Safety summary

What happened

On 29 December 2015, Pacific National grain train 9156 was travelling on the V/Line regional network from Carwarp in north-western Victoria to Geelong. The train consisted of two locomotives and 40 wagons.

At about 1713, the train was passing over the William Street level crossing in Ouyen travelling at about 40 km/h and was braking to stop at Ouyen Railway Station. As it crossed William Street, 12 loaded grain wagons located mid-consist derailed. The train came to a stand straddling the crossing. There were no injuries to train crew or members of the public.

There was extensive damage to the derailed wagons, trackside infrastructure and about 200 m of track. Community power, water and gas services were also disrupted. The level crossing was closed for three days and the rail line closed for five days.

What the ATSB found

The ATSB found that the derailment was probably the result of a track lateral misalignment that developed during the passage of train 9156. Over time the track had bunched at the William Street level crossing increasing the potential for a lateral misalignment in the hot conditions of that day.

Several safety factors were identified in this investigation that were similar to factors found in the investigation of a derailment at Nunga (8 km south of Ouyen) that had occurred seven weeks earlier. The asset management systems used to identify problematic levels of rail creep (the longitudinal movement of rail over time) did not incorporate algorithms to flag rail creep that had accumulated over an extended period. In addition, the management systems did not adjust creep measurements for fixed points. The network relied on this asset management system to identify problematic creep and there was no other supplementary system of identifying rail creep in jointed track.

V/Line had also identified deficiencies in the training and development of track maintenance personnel across its network and had commenced restructuring its training to address these deficiencies.

What's been done as a result

Given that this event occurred shortly after a similar derailment at Nunga (RO-2015-022), several safety actions are common to both occurrences. Following both events, V/Line made changes to its asset management system to better address cumulative creep and to correct for fixed points.

V/Line has also updated its network standard for the inspection and assessment of lateral stability, developed training materials for rail adjustment and the management of stress in rail, and undertaken additional training of track maintenance personnel.

Safety message

Asset management systems, track standards and training should provide a complementary suite of systems for the effective management of rail creep of jointed track and track stability in extreme weather conditions.

At 1615 on 29 December 2015, Pacific National grain train 9156 departed the grain facility at Carwarp (Figure 1), bound for Geelong. The train consisted of locomotives G542 and XR554 and 40 grain wagons having a total trailing mass of 3,037 t. Each wagon was loaded to a mass of about 76 t. The train was being operated by a crew of two persons who were qualified and medically fit to perform their respective duties.

Figure 1: The location of the derailment at Ouyen between Carwarp and Geelong

Source: Google Earth annotated by Chief Investigator, Transport Safety (Vic)

The journey between Carwarp and Ouyen was uneventful. The train was to stop at Ouyen Railway Station a short distance beyond the William Street level crossing for a change of crew. As the train approached Ouyen, the train crew observed that signal aspects and points were set to permit them to proceed on the mainline towards the station.

On the approach to and when passing over the William Street level crossing, the crew did not notice any track irregularity. The driver was controlling the train’s approach to Ouyen station with dynamic braking and after passing across William Street supplemented this with an air brake application. It was shortly after the air brake application, with the train travelling at about 40 km/h, that the crew experienced what they believed to be a runout (when the status of the couplings change in an uncontrolled manner from being in compression to being in tension) together with a rapid loss of brake pipe air pressure.

As a result of the loss of brake pipe air, the train quickly came to a stop. It was identified that twelve wagons (the 25th to 36th) had derailed at the William Street level crossing (Figure 2).

Figure 2: View of derailed train at the William Street level crossing.

Source: Chief Investigator, Transport Safety (Vic)

Source: Chief Investigator, Transport Safety (Vic)

There were no injuries as a result of the derailment and a car that was stopped on the east side of crossing and a motorbike stopped on the west side were not impacted. There was severe infrastructure damage ahead of, and at, the level crossing (Figure 3).

Figure 3: Track damage on the approach side of the William Street level crossing

Source: Chief Investigator, Transport Safety (Vic)

Source: Chief Investigator, Transport Safety (Vic)

Post-incident

As a result of the derailment, a range of community services including gas, water, and power were interrupted for several hours. The road crossing was closed for three days and the line closed for five days.

The train crew were tested for the presence of drugs and alcohol and recorded nil results. The locomotive event recorders were analysed and no evidence was identified to suggest that train handling contributed to this occurrence.

The first seven bogies to derail were inspected and no evidence was identified to suggest that they may have contributed to the derailment.

Previous event

This derailment in Ouyen followed a derailment seven weeks prior at Nunga, about 8 km south of Ouyen. That derailment was also investigated by ATSB and reported under RO-2015-022.

