Executive summary

What happened

On the afternoon of 23 May 2024, loaded WATCO grain train 6839 was being operated between Thallon and Brisbane (Fisherman Island), Queensland. At 1325, the train was travelling through Gooray and approaching a passive level crossing with Gooray Road from the west at about 60 km/h, when the train crew sounded the horn about 440 m in advance of the crossing.

At that time, a heavy vehicle consisting of a prime mover and low-loader trailer carrying a skid steer was travelling southbound on Gooray Road at about 40–60 km/h towards the level crossing. This vehicle had departed a farm in Gooray several minutes earlier. Prior to departure, the driver had conducted several tests to check whether the trailer was connected to the prime mover and whether the brakes were functioning on the consist. During these tests, the truck driver observed a potential problem with the brakes, but did not investigate this issue before departing.

The train and truck should have been visible to each other for about 1 km as both approached the level crossing, but they did not see each other before the sightlines between the road corridor and the rail corridor were impeded by vegetation. The train crew first saw the truck about 300 m before the crossing, and at that moment, they assessed it was not going to stop and applied the train’s emergency brakes and braced for impact.

The truck driver did not see the train until about 50 m before the crossing, having cleared the vegetation. When the truck driver sighted the train, they attempted to brake but assessed they could not stop safely before the crossing. Instead, the truck driver attempted to veer slightly and accelerated through the crossing in front of the train. The prime mover was able to clear the railway line, but the trailer was still across the tracks when the train reached the crossing.

The lead locomotive impacted the trailer, the second locomotive impacted the lead locomotive and 14 grain hoppers derailed. The prime mover, low-loader trailer, both locomotives and 12 grain hoppers were damaged beyond repair, while 2 other grain hoppers and the skid steer were substantially damaged. The train crew and truck driver sustained serious injuries.

What the ATSB found

The ATSB found that the truck driver did not stop prior to the level crossing as required by the road signage. Due to the infrequency of trains on that corridor, it is likely that the truck driver had not seen a train at the Gooray Road crossing on previous journeys. This created an expectation that there would be no conflicting rail traffic at the crossing, which probably reduced the effectiveness of the truck driver’s scan and led to them approaching the intersection at a speed too high to stop prior to the level crossing.

The ATSB also found that the configuration of the Gooray Road level crossing provided appropriate signage and stopping distance for a road vehicle driver to notice the passive level crossing controls and bring the vehicle to a controlled stop before the level crossing. Once stopped, there was adequate visibility for a driver to sight a train and give way.

What has been done as a result

Following the incident, Queensland Rail initiated an Australian Level Crossing Assessment Model (ALCAM) assessment and looked at road geometry, traffic volumes (road and rail), visibility and sighting distances, and the existing passive controls. The assessment determined that there were no obstacles to sighting distances or the visibility of signage, which, on the northern side of the crossing was deemed to be compliant. However, the Office of the National Rail Safety Regulator identified that the advance warning signs on the northern side of the crossing were in the incorrect order. Goondiwindi Regional Council advised that it would schedule works to alter the order of the signs.

The ALCAM assessment also noted that sun glare could impact visibility for all drivers, although this was only relevant at dawn or dusk. Additionally, the assessment found that the approach from the southern side of the crossing lacked an additional advance warning sign, although this had no bearing on this accident. It also found that the stop lines on both sides of the crossing had become faded and scuffed, most likely through a combination of spillage and impact damage during the collision sequence, and vehicle movements and dirt transfer during recovery activities. Although the stop lines remained compliant and visible, it was recommended that these be repainted. Under the existing interface agreement, this work is the responsibility of Goondiwindi Regional Council, and it has been notified.

Safety message

This accident highlights the risk of expectation bias in road users when negotiating passive level crossings. Passive controls are common at level crossings where road and rail traffic volumes are low, and it is unlikely that most road users will encounter a train at a level crossing. As road users become familiar with a level crossing, at which they have not previously encountered trains, they can unconsciously form an expectation that no trains will be present each time they approach the level crossing. Accordingly, road users can habituate to behaviours which influence their ability to scan for approaching trains, or detect and respond to relevant signage and road markings.

Passive controls cannot physically prevent vehicles from entering a crossing, and the onus is on road users to follow these controls. This makes passive level crossings particularly vulnerable to driver error (unintentional) or driver decisions (intentional), which can place road users at imminent risk of collision with rail traffic. Where stop signs are provided, the maximum sighting distance occurs when a vehicle is stopped at the stop line. When conducting a ‘rolling stop’ a road vehicle driver will spend less time scanning for oncoming trains, increasing the likelihood of an incorrect decision to proceed into the crossing when it is not safe to do so.

This incident also highlights, for truck drivers, the importance of completing preparatory checks and rectifying any problems which may be observed prior to moving their vehicle, as there is a significant risk of harm and damage when driving vehicles with mechanical issues.

The investigation

| Decisions regarding the scope of an investigation are based on many factors, including the level of safety benefit likely to be obtained from an investigation and the associated resources required. For this occurrence, a limited-scope investigation was conducted in order to produce a short investigation report, and allow for greater industry awareness of findings that affect safety and potential learning opportunities. |

The occurrence

On 23 May 2024, loaded WATCO grain train 6839 was being operated between Thallon and Fisherman Island (Port of Brisbane), Queensland (Qld). This train was a regular scheduled grain‑haulage service operated by WATCO for GrainCorp, and Queensland Rail (QR) was the rail infrastructure manager (RIM).[1] Train 6839’s crew comprised one driver-in-control (DIC) and one driver-assisting (DA), who were rostered to drive the train from Thallon to Goondiwindi. The crew signed on at Goondiwindi station at 0600 local time, and drove a WATCO truck to Thallon. As the train crew were driving west to Thallon, a truck driver was preparing to take a prime mover and flat-top trailer from the St George area to a farm on Gooray Road, Gooray (Figure 1).

