) specifically for the Australian rail industry. The ATSB strongly advises rolling stock operators and developers of rail systems to apply system safety methodologies so that they can have a high level of confidence in the overall safety of the system. The ATSB additionally encourages the continuing development of guidelines and standards to enhance the accessibility and practical application of system safety principles for all rail operations.

In addition, this investigation has also highlighted that rolling stock operators should ensure that event recorders are recording sufficient parameters for optimal outcomes of safety investigations, including those conducted by the operator.

The occurrence

Overview

TasRail operated train services between Railton and Devonport, Tasmania, for the purpose of transporting cement powder. The trains were operated by a single driver using remote control equipment (RCE).[1] The trains consisted of a TR class locomotive, cement wagons and a driver’s van.

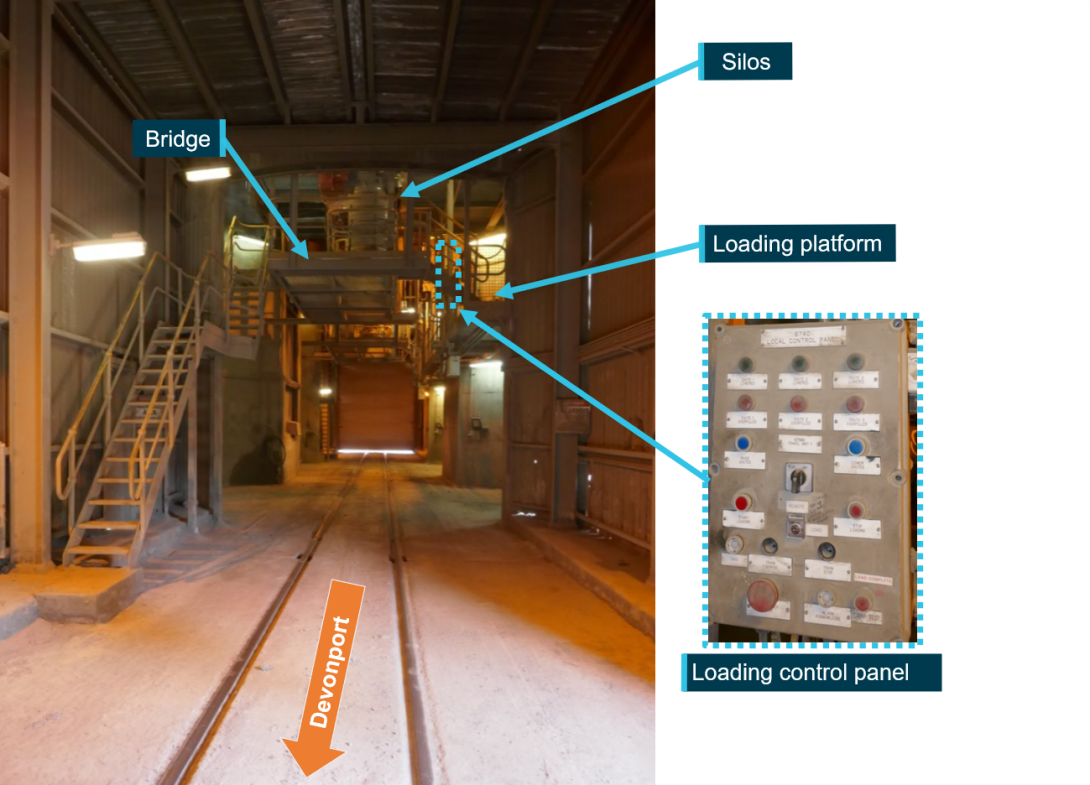

When a train was being loaded with cement at the Railton loading facility, the driver was outside the train and no-one else was on board. The driver operated both the RCE and the loading equipment to transfer the cement powder from silos via chutes into the train’s wagons.

At 0846[2] on 21 September 2018, train no. 604 was being loaded. While the train driver was attempting to manoeuvre the last 2 wagons into position for loading, the train did not respond to remote control commands from the driver. The train (which was on a downhill grade) then rolled away from the facility without any train crew on board and in an uncontrollable state. The train driver informed the network control officer (NCO) about the runaway train, and then arrangements were made for it to be rerouted away from sensitive infrastructure.

The train travelled for about 20 km before reaching a dead-end siding in Devonport at 0909. The train collided with the end of the dead-end siding, and travelled in a derailed state for about 60 m into a public area.

Operations before the occurrence event

At 0130 on 21 September 2018, the driver signed on at Devonport Yard to work the service between Devonport and the Railton cement loading facility, taking over from another driver who had worked the preceding shift. The drivers performed a handover at the cement silos at Devonport where train no. 512[3] was being unloaded, with the previous driver advising that there were no faults or issues with the train or the RCE.

At 0220, the driver departed with the empty train from Devonport for Railton, where the 16 wagons were to be loaded. The train returned to Devonport to unload, before returning to Railton at 0740 to load again. During these cycles between Devonport and Railton, the RCE and train continued to perform as expected, with no faults or issues identified.

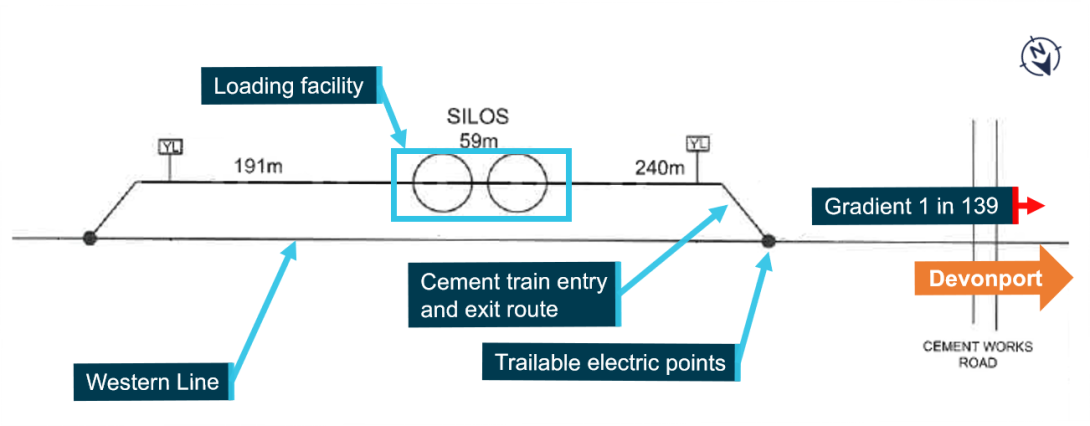

On arrival at Railton, the driver alighted from the train in preparation for checking the wagon doors prior to loading the train (now train no. 604). The Railton cement siding was located on the southern side of the main line between Devonport and Railton Yard. The loading facility (consisting of 2 cement powder silos) was situated on the siding (Figure 1). From the loading facility, the track had a downhill grade of 1 in 139[4] westward towards Devonport. Access to the main line was through a set of trailable electric points.

Figure 1: Railton cement siding and loading facility

Source: TasRail, modified by the ATSB

Loading train no. 604

At about 0746, after checking the bottom discharge doors on the wagons as the train passed through the loading facility towards Railton Yard, the driver aligned wagons 1 and 2 under the silos in preparation for loading. As the loading process was designed to be a single person operation, the driver then entered the loading facility and proceeded to the upper level where the loading control panel was positioned (see Train loading process).

The driver removed the key from the RCE transmitter and placed it into the loading control panel to allow operation of the panel’s loading controls.[5] The driver then commenced loading of the first 2 wagons with cement powder.

Once the 2 wagons were full, the driver removed the transmitter key from the loading control panel and placed it back in the RCE transmitter, allowing driver commands to be sent to the RCE receiver on the locomotive. The driver then moved the train forward towards Devonport using the transmitter, aligning the next pair of wagons for loading. This process continued for the first 14 wagons (that is, the first 7 placements).

At about 0841, the driver removed the transmitter key from the loading control panel and placed it into the RCE transmitter to facilitate the next train movement forward to load the final 2 wagons. Using the transmitter, the driver released the automatic (train) brake, placed the direction controller in forward, released the independent (locomotive) brake, and applied light traction power. As the train came to a stop, the driver noticed that they had misjudged the wagon alignment, overshooting the stopping mark[6] by about 20 cm.

Remote control equipment failure

The driver recalled that, after the train came to a stop, they requested the direction to change (via the RCE transmitter) in preparation to reverse the train. The data recorded on the locomotive showed that the direction went immediately from forward to reverse without registering in neutral.

The driver informed the ATSB that, after releasing the train’s brakes, they applied traction power to facilitate the rearward realignment of the wagons. After about 1 minute, allowing for the train’s brakes to settle and traction power to take effect, the driver noticed that the train was still not moving. The driver stated that the RCE transmitter display screen was showing the text ‘Connecting 9863 v1.4’, instead of the usual system status information.

On observing the displayed message, the driver believed that the RCE had a communications failure,[7] so they configured the RCE transmitter controls for a reset (direction in neutral, throttle idle, independent brake fully applied, and automatic brake set) and pressed the train set button to reset the fault. The displayed message did not clear as it normally would.

Given the lack of response, the driver then believed that the RCE was experiencing a control fault.[8] They reported following the procedure to reset the control fault mode, which was to:

- retain the transmitter configuration as described above

- turn the transmitter’s key switch off, wait about 10 seconds

- turn the transmitter key switch on again and press the train set button to return to ‘run’ mode.

The displayed message immediately reappeared on the transmitter display screen, so the driver repeated the process. Immediately after the second attempt at a control fault mode reset, the same message reappeared, so the driver determined a ‘cold start’ reset would be required to clear the fault. This required the driver to proceed to the rear of the locomotive (14 wagons away) to disconnect and reconnect the multiple unit cable[9] between the RCE receiver and the locomotive.

The driver informed the ATSB that the transmitter display screen continued to display the message ‘Connecting 9863 v1.4’ throughout the initial occurrence sequence. This indicated that the driver’s RCE transmitter did not have a communication connection to the RCE receiver on the locomotive.

The runaway

At 0846:42, just as the driver had started to walk along the loading platform (while carrying the RCE transmitter) to perform an RCE reset at the locomotive, they noticed the train start to move forward. As the independent (locomotive) brake was still applied on the RCE transmitter, the driver thought that the train was momentarily ‘bunching’ coupler slack[10] on the downhill grade against the stationary locomotive.

The driver quickly realised that the train was moving past the expected extent of a bunch movement and they applied a full-service automatic (train) brake application on the RCE transmitter. When that did not work, they turned off the transmitter key switch to cause a communication failed mode automatic brake application. When the train still did not respond, the driver tilted the RCE transmitter[11] and then removed the battery as further attempts to command a brake application, which were also ineffective.[12] The driver also stated that they thought they had tried to use the ‘emergency stop’ switch on the RCE transmitter but did not recall when in the sequence this occurred.

The driver observed the driver’s van at the rear of the train exit the Railton loading facility in the direction of Devonport. Believing that the RCE’s vigilance function[13] would automatically apply the brakes, the driver crossed the loading platform bridge and walked down the stairs to observe the train’s stopping position. The train continued to roll out of the cement siding and onto the main line out of the driver’s view. With no further method to stop the train available, the driver immediately rang the network control centre to report the runaway train.