Location

Ouyen is a rural town in north-western Victoria with a population of about 1,100. The derailment occured immediately to the north of the William Street level crossing located 509.492 km[1] from Melbourne.

Weather

The forecast maximum temperature for the area was 35 °C. The recorded temperature in the region on the day of the derailment was also about 35 °C with 12.4 hours of sun.[2]

Track infrastructure

The regional rail network, that includes the section of track from Carwarp to Ouyen, is managed by V/Line.

Approaching Ouyen from the 511 km post the track was undulating. There was a sag before the 510 km post, then an uphill grade (Figure 9). The track then crested before a slight undulation through to the William Street crossing where it decended on another slight grade towards to the yard and station. The track approaching and through the crossing had a right-hand curve of about 2000 m radius (Figure 4).

Figure 4: Approach to the William Street level crossing from Carwarp. The photograph was taken after track restoration that did not include the turnout on the Melbourne side of the crossing.

Source: Chief Investigator, Transport Safety (Vic)

Source: Chief Investigator, Transport Safety (Vic)

Infrastructure layout

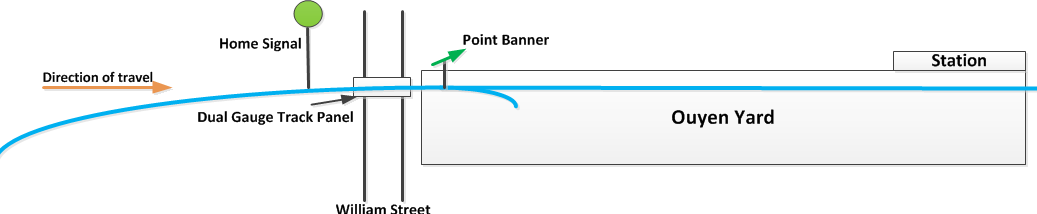

About 31 m on the Carwarp side of William Street there was a colour light Home signal to protect the crossing and control the movement of south-bound trains into Ouyen (Figure 5).

About 26 m beyond the crossing there was a set of facing points that provided access to and from the Ouyen yard. Their normal position was to be set and locked for the mainline.

Figure 5: Track layout and key features (not to scale)

Source: Chief Investigator, Transport Safety (Vic)

Source: Chief Investigator, Transport Safety (Vic)

Track construction

The line between Carwarp and Ouyen was classified as Class 3 (minor passenger and major freight line) although it was not servicing passenger traffic. The line speed for freight traffic was 80 km/h.

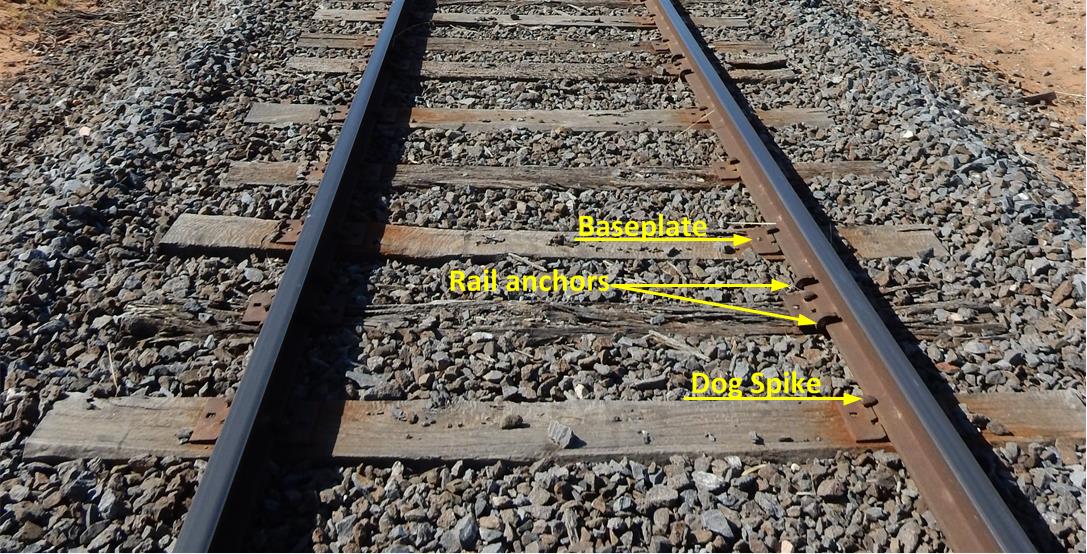

Nominal track construction was timber sleepers and sleeper plates (baseplates) supporting mechanically jointed 47 kg/m rail in 82 m lengths affixed with non resilent fasteners. Intermittent boxed anchoring of rail was used to reduce rail movement (Figure 6). Ballast for new and upgrade works was required to be 300 mm deep under the sleeper and level with the sleeper top, and extend at least 400 mm beyond the sleeper ends.