Figure 1: Geographic overview of area of operations for train 6839 and truck

Source: Google Earth, annotated by the ATSB

At about 0700, the truck driver hitched the trailer to the prime mover and found no brake or other mechanical issues with the heavy vehicle during their standard pre-departure tests. The truck driver then drove the heavy vehicle to the farm on Gooray Road and arrived several hours later. En route, the truck driver crossed the Gooray Road level crossing from the south, which they had done at least once before.

The train crew arrived at Thallon in the WATCO truck at about 0815 and conducted a handover with the outgoing crew as the train was still being loaded. Train 6839 finished loading at about 0945, but was then held for 45 minutes by network control to allow the operation of hi-rail vehicle ZE09. The hi-rail vehicle was a 4WD equipped to drive on railway tracks, and departed Thallon at 0932 on a regular track inspection patrol between Thallon and Goondiwindi. Although train 6839 was timetabled to depart Thallon at midday, the crew was granted a proceed authority[2] to depart at 1030.

Train 6839 arrived at Toobeah at around 1256, where it was held for several minutes while the hi‑rail vehicle entered Goondiwindi Yard. Train 6839 was then granted an extended limit of authority[3] to hold short of Signal GI28 on the outskirts of Goondiwindi. Train 6839 departed Toobeah at 1306, with a run time of around 18 minutes to Gooray and around 50 minutes to Goondiwindi.

By the time train 6839 arrived at Toobeah, the truck driver had exchanged the flat-top trailer for a low-loader trailer at the farm on Gooray Road. The farm workers placed a bobcat or skid steer onto the low-loader, and the truck driver secured this equipment to the trailer. The truck driver intended to take this equipment back to the St George area via the Barwon Highway (Figure 2).

Figure 2: Direction of travel for the truck and train through Gooray

Source: Google Earth, annotated by the ATSB

Prior to departure, the truck driver reported having conducted their standard checks, including a tug test and checks of the lights, air hoses and brake lines. The truck driver reported that during the tug test, the trailer was moving and the wheels were turning, which should not occur when a trailer is hooked up and before the air hoses are connected.

At about 1320, the truck departed the farm and turned left onto Gooray Road, heading south towards the Barwon Highway. To reach the highway, the truck driver had to negotiate the passive level crossing they had crossed that morning, but this time from the north. As the truck and train converged on the crossing at about the same speed, neither vehicle’s driver sighted the other vehicle.

In the prevailing light and weather conditions, all advance warning signs, level crossing signage, and the crossing itself would have been visible to the truck driver from up to 400 m away. At the posted speed limit of 100 km/h, from 400 m, road vehicle drivers would have up to 15 seconds to react and slow in preparation to stop. However, the truck driver reported driving at around 40–60 km/h, which would have provided them at least 30 seconds to see and respond to the crossing or the signs once these became visible.

At about the same moment the crossing and warning signs would have come into the truck driver’s view, the train DIC first sounded the train horn. Train drivers were required to sound the horn at a whistle board located about 316 m from the crossing. However, the train DIC sounded the horn earlier, 442 m prior to the crossing, aware that trees immediately prior to the crossing prevented extended line of sight for drivers of vehicles and trains (Figure 3).

Figure 3: Location of train and truck 30 seconds prior to the collision

Source: Google Earth, annotated by the ATSB

As train 6839 passed the whistle board, the DIC first became aware of the truck and estimated the truck was doing at least 40 km/h and did not look like stopping. The train was 19 seconds from the crossing at that time, and the train crew sounded the horn almost continuously from this point.

The truck was then about 210 m from the level crossing, and the truck driver recalled taking their foot off the accelerator. Aware they were approaching the rail corridor, the truck driver then coasted towards the level crossing where they were required to stop. However, the truck driver was not aware of the train until they passed the vegetation (Figure 4), but the truck driver reported that the train horn was audible from the roadway as the train and truck both approached the crossing.

Figure 4: View of railway line as the truck passed the vegetation

Source: WATCO

As the truck driver passed the trees and rounded a slight bend in the road, they saw the train, which was just over 100 m from the crossing. At that point, the truck was around 50 m from the crossing and travelling at around 40 km/h. The truck driver reported that they started to brake but that it felt like the trailer was pushing the prime mover, and assessed that they did not have sufficient braking power to stop before the crossing. As a result, the truck driver decided to accelerate past the stop sign and across the railway line into the path of the train.

Simultaneously, the train crew assessed that the truck was not slowing down or under heavy braking action, as they did not see smoke, skidding, or locked tyres. The train DIC applied the emergency brakes, and both train crew braced against the control console, realising a collision was imminent. The DIC pressed the horn until their toggle broke, after which the DA sounded the horn until moments before impact. The prime mover of the truck cleared the tracks, but the low‑loader trailer was still across the tracks when train 6839 reached the crossing at around 1325.

The lead locomotive of train 6839 hit the middle of the trailer. The locomotive body was sheared off the leading bogies and forced perpendicular to the track before coming to a rest on its side in muddy ground within the rail corridor. The trailing locomotive was also turned perpendicular to the track and impacted the lead locomotive during the collision sequence (Figure 5), and 14 grain hoppers derailed and bunched up in a concertina effect. The locomotives and a dozen grain hoppers were damaged beyond repair, and another 2 grain hoppers sustained substantial damage.