Emergency response

At 0848:05, the network control officer (NCO) answered the driver’s phone call and was advised that there was a runaway train. The NCO immediately checked the section of track from Railton to Devonport was clear and discussed with the driver where the train was likely to stop. It was determined that this could be prior to Devonport at Horsehead Creek, due to a rising grade and 40 km/h curves. In a scenario where the train continued to roll past Horsehead Creek, background conversations of other TasRail staff in attendance determined that the best course of action was to set the points to divert the runaway train into Devonport Yard, away from the main line and several level crossings. There it would derail at a dead-end siding, away from the township.

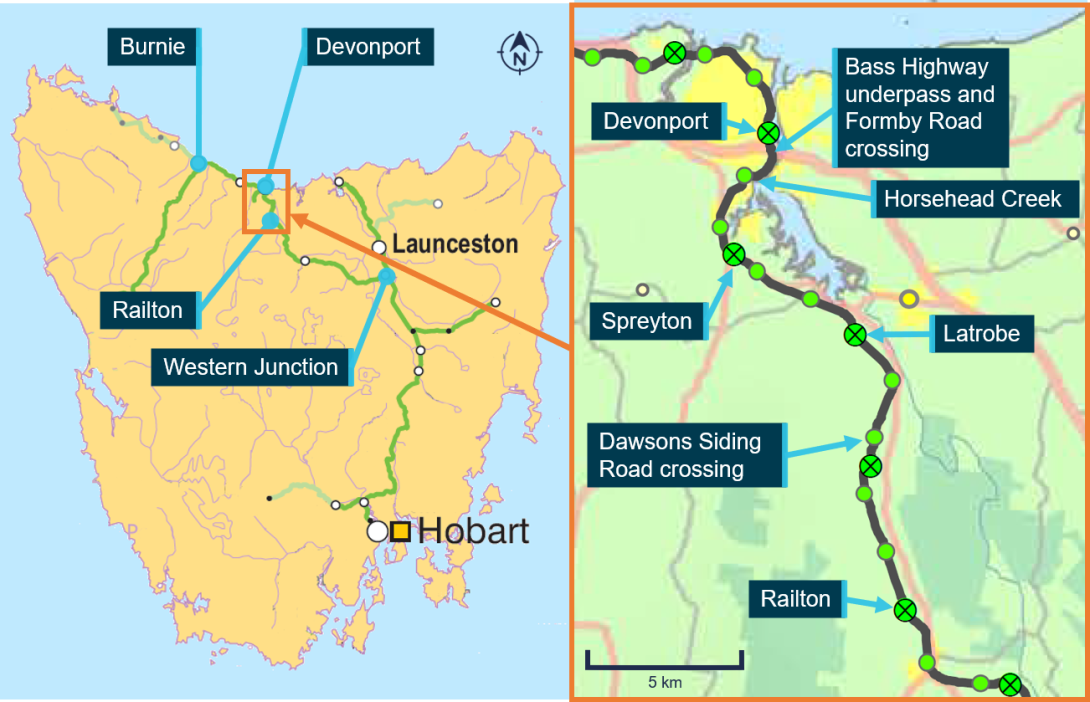

To facilitate the switch in points, the general manager freight services (who had been alerted to the runaway and was able to assist) contacted the shunter based at Devonport at 0852 and instructed them to set the points (no. 85 and no. 88) for no. 2 road Devonport (silo siding) (Figure 2). When the shunter advised this had been done, the general manager instructed the shunter to warn local businesses near the yard to evacuate.

Figure 2: Devonport Yard showing the route taken by the train to the dead-end siding

Source: TasRail, modified by the ATSB.

At 0853:52, 1 minute after the phone call with the driver concluded, the NCO contacted emergency services. The NCO advised Tasmania Police of the runaway event and the location of major level crossings between Spreyton and Devonport that would require police protection, with derailment now deemed likely to occur at the end of Devonport Yard.

The TasRail rolling stock asset manager had been alerted to the runaway. They logged into a computer in a room near to but separate from the network control centre to view the train’s GPS speed and location information to allow monitoring of the train in real time. They relayed this information verbally to the network access manager, who was present in the network control centre at the time the runaway train was reported by the driver.

At 0858:41, the network access manager took over from the NCO communicating with the police to streamline the relay of messages. Over the next 11 minutes, the network access manager liaised with emergency services to deal with the emergency, including:

- providing regular GPS train speed and location updates

- advising likely derailment points between Latrobe and the entry to Devonport Yard

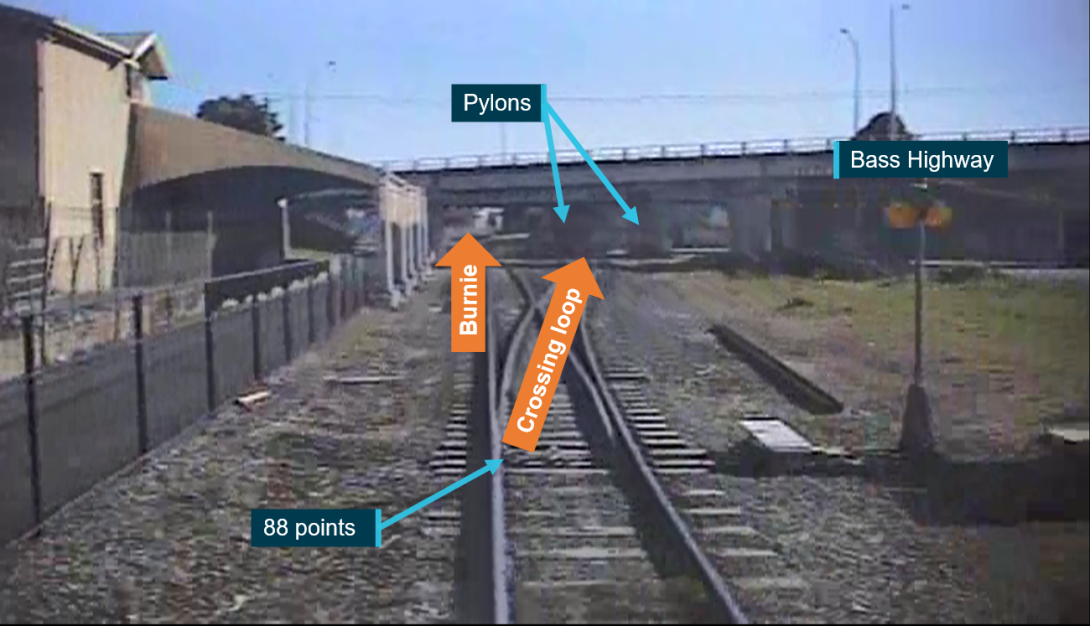

- discussing the possibility of a derailment at no. 88 points near the Bass Highway causing a bridge pylon strike

- requesting fire services and ambulances to attend Devonport Yard

- advising the final stop location after the train had derailed.

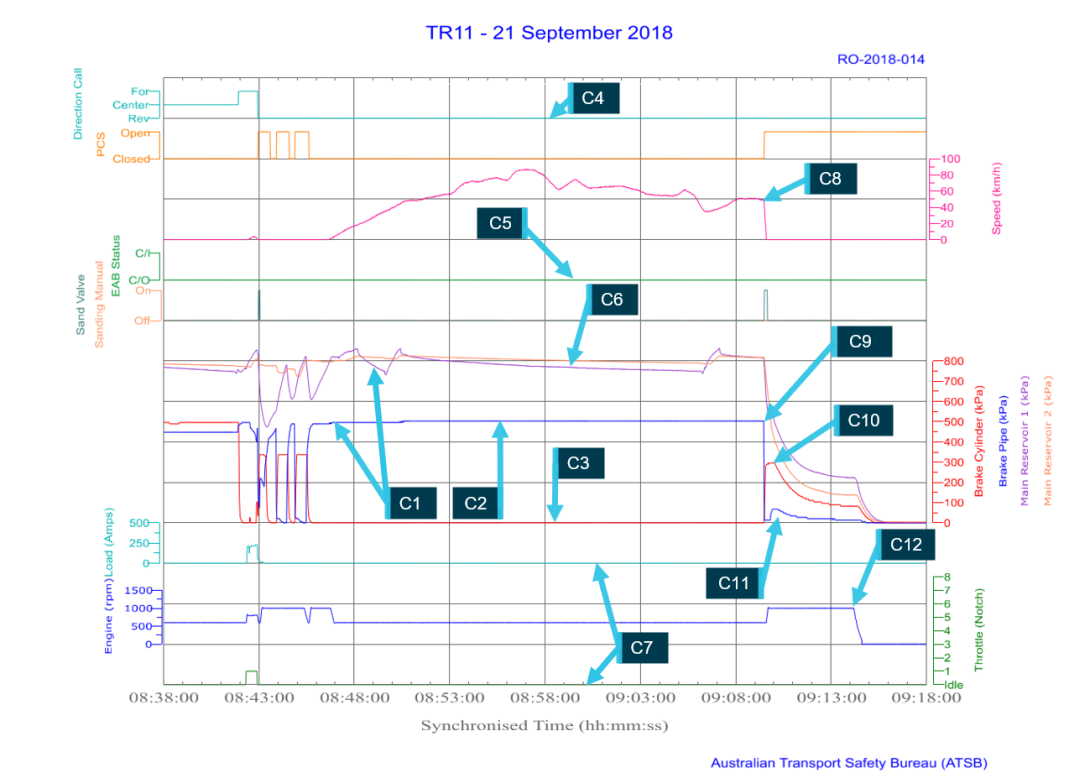

The train travelled through 10 active and 3 passive public level crossings, beneath a highway overpass, and through 5 sets of points,[14] mostly at speeds greater than the maximum track speed at each location. It reached a maximum recorded speed of 87.5 km/h. A summary of the train’s location and speeds during key events of the runaway sequence are summarised in Track features.

At about 0900, Tasmania Police despatched 20 police units to respond. The police response focussed on protecting the public in front of the train by alerting pedestrians and vehicles to the danger through activation of lights and sirens on all attending police vehicles and the closure of level crossings. However, not all road-rail interface points could be protected in time, including the Bass Highway overpass.

The derailment

At 0909:29, the cement train collided with a concrete footing and fences at the end of the silo siding in Devonport Yard. The train derailed, and then came to a stop adjacent to the Mersey River Torquay Ferry pontoon in Pioneer Mariner’s Park.

Shortly before the derailment, 2 pedestrians who were walking in the area heard the police sirens and looked up and saw the oncoming train. Although they quickly moved away, they were both struck by fence debris, resulting in minor injuries.

In addition to the damage to the end of the silo siding, fences and park surrounds, 7 cement wagons and the locomotive were significantly damaged, with wagon wreckage blocking the main line between Devonport and Burnie (Figure 3).

Figure 3: Derailment site in Devonport, Tasmania

Image shows the location of the injured pedestrians at the time of the derailment, as well as the cement train consist configuration.