The track condition was fair with a good ballast profile (Figure 6). The condition of sleepers varied, with intermittent higher quality sleepers used to supplement sleepers that were nearing end-of-life.

Figure 6: Undisturbed track on the Carwap side of the derailment site, showing intermittent higher quality sleepers and typical ballast condition. Rail was affixed with dog-spikes with intermittent use of box anchoring to reduce rail creep.

Source: Chief Investigator, Transport Safety (Vic)

Recent track works

In order to address multiple Temporary Speed Restrictions (TSRs) between Carwarp and Ouyen, substational track works were conducted in the section in May and June 2015. The scope of works included the renewal of 28,000 sleepers, ballast top up, and resurfacing. Rail adjustment[3] was not included in the scope.

William Street level crossing

The William Street level crossing was located at 509.492 km. It was sealed with bitumen and consisted of a dual-gauge concrete sleepered track panel with 47 kg/m rail fixed using resilient fasteners.[4]

When reinstated following the derailment the configuration was similar except timber sleepers were used (Figure 7).

Figure 7: The William Street level crossing after reinstatement, similar in construction to the pre-derailment installation except timber sleepers used instead of concrete.

Source: Chief Investigator, Transport Safety (Vic)

Rail joint measurements

Rail joints behind the derailed train (on the Carwarp side) were inspected following the derailment. Through 30 December all joints remained closed in the continuing hot weather. The joints were reassessed in the early morning on 31 December and all joints had opened by varying amounts. Measurements were taken between 0630 and 0700 with a stable mean rail temperature of 21.6 °C (Figure 8).

Figure 8: Measurement of the gap at the second joint to the north of the derailed train on the left (Up) rail.

Source: Chief Investigator, Transport Safety (Vic)

Source: Chief Investigator, Transport Safety (Vic)

Measurements (Figure 10) were taken at joints on the undisturbed track over a distance of about 900 m including through the location of the 510 km creep monument (Figure 9).

Figure 9: The 510 km post and creep monuments on uphill grade approaching Ouyen.

Source: Chief Investigator, Transport Safety (Vic)

Figure 10: Joint gap measurements taken on the morning of 31 December 2015 at a mean rail temperature of 21.6 °C

Source: Chief Investigator, Transport Safety (Vic)

Rail gaps were found to progressively increase the further the distance from the rear of the train. Gaps as high as 20 mm were measured even though the nominal maximum gap in rail joints is 11 mm. This was probably the result of variations and wear in bolts and holes and it is probable that all joints in this track could extend to a gap of at least 15 mm.

Considering the data for the three rail joints to the north of the derailment site, the mean rail temperatures at which these joints would close was estimated to be about 26 °C for the Down leg and 32 °C for the Up leg.

Installation of jointed track and lateral stability

Jointed track

Jointed track made of 82 m welded lengths of rail has expansion gaps (nominally 11 mm) that provide a range of 12 degrees in rail temperature in which the rail is stress free.

V/Line construction standard NIST-2650 Use and Laying of Rail specified procedures to ensure that rails were installed to achieve design optimum levels of stress in weather extremes. For jointed 82 m lengths of rail, correctly installed rails are effectively stress free within the working limits of the expansion gap at rail temperatures of between about 26 and 38 °C. At temperatures below this range, the gap should be fully open and contracted rails would be in tension, and at temperatures above 38 °C joints would be expected to be fully closed and rails in compression.

The temperature range at which jointed rail is stress free can be affected by rail creep, the longitudinal movement of rail over time. Creep can result in rail bunching in some areas and being stretched in others. Bunching results in excess rail through a location, and the lowering of the stress free temperature range.

Rail behaviour in hot conditions

Rail temperatures in excess of 50 °C in the region are not uncommon. Rail temperatures can typically be 50 per cent more than ambient[5] or higher, depending on several environmental factors including solar radiation. As a result, in hot weather, rail temperatures normally exceed the nominal upper limit of the stress free temperature range (38 °C), resulting in rails being in a longitudinally compressed condition. Track stability then relies on rail fastenings and track supporting formations, including ballast, to resist the forces that induce rails to buckle (move laterally) when in compression.

Where there has been creep resulting in the bunching of rail, the rail will enter a state of longitudinal compression at a lower temperature to that intended. As a result, in hot weather these compressive forces will be greater and lateral buckling forces on fixings and track support higher. The potential for the lateral misalignment of rail is therefore increased.

Inspection and other measures for managing lateral stability

Regimes

The condition of track to withstand hot weather is managed by V/Line in a number of ways, including:

- general inspections

- the management of rail creep

- heat related speed restrictions (WOLO[6]) and heat patrols.