Figure 5: The WRA-class locomotives, post-collision

Source: WATCO

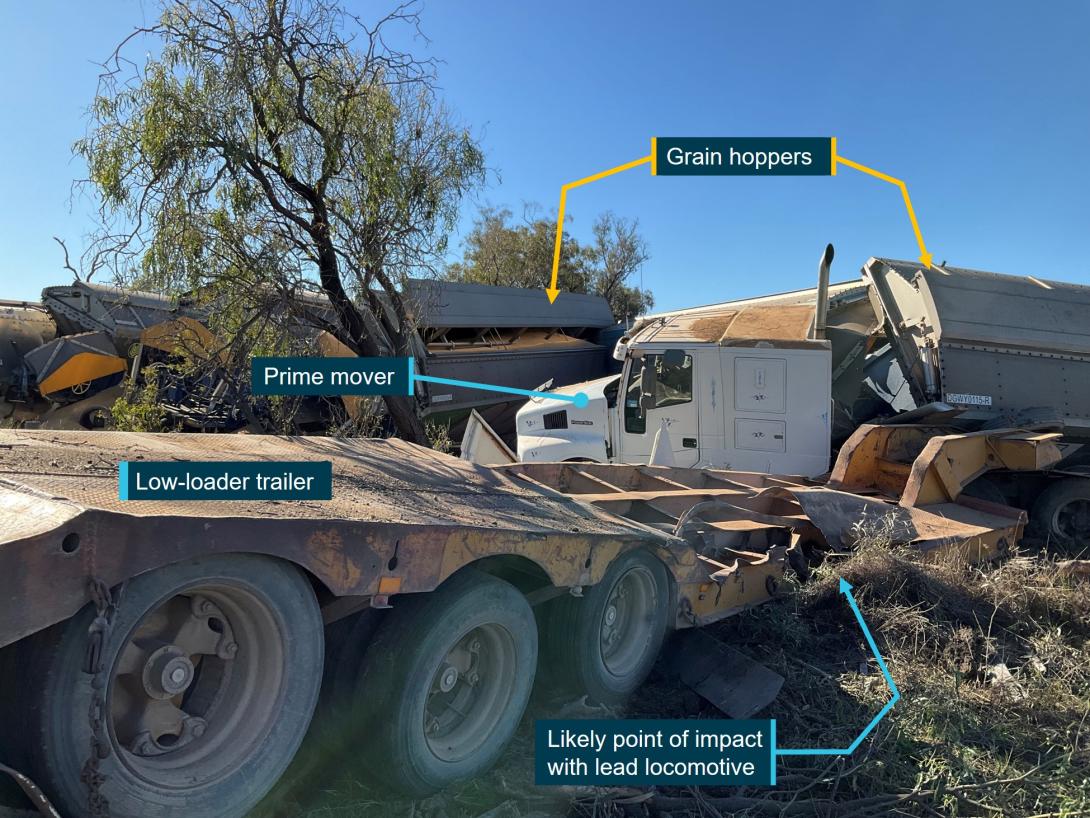

The prime mover experienced secondary impact damage most likely from the grain hoppers (Figure 6), and the bobcat on the trailer landed a short distance away. The prime mover and low‑loader trailer were damaged beyond repair and the bobcat was substantially damaged.

After the collision, the train crew radioed network control and requested emergency services. The truck driver escaped from the prime mover and assisted the train DA with removing the emergency exit window, through which the train crew subsequently evacuated. The train crew and truck driver sustained serious injuries.

Figure 6: Grain hoppers, prime mover, and low-loader trailer post-collision

Source: Queensland Police Service, annotated by the ATSB

Context

Train driver information

The DIC and DA were experienced train drivers who had worked for over 4 decades in several operational and front-line roles with multiple operators across Qld. They had both been driving trains on the South Western system since the early 2000s and had recently recommenced driving with WATCO after several months of inactivity due to the seasonal nature of the grain harvest.

Train information

Train 6839 consisted of 2 National Railway Equipment Company E2250CC (also known as WRA‑class) locomotives, followed by 40 DGWY-class loaded grain-hopper wagons. The total length of the train was around 600 m, which weighed around 2,500 tonnes prior to departure.

The train crew reported that the train was operating normally throughout the journey prior to the collision. There were no warning lights, error messages, or known or observed mechanical problems with either the locomotives or the consist.

Data from the locomotive event logger showed that the train was travelling at or below the speed limit of 60 km/h between Toobeah and the Gooray Road crossing. The event logger also showed that:

- the train was maintaining a near-constant speed at a consistent throttle setting in the minutes immediately preceding the collision

- activation and acknowledgement of the vigilance system[4] occurred at regular time intervals

- there was no uncommanded decrease in brake pressures or degradation in brake performance

- the status of headlights and ditch lights was high/bright and operational prior to collision

- full service/emergency brakes activated seconds prior to collision

- there was near-continuous sounding of the horn from before the whistle board to the crossing.

Truck information

The truck was an articulated heavy vehicle consisting of an Iveco Power Star prime mover, and a Drake low-loader trailer carrying a small CAT skid-steer bobcat. The truck driver reported that they had never towed that trailer before. The driver also reported that during their pre-departure checks, the trailer wheels were moving when they should have been fully locked. This should not have occurred as the air hoses had not been connected to the trailer to release the brakes and allow the wheels to move.

