Executive summary

What happened

On 16 January 2022, an instructor and student pilot were conducting circuit training at Devonport Airport, Tasmania, in a Jabiru J120-C aircraft, registered 23-1531 and operated by Freedom Flight Pty Ltd.

While on the downwind leg, the student in the left seat saw a white flash and called ‘seagull’, believing they saw a bird. At the same time, the instructor felt a jarring and observed that the propeller had separated from the aircraft. The instructor immediately took control of the aircraft, closed the throttle and conducted an unpowered landing onto the runway. There were no reported injuries or damage to the aircraft.

What the ATSB found

In-flight separation of the propeller occurred as a result of fracture of the propeller bolts. Notwithstanding the reported bird strike, the propeller bolts showed extensive fatigue crack propagation. The extent of cracking was such that the propeller could also have separated without an external influence, or would have separated with continued operation.

The propeller washers were not installed in accordance with the maintenance manual, which may have contributed to accelerated wear and subsequent cracking of the bolts.

Safety message

It is important to conduct maintenance and thorough inspections of hardware in accordance with the manufacturer’s requirements and recommendations, as deviations can have unintended, and potentially hazardous consequences. Particular attention should be paid to evidence of abnormal contact or movement between components as indications of loose or fretting components.

The investigation

| Decisions regarding whether to conduct an investigation, and the scope of an investigation, are based on many factors, including the level of safety benefit likely to be obtained from an investigation. For this occurrence, a limited-scope investigation was conducted in order to produce a short investigation report and allow for greater industry awareness of findings that affect safety and potential learning opportunities. |

The occurrence

On 16 January 2022, an instructor and student pilot were conducting circuit training at Devonport Airport, Tasmania, in the Jabiru J120-C aircraft, registered 23-1531 and operated by Freedom Flight. The weather was fine and the aircraft was operating as normal.

While on the downwind leg, the student in the left seat saw a white flash and called ‘seagull’, believing it was a bird. At the same time, the instructor felt a jarring and observed that the propeller had separated from the aircraft. The engine revolutions immediately increased as the engine was unloaded, however there was no other unusual noise, vibration or indications associated with the propeller separation.

The instructor immediately took control of the aircraft, closed the throttle and conducted an unpowered landing onto the runway. There were no reported injuries or damage to the airframe. The propeller assembly (Figure 1) was subsequently located in two pieces on the beach adjacent to the airport.

Figure 1: Propeller as found

Source: Supplied

Context

Aircraft and propeller information

The Jabiru J120-C was a 2-seat, light sport aircraft with a high-wing and fixed undercarriage. It was powered by a Jabiru 2200B 4-cylinder engine, driving a Jabiru C000242 series, 2-blade, fixed-pitch propeller, constructed of laminated hoop pine, sheathed in fibreglass. The occurrence propeller, serial number 3416, was manufactured in April 2013.