General inspections

For Class 3 track, V/Line procedures specified weekly track patrols that were expected to identify the following defects and conditions that may relate to lateral stability:

- lateral misalignments

- poor track geometry

- sharp or flat areas in curves

- track movement.

The most recent track patrol through this location prior to the derailment was conducted by road-rail vehicle on the day of the derailment (29 December 2015); no defects were identified.

For Class 3 track, V/Line procedures also specified annual walking inspections. The most recent walking inspection was conducted on 1 July 2015 and did not identify any conditions at the derailment location requiring remedial action.

Management of rail creep

Rail creep changes the stress condition of the rails and therefore its management over time is a critical part of ensuring track stability. Creep that results in the bunching of rail at a particular location will result in higher compressive forces within the rail, increasing the potential for a rail to buckle. This is most likely to occur on the approaches to fixed points such as turnouts and level crossings.

V/Line managed creep using permanent trackside points called creep monuments that are typically 1 km apart. V/Line procedures required each creep measurement at each monument to be compared with the previous measurement and also to be assessed for long term accumulation (cumulative creep) since the creep point was last reset (Figure 11).

Figure 11: V/Line limits for rail creep

|

Change in creep since previous measurement |

Cumulative gain or loss of rail between adjacent monitoring points |

|

|

Priority 1 (C1 Defect) |

50 mm or more |

100 mm or more |

|

Priority 2 (C2 Defect) |

30 mm or more |

50 mm or more |

Source: V/Line network standard NIPR- 2708

Track maintenance personnel measured rail creep in the autumn and spring of each year. These measurements were recorded in a centralised asset management system and creep exceedance reports generated. These exceedance reports were then assigned to track supervisors for remediation.

The asset management system used by V/Line changed on 1 July 2015. Both the previous and new system had been tailored by V/Line to meet its business requirements. Both systems included algorithms for evaluating the ‘creep since previous measurement’ criterion but neither evaluated cumulative creep.

Additional heat-related controls

Additional controls to manage the risk of rail misalignment in hot weather included reduced train speeds (WOLO) and heat patrols. For this section of line, WOLO precautions were implemented when temperatures were forecast to exceed 36 °C. This temperature was consistent with or lower than other Australian regional networks and was established in the context of the condition of the network and other network measures for controlling track lateral stability.

The forecast (and actual) maximum temperature on 29 Decmber 2015 was 35 °C and as a result these heat-related controls were not applied.

Network standards for lateral stability in hot weather

At the time of this occurrence V/Line had two standards for maintaining lateral stability.

NIPR-2708 Inspection and Assessment of Lateral Stability (2013) specified track conditions to observe during inspections, instruction on creep measurement and joint gap assessment, and guidance on temperatures at which gaps should be closed and open. The standard did not include significant guidance material on understanding creep, nor tools for assessing joint gaps over a range of rail temperatures.

NIPR-2751 Management of Infrastructure During Hot Weather (2009) was a brief instruction on speed restrictions and heat patrols in hot weather and seasonal restrictions on track maintenance activities.

Following a number of heat related derailments, V/Line commenced a review and redevelopment of its standards for the assessment of track lateral stability. The reviews were not complete at the time of this (Ouyen) derailment.

Training for track maintenance personnel

Track inspection and maintenance training consisted of nine stages commencing at Way Maintainer and culminating at Supervisor (Figure 12). The stages used training components aligned with industry competencies as described in the Transport Logisitics Training Package TLI10.

Figure 12: Progression steps for track maintenance personnel

Source: V/Line

Source: V/Line

Certified training

Qualification as a Track Inspector required technical training to Certificate II level. Progression to Ganger was dependent on the application of these Certificate II competencies on-the-job, and then the successful completion of the Certificate III training in Transport and Distribution (Rail Infrastructure).

For experienced Gangers selected to progress to Supervisor, further formal training consisted of a range of management and workplace courses, including the Certificate IV in Training and Assessment. Refresher training or assessment in the core competencies associated with maintaining rail infrastructure in Certificate II and III was not a specified requirement.

Training 1999 to 2013

The Victorian regional network was privatised in 1999 after which it was managed by several private entities before returning to public management under V/Line in 2007. During this period of private management, Technical Inspector and Ganger training was conducted by private training providers under their Registered Training Organisation (RTO) accreditation. This continued during V/Line’s management of the network until 2013. On-the-job training and mentoring was by local arrangement.

Internal audits (by V/Line) of maintenance personnel competencies identified gaps in knowledge, and as result V/Line brought the technical training of Technical Inspectors and Gangers ‘in-house’ in 2014. V/Line advised the ATSB that, since 2014, the new regime of internal training involved considerably more mentoring and rigorous assessment. Refresher technical training for those with existing qualifications was also being considered.