Although the truck driver had observed this condition prior to departure, no further tests were conducted, and no mechanical repairs or brake adjustments were made to the trailer. The truck driver reported that the first time they attempted to apply the brakes was as they approached the level crossing. When the truck driver applied the brakes to come to a stop, they felt the trailer was pushing the prime mover to the extent that the cab would have been struck by the train. As a result, the driver assessed that their only option was to veer away from the train and accelerate through the crossing.

After the collision, Queensland Police conducted a forensic examination of the prime mover, but did not examine the trailer. The investigator noted that they were ‘unable to make an accurate determination as to the overall mechanical condition of this vehicle due to the extent of impact damage sustained to the pneumatic braking and suspension systems’. It was also found that ‘the first drive axle left side brake servo exhibited a noticeable air leak with the brake pedal applied’. The police concluded that this condition was ‘unsatisfactory’ and could ‘decrease the overall braking efficiency of the prime mover if brake application was continuous’.

The forensic examination also assessed the condition of the tyres on the prime mover but were ‘unable to make an accurate determination as to the overall tyre condition due to the extent of incident damage and tyres not being located within the inspection site’. However, it also concluded that ‘all mounted tyres on the subject prime mover were of a satisfactory tread condition’.

Level crossing information

Gooray Road

Gooray Road was the main vehicle thoroughfare through Gooray. In the year to 26 May 2024, there were 152 recorded train movements through the Gooray Road level crossing (averaging 3 per week), but frequencies varied due to the nature of the grain harvest. QR advised that 3 train movements per week was standard for the month of May, and that this would increase to 1–3 trains per day through Gooray in peak grain season. Prior to the hi-rail vehicle, the last train went through Gooray 3 days before the collision.

The Gooray Road level crossing was a public crossing in a rural location surrounded by farmland which saw limited road and rail traffic throughout the year. The crossing had passive controls protecting both approaches on Gooray Road. Passive level crossing controls use signage and road markings to warn road users about an approaching level crossing, but do not activate or change when a train is approaching.

Advance warnings

Two advance warnings were provided on the northern approach to the Gooray Road crossing:

- Stop Sign Ahead signage, with accompanying ‘RAIL’ block text painted on road surface (W3-1)

- Rail Crossing Ahead signage, with accompanying ‘X’ painted on road surface (W7-7).

The first advance warning, about 270 m from the crossing, consisted of W3-1 Stop Sign Ahead signage, and a ‘RAIL’ marking on the road surface, which was required due to the high-speed approach (Figure 7).

Figure 7: First advance warning, northern approach

Source: WATCO

The second advance warning, about 180 m from the crossing, consisted of W7-7 Rail Crossing Ahead signage on both sides of the road and an ‘X’ marking on the road surface (Figure 8).

Figure 8: Second advance warning, northern approach

Source: WATCO

According to the Australian Standard,[5] the W3-1 Stop Sign Ahead sign was required to be placed 180–250 m before the stop sign at the crossing, and the W7-7 Rail Crossing Ahead sign was required to be placed 70 m before the W3-1 sign. The ‘RAIL’ and ‘X’ road markings were in the correct order, but the signs were in the reverse order.

Passive controls at crossing

The passive control installed at the Gooray Road level crossing was an RX-2 Stop Sign Assembly, with an accompanying solid white block line painted on road surface. This sign had been installed in 2004 following an Australian Level Crossing Assessment Model (ALCAM) assessment, and the assembly consisted of 4 components and a QR incident plaque (Figure 9).

A white, unbroken stop line accompanied the Stop Sign Assembly. The stop line was required to be placed in a position that maximised sightlines for road traffic, 3.5 m from the nearest rail. A roadside white post with red reflective marker for night visibility next to the assembly was impacted during the collision sequence.