Source: ATSB

Following the accident, TasRail suspended RCE operations. The cement train service recommenced 2 days after the accident with a locomotive at both ends and with a 2-person crew configuration. The main line between Devonport and Burnie reopened to trains at about 2300 on 24 September 2018.

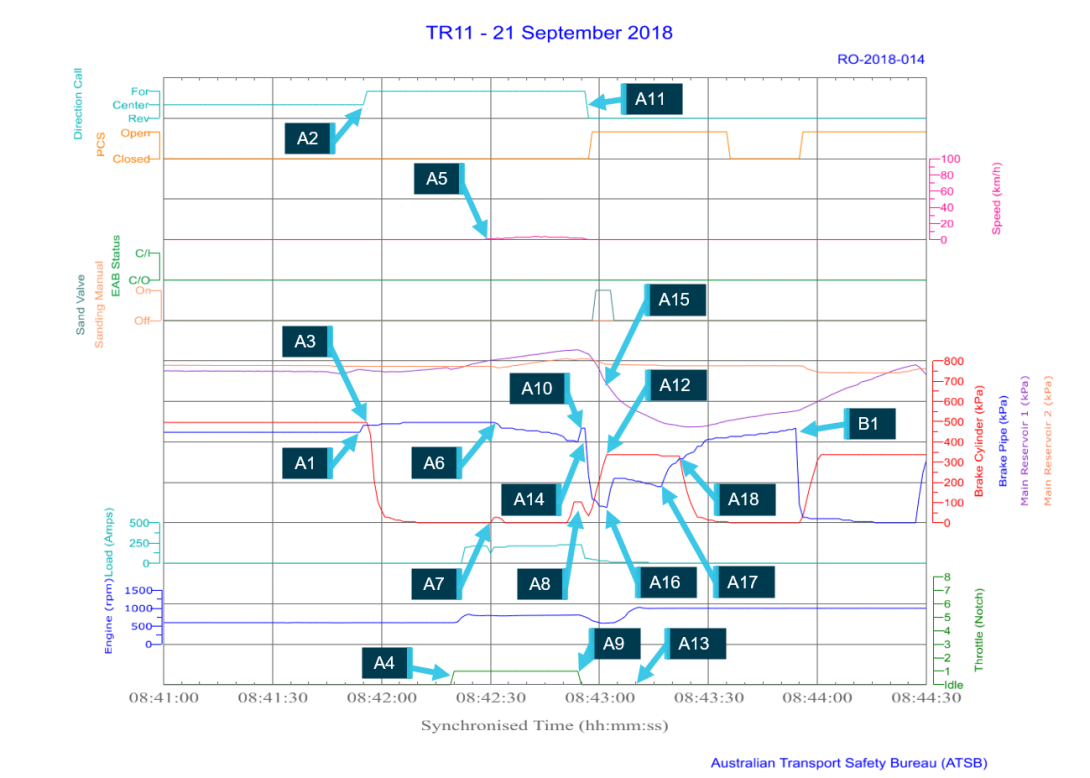

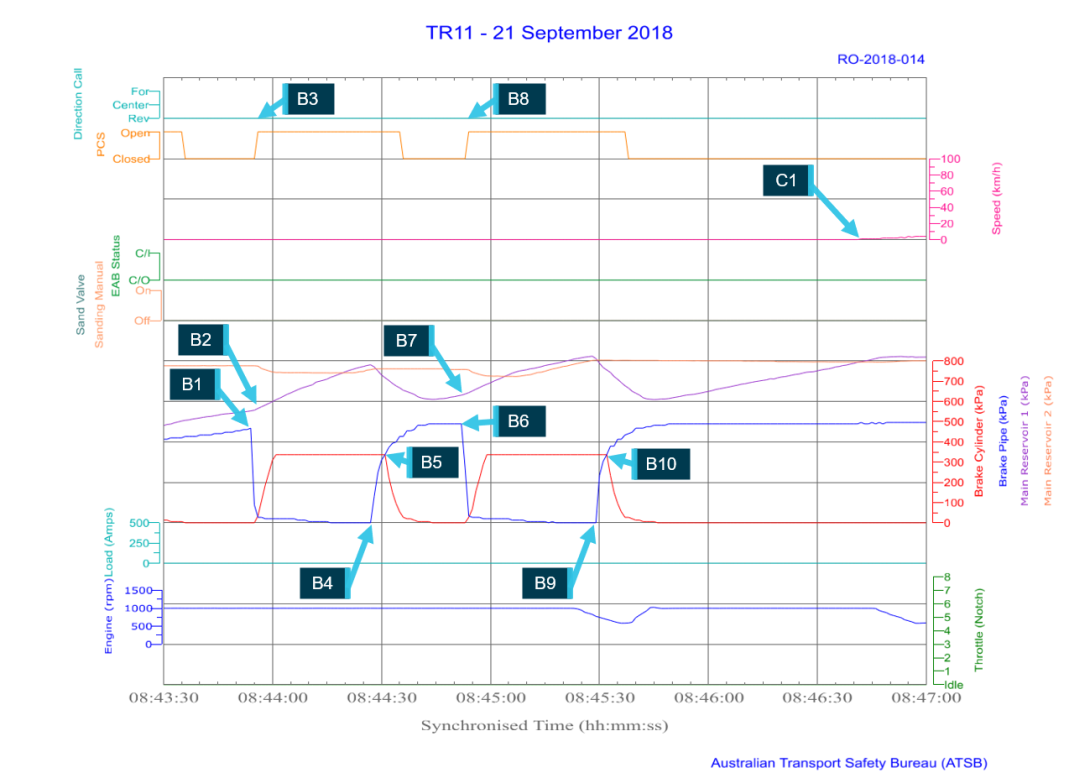

Additional occurrence sequence information

The ATSB’s analysis of information relating to the accident sequence (including during loading, the runaway, and the derailment) is presented in Appendix A. The analysis drew on information from multiple sources, including data recorded on the locomotive, the driver’s recollection, and both data and observation of system behaviour obtained during subsequent testing.

The TR class locomotive and the driver’s van [15] were fitted with data recording devices (see Event recorders for more information). The RCE had no data recording capability, which limited the investigation’s ability to identify or understand some of the key events.

Based on the available evidence, including the data recordings, the ATSB analysis identified that the following occurred during the accident sequence:

- The RCE became unresponsive to driver commands at the point of, or soon after, a fast direction change from forward to reverse.

- The RCE initiated a momentary emergency vent of the brake pipe, likely due to a momentary ‘dual direction fault’ being detected. The emergency vent resulted in the locomotive’s VX vent valves and emergency magnet valve (EMV) activating to exhaust the brake pipe further, which the RCE tried to oppose after the fault state cleared by supplying pressurised air from main reservoir no. 1 to the brake pipe.

- The RCE triggered 2 further emergency brake applications and releases.

- The RCE ultimately entered an unsafe state with the brakes on the train and locomotive fully released, allowing the train to roll away on the downhill grade towards Devonport.

- The RCE did not command a ‘communication failed mode’ or apply the train’s automatic brake, either when the transmitter and receiver were unlinked, or once the receiver was out of radio range of the transmitter.

- The emergency brake applications and releases, and subsequent state with brakes released without a radio link, were not consistent with any documented fault condition behaviour.

- The RCE remained in an unsafe state, which caused the brakes on the train and locomotive to be maintained in a fully-released condition, until the train’s brake pipe was ruptured in the derailment.

After comprehensive testing and analysis, the ATSB also determined that:

- The locomotive, including its control and safety systems, operated as designed.

- The locomotive electronic airbrake system operated as designed.

- There was no evidence of malicious interference to the RCE or train systems.

Given this pattern of evidence, the ATSB concluded that the RCE entered a spurious fault condition (which applied the emergency brake) when the driver rapidly commanded a direction change, and then entered a persistent unresponsive state in which the train’s brakes were not applied.

This unresponsive state was not reproduced during post-accident testing activities and the specific mechanism involved was not identified. Nevertheless, the fact that the unresponsive state occurred on this occasion indicated that a latent failure mode existed within the RCE system that could not be readily diagnosed.

The following sections provide further information regarding the cement train service, the train’s braking systems, the RCE (which was being used to operate the train and its braking systems), the design process and in-service history of the RCE, and other relevant subjects.

Context

Track and network

General information

The Western Line (which included the track section from Railton to Devonport) consisted of 160 km of 1,067 mm narrow gauge railway between Western Junction and Burnie, Tasmania. TasRail was the rail transport operator (RTO)[16] accredited as the rail infrastructure manager for this track section.

Devonport, located on the northern coast of Tasmania, had a ship loading facility. Devonport Yard was located near the facility at an elevation of 3 m above mean sea level (Figure 4).

Figure 4: Map of TasRail network

Source: Australasian Railways Association and TasRail, modified by the ATSB

Railton, located 21 km to the south of Devonport, was the location of a cement plant with a train loading facility. It was at an elevation of about 59 m.

The track descended from Railton towards Devonport with brief rising gradients encountered at 3 locations, the most substantial being in the vicinity of Horsehead Creek (Figure 4).

The safeworking system[17] on the Western Line was the advanced network train control system (ANCS) track warrant (see Network control).

Railton loading facility

Access from the Railton loading facility to the main line was through a set of trailable electric points where the main line and the track to the siding converged (Figure 1). On approach to the Railton cement siding with an empty cement train, a driver would (using the radio) remotely operate the points for entry into the siding. Once the train had entered the siding and was clear of the points, the points would automatically reset to the Western Line.

When departing Railton, the train would ‘trail’ through the points where the main line and track to the siding converged, which would automatically reset to the Western Line once the train was clear.

Onsite inspection by the ATSB at Railton on 22 September 2018 found no damage to infrastructure, including to the trailable electric points.

As previously noted, from the loading facility, the track had a downhill grade of 1 in 139[18] from the loading facility westward towards Devonport. There were no catch points or derailers fitted at the Railton cement siding (Figure 1). The purpose of catch points is to divert and derail an uncontrolled movement from a siding away from the main line. They are often installed on sidings with a downhill grade to the main line.

During March–April 2018, TasRail conducted a generic risk assessment for a runaway train across its entire network. An identified risk control was the provision of derailers or catch points at strategic locations based on a ‘…risk based approach of topography in yards to identify addition of catch points’ (that is, those with descending gradients to the main line).

TasRail advised that, at the time of the 21 September 2018 accident, Railton had not been risk assessed for consideration of catch point installation.

Track features

The maximum track speed between Devonport and Railton was 60 km/h, with lower speeds of between 40 km/h and 50 km/h at 3 locations associated with track curves.

Between Railton and Devonport, the line passed through 13 public level crossings, 10 of which were actively protected by flashing lights, which were designed to activate 20 seconds before the arrival of a train travelling at maximum track speed. The remainder were passive level crossings protected by stop signs only, relying on sighting distance. There were also some private level crossings. Table 1 shows the time and speed that the runaway train passed through the level crossings and other locations, together with the track speed at these locations.