Track supervisor for Ouyen

The Track Supervisor for Ouyen had 28 years track maintenance experience and had completed all requisite training required for a Track Supervisor including Certificate III in Transport and Distribution (Rail Infrastructure) in 2004 and a Certificate IV in Training and Assessment in 2012.

Mildura Rail Corridor Freight Upgrade Project (Line rehabilitation)

Project scope

In 2008 and 2009 there was a major upgrade of the Mildura rail corridor, that included the track through Ouyen. The project included:

- Sleeper and fastener replacement and upgrade works

- Formation restoration and ballast shoulder rehabilitation

- Track surfacing works

- Rail joint rehabilitation

- Level crossing upgrade works

- Rail stress and lateral stability management works.

Rail stress and lateral stability management works

This component of the project scope included the final de-stressing of track and rail joint gap correction on completion of all works. The work components pertinent to the final rail adjustment included:

- preparation of a Rail Stress and Lateral Stability Management Plan

- measuring rail joint gaps and carrying out corrective works

- carrying out work to ensure that the neutral temperature and the rail joint gaps were within tolerance.

Project documentation specified that at the end of project works, a rail neutral temperature of between 35 and 48 °C was acceptable, and where the calculated rail neutral temperature was between 32 and 35 °C, V/Line approval was required. For jointed track, the rail neutral temperature was defined as the temperature at which the joint gap became closed.

Rail adjustment at Ouyen

Records indicate that there were no rail adjustment works between the William Street level crossing and the 510 km post as part of this upgrade project. There were minor repair works to two mechanical joints (one on each rail) about 40 m to the north of the level crossing. There were no other works on joints between the level crossing and the 510 km post.

Neutral (stress free) temperature

The project undertook joint gap measurements and neutral temperature calculations to identify rail adjustment requirements to meet the allowable stress free temperature at project end. For the works module north of the William Street level crossing, the project’s calculation (Figure 13, scenario A) identified a neutral temperature of 35 °C for the Up rail (meeting the permitted figure), and 34 °C for the Down rail (that would be permitted if approved by V/Line).

The project based its calculations for this module on an average rail length of 73 m. This average was obtained by dividing the total module length (802 m) by the number joints (11).

Further analysis of the project data using the joint gap measurements for a four joint subset of the module joint data (positions 3 to 6 from the crossing)[7] shows that bunching was probably more severe near the crossing. The calculated localised rail neutral temperatures (across these four joints) are at or about the 32 °C project threshold[8] (Figure 13, scenario B).

Figure 13: Estimated neutral temperatures calculated by the project (scenario A) and for a four joint subset of this data (scenario B) nearer to the crossing.

|

Scenario |

Input values |

Neutral temperature (gap closed) |

|||

|

Number of joints |

Rail length |

Up Rail °C |

Down Rail °C |

||

|

A |

Project data (baseline) |

11 |

73 m |

35 |

34 |

|

B |

Using 4 joints nearer to the crossing, 82 m rail |

4 |

82 m |

32 |

33 |

Source: Based on joint gap measurements taken as part of the Mildura Rail Freight Corridor Upgtade Project

Similar occurrences

Derailment of train 9130 at Emu on 12 February 2014 (RO-2014-003)

On 12 February 2014 at around 1400, ten wagons of a loaded grain train travelling south from Birchip to North Geelong derailed at Emu in North Central Victoria. Emu is located about 230 km south of Ouyen.

The ATSB investigation concluded that the derailment was the result of the lateral misalignment of the track that developed during the passage of the train in the hot conditions of that day. It was found that V/Line’s processes for responding to identified rail creep defects did not ensure remedial action before the onset of warmer seasonal conditions.

Derailment of train 9150 at Nunga on 9 November 2015 (RO-2015-022)

On 9 November 2015 at around 1530, the trailing wagon of a loaded grain train travelling south from Carwarp derailed immediately ahead of the Janiels Road level crossing in Nunga (8 km south of Ouyen). The ATSB concluded that rail creep over a prolonged period had resulted in the bunching of rail on the north side of the crossing. This rendered the rails vulnerable to lateral instability in the hot weather and a lateral misalignment developed during the passage of the train. Safety issues identified included:

- Asset management systems that were used to identify problematic levels of rail creep did not evaluate nor assess cumulative creep. [Safety Issue]

- There was no supplementary system of inspection that was effective in identifying rail creep in jointed track. The network placed a high reliance on the asset management system to initiate closer inspection of track potentially affected by creep. [Safety Issue]

- The procedures for measuring, assessing and remediating rail creep in spring did not ensure creep defects were addressed in a timely manner and prior to the onset of hot weather. A creep defect identified by the spring measurements was not corrected before the derailment. [Safety Issue]

- Asset management systems used to identify problematic levels of rail creep did not correct for fixed points between creep monuments. [Safety Issue]

__________

-

- Rail kilometres from a reference point in Melbourne.