Figure 9: Stop sign assembly and stop line, northern approach

Source: Queensland Rail

Sightlines

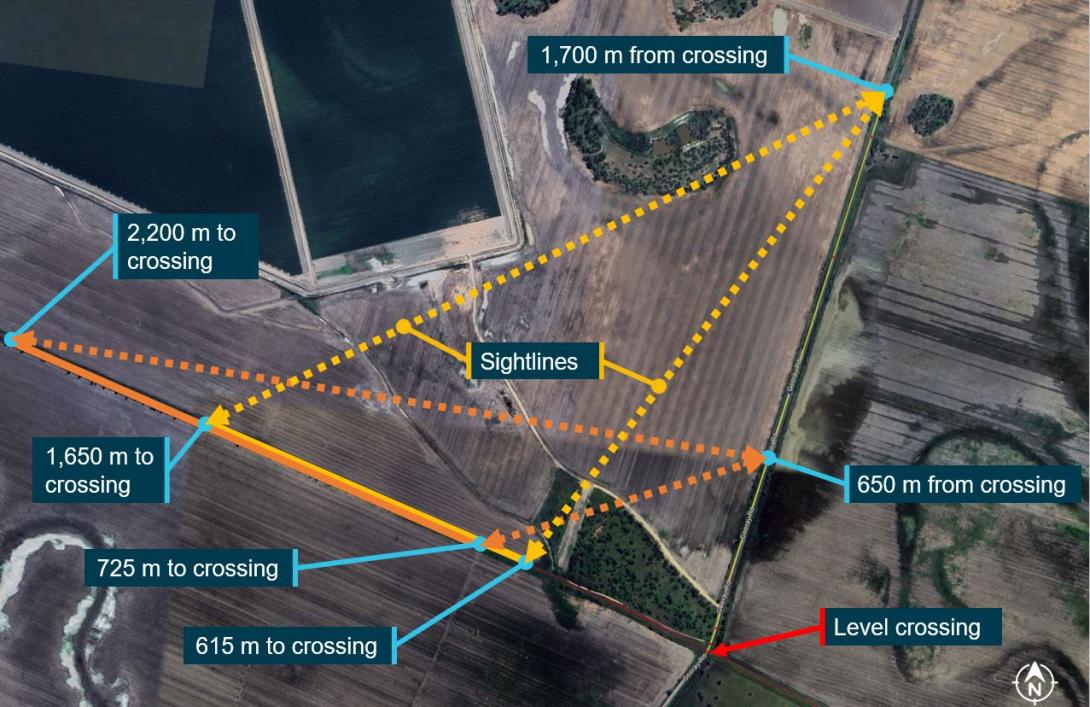

Queensland Police also found that road users approaching the crossing from the north had ‘clear, unobstructed views’ in an arc of 180° from 1,700 m before the crossing, including of the rail corridor. Further, at the truck’s reported speed, the truck driver had an opportunity of 60–75 seconds to see the train before the vegetation blocked their view.

Similarly, Gooray Road should have been visible to rail traffic from about 1,650 m before the crossing. These sightlines did not change greatly until about 650 m before the crossing, when the vegetation started to obstruct them (Figure 10). However, the train crew reported first seeing the truck about 320 m prior to the crossing and the truck driver first sighted the train after passing the end of the vegetation 20 m before the stop line.

Figure 10: Available sightlines as the train and truck approached the crossing

Source: Google Earth, annotated by the ATSB

QR calculated that the sightlines down the rail corridor were at least 1 km at the Stop Sign Assembly in both directions. However, 120 m from the crossing, vegetation obstructed the view of the western side of the rail line from the northern approach on Gooray Road. The rail corridor was then not visible until about 20 m prior to the crossing where the vegetation cleared, after which the sighting distance increased exponentially to almost 1 km at the stop line. This vegetation was the primary factor for the installation of the Stop Sign Assembly in 2004.

The railway line had a shallow right curve, which began at about the whistle board on the western side of the crossing, but this straightened out 130 m before the crossing. Outside of this curve, there was a straight of almost 9 km on the western side and a 7.5 km straight on the eastern side.

QR also assessed that approaching the crossing from the north, Gooray Road had a minor right curve about 50 m before the crossing, and a minor left curve about 150 m prior to the crossing. However, the road was straight for 2.3 km preceding these curves, and the road alignment maintained direct line-of-sight of the advanced warning signs, the stop sign assembly, and the level crossing from up to 400 m away in clear conditions.

Road and rail corridor visibility

The truck driver reported that their in-cab visibility and sighting distance was not compromised by the prime mover cab design or any external structures or monuments around the road corridor. Post-incident photos and videos supported this recollection. The truck driver also reported that although there was a crack in the windscreen and a problem with a headlight switch, neither of these factors affected their ability to see the road, the signage, or the crossing. The truck driver also reported that about 1 minute before reaching the crossing, they looked in their side mirror and observed a loose chain on the trailer. However, the driver also reported not having been distracted by anything prior to the accident.

The train crew reported that there were no impediments to in-cab visibility caused by locomotive cab design, windscreen deformities, or track grade and curvature. They also reported that there were no lineside structures, monuments, or foliage that could have prevented them from seeing the crossing or the whistle boards. Trackworkers on the hi-rail in front of train 6839 similarly did not record any obstructions or any limitations of visibility within the rail corridor prior to the incident. QR also noted that trackside fencing was in good condition and was not tall enough to obstruct visibility within the rail corridor.

Track condition

The South Western line through Gooray consisted of a single narrow gauge bi-directional track and used Direct Traffic Control[6] as the primary means of safeworking. Although the published speed limit was 70 km/h in this section, QR implemented a temporary limit of 60 km/h through a series of Train Notices to protect the track condition and structure. This preventative measure was first imposed in 2022 and remained in place at the time of the incident.

Although the track condition was reported as ‘good’, the train DA reported that drivers would travel below the speed limit in that section as it was ‘a smoother ride’. The grade was almost entirely flat between Toobeah and Goondiwindi, including through the Gooray Road crossing.

Scheduled inspections

As the RIM, QR conducted regular inspections of all crossings between Thallon and Goondiwindi. This consisted of twice-weekly visual inspections from the rail corridor to monitor track condition and known defects, and an annual inspection from the road corridor to assess overall compliance.

The most recent visual inspection of the Gooray Road crossing had been completed less than 30 minutes before the collision, by the hi-rail that train 6839 had been following since Thallon. The trackworkers onboard hi-rail ZE09 did not identify any track misalignment, defects, or faults at the Gooray Road level crossing on 23 May 2024. They also did not identify any observable issues with the road surface or the road/rail interface as the hi-rail passed through the crossing.

The annual inspection for compliance with civil engineering standards was conducted in February 2024. This inspection found that the road surface within the 10 m approaching the crossing was in average condition, and that the bitumen around the rails was also in average condition. It was also noted that the flangeway and guard rails were compliant and in good condition, as were the signs that formed the passive controls. The inspection further determined that vegetation did not impact visibility and sightlines of the rail corridor from the crossing to the whistle boards on both sides.

Interface agreement

An interface agreement was signed in August 2018 between the RIM (QR) and the Road Manager (Goondiwindi Regional Council), and this agreement remained current at the time of the collision. The agreement stated that ALCAM would be used to identify, monitor, and manage risk at all 42 level crossings in the area, including the one on Gooray Road. The interface agreement outlined the responsibilities that QR and Goondiwindi Regional Council each had for corridor maintenance as well as the provision and the upkeep of relevant signage and markings.