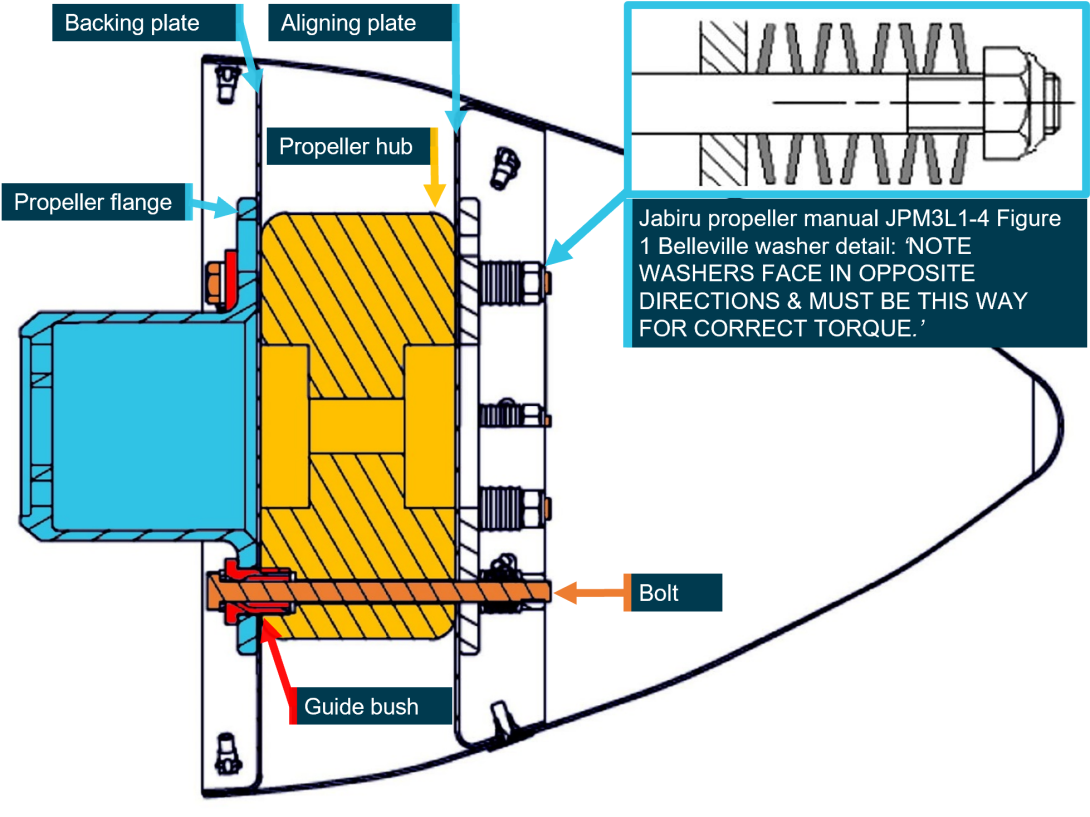

Propeller assembly

The Jabiru C000242-series wooden propeller was attached to the propeller flange by 6 propeller bolts (Figure 2). The bolts were specified as either AN4-37A or AN4-40A.[1] They were installed with the bolt heads facing rearwards, through stainless steel guide bushes inserted into the flange. The bushes were a close fit (no free-play) in the rear of the propeller hub.

A woven fibreglass composite backing plate and aligning plate was positioned either side of the propeller hub and provided for attachment of the spinner. The aligning plate effectively provided a sealed cavity (minus the bolt holes) in the front of the spinner.

Figure 2: Propeller assembly

Source: Jabiru technical manual JTM001-9 except detail as indicated (annotated by ATSB)

The bolts were assembled with Belleville washers,[2] which was a recommended alternate propeller mounting system introduced by Jabiru in 2005. Wood shrinks or expands as a result of changes in its moisture content, which in turn is related to changes in humidity in the environment in which it is stored and used. Belleville washers deflect during assembly with the application of bolt/nut torque. That deflection allows for the assembly to better account for seasonal changes in the wooden hub dimensions and as such, reduce the frequency of inspections required to check and maintain correct propeller bolt tension. Jabiru Service Bulletin JSB014-1 indicated that a loss of bolt tension can cause the propeller to move and fret[3] on the mounting flange.

Component examination

The propeller assembly, forward of the propeller flange was found intact, with the exception of the fracture and separation of approximately 35 cm of the tip of one blade (Figure 1). The separated blade tip was located a short distance away from the main assembly. The propeller had been disassembled prior to receipt by the ATSB.

The six propeller bolts had fractured under the head. The bolts and two types of washers were contained by the spinner and aligning plate along with a covering of sand (Figure 3). Three of the bolts had retained washers and the rest of the washers were loose in the spinner. There were a total of 36 (dull, grey) Belleville washers recovered out of the 48 required by the Jabiru Propeller Technical Manual JPM3L1-4. There were also 17 (bright) flat washers, with a smaller diameter than the Belleville washers. The reason for the odd number of flat washers was not established. It was possible that one was misplaced during the disassembly. The 18 flat washers would have allowed for six Belleville and three flat washers per bolt, as seen on one of the bolts in Figure 3.