- Sunshine observations are from Mildura airport.

- Rail adjustment is the process of adding, removing or adjusting rail to reduce the risk of rail fracturing or buckling at temperature extremes.

- Pandrol fastclips and e-clips.

- Wu Y., Munro P., Rasul M.G., Khan M.M.K., A review of Recent Developments in Rail Temperature Prediction for use in Buckling Studies, RTSA Conference on Railway Engineering, Wellington, 2010.

- WOLO was a railway telegraph code to notify of heat-related restrictions, and continues to be used in the industry.

- The two joints closest to the crossing have not been included in the calculations, as project documentation suggests that the rail length was something less thatn 82 m. The precise joint spacing between these two joints is not known.

- The project was not required to undertake localised assessment, but rather look at the complete module (that contained 11 joints in this instance).

Track lateral instability

Creep is the longitudinal movement of rails and track caused by the action of traffic over time. It is most likely to occur on grades, at locations where trains brake, and in the direction of predominant traffic tonnage. Rail is also prone to bunching on the approach to level crossings. This was the scenario at the William Street level crossing with loaded traffic predominant in the Up direction (travelling south) and rail bunching on the north side of the crossing.

A creep monument was located 508 m to the north of the level crossing at the 510 km post. The measured values of rail creep at this location are shown at Figure 14. A corrected value for the level crossing fixed point (giving creep standardised to creep/1000 m) is also included.[9]

Figure 14: Measurements at the creep monument located at the 510 km post

|

Up (eastern) rail |

Down (western) rail |

|||||

|

Creep reading |

Change since previous |

Corrected for 1000 m |

Creep reading |

Change since previous |

Corrected for 1000 m |

|

|

2008 autumn |

65 |

n/a |

128 |

40 |

n/a |

79 |

|

2008 spring |

60 |

-5 |

118 |

35 |

-5 |

69 |

|

2009 autumn[10] __________ |

0 |

0 |

0 |

0 |

0 |

0 |

|

2009 spring |

10 |

10 |

20 |

10 |

10 |

20 |

|

2010 autumn |

5 |

-5 |

10 |

20 |

10 |

39 |

|

2010 spring |

10 |

5 |

20 |

20 |

0 |

39 |

|

2010 autumn |

10 |

0 |

20 |

25 |

5 |

49 |

|

2011 spring |

0 |

-10 |

0 |

15 |

-10 |

30 |

|

2012 autumn |

25 |

25 |

49 |

40 |

25 |

79 |

|

2012 spring |

30 |

5 |

59 |

50 |

5 |

99 |

|

2013 autumn |

25 |

-5 |

49 |

50 |

0 |

99 |

|

2013 spring |

35 |

10 |

69 |

50 |

0 |

99 |

|

2014 autumn |

70 |

35 |

138 |

50 |

0 |

99 |

|

2014 spring |

75 |

5 |

148 |

50 |

0 |

99 |

|

2015 autumn |

70 |

-5 |

138 |

45 |

-5 |

89 |

|

2015 spring |

75 |

5 |

148 |

65 |

20 |

128 |

Source: Tabulation of V/Line supplied data

Calculations based on this 510 km post creep data and post-incident measurement of joint gaps between the 510 km post and the derailed train, suggest that there was uneven distribution of rail creep between these points. More severe localised bunching in the 250 m before the crossing is probable. Estimations suggest that the joint gaps close to the crossing were probably fully closed at a rail temperature of about 20 °C or lower.[11] This reduced the rail stress free temperature resulting in higher compressive forces in the rails in hot conditions.

In the ambient and solar conditions of the afternoon of the 29 December 2015, the rail temperature was probably in the mid-50s °C and the rails in a state of longitudinal compression. It is probable that the track-train dynamics generated by the passage and braking of train 9159, in combination with this compression, resulted in lateral forces that could not be contained by the rail and track support, and at least one of the rails moved laterally.

The hypothesis of misalignment under the train is supported by the train crew in that they did not observe any misalignment in the track as they approached and traversed the level crossing. The derailment occurred soon after the application of the air brakes, which would indicate that the braking probably triggered the track misalignment event.

Asset management systems

Cumulative creep

V/Line network standards identified that creep could occur over a short period or may accumulate over time. Since the resetting of the creep in 2009, there had been regular southward creep in both rails at the 510 km measurement point (Figure 15).