The interface agreement stipulated that all elements needed to follow the relevant Australian Standard[7] and responsibility for each individual aspect of the Gooray Road level crossing was allocated as shown in Table 1.

Table 1: Agreed division of responsibilities for the Gooray Road level crossing

| Rail: Queensland Rail | Road: Goondiwindi Regional Council |

|

Responsible for:

|

Responsible for:

|

Previous incidents at the Gooray Road level crossing

The train DA did not recall any near-collisions with vehicles, but the DIC reported several previous near-collisions on the South Western line. QR did not identify any previous incidents or collisions at the Gooray Road crossing, but reported that the hi-rail would slow down significantly at the Gooray Road crossing from their usual speed of between 20–40 km/h. This was a precaution as trackworkers had regularly observed vehicles cross in front of the hi-rail without stopping, and that this was particularly common on the northern approach to the level crossing. The train DIC attributed this behaviour to expectation bias caused by the infrequency of trains.

Environmental conditions

Gooray Road was sealed with rough bitumen, around 6 m in width, with a speed limit of 100 km/h. The truck driver described the road as narrow and rough. Photos and videos taken post-incident confirmed the absence of any environmental contamination or degradation of the road surface that could have impacted traction, braking, or steering.

The train crew did not identify any conditions affecting the rail head, or any issues with the grade and curvature of the track that could have influenced the operation of the train. Similarly, no such issues with track condition or weather conditions were reported by the trackworkers on the hi-rail that preceded train 6839. QR analysis and post-incident photos confirmed that weather conditions were sunny with partly cloudy skies and good ground visibility. The road surface and rail head were both dry with zero rainfall recorded, and the temperature was 24–27 °C, which reduced the risk of heat-related track deformities and operating restrictions.

The ATSB assessed whether sun glare may have affected visibility due to the north-south alignment of Gooray Road and east-west alignment of the railway line. However, the collision occurred at 1325 when the sun was at or near its zenith and directly above the vehicles. The truck driver and train drivers all confirmed sun glare was not present prior to the collision.

ATSB safety study

The ATSB safety study Review of level crossing collisions involving trains and heavy road vehicles in Australia (RS-2021-001) analysed collisions between trains and heavy vehicles at Australian level crossings between 1 July 2014 and 31 August 2022, in which 24 rail or road users were fatally or seriously injured. The aim of the study was to improve understanding of the risks associated with level crossing collisions involving heavy vehicles. Common factors identified that may have contributed to the actions of heavy vehicle drivers included the following:

- In at least 12 collisions the heavy vehicle driver had regularly used the level crossing prior to the collision with the train. The drivers' previous experience at the level crossings may have led to a low expectancy for trains and contributed to them not detecting a requirement to stop and give way.

- In at least 14 collisions, the heavy vehicle driver’s view of the track or level crossing protection equipment was obstructed by vegetation, the design of the heavy vehicle cab, poor crossing lighting, or sun glare.

- Consistent with prior research showing that train horns have limited effectiveness for alerting road vehicle drivers approaching level crossings, in at least 25 accidents the horn was not effective at alerting the heavy vehicle driver to the presence of the train.

The report also described a ‘rolling stop’, which involves slowing a road vehicle until a decision is made to proceed into the crossing, without coming to a complete stop. When conducting a ‘rolling stop’ a road vehicle driver will spend less time at the stop point for a passive level crossing and therefore will probably employ less time scanning for oncoming trains. In turn, that increases the likelihood of an incorrect decision to proceed into the crossing when it is not safe.