The inset of Figure 3 shows an absence of gaps between some pairs of Belleville washers, indicating that some of the washers were stacked in parallel (nested), rather than in series (facing in opposite directions) as required by JPM3L1-4 and illustrated in Figure 2. Altering the washer stack in terms of the number or orientation of Belleville washers will change the total deflection available (combined height under the individual discs) and/or the spring rate.[4]

The bolt fracture surfaces showed marks consistent with high-cycle fatigue crack progression (Figure 4). Some of bolts had fretting wear adjacent to the fatigue crack origin, as well as helical wear part way along the bolt shank. The wear was coincident with the narrowest section of the bore in the guide bush. The bolt material was consistent with the AN4 specification and there was no observed corrosion or other gross defects.

Figure 3: Propeller bolts and washers as recovered

Source: Supplied and ATSB (inset)

Figure 4: Bolt fatigue crack and adjacent wear

Source: ATSB

The nylock nuts[5] were all present, in good condition with approximately the same amount of engagement with the threads. The nuts were very close to bottoming out on the bolt threads. Each nut had between one-half to three-quarters of a turn before reaching the end on the thread runout.

There was no evidence of a propeller blade defect at the fractured tip. There was also no observed organic matter or smearing to indicate a bird strike. A chord segment of the propeller hub, between two boltholes, had fractured. Discolouration of the timber on the flange side, adjacent to the guide bushes indicated a small amount of pre-existing cracking, however the bulk of the fracture was recent. Similar pre-existing cracking through the boltholes was also evident on the intact portion of the hub. The guide bush holes were damaged during the failure sequence and unable to be fully examined, however two holes that were able to be test fitted were snug with a bush inserted to the appropriate depth. The drive side of the propeller and spinner backing plate were blackened and worn, indicating relative movement between the two surfaces.

A set of exemplar washers were purchased for comparison to those from the occurrence (Figure 5). The occurrence washers were visibly (edge quality and coating) and dimensionally different. They were also a different alloy to the exemplars, however both conformed to the dimension and material requirements of the supplier specifications.[6]