Table 1: Location of runaway train and instances of excess speed (orange cells)

| Track km | Time | Location |

Track speed (km/h) |

Recorded speed (km/h) |

| 109.700 | 0846:42 |

Cement siding – Railton (Commencement of runaway) |

Restricted[1] | 0 |

| 109.900 | 0848:18 | Cement Works Road level crossing (active) | Restricted | 20 |

| 112.000 | 0851:41 | Youngmans Road level crossing (passive) | 60 | 51 |

| 116.100 | 0855:28 | Dawsons Siding Road (active) | 60 (exit 40) | 76 |

| 118.000 (approx.) | 0856:56 | Fastest recorded speed | 60 | 87.5 |

| 119.900 | 0858:18 | Coal Hill Road (active) – Latrobe township | 60 | 70 |

| 121.500 | 0859:48 | Henslow Street (passive) | 60 | 71 |

| 122.300 | 0900:22 | Tarleton Road (active) – Tarleton locale | 60 | 64 |

| 122.900 | 0900:54 | Fosters Road (passive) | 60 | 64 |

| 123.400 | 0901:23 | Cornicks Road (active) | 60 (enter 50) | 65 |

| 125.100 | 0902:53 | Sheffield Road (active) – Spreyton township | 40 | 61 |

| 125.700 | 0903:29 | Kelcey Tier Road (active) | 40 | 56 |

| 126.500 | 0904:25 | Stoney Rise Main Road (active) | 40 | 54 |

| 126.900 | 0904:51 | Durkins Road (active) | 40 | 55 |

| 127.720 | 0905:13 | Start of Horsehead Creek vicinity | 40 | 60 |

| 128.520 (approx.) | 0906:08 | End of Horsehead Creek vicinity | 40 | 43 |

| 128.870 (approx.) | 0906:32 | Slowest recorded speed | 40 | 34 |

| 129.300 | 0907:47 | Formby Road (active) | Restricted | 47 |

| 129.380 | 0907:56 | Devonport Yard entry (no. 88 points) | Restricted | 48 |

| 129.440 | 0907:59 | Bass Highway overpass | Restricted | 49 |

| 129.530 | 0908:09 | No. 85 points (adjacent fuel loading area) | Restricted | 51 |

| 130.570 | 0909:06 | Devonport cement silo | 5 | 51 |

| 130.820 | 0909:29 |

Dead-end cement silos siding (Train derailled) |

Restricted | 47 |

|

As the train travelled through most of these crossings at higher than the maximum track speed, the warning time was reduced. In the worst cases, the actual warning times were about 10 seconds at Formby Road crossing and 14 seconds at Dawsons Siding Road crossing (see Figure 4).

Train drivers were also required to have the train’s headlight illuminated and sound the horn twice on approach to level crossings. In addition to the runaway train being uncontrolled, the locomotive’s headlight (which increased visibility of the train to the public) was extinguished and the locomotive’s warning horn could not be sounded.

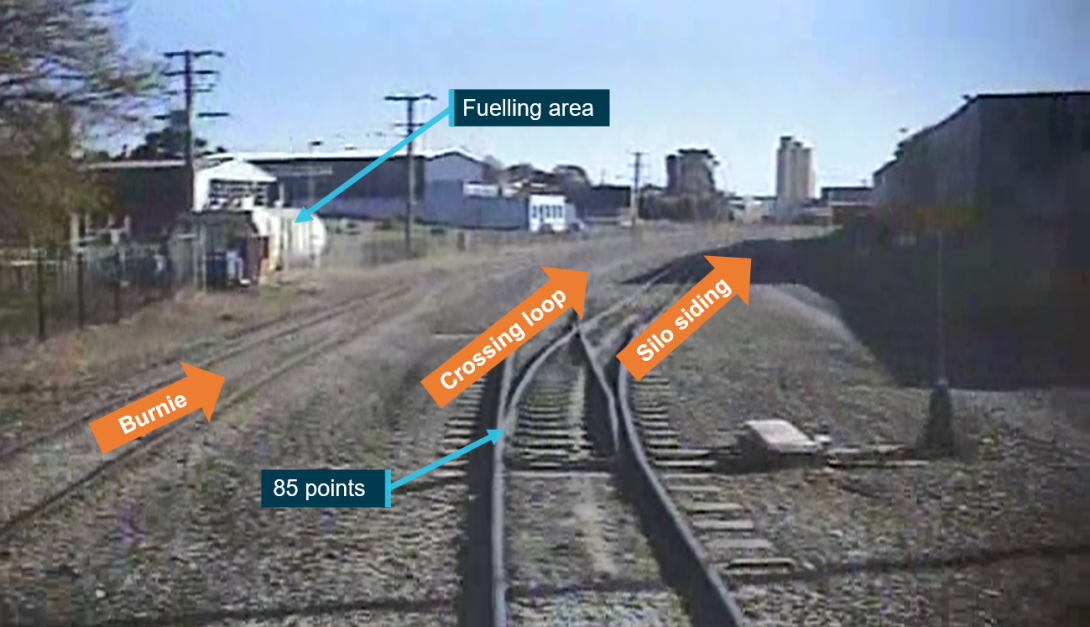

On entering Devonport Yard, the train was diverted from the main line towards no. 2 road (silo siding) for unloading, via radio-operated points no. 88 and no. 85 (Figure 2). The Bass Highway from Launceston to Marrawah (in north-west Tasmania) crossed over the line on an overbridge just to the north of no. 88 points (Figure 5). A fuelling area was located just past no. 85 points (Figure 6).

Figure 5: Devonport Yard, no. 88 points

Diversion point from the main line (towards Burnie) via no. 88 points into Devonport crossing loop. The Bass Highway passed over the line shortly after the points. The speed limit for no. 88 points was ‘restricted speed’ (maximum 25 km/h). The runaway train was travelling at 48 km/h at this point.

Source: TasRail, annotated by the ATSB

Figure 6: Devonport Yard, no. 85 points

Diversion point from the Devonport crossing loop via no. 85 points into no. 2 road (silo siding). A fuelling area was located on the left, shortly after the points. The speed limit for no. 85 points was ‘restricted speed’ (maximum 25 km/h). The runaway train was travelling at 51 km/h at this point.

Source: TasRail, annotated by the ATSB

Network control centre

Overview

Network control services for the entire TasRail network were conducted from the network control centre located within the head office building in Launceston, Tasmania. It consisted of a primary workstation under the control of the shift network control officer (NCO), with a secondary adjacent workstation available if required for backup or supervisory purposes.

During business hours, other network control centre staff that were present included the network access manager, a relief NCO and roster clerk. However, outside business hours the NCO would be the only staff member in attendance.

Network control centre personnel

The NCO who was on duty at the time of the runaway, and answered the emergency phone call from the cement train driver, had 6 years experience, having joined TasRail as a trainee NCO.

The network access manager who liaised with emergency services during the accident had previously been a driver, operations manager and NCO. In 1999 they were involved as the planning manager during the introduction of remote control equipment (RCE) operations for the cement train service (see Operations with previous remote control equipment).

Network control

Safeworking on the TasRail network was administered through the Advanced Network train Control System (ANCS). This system involved the issuance of GPS-tracked electronic track warrants and authorities to trains and track users, using digital radio technology. ANCS would use GPS to monitor both track warrant authority exceedances and train overspeed, providing an alarm to the network control centre in the event of detected breaches.

Yards were under local control, with the ANCS system deactivated once a train was registered within yard limits. This meant that, in the event of a runaway from a yard, the train would be invisible to the ANCS system and no alarm would be registered in the network control centre by the ANCS. Rather, the NCO was reliant on a report of the runaway from either the driver or a member of the public.

Additional Selcall[19] alarms could be sent to the network control centre from the train (independently of the ANCS). Conditions that activated a Selcall alarm included:

- emergency ‘cell call’ button on the TR class locomotive (this button provided the driver a direct means to activate the Selcall alarm)

- RCE- or locomotive-induced vigilance penalty

- RCE tilt function activation

- any event that caused an emergency reduction of brake pipe pressure when the train was travelling over 3 km/h.

Alarms received by the network control centre were presented for actioning by the NCO on the communications screen to the right of the workstation. Phone and radio communications were also managed through this screen.

No Selcall alarms were triggered by train no. 604 during the runaway sequence. This was because the driver was not in the locomotive cab, the vigilance function and tilt function required communications between the RCE transmitter and receiver, and the train was stationary when emergency brake applications were applied.

In addition, the TR class locomotive was fitted with a system for automated locomotive (SAL) computer control, an electronics and automation system that included recording of input and output data. An aspect of this functionality was the provision of a remote connection to the locomotive that provided one-way viewing access to real-time information of digital and analogue locomotive inputs and outputs, including GPS location and speed. This is the system that the rolling stock access manager utilised to monitor the train’s position and speed during the runaway. Although access to this information (via the locomotive manufacturer’s online portal) was available to all TasRail staff, knowledge of this access was limited. For example, the NCO who was on duty at the time of the runaway was not aware that they had access and the network access manager advised they had never tried to access it.

Emergency procedures for runaway events

When an RCE-induced alarm, locomotive alarm or emergency call was received by the network control centre, NCOs were to follow the procedure in NA-PRO-800 (Emergency response). If an emergency was confirmed, the NCO was to immediately protect the area from other trains and call emergency services, advising of the incident and any secondary hazards (for example, dangerous goods).

TasRail procedure SHE-PRO-201 (Administering the incident and emergency response procedure) required the NCO to conduct an evaluation of the potential magnitude of the event using the ‘TasRail 6 x 6 risk assessment matrix’. This would inform the internal TasRail response (for example, appointment of an incident site controller, organising drug and alcohol testing, and reporting of the incident to external authorities). All incidents were to be recorded in the ‘risk wizard’ computer system for tracking and, where required, follow up.

The emergency response procedures did not contain any additional instructions for managing incidents that may have required a time-critical tailored response (for example, a runaway or track warrant authority exceedance).

Driver information

The driver of train no. 604 on 21 September 2018 had worked for TasRail since the early 1970s in various roles including as a driver, based at Devonport for almost all of this time. The cement train was exclusively operated with remote control equipment (RCE) since its introduction in 1999.

The driver was assessed competent as a train driver, with Australian Qualifications Framework qualification TLI42615 (Certificate IV in train driving) awarded to the driver in March 2017. The last reassessment of the driver’s competence for ‘safety critical competency units’ of this qualification was conducted on 9 March 2018, with the driver deemed competent.

In relation to operation of the RCE, the driver was assessed as competent in the unit of competency TLIC3082A (Operate a locomotive by portable remote control) in February 2015. The last reassessment of the driver’s competence for TLIC3082A was conducted on 22 February 2017 (using generation 2 RCE), with the driver deemed competent. Assessed observations included direction change, interpreting communication failed mode and control fault mode, resetting a communication failed mode occurrence, commanding and resetting an emergency stop application, and loading procedures at Railton.

There was no indication that the driver was in any way impaired at the time of the runaway accident. The driver reported they had been sleeping well prior to the shift and they did not report any issues with fatigue. They were about 7 hours into their work shift at the time of the accident. A drug and alcohol test was administered after the accident and returned a negative result (that is, no alcohol or drugs was detected).

Train information

General information

Cement train no. 604 was 220 m long and weighed about 1,132 t. It consisted of:

- a TR class locomotive (TR11) at one end

- 16 cement powder wagons (14 of which were loaded at the time of the accident)

- a driver’s van wagon (DV1) at the opposite end.