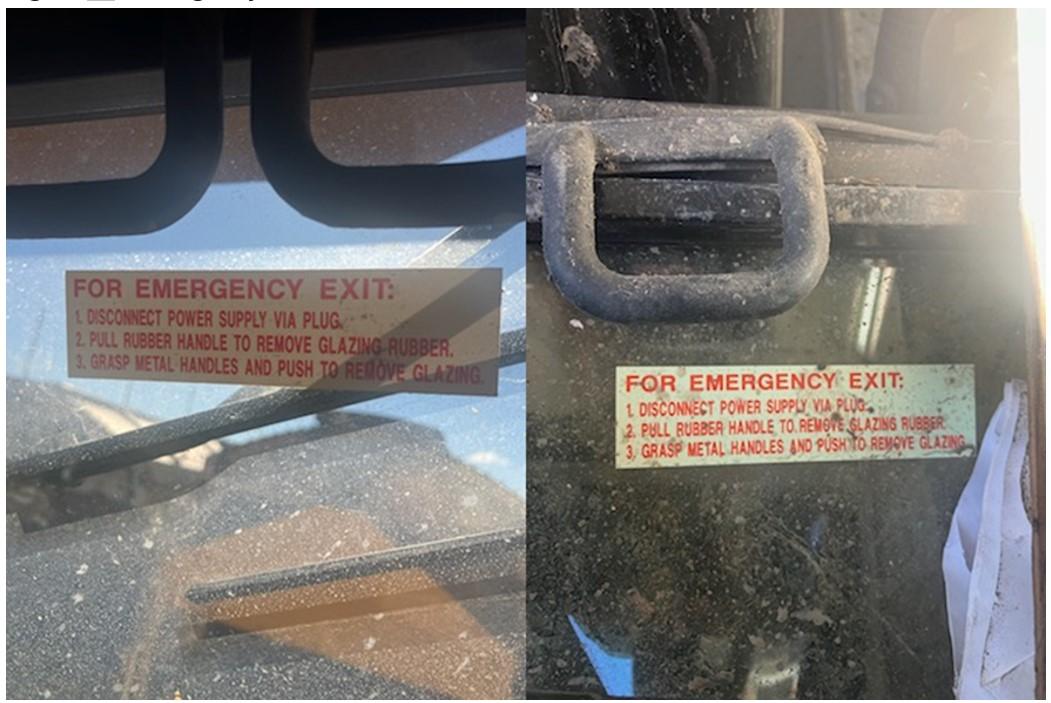

Locomotive emergency windows

The WRA-class locomotives entered service in 2020 and had been designed so that the windscreen panels in the cabs could be used for emergency egress, unlike older locomotives, which did not have designated emergency exits. Inside the WRA-class cab, 2 stickers were fixed to the windscreen to assist emergency egress. The first sticker illustrated the use of a fire hammer to crack the glass and consisted of a graphic in the corner of the windscreen. This graphic was accompanied by block text which stated ‘In an emergency break glass’ (Figure 11).

Figure 11: Emergency exit sticker with illustration and block text

Source: WATCO

The second sticker was affixed to the top of the windscreen under 2 black handles and listed a 3‑step process to remove the window. On the exterior of the cab, an identical sticker with these instructions enabled people outside to remove the glass (Figure 12).

Figure 12: Emergency exit sticker with written instructions

Source: WATCO

WATCO did not have a specific training module for emergency egress, but drivers were told how to remove the windows as part of their overall ‘shed tuition’. Information about the windows was incorporated into the overall teaching of locomotive mechanical and electrical functionality and componentry. This was supported by the train DA, who explained that drivers had general awareness of the exit windshield, and that the relevant information would likely be in the locomotive manuals. The DIC reported that they had not been shown how to open the window in training but had read the instructions on previous journeys.

The train DIC reported that they had difficulty seeing and reading the instructions after the collision due to debris and dust inside the cab. They also noted that reading the instructions and escaping from the cab would be more difficult at night or in low-light conditions. However, the train DA and truck driver were able to follow the instructions and remove the glass, although the final position of the locomotive and the sticker location may have made it harder to do so. The train DA reported that the glass came out easily, and that the space and access available was sufficient to escape through the window despite the build-up of mud in the cab.

Although the train DIC suggested that training may have assisted in understanding how to use the emergency exit, the DA found the instructions were clear, and the exit was easy to manipulate despite the cab being compromised and the sustained injuries.

Safety analysis

Passive level crossing

Although the Gooray Road level crossing and its associated infrastructure largely complied with the relevant standards, and the signs and road markings were visible, approaching from the north, vegetation obstructed the view of the rail corridor from the road from 650 m until 20 m before the stop line. There were minor curves on Gooray Road in advance of the crossing, there was sufficient sighting distance for a driver scanning for hazards along the road ahead to react and stop before the level crossing. At the stop line prior to the crossing, the truck driver would have had an unobstructed view of the train.

The level crossing used passive controls and advance warnings to alert road users to stop and look for rail traffic. Although the advance warning signs were in the incorrect order according to the standard, this did not alter the overall meaning of the signs and road markings, and was unlikely to have influenced the ability of the driver to view, interpret, and respond to the warnings as they approached the crossing.

The passive controls at the crossing were the primary risk control against collisions but did not activate or change to indicate the presence of a train or physically prevent road users from crossing in front of trains. Consequently, the onus was on road users to stop, sight, and remain clear of rail traffic.

Truck driver actions

As the truck and train converged on the level crossing at similar speeds, the truck driver did not see the train before vegetation blocked their view of the rail corridor.

When the train crew sounded the horn approaching the Gooray Road level crossing, the truck was approaching the first of 2 advance warning signs at about 40–60 km/h. The truck driver could not see the train or hear the train horn at that distance, but the crossing and advance warnings would have been visible. Although at that point the truck driver had sufficient reaction time and braking distance to stop, they did not attempt to brake until they passed the vegetation just before the crossing and saw the train approaching.

By that time, it was too late for the truck to stop prior to the crossing. There was no evidence that the driver then braked heavily, and the prime mover and trailer brakes may have had reduced effectiveness. Given that the truck driver was aware that the trailer brakes may have been defective, it was likely that they had not slowed the truck sufficiently to stop safely prior to the level crossing. Assessing that the truck would not stop before entering the crossing in front of the train, the driver elected to accelerate to get the truck cab past the train, resulting in the locomotive impacting the trailer.

Expectation bias

Given the infrequency of rail movements at the Gooray Road level crossing and that the truck driver had not seen trains when crossing there on previous occasions, they likely did not expect to encounter a train. Research showed that drivers with a low expectancy of trains may be less likely to look for trains or respond appropriately to signage and road markings. The truck’s approach to the crossing was consistent with the driver conducting a rolling stop, in which they would proceed unless a train was sighted. In this case, that resulted in insufficient distance remaining to stop prior to the crossing.

Findings

|

ATSB investigation report findings focus on safety factors (that is, events and conditions that increase risk). Safety factors include ‘contributing factors’ and ‘other factors that increased risk’ (that is, factors that did not meet the definition of a contributing factor for this occurrence but were still considered important to include in the report for the purpose of increasing awareness and enhancing safety). In addition ‘other findings’ may be included to provide important information about topics other than safety factors. These findings should not be read as apportioning blame or liability to any particular organisation or individual. |

From the evidence available, the following findings are made with respect to the Level crossing collision between freight train 6839 and truck at Gooray Road, Gooray, Queensland on 23 May 2024.

Contributing factors

- The truck driver did not stop prior to the level crossing as required by the signage.