Figure 15: Trend in creep measurements at the 510 km monument

Source: Graphical representation of V/Line supplied data

By 2014, cumulative creep had exceeded defect criteria. However, the asset management system did not flag this exceedance. Neither the previous nor the new systems included algorithms to identify and assess creep that had accumulated since the last creep reset. The asset management systems only compared creep measurements with the previous two readings. As a result, the slow but regular rail creep southward towards the William Street level crossing was not identified for remedial action.

Correction for fixed points

The asset management system did not correct the creep measurements to take account of the William Street level crossing acting as a fixed point. Given that the monument was about 500 m from the crossing, a correction would have effectively doubled the creep measurements. This would have resulted in the system identifying several creep defects for closer inspection in the years prior to the derailment.

Creep near fixed points

The movement of rail between the 510 km creep monument and the William Street level crossing was uneven and the creep measurements at the 510 km mark did not fully reflect the localised bunching of rail at the crossing.

Other track inspections

The scope of annual walking inspections included checking that joints were not frozen or had incorrect gaps. However, the consistent assessment of gaps requires inspection within a specific (and known) rail temperature range and it was unlikely that the annual walking inspection would provide a reliable assessment of rail stress condition.

There was no other inspection regime that might have consistently identified changes in rail stress condition at high-risk locations. As a result, the network placed a high reliance on the asset management system to initiate closer inspection of track potentially affected by creep.

The creep between the 510 km creep monument and the level crossing was also uneven. There was no structured inspection regime that may have identified any localised issues at the crossing. This and two other recent heat related derailments[12] have all occurred close to a fixed point.

Maintenance personnel

Training

Internal audit by V/Line across its network had identified gaps in maintenance personnel knowledge and raised concerns about outcomes of external training conducted between 1999 and 2013.

Loss of experienced personnel together with inconsistency in the training outcomes probably resulted in these gaps. V/Line brought training ‘in-house’ in 2014 with the aim of improving training and rectifying latent gaps in personnel knowledge. These reforms had not been fully implemented at the time of this derailment.

Track standards

The network standards for the management of creep and track lateral stability of the Victorian regional network comprised the minimum amount of information required by maintenance personnel to undertake their role. The standards were limited in the information included to support an understanding of creep, and the standard for assessing rail joint gaps did not include information on the expected gaps over a range of rail temperatures.

V/Line had recognised the limitations of these network standards and had initiated a review.

Rail adjustment and resetting of creep in 2009

At the conclusion of the Mildura Rail Freight Corridor Upgrade Project in 2009, the rails to the north of the William Street crossing already had a degree of bunching. The mean temperature at which the joint gaps closed was at the lower end of the acceptable range and near the crossing bunching was more severe.

By resetting the creep to zero at this point in time without any rail adjustment, the record of residual southward creep towards the William Street level crossing was lost.

__________

- For the 510 km measurments, the distance to the level crossing (509.492) is 508 m, resulting in a correction to creep readings of 1000/508 (about a factor of 2).

- Creep was reset to zero in 2009 at the completion of major rail works.

- Estimations are approximate and are subject to a number of variables.

- RO-2014-003 (Emu) and RO-2015-022 (Nunga).

From the evidence available, the following findings are made with respect to the derailment of train 9156 at Ouyen on 29 December 2015.

Safety issues, or system problems, are highlighted in bold to emphasise their importance. A safety issue is an event or condition that increases safety risk and (a) can reasonably be regarded as having the potential to adversely affect the safety of future operations, and (b) is a characteristic of an organisation or a system, rather than a characteristic of a specific individual, or characteristic of an operating environment at a specific point in time.

Contributing factors

- Rail creep over a prolonged period resulted in the bunching of rail on the north side of the William Street level crossing. This rendered the rails vulnerable to lateral instability in hot weather and a lateral misalignment developed during the passage of train 9156.

Safety issues previously identified[13] and contributory safety factors in this occurrence are:

- Asset management systems that were used to identify problematic levels of rail creep did not evaluate nor assess cumulative creep. [Safety Issue]

- Asset management systems used to identify problematic levels of rail creep did not correct for fixed points between creep monuments. [Safety Issue]

- There was no supplementary system of inspection that was effective in identifying rail creep in jointed track. The network placed a high reliance on the asset management system to initiate closer inspection of track potentially affected by creep. [Safety Issue]

Other factors that increased risk

- Across the network there were gaps in the knowledge of track maintenance personnel that were probably the result of deficiencies in training and development. In addition, network standards for the assessment of track lateral stability, including creep management, provided limited information and tools for maintenance personnel. [Safety Issue]

- The movement of rail between the 510 km creep monument and the William Street level crossing was uneven and the bunching was more severe near the crossing. The creep measurements at the 510 km mark did not fully reflect this localised rail bunching.