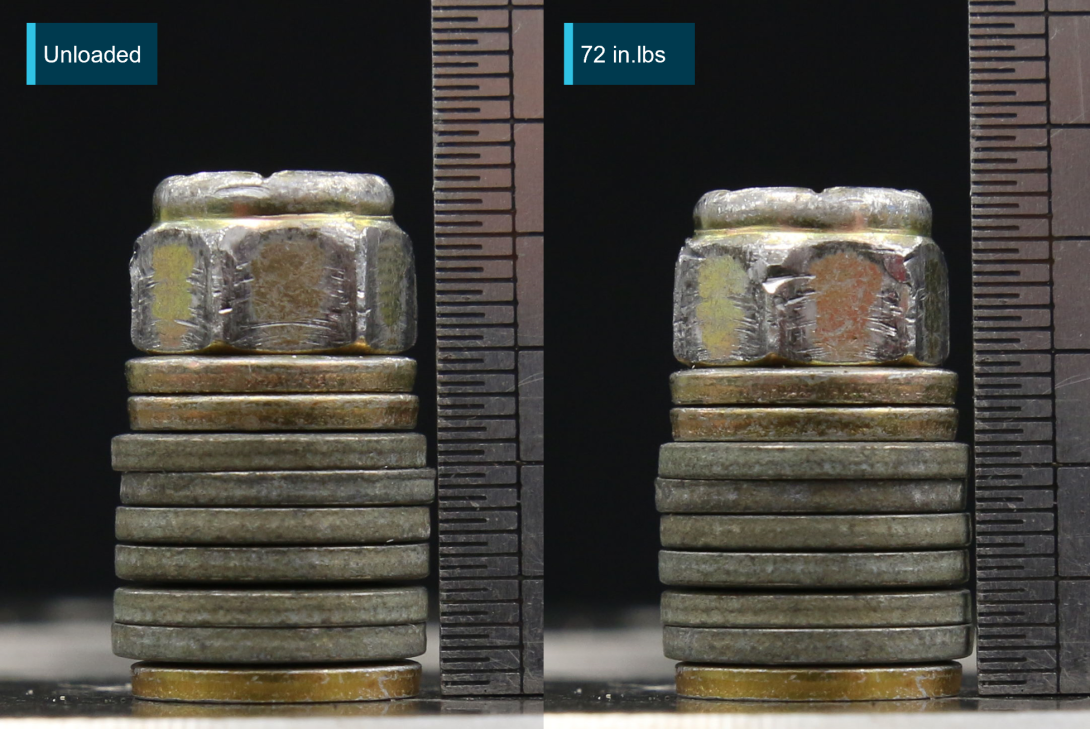

Washer stack deflection was compared between occurrence washers oriented in series and arranged as-recovered, per Figure 3. The stack height was measured with vernier callipers in the

Figure 5: Comparison between a stack of occurrence (left) and exemplar (right) washers in series.

Source: ATSB

unloaded condition (nut finger-tight) and then the nut was torqued to 72 inch-pounds (the required installation torque) and remeasured. The washers in series deflected approximately 1 mm before becoming effectively flat. When arranged as recovered, with a number of the washers in parallel, the stack compressed approximately 0.5 mm (Figure 6).

In order to estimate the effectiveness of the washer deflection in service, monthly weather statistics were obtained from the Bureau of Meteorology to determine the average relative humidity changes in the north of Tasmania. Propeller hub shrinkage or expansion was then calculated for 0.1% radial dimensional change for hoop pine per 1% moisture content change, and a 1% change in equilibrium wood moisture content for every 5% change in relative humidity. Based on this, the as-received washer stack was theoretically able account for the changes in average relative humidity and the corresponding propeller hub dimensional changes due to wood moisture content, although it was close to the estimated maximum.

Figure 6: Deflection test using washers from the occurrence propeller, arranged as recovered

Minor scale in 0.5 mm for illustrative purposes.

Source: ATSB

Instructor comments

The instructor commented that the jarring felt at the time of the propeller separation and the fracture of the blade was consistent with what they had experienced previously in a wooden propeller-driven aircraft as a result of a bird strike during take-off.

Propeller maintenance

Jabiru propeller technical manual JPM3L1-4 contained maintenance information for C000242‑series propellers. The manual indicated that the propeller bolts must be checked after the first flight following installation[7] and then every 100 hours and/or annually thereafter. Guidance for the 100-hourly inspection included:

- Remove the spinner and carry out a thorough visual inspection checking for cracking, fraying, corrosion and other damage.

- Check for loose, missing, corroded or damaged fasteners and hardware.

- Check for deposits and radial markings which indicate fretting between moving parts.

- Visually check the condition of the propeller, looking for damage to the leading-edge protection, glass de-lamination and cracks, splits or crushing of the propeller timber.

- Check the tension of the propeller bolts/nuts – Tension if required.

- Check spinner and Prop Tracking.

In addition to the above, the annual inspection also recommended removal of the propeller from the aircraft, to enable a more thorough inspection for cracking, wear and damage, a test fit of the propeller drive bushes and a check of the propeller balance.

The operator advised that the propeller had been with the aircraft since purchase and was maintained in accordance with the maintenance manual. The maintenance logs indicated that the aircraft and therefore the propeller assembly, had approximately 1,100 hours in service since new. There was no record of the attachment hardware being changed.

There were no recent aircraft maintenance log entries that included specific notes on the propeller. The most recent engine and airframe 100-hourly inspection was recorded 2 months (56 hours) prior to the occurrence, with nil defects noted. This inspection was endorsed by the operator, who previously held the required[8] Level 2 maintenance authority, but which had expired in 2016. During interview, the operator noted the importance of the Belleville washers and installation torque and indicated that they hadn’t had to re-tension the bolts during inspections since the washers were introduced.