- Due to the infrequency of trains on that corridor, it is likely that the truck driver had not seen a train at the Gooray Rd crossing on previous journeys. This created an expectation that there would be no conflicting rail traffic at the crossing, which probably reduced the effectiveness of the truck driver’s scan and led to them approaching the intersection at a speed too high to stop prior to the level crossing.

Other findings

- The Gooray Road level crossing configuration provided appropriate signage and stopping distance for a road vehicle driver to notice the passive level crossing controls and bring the vehicle to a controlled stop before the level crossing. Once stopped, there was adequate visibility for a driver to sight a train and give way.

Safety actions

| Whether or not the ATSB identifies safety issues in the course of an investigation, relevant organisations may proactively initiate safety action in order to reduce their safety risk. All of the directly involved parties are invited to provide submissions to this draft report. As part of that process, each organisation is asked to communicate what safety actions, if any, they have carried out to reduce the risk associated with this type of occurrences in the future. |

Safety action by Queensland Rail

On 12 June 2024, Queensland Rail initiated an ALCAM assessment and looked at road geometry, traffic volumes (road and rail), visibility and sighting distances, and the existing passive controls. The assessment determined that there were no obstacles to sighting distances or the visibility of signage. The ALCAM assessment deemed the northern side signage to be compliant, however, ONRSR subsequently identified that the advance warning signs were in the reverse order to the standard. It was noted that sun glare could impact visibility for all drivers, although this was only relevant at dawn and dusk.

The assessment found that the signage on the southern side of the crossing lacked an additional advance warning sign, although this had no bearing on this accident. It also found that the stop lines on both sides of the crossing had become faded and scuffed, most likely through a combination of spillage and impact damage during the collision sequence, and vehicle movements and dirt transfer during recovery activities. Although the stop lines remained compliant and visible, it was recommended that these be repainted. Under the existing interface agreement, this work is the responsibility of Goondiwindi Regional Council, and it has been notified.

Safety action by Goondiwindi Regional Council

On 6 December 2024, Goondiwindi Regional Council was advised that the advance warning signs on the northern side were in the reverse order to the standard. The council reported that it would alter the order of the signs on the northern approach to conform with the national standard, and that this rectification work would be scheduled.

Sources and submissions

Sources of information

The sources of information during the investigation included:

- the train crew

- the truck driver

- Queensland Rail

- Queensland Police

- WATCO.

Submissions

Under section 26 of the Transport Safety Investigation Act 2003, the ATSB may provide a draft report, on a confidential basis, to any person whom the ATSB considers appropriate. That section allows a person receiving a draft report to make submissions to the ATSB about the draft report.

A draft of this report was provided to the following directly involved parties:

- the train crew

- the truck driver

- Queensland Rail

- WATCO

- ONRSR.

Submissions were received from:

- ONRSR.

The submissions were reviewed and, where considered appropriate, the text of the report was amended accordingly.

Purpose of safety investigationsThe objective of a safety investigation is to enhance transport safety. This is done through:

It is not a function of the ATSB to apportion blame or provide a means for determining liability. At the same time, an investigation report must include factual material of sufficient weight to support the analysis and findings. At all times the ATSB endeavours to balance the use of material that could imply adverse comment with the need to properly explain what happened, and why, in a fair and unbiased manner. The ATSB does not investigate for the purpose of taking administrative, regulatory or criminal action. TerminologyAn explanation of terminology used in ATSB investigation reports is available here. This includes terms such as occurrence, contributing factor, other factor that increased risk, and safety issue. Publishing informationReleased in accordance with section 25 of the Transport Safety Investigation Act 2003 Published by: Australian Transport Safety Bureau © Commonwealth of Australia 2024

Ownership of intellectual property rights in this publication Unless otherwise noted, copyright (and any other intellectual property rights, if any) in this report publication is owned by the Commonwealth of Australia. Creative Commons licence With the exception of the Commonwealth Coat of Arms, ATSB logo, and photos and graphics in which a third party holds copyright, this report is licensed under a Creative Commons Attribution 4.0 International licence. The CC BY 4.0 licence enables you to distribute, remix, adapt, and build upon our material in any medium or format, so long as attribution is given to the Australian Transport Safety Bureau. Copyright in material obtained from other agencies, private individuals or organisations, belongs to those agencies, individuals or organisations. Where you wish to use their material, you will need to contact them directly. |

[1] Rail Infrastructure Manager: The person or organisation which has effective control and management of the rail infrastructure, whether or not this person or organisation owns the rail infrastructure; or who has a statutory or contractual right to use the rail infrastructure or to control, or provide, access to it.

[2] Proceed authority: Authorises rail traffic to enter and occupy section or block and proceed in the forward direction.

[3] Limit of authority: The location to which rail traffic may travel under a Proceed Authority or the limits of a work on track authority, typically defined by a sign, a signal capable of displaying a STOP indication, or a specific kilometrage point.

[4] Vigilance system: Also known as ‘dead man’s switches’, vigilance systems are safety systems which monitor driver activity and responsiveness, and will automatically apply emergency braking in order to stop the train if a control input or system acknowledgment from the driver is not received within a specified time increment.

[5] AS 1742.7:2 16 'Manual of uniform traffic control devices - Part 7: Railway Crossings’

[6] Direct Traffic Control: an absolute block safeworking system used to control the movement of trains in non-signalled territory. This prevents more than one train being authorised into a defined section or block at any one time.

[7] AS 1742.7:2 16 'Manual of uniform traffic control devices - Part 7: Railway Crossings’