The cement train was a regular bulk freight service that operated 24 hours per day, 7 days per week, completing about 6 service cycles between Railton to Devonport and return each day. TasRail was the rolling stock operator, and the cement train service was considered one of its most important, hauling more than 1 million tonnes of cement powder annually.

The cement train was operated as a driver only operation,[20] with motive power provided from the TR class locomotive, which was always positioned at the Devonport end of the train. This locomotive was always controlled by a driver using RCE:

- from Railton to Devonport, with the driver located in the cabin of the locomotive (the locomotive was hauling the consist as the leading vehicle)

- from Devonport to Railton, with the driver located in the cabin of the driver’s van (the locomotive was propelling the consist as the trailing vehicle)

- with the driver outside of the train in the loading facility at Railton, while loading cement powder

- with the driver outside of the train in the unloading facility at Devonport, while unloading cement powder.

The loading and unloading operations took longer than the transits; therefore, the driver was outside of the train for the majority of an operational cycle.

The driver’s van was a reclaimed Y class locomotive with no engine or traction motors. It was solely used for the driver to observe the track ahead while controlling a locomotive at the rear of the train using the RCE.

On a non-remotely-controlled train, the leading locomotive in the direction of travel has sole control authority over the train’s airbrake systems. To enable this, the lead locomotive’s braking system is conditioned to ‘lead cut-in’ mode. This controls the application and release commands of the braking systems. Trailing locomotives (under command of the lead locomotive) are conditioned to ‘trail cut-out’ mode, their response being similar to that of a trailing wagon.

For TasRail’s remotely-controlled trains, the locomotive was conditioned to the trail cut-out mode, and so was essentially the equivalent to a trailing locomotive. The RCE took the place of a ‘lead’ locomotive, giving all electrical and airbrake commands to the physical ‘trailing’ locomotive.

Further information about the braking systems on the train is provided in Train braking systems.

The RCE on train no. 604 was the generation 3 RCE developed and manufactured by Air Digital Engineering (ADE) for TasRail. Further information about the RCE is provided in Remote control equipment.

Post-accident inspection

Onsite inspection of the accident scene in Devonport by the ATSB on 21 September 2018 found that the TR class locomotive and first 8 cement wagons were in a derailed state. The continuity of the brake pipe, operational status of the triple valve braking equipment (see Automatic brake) and condition of brake blocks on the rolling stock was examined, where possible.

It was observed that the RCE receiver was correctly connected to the TR class locomotive, with the locomotive brake pipe continuous to the first wagon. Derailment damage prevented verification of brake pipe continuity across wagons 1 to 5 and across wagons 6 to 7. Likewise, the operational status of the triple valve on wagon 4 and brake block condition on wagons 1–7 were unable to be verified due to accident damage. The status of all other brake pipe continuity points and triple valves on the train was found to be correct, and brake blocks present and within wear tolerances.

When the ATSB inspected the TR locomotive, it was shut down with the batteries turned off and with all circuit breakers in the ‘off’ position. However, TasRail advised the ATSB that these actions were performed as part of the emergency shutdown after the derailment and that all circuit breakers were correctly configured for operation when its personnel arrived at the site. All other cab switches and equipment were observed to be generally conditioned correctly for RCE operation. The following was also noted:

- the locomotive’s automatic brake handle was in ‘release’ (no effect as in ‘trail cut-out’ mode)[21]

- the locomotive’s independent brake handle was in ‘release’ (no effect as in ‘trail cut-out’ mode).

In summary, although anomalies were noted, the ATSB did not identify any locomotive configuration issue that would have caused the train not to respond to RCE commands from the driver. In addition, as previously discussed (see also Appendix A), analysis of available evidence identified that the locomotive, including its control and safety systems, operated as designed.

Operational inspections and maintenance

There was one train consist dedicated to the cement service between Devonport and Railton. The TR class locomotive was swapped every 30 days for servicing.

The cement wagons were inspected every 4 months at the East Tamar Junction wagon maintenance facility. Between these inspections, the driver of the cement service would perform a general inspection for obvious mechanical wear and damage. One side would be checked at Devonport after unloading and the other side at Railton prior to loading.

The driver’s van was inspected at 2-monthly intervals at either East Tamar Junction or Burnie maintenance facility, with a general inspection undertaken in-between as with the cement wagons. Basic safety checks occurred every 7 days.

In-service tests of the train braking systems (noted on the brake test certificate) were valid for 7 days unless the train was idle for more than 4 hours or a shunt of the rolling stock had occurred.[22] Records showed that the last shunt of the consist had occurred on 10 September 2018, with the last terminal examination (including all relevant brake tests and a test of the RCE tilt[23] and vigilance[24] functions) conducted the day before the accident.

During its 30-day operational period, the locomotive was given a basic safety and operational check every 7 days, which was to include (among other things) provision of consumables, multiple unit functionality, sand, direction, traction power and brake tests. The record of the basic safety and operational check, completed for TR11 the night before the accident, did not mark off the multiple unit functionality, sand, direction, traction power and brake checks. A review of TR11’s previous basic safety and operational checks found these items were not always recorded. TasRail reported that, as the train was operated almost continually, functions such as traction power and braking were effectively being checked on an ongoing basis. As previously noted, no problems with the serviceability of the locomotive were considered to be involved in the development of the runaway sequence.

Propelling operations

A unique aspect of TasRail’s cement train operation was the use of a single motive power source, the TR class locomotive, at the rear of the consist (in a propelling configuration). This occurred when the train was operated in the empty direction, from Devonport to Railton, with the locomotive propelling (pushing) the train at track speed on the main line. This generated increased buff (compressive) forces and vertical loads in the couplings between wagons, particularly between the locomotive and first few wagons compared to a train that was being pulled by a locomotive.

Propelling was not a factor in the runaway accident sequence. However, as part of its investigation, the ATSB considered how RCE was integrated into the rail operation. TasRail’s use in a propelling configuration on a main line from Devonport to Railton was permitted without restriction while being controlled from the driver’s van. As far as could be determined, no other train service in Australia used a similar rear-propelling-only configuration.

Due to the increase in lateral force against the rail head and reduction in wheel load, excessive buff forces can be a cause of wheel lift and flange climb or jack-knife derailments.[25] Careful and gradual increase of buff forces by the driver is therefore required during propelling movements to minimise the chance of derailment. Although these effects are greatest with loaded wagons, they remain present with empty wagons.[26]

TasRail provided some train handling instruction to drivers, with emphasis on efficiencies of train movement (for example, reduction in fuel usage and brake block wear). It did not provide instructions related to the rear-propelling configuration used with its RCE, including at maximum track speed.

Further aspects of the use of the RCE with propelling operations are discussed in Reduced effectiveness of automatic emergency brake.

Train braking systems

General description

On non-remotely-controlled (or conventional) TasRail trains, a driver operated the controls from within a locomotive cabin at the lead of the train consist. With these controls, a driver could issue commands for tractive effort to move the train and braking effort to slow and stop the train. In addition, several safety features were available to the driver, such as the vigilance system and the emergency engine stop function (which shut off the diesel engine).

This section provides an overview of the braking systems on the TR class locomotive and how they are applied on a non-remotely-controlled train. The RCE, and the means of using it to control braking, is discussed in the next section.

There were 3 braking control systems fitted to the TR class locomotive:[27]

- automatic brake (a type of airbrake that controlled brakes on the entire train)

- independent brake (a type of airbrake that controlled brakes on the locomotive only)

- electrical dynamic brake on the locomotive.

The use of each of the 3 braking systems depended on the circumstance during which braking effort was required. For both airbrake systems, braking was achieved by the air-powered application of brake blocks[28] directly to locomotive or wagon wheels.

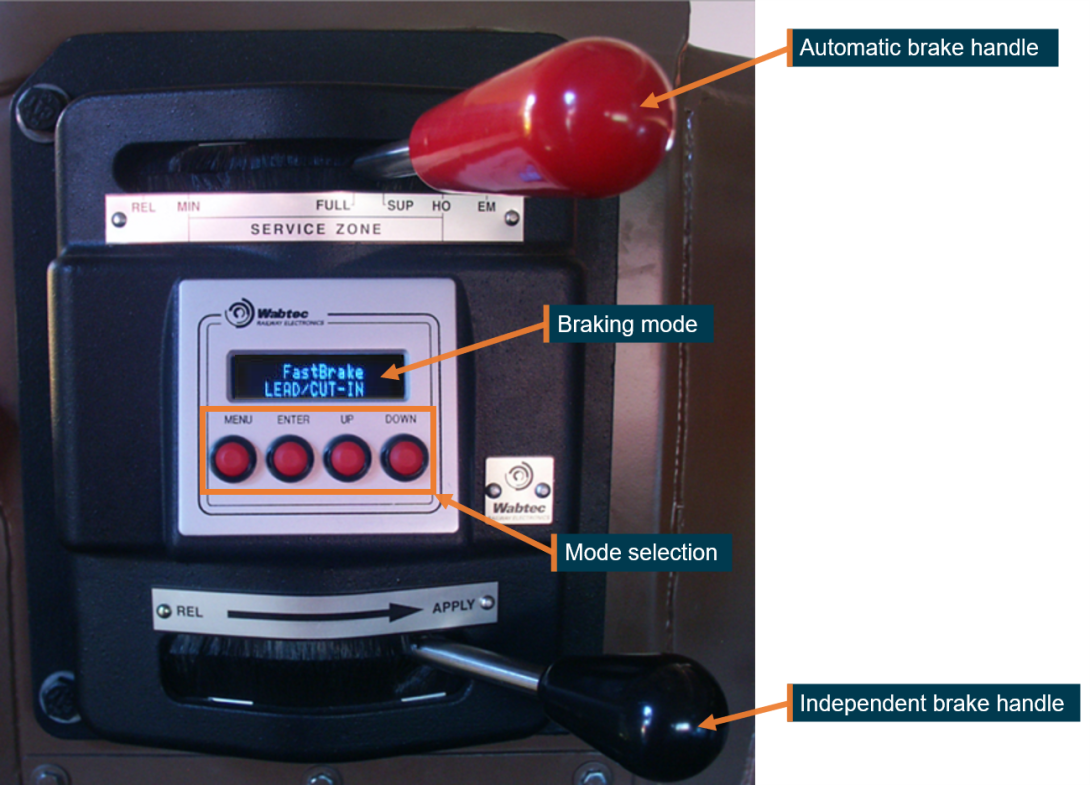

The 2 airbrakes (automatic and independent) were electronically-controlled and air-actuated on the leading locomotive. The airbrake system consisted of a driver’s cab handle unit (CHU, Figure 7), which sent electronic commands to the pneumatic operating unit (POU) located in the locomotive engine room. The POU then controlled the pneumatic responses to slow or stop the train.

Figure 7: Cab handle unit in TR locomotive

Source: TasRail, modified by the ATSB

Compressed air for the airbrake system was provided by a compressor and stored in 2 main reservoirs, both of which were on the locomotive:

- Main reservoir no. 1 (MR1) air was supplied to other rolling stock by means of the main reservoir equalising pipe (MREQ).