Other findings

- A reduced rail neutral temperature probably existed when the rail creep values were reset in 2009.

__________

The safety issues identified during this investigation are listed in the Findings and Safety issues and actions sections of this report. The Australian Transport Safety Bureau (ATSB) expects that all safety issues identified by the investigation should be addressed by the relevant organisation(s). In addressing those issues, the ATSB prefers to encourage relevant organisation(s) to proactively initiate safety action, rather than to issue formal safety recommendations or safety advisory notices.

All of the directly involved parties were provided with a draft report and invited to provide submissions. As part of that process, each organisation was asked to communicate what safety actions, if any, they had carried out or were planning to carry out in relation to each safety issue relevant to their organisation.

The initial public version of these safety issues and actions are repeated separately on the ATSB website to facilitate monitoring by interested parties. Where relevant the safety issues and actions will be updated on the ATSB website as information comes to hand.

In this instance, several safety issues and safety actions are in common with ATSB investigation RO-2015-022 into the Nunga derailment that occurred shortly before the Ouyen derailment. The combination of both incidents triggered safety action by V/Line.

Rail creep

Safety issue number: RO-2015-029-SI-01

Safety issue description: Asset management systems that were used to identify problematic levels of rail creep did not evaluate nor assess cumulative creep.

Correcting rail creep for fixed points

Safety issue number: RO-2015-029-SI-02

Safety issue description: Asset management systems used to identify problematic levels of rail creep did not correct for fixed points between creep monuments.

Other track inspections

Safety issue number: RO-2015-029-SI-03

Safety issue description: There was no supplementary system of inspection that was effective in identifying rail creep in jointed track. The network placed a high reliance on the asset management system to initiate closer inspection of track potentially affected by creep.

Track maintenance personnel training and development

Safety issue number: RO-2015-029-SI-04

Safety issue description: There was an identified gap in the knowledge of track maintenance personnel that was probably the result of deficiencies in training and development. In addition, network standards for the assessment of track lateral stability, including creep management, provided limited information and tools for maintenance personnel.

Sources of information

- V/Line Pty Ltd

- Pacific National Pty Ltd

- Interface Rail Engineering (regarding the Mildura Rail Corridor Freight Upgrade Project)

References

V/Line Standards, Procedures, and Work Instructions

Mildura Rail Corridor Freight Upgrade Project Scope of Works and Project Data

Submissions

Under Part 4, Division 2 (Investigation Reports), Section 26 of the Transport Safety Investigation Act 2003 (the Act), the Australian Transport Safety Bureau (ATSB) may provide a draft report, on a confidential basis, to any person whom the ATSB considers appropriate. Section 26 (1) (a) of the Act allows a person receiving a draft report to make submissions to the ATSB about the draft report.

A draft of this report was provided to V/Line, Pacific National, the Office of the National Rail Safety Regulator and Interface Rail Engineering (extract only provided regarding the Mildura Rail Corridor Freight Upgrade Project).

Submissions were received from V/Line, the Office of the National Rail Safety Regulator and Interface Rail Engineering. The submissions were reviewed and where considered appropriate, the text of the report was amended accordingly.

Purpose of safety investigationsThe objective of a safety investigation is to enhance transport safety. This is done through:

It is not a function of the ATSB to apportion blame or provide a means for determining liability. At the same time, an investigation report must include factual material of sufficient weight to support the analysis and findings. At all times the ATSB endeavours to balance the use of material that could imply adverse comment with the need to properly explain what happened, and why, in a fair and unbiased manner. The ATSB does not investigate for the purpose of taking administrative, regulatory or criminal action. TerminologyAn explanation of terminology used in ATSB investigation reports is available here. This includes terms such as occurrence, contributing factor, other factor that increased risk, and safety issue. Publishing informationReleased in accordance with section 25 of the Transport Safety Investigation Act 2003 Published by: Australian Transport Safety Bureau © Commonwealth of Australia 2017

Ownership of intellectual property rights in this publication Unless otherwise noted, copyright (and any other intellectual property rights, if any) in this report publication is owned by the Commonwealth of Australia. Creative Commons licence With the exception of the Coat of Arms, ATSB logo, and photos and graphics in which a third party holds copyright, this publication is licensed under a Creative Commons Attribution 3.0 Australia licence. Creative Commons Attribution 3.0 Australia Licence is a standard form licence agreement that allows you to copy, distribute, transmit and adapt this publication provided that you attribute the work. The ATSB’s preference is that you attribute this publication (and any material sourced from it) using the following wording: Source: Australian Transport Safety Bureau Copyright in material obtained from other agencies, private individuals or organisations, belongs to those agencies, individuals or organisations. Where you wish to use their material, you will need to contact them directly. |