The operator also advised that the propeller had most recently been removed 6 months (around 150 hours) prior to the occurrence, and that the wear on the propeller was within limits at that time. The propeller removal was not recorded in the logs and the operator was unable to recall who had removed, inspected and reinstalled the propeller.

Previous occurrences

Review of the ATSB aviation occurrence database over the past 10 years, found five other instances of Jabiru in-flight propeller separation from the mounting flange.

The only other occurrence investigated by the ATSB occurred in December 2021 (AO-2022-004). In that instance, the propeller separated from a J170-C approximately 8 hours after installation, after the pilot experienced a transient period of unusual engine vibration. The propeller bolts had fractured and there was evidence of movement/fretting on the propeller flange, however the propeller assembly was unable to be located and therefore an assessment of the propeller hardware was not able to be conducted.

Safety analysis

While there was no physical evidence of a bird strike on the propeller, the student’s observations and instructor pilot’s previous experience could not be discounted. That aside, and more importantly, the high-cycle fatigue cracking of the propeller bolts was indicative of a latent issue that predated any external influence at the time of the occurrence. It was possible that the propeller separated as a result of the cracking in conjunction with a bird strike. However, the extent of cracking was such that the propeller could also have separated without an external influence, or would have separated with continued operation.

The wear on the bolt shank adjacent to cracking, the spinner backing plate and the propeller mounting plate indicated relative movement between the assembly components, which would typically result from low clamping force / bolt tension, or a lack of security in the assembly. In the absence of material defect in the components or hardware, the possible reasons for this included loose-fitting guide bushes, misassembly and/or loosening of the assembly during operation.

The fracture of the propeller hub and damage to the propeller guide bush holes precluded a thorough test for guide bush fitment. While it remained a possibility, the fit of those that could be tested suggested that loose bushes was unlikely. Similarly, it was not possible to assess whether the observed low bolt tension had been influenced by low nut torques at installation.

The deviation of the washer stack from Jabiru’s assembly instructions had the potential to affect the security of the assembly. This was primarily due to the reduction in the environmental dimensional change (shrinkage) in the wooden propeller hub that could be accommodated before a loss of bolt tension resulted. In this instance, the complete washer stack as recovered was, although marginal, theoretically able to cope with the estimated changes (shrinkage and expansion) from propeller moisture content. However, the partial stacks recovered were inconsistent, which left the possibility that one or more of the washer stacks had a smaller deflection than that tested. With a reduced tolerance for dimensional changes, the risk of movement and fretting of the components increased.

The operator reported that the propeller was maintained in accordance with the maintenance manual. As such, there were inspections pertaining to the installation hardware at the most recent 100-hourly inspection. The propeller was not required to be fully disassembled and removed during that inspection, however the difference in size and colour between the flat and Belleville washers should have been identifiable during the checks for loose, missing, damaged or corroded hardware, or checking of bolt tension. The reason that the operator did not detect the assembly error was not known, but it was a missed opportunity to not only identify the error, but to further examine the affected components for unusual wear.

While it is unclear if there was any influence on this occurrence, the operator had continued to exercise the privileges of an expired maintenance authority. In doing so, it removed any regulatory oversight checks with respect to the operator’s maintenance currency and recency. In general, while this is not necessarily directly reflective of an individual’s maintenance competency, it did prevent opportunities for assuring ongoing suitability to correctly maintain an aircraft to the expected standard.

Findings

|

ATSB investigation report findings focus on safety factors (that is, events and conditions that increase risk). Safety factors include ‘contributing factors’ and ‘other factors that increased risk’ (that is, factors that did not meet the definition of a contributing factor for this occurrence but were still considered important to include in the report for the purpose of increasing awareness and enhancing safety). In addition ‘other findings’ may be included to provide important information about topics other than safety factors. These findings should not be read as apportioning blame or liability to any particular organisation or individual. |

From the evidence available, the following findings are made with respect to the In-flight propeller loss involving Jabiru J120-C, registration 23-1531 at Devonport Airport, Tasmania on 16 January 2022.

Contributing factors

- Fatigue cracking of the propeller bolts contributed to the propeller separating from the aircraft.