- Main reservoir no. 2 (MR2) was supplied air pressure from MR1 via a one-way check valve. MR2 air was used by the POU to effect braking commands.

Automatic brake

Introduction

The automatic brake applied and released brakes on both the hauling locomotive(s) and any trailing rolling stock (that is, across the entire train). It was termed the ‘automatic’ brake because the brakes automatically applied when air pressure was lost, such as in a major derailment or train separation.[29] In normal operation, the automatic brake was used as the main mechanism for slowing and stopping the train. The driver did this using the CHU automatic brake handle.

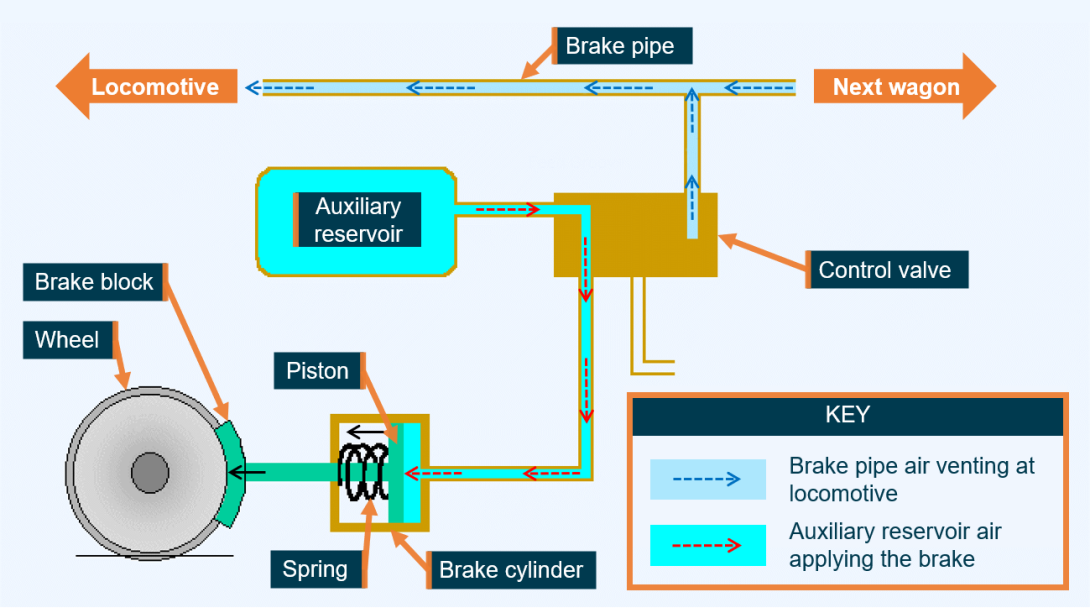

Integral to the function of the automatic brake was a continuous pipe of air that ran from the front to the rear of the train, known as the ‘brake pipe’. Flexible rubber hoses at each end of a wagon allowed connection of the brake pipe with a locomotive or other wagons.

In simplified terms, air pressure in the brake pipe performed 2 functions:

- acted as a signal to control brake application and release on both the locomotive(s) and the rest of the train

- provided a conduit for ‘charged’ (pressurised) air from the locomotive(s) to storage reservoirs in the wagons, which then provided the braking application force.

Decreases in brake pipe pressure applied proportional increases in pressure in locomotive and wagon brake cylinders, as long as there was enough air in the storage reservoirs to make the application. Increases in brake pipe pressure, above a small amount, fully released the brakes.

Means of operation

The lead locomotive charged the brake pipe with air from MR2 to an air pressure of 500 kPa when brakes were fully released. In addition to the brake pipe, each cement wagon[30] was fitted with a pneumatic control valve (‘triple valve’), auxiliary (storage) reservoir, and brake cylinders.[31] The control valve responded to changes in pressure within the brake pipe. On sensing a reduction in brake pipe air pressure, the control valve would transfer air from the auxiliary reservoir to the brake cylinder, which would apply brakes. Figure 8 shows how this system worked in practice for a brake application.

Figure 8: Wagon airbrake application process

The image is a simplified representation of an airbrake application on a wagon. The control valve consisted of rubber diaphragms, springs and ports that responded to reductions in brake pipe air pressure to perform the required brake apply response.

Source: The Railway Technical Website, modified by the ATSB

A reduction in brake pipe pressure would similarly apply the brakes on the hauling locomotive. The locomotive’s POU would read the brake pipe pressure and command a corresponding brake cylinder pressure of up to a maximum of 350 kPa on the locomotive.

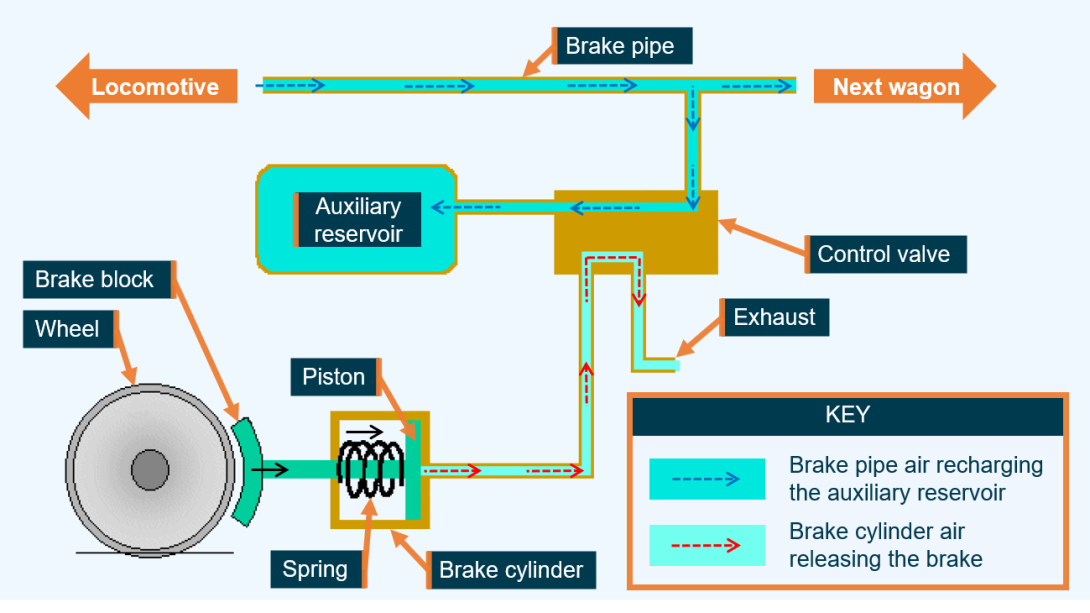

Once the required speed reduction had taken effect, the driver would place the CHU automatic brake handle in release, which restored the brake pipe pressure to 500 kPa (Figure 9). On sensing an increase in brake pipe air pressure, the control valve would vent air from the brake cylinder to release the brakes, and also allow air from the brake pipe to recharge the auxiliary reservoir to 500 kPa.

Figure 9: Wagon airbrake release process

The image is a simplified representation of an airbrake release on a wagon. The control valve consisted of rubber diaphragms, springs and ports that responded to an increase in brake pipe air pressure to perform the required brake release response.

Source: The Railway Technical Website, modified by the ATSB

Driver controls

The CHU automatic brake handle had 6 detent positions for driver control (Figure 7):

- release (REL) – brake pipe charged to 500 kPa

- minimum service (MIN) – brake pipe reduced to 450 kPa at a service rate

- full service (FULL) – brake pipe reduced to 350 kPa at a service rate

- suppression (SUP) – brake pipe reduced to 350 kPa at a service rate (for penalty brake reset)

- continuous service / handle off (HO) – brake pipe reduced to 0 kPa at a service rate

- emergency (EM) – brake pipe reduced to 0 kPa at a rapid rate.

The operational area between minimum service and handle off detents reduced the brake pipe pressure at a steady service rate. The emergency position vented brake pipe pressure at a rapid rate. Maximum braking effort occurred when brake pipe pressure was reduced to 350 kPa, known as a full-service brake application. At this point, the brake pipe, auxiliary reservoir and brake cylinder pressures all equalised with each other at about 350 kPa. The ATSB was advised by the airbrake manufacturer that a 350 kPa brake cylinder pressure on both wagons and locomotives was unlikely to result in wheel lock.[32]

Although the driver could graduate an increase in automatic brake effort by reducing brake pipe pressure incrementally between minimum-service and full-service positions, it was not possible to graduate a release. Once the control valve on the cement wagons sensed a pressure rise over 12.5 kPa in the brake pipe, it would release the brakes.

Brake pipe charging flow indicator

During an automatic brake release, MR2 air supply, which was fed from MR1, would recharge the brake pipe. The brake pipe charging flow indicator provided an indication of the flow rate from MR2 to the brake pipe. It was displayed to the driver on the TR class locomotive in-cab display screen. The purpose of the brake pipe charging flow indicator was to indicate:

- when the brake pipe (and thereby wagon auxiliary reservoirs) was fully charged. This avoided the circumstance of ‘running out of air’, whereby repeated brake applications with short release (brake pipe recharge) periods could result in loss of auxiliary reservoir air pressure. As a result, no air pressure would be available for the wagon brake cylinders.

- when tractive power could be applied from a standing start (that is, once the train’s brakes were fully released). This avoided high locomotive tractive effort against the train’s brakes causing high draft forces, resulting in possible coupling or draft gear[33] damage, train separation or rail burn.[34]

- uncommanded loss of brake pipe pressure. This could indicate a broken brake pipe hose, derailment or train separation event; all of which required an immediate driver response.

Indicators of main reservoir pressure were also available, and a driver could monitor for changes in these pressures for the same purposes.

Penalty conditions

In addition to the handle off position on the CHU automatic brake handle, there were a number of penalty conditions for a locomotive set to ‘lead cut-in’ mode that would result in a brake pipe pressure vent to 0 kPa (brake application) at a service rate. These included:

- Vigilance penalty: a penalty mode triggered by the vigilance system on the locomotive. The vigilance system was a protection against driver incapacitation. A penalty occurred if a driver did not acknowledge an audible warning light and alarm or make a control input within a periodic 15-second invitation period. This system was active when the locomotive was in lead cut-in mode and brake cylinder pressure was <170 kPa (that is, likely moving).

- Overspeed penalty: a penalty mode triggered by the detection of locomotive overspeed. The TasRail TR class locomotives were configured so that an overspeed penalty occurred if the locomotive speed reached or exceeded 88 km/h. The maximum speed on the TasRail network was 70 km/h.

- CHU to POU communications loss

- braking system power supply failure.

When the brake pipe pressure fell below 297 kPa, the locomotive would operate the power control switch (PCS). This would remove the locomotive’s generator excitation, preventing further tractive power and dynamic brake from being generated. The driver reset the penalty condition by clearing the cause of the penalty and placing the CHU automatic brake handle in suppression, before returning it to release. The PCS would reset once the brake pipe pressure reached over 428 kPa.

Emergency brake

The driver could activate emergency braking by either the CHU automatic brake handle or by activating a separate emergency dump valve in the locomotive cabin. In addition, the brakes would automatically apply across the train in the event of a brake pipe rupture, such as during a derailment or train separation. In both cases, braking would be initiated by venting the brake pipe to 0 kPa.

On sensing a rapid (emergency) brake pipe pressure drop (that is, more than 69 kPa / second, either commanded by the driver or initiated by brake pipe rupture), the hauling locomotive POUs would energise the emergency magnet valve (EMV), increasing the rate of pressure drop. In the case of a leading locomotive set to lead cut-in mode, the POU would also prevent recharge of the brake pipe. The hauling locomotive would enact a PCS request and emergency sanding,[35] the latter if the train speed was over 3 km/h. As no further braking effort was achieved once the brake pipe reduced below 350 kPa (due to pressure equalisations), emergency braking only increased the rate at which brake application occurred. Emergency braking did not increase the level of braking effort.

For a locomotive configured to lead cut-in mode, a reset of an emergency brake application by the driver (after clearing the cause) required the CHU automatic brake handle to be placed in the emergency position for a minimum of 60 seconds. The purpose of this timeout was to ensure the train had come to a complete stop before a brake release. This prevented train separation from coupler breakage due to heavy braking at the rear of the train coinciding with releasing brakes at the front. On trailing locomotives configured to ‘trail cut-out’ mode, the POU’s EMV would self-reset after 20 seconds in preparation for a brake pipe recharge command from the lead locomotive.

Emergency vent valves

The TR class locomotive was fitted with 2 emergency vent valves, called ‘VX vent valves’ by the manufacturer. They were a pneumatic addition to the brake pipe at each end of the locomotive (see inset Figure 11), which was a requirement in the Australian Standard for locomotive braking systems.[36]

On sensing a rapid (emergency rate) reduction of brake pipe pressure, the VX vent valves released brake pipe air pressure, increasing the speed of brake pipe pressure drop in the event of an emergency. After the brake pipe pressure reduced sufficiently, the valve would internally equalise and reseat (stop venting). As VX vent valve operation was related to internal pressure equalisation, if air was still being supplied to the brake pipe when equalisation occurred, the VX vent valves would reseat, stop venting, and permit recharge at pressures above 0 kPa.

Vent valves were not fitted to the cement wagons or the driver’s van. Prior to using TR class locomotives, TasRail used DQ class locomotives. These also were not fitted with vent valves.

In summary, both the locomotive’s VX vent valves and EMV were designed to assist the rapid exhaust of the brake pipe on detection of an emergency brake command, either by the driver or through brake pipe rupture. Additionally, this ensured activation of the locomotive’s PCS, thereby removing traction power. Timeouts for EMV reset applied to prevent early emergency brake release and possible train separation.

Independent brake

The independent brake applied and released brakes on hauling locomotives only, independently of any trailing rolling stock. The driver controlled this using the CHU independent brake handle to adjust pressure in a ‘control pipe’. The braking could be graduated between the release (REL) and apply positions, the latter resulting in an air pressure charge (effected by the POU) of up to 350 kPa in the control pipe.

Flexible rubber hoses on each end of the locomotive were provided to allow connection of the control pipe with other locomotives. This provided a facility for one or more trailing locomotives (if used) to receive the control pipe pressure from the lead locomotive to effect independent brake applications on the trailing locomotive(s).

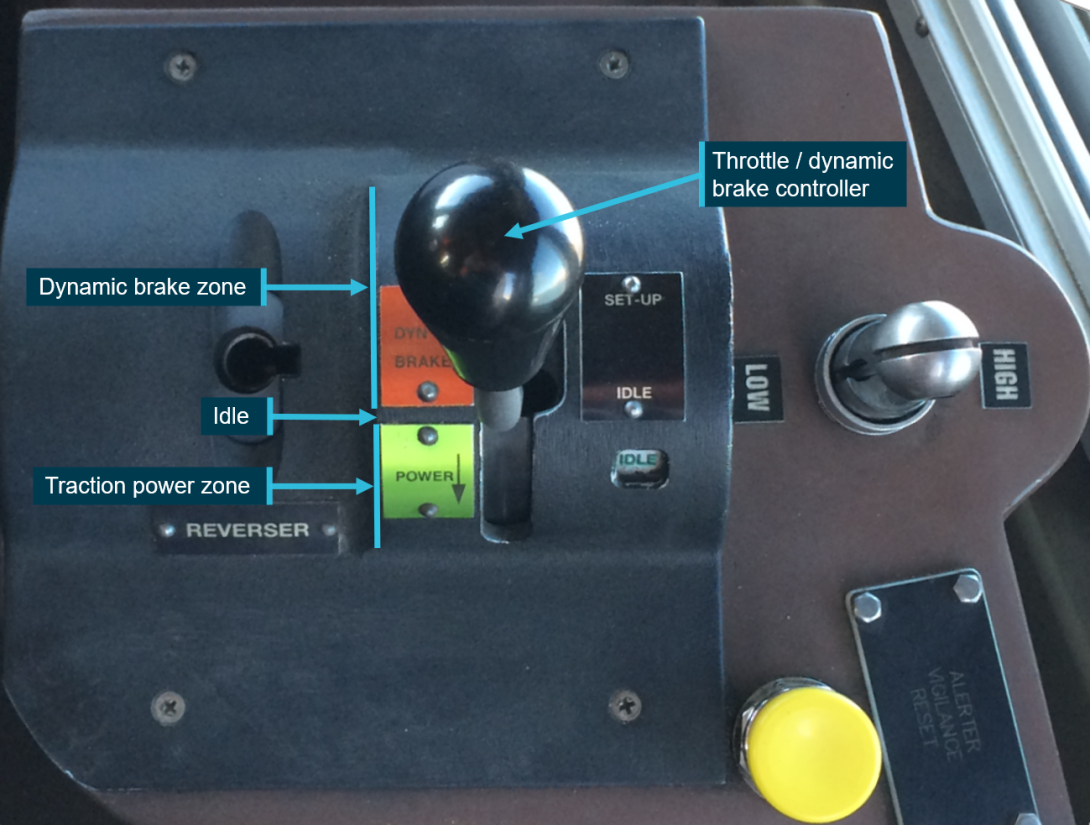

Dynamic brake

On the TR class locomotive,traction motors could also be used to slow (but not stop) the train using the dynamic brake system. This reduced wear on braking components and reduced the risk of having insufficient air pressure to apply brakes after repeated applications and releases.

To engage the dynamic brake, the driver would return the throttle / dynamic brake handle to idle from the traction power zone then move it into the dynamic brake zone (Figure 10). This action would change the traction motor fields from a tractive power to a generator configuration. The subsequent power generated by the moving locomotive wheels was fed to resistor grids and dissipated as heat, resulting in a retarding force.

Figure 10: Driver’s throttle (traction power) and dynamic brake controller

Source: TasRail, annotated by the ATSB

As previously discussed (see also Appendix A), analysis of available evidence identified that during the accident sequence the RCE initiated a momentary emergency vent of the brake pipe, which resulted in the locomotive’s VX vent valves and EMV applying to exhaust the brake pipe further. The RCE also triggered 2 emergency brake applications and releases, which did not replicate any fault condition behaviour documented for the RCE. The locomotive electronic airbrake system operated as designed.

Remote control equipment

Background

In about 1999, TasRail’s predecessor, ATN Tasrail, altered the business operating model for its existing cement train service, changing from a 2-person crew configuration to a driver only operation configuration using RCE. In addition to reducing staffing costs and exposing fewer staff to hazards during loading and unloading, this operating model allowed for the use of a single locomotive, without the requirement to either run-around or turn the consist at Devonport and Railton.

ATN Tasrail found during the tendering process that there was limited market availability of portable main-line RCE units.[37] Shortly afterwards, ADE proactively approached ATN Tasrail with its developmental RCE system. Based on the outcome of trials, in August 1999, the generation 1 RCE system was purchased by ATN Tasrail, being ADE’s first RCE customer.

In about August 2010, the operator (now TasRail) replaced generation 1 RCE with ADE’s generation 2 RCE. In turn, following issues with the ongoing reliability of generation 2 RCE and other factors, TasRail commissioned ADE to develop the generation 3 RCE, and it was introduced in February 2018 (see Remote control equipment development). Generation 3 RCE was fitted to train no. 604, and unless otherwise noted, references to RCE in this report relate to the generation 3 RCE.

ADE advised the ATSB that, in addition to TasRail, 5 Australian rail transport operators (RTOs) used the generation 2 RCE. However, all had ceased to do so by the time of the accident in September 2018. TasRail was the only RTO that used the generation 3 RCE.

TasRail primarily used the RCE for cement train services on the section of railway between Devonport and Railton. In addition, it permitted RCE operations for:

- emergency banking[38] purposes (assisting with heavy loads) over Don Hill between Devonport and Leith

- transfer of a locomotive and driver’s van to Burnie for maintenance purposes

- transfer of cement wagons to East Tamar Junction for maintenance purposes.

System overview

The RCE comprised 3 main components:

- a transmitter, a portable unit carried by the driver

- a receiver, mounted on the locomotive, which interfaced with the locomotive’s electrical systems via a multiple unit cable

- an air box, mounted on the locomotive, which interfaced with the locomotive’s airbrake system via air hoses.

The RCE receiver received commands from the RCE transmitter, with communications between the 2 components linked on start-up of the RCE system. When operated by the driver, the transmitter sent remote control signals via radio to the receiver. The receiver then sent electrical signals to the air box to enact airbrake commands, or to the locomotive for throttle, direction, and other commands.

The RCE replicated most of the controls available on the locomotive, including automatic brake, independent brake, dynamic brake, engine, and direction controls. An emergency stop switch was intended to imitate the response to placing the locomotive’s automatic brake handle in the emergency position (see Emergency stop function).

Interface with the locomotive

Generation 2 RCE’s receiver and air box were located at the front of the previously-used DQ class locomotives. On introduction of the TR class locomotives, the location was changed to the rear of the locomotive, due to the absence of a footplate or handrails to allow mounting of the receiver and air box at the front of the locomotive. The rear location was continued with generation 3 RCE. In this arrangement, the receiver was placed on the rear locomotive footplate with the air box located on the right-side footplate (Figure 11).