Other factors that increased risk

- The propeller washers were not installed in accordance with the maintenance manual, which reduced the ability of the assembly to tolerate environmental dimensional changes.

- The operator had exercised privileges of an expired maintenance authority.

Sources and submissions

Sources of information

The sources of information during the investigation included:

- Freedom Flight Pty Ltd

- The student pilot

- Jabiru Aircraft Pty Ltd

- Recreational Aviation Australia

References

Simpson WT, 1998, Equilibrium Moisture Content of Wood in Outdoor Locations in the United States and Worldwide. U.S. Department of Agriculture, Forest Service, Forest Products Laboratory research note.

Department of Agriculture, Fisheries and Forestry, Queensland, 2013, Hoop Pine – Araucaria (plantations), factsheet.

Submissions

Under section 26 of the Transport Safety Investigation Act 2003, the ATSB may provide a draft report, on a confidential basis, to any person whom the ATSB considers appropriate. That section allows a person receiving a draft report to make submissions to the ATSB about the draft report.

A draft of this report was provided to the following directly involved parties:

- Freedom Flight Pty Ltd

- The student pilot

- Jabiru Aircraft Pty Ltd

- Recreational Aviation Australia

There were no submissions received.

Purpose of safety investigationsThe objective of a safety investigation is to enhance transport safety. This is done through:

It is not a function of the ATSB to apportion blame or provide a means for determining liability. At the same time, an investigation report must include factual material of sufficient weight to support the analysis and findings. At all times the ATSB endeavours to balance the use of material that could imply adverse comment with the need to properly explain what happened, and why, in a fair and unbiased manner. The ATSB does not investigate for the purpose of taking administrative, regulatory or criminal action. TerminologyAn explanation of terminology used in ATSB investigation reports is available here. This includes terms such as occurrence, contributing factor, other factor that increased risk, and safety issue. Publishing informationReleased in accordance with section 25 of the Transport Safety Investigation Act 2003 Published by: Australian Transport Safety Bureau © Commonwealth of Australia 2023

Ownership of intellectual property rights in this publication Unless otherwise noted, copyright (and any other intellectual property rights, if any) in this report publication is owned by the Commonwealth of Australia. Creative Commons licence With the exception of the Coat of Arms, ATSB logo, and photos and graphics in which a third party holds copyright, this publication is licensed under a Creative Commons Attribution 3.0 Australia licence. Creative Commons Attribution 3.0 Australia Licence is a standard form licence agreement that allows you to copy, distribute, transmit and adapt this publication provided that you attribute the work. The ATSB’s preference is that you attribute this publication (and any material sourced from it) using the following wording: Source: Australian Transport Safety Bureau Copyright in material obtained from other agencies, private individuals or organisations, belongs to those agencies, individuals or organisations. Where you wish to use their material, you will need to contact them directly. |

[1] ‘Army-Navy’ US military specification bolts. The first number refers to the bolt diameter in 1/16 of an inch. The dash number denotes the bolt grip length in relation to a size chart. The bolts were typically made from one of a number of grades of high strength steel (minimum 125,000 psi tensile strength) and were cadmium plated.

[2] Conical disc spring washers.

[3] Fretting refers to wear involving small amplitude relative movement or vibration between contact surfaces.

[4] The load required to compress a spring by a unit distance.

[5] Nuts with a self-locking feature, consisting of an internal, reduced-size nylon or polymer ring designed to increase the torque required to move the nut on a bolt and make it more resistant to loosening in service.

[6] Dimensions to Deutsches Institut für Normung DIN 6796-6, and spring steel to DIN 17221 or 17222. The height of the occurrence washers was the minimum allowable after a permanent set test per DIN 267 part 26.

[7] This requirement was originally in reference to CASA Airworthiness Directive AD/PFP/1, which was cancelled in 2016. Jabiru updated the manual to version JPM3L1-5 in August 2022. Which removed the reference to the AD, but retained the inspection requirements.

[8] To perform maintenance on RAAus-registered aircraft used for flight training.