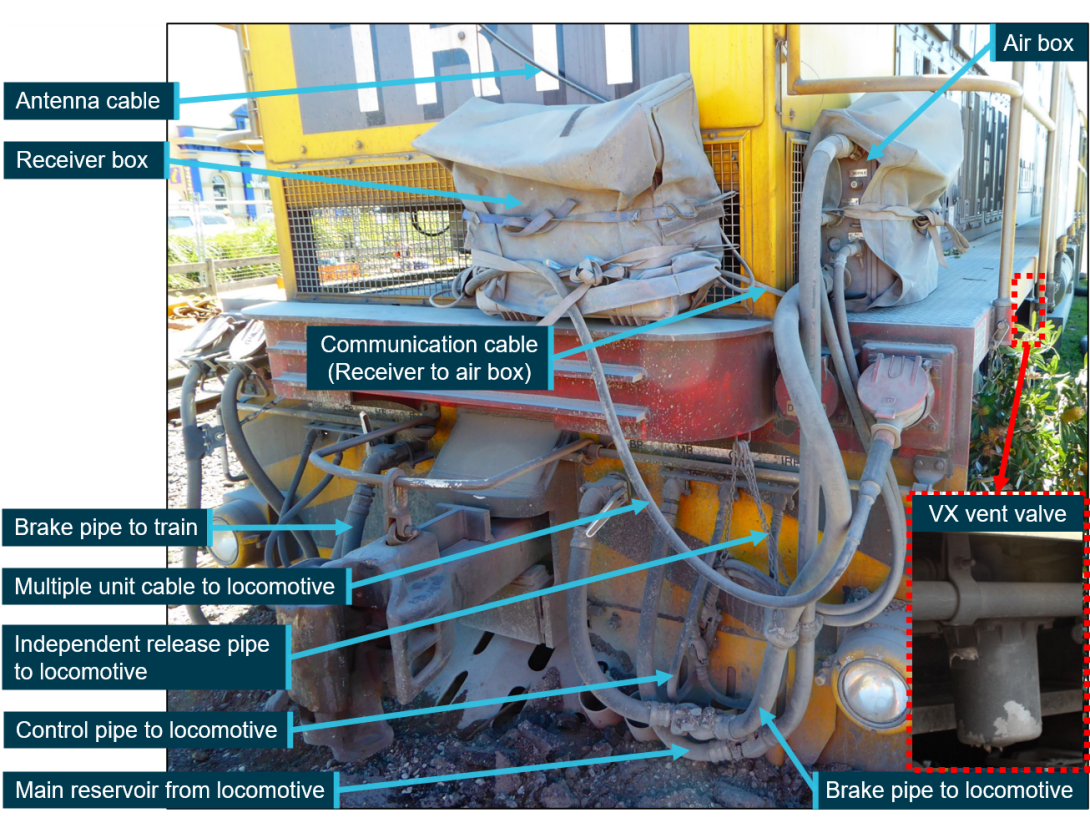

Figure 11: Rear of TR class locomotive, showing interface with generation 3 RCE

Image taken at the accident site after removal of the wagons. Note: the brake pipe tap which connected the air supply to the train has been closed during the wagon removal process. Operation of the VX vent valve is discussed further in Train braking systems.

Source: ATSB

The air box location affected some aspects of the braking system response, due to it being connected to the airbrakes at a different point in the pneumatic circuit (see Remote control equipment emergency brake reset).

A multiple unit electrical cable from the RCE receiver was plugged into the TR class locomotive’s multiple unit socket to provide the receiver with a 74 V DC power supply. The multiple unit cable also carried electrical commands (for example, direction, throttle and dynamic brake settings, sand and horn) from the receiver to the locomotive.

A communication cable from the receiver to the air box carried electrical airbrake commands for the pneumatic system within the air box to enact. The air box was supplied with pressurised air from main reservoir no. 1 (MR1) by the main reservoir equalising pipe (MREQ). To allow this, the driver was required to condition the TR class locomotive’s braking system to ‘trail cut-out’ mode. This gave control of the airbrake to the RCE, which could directly command:

- application of the train’s automatic brake through brake pipe pressure reduction via a brake pipe valve and/or a separate emergency brake valve in the RCE air box

- release of the train’s automatic brake by recharging the brake pipe with MREQ air (not MR2 air as on a TR class locomotive without RCE)

- release of the locomotive’s brake cylinder pressure during an automatic brake application through charging the independent release pipe (‘bail-off’ function)[39]

- application of the locomotive’s independent brake through charging the control pipe with MREQ air (not MR2 air as on the TR class locomotive without RCE)

- release of the locomotive’s independent brake through exhausting the control pipe

- penalty brake applications.

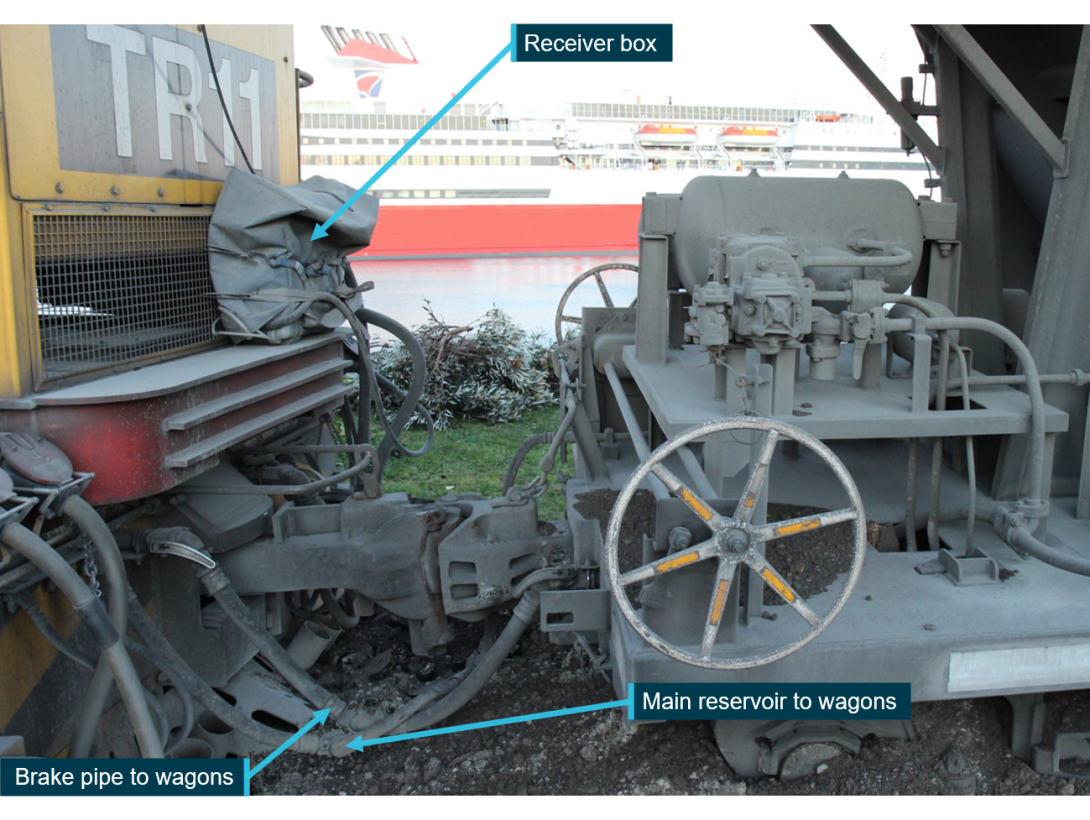

Figure 12 shows the interface between the locomotive and the first wagon. The brake pipe connection shown allowed reductions and increases in brake pipe pressure by the RCE, enacted through the adjacent brake pipe connection (Figure 11), to be registered by the wagons and driver’s van. The MREQ air hose connected to the first wagon provided MR1 air supply to the wagon roof hatches, which were operated for cement powder loading purposes at Railton.

Figure 12: Interface of RCE from rear of TR class locomotive to first wagon

Image taken on the day of the accident.

Source: ATSB

Driver operation

The RCE transmitter (Figure 13) was designed to replicate several controls available to the driver as if they were operating a non-remotely-controlled train consist from the cabin of a locomotive. These were:

- direction controller

- throttle control

- brake controls (independent brake, automatic brake, dynamic brake and emergency stop)

- sand

- horn

- vigilance function

- generator field switch (by selecting a throttle notch while in forward or reverse)

- engine run switch (by entering ‘run’ mode).

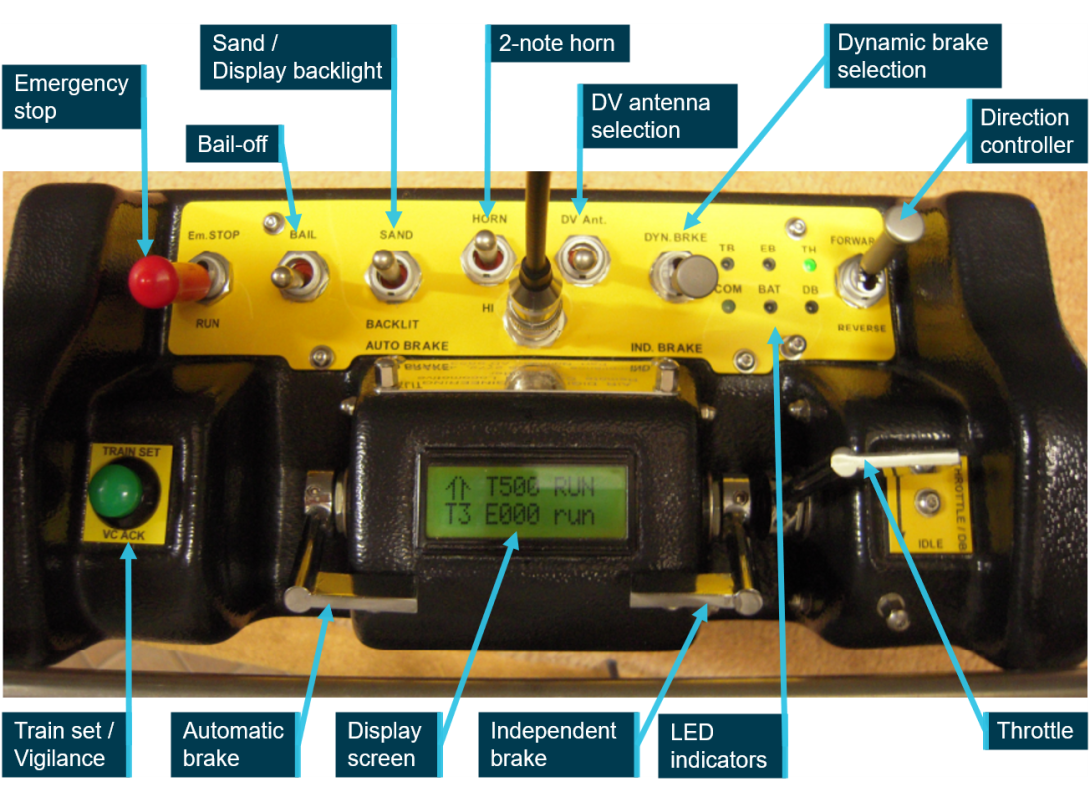

Figure 13: Generation 3 RCE transmitter

Image shows the RCE transmitter as initially supplied to TasRail for generation 3 RCE. Differences to generation 2 RCE’s transmitter included reversal of the emergency stop position, and the addition of the dynamic brake switch. The transmitter’s key switch was located on the left side of the transmitter (not shown).

Source: Air Digital Engineering, annotated by the ATSB

The direction controller had 3 positions:

- forward (up)

- neutral (middle)

- reverse (down).

The neutral position was gated; that is, the driver had to lift the selector switch up to go past the neutral position. Although not recommended by ADE in its RCE operation manual, it was possible to immediately change direction from forward to reverse and vice versa on the transmitter without pausing in the gated neutral position, if the selector switch was lifted clear of the gate. In contrast, on a locomotive the change of direction was delayed through the length of travel of the direction controller between the forward and reverse positions and a detent for the neutral position.