Executive summary

What happened

On 30 October 2021, empty coal train 9QJ5 travelling west to Moura mine, derailed at the 99.270 km point between Mount Rainbow and Dumgree, Queensland. A total of 20 wagons and 2 remote locomotives (mid-train) derailed.

The derailment occurred following ballast undercutting work that had been completed 2 days prior. Two empty coal trains heading west had travelled over the section, without incident, prior to train 9QJ5.

What the ATSB found

The ATSB found that train 9QJ5 derailed likely due to a track irregularity following track disturbance works between Mount Rainbow and Dumgree. The track irregularity likely developed under the passage of the train.

The rail stress-free temperature, near the point of derailment, was not adjusted following the track work as planned. Consequently, the track was likely left in a stressed condition when the track was handed back fit for service.

It was also established that temporary track monuments had not been regularly placed throughout the worksite, being only used for about the final 200 m of work. While this was not considered contributory to the derailment, this increased the risk of the track not being returned to the correct position following track disturbance work.

Further, after the track disturbance works had been completed, a temporary speed restriction of 40 km/h was not applied to assure safe passage over that section of track. This was particularly important given that the rail stress-free temperature was unknown at that time.

What has been done as a result

Aurizon has implemented various safety actions, including developing and implementing a rail stress worker course, conducting roadshows to discuss the Track Stability Manual, reviewing and updating the manual, and creating a rail stress appreciation course. In addition, they have updated the site assessment walkout templates with rail stress information and issued a toolbox talk to infrastructure workers, reinforcing procedural requirements during track-disturbing work to maintain track stability.

Safety message

This accident highlights the importance of assuring track stability following disturbance work through having a correct rail stress‑free temperature, which is critical to rail safety. Likewise, track stability assurance also relies on the use of accurate track offsets, during, and temporary speed restrictions, following, track disturbance work.

The investigation

| Decisions regarding the scope of an investigation are based on many factors, including the level of safety benefit likely to be obtained from an investigation and the associated resources required. For this occurrence, a limited-scope investigation was conducted in order to produce a short investigation report, and allow for greater industry awareness of findings that affect safety and potential learning opportunities. |

The occurrence

Scheduled maintenance

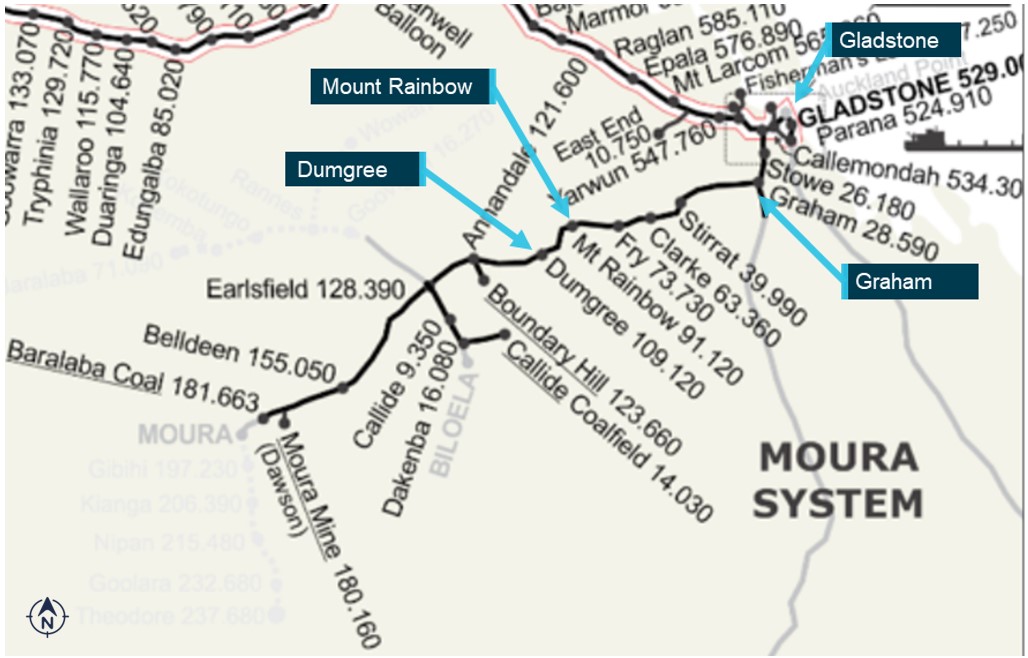

On 27 October 2021, at about 1230 local time, Aurizon’s RM902 ballast cleaning machine began ballast undercutting work along a section of track between Dumgree and Mount Rainbow, Queensland, from 99.800 km to 98.300 km. The work was part of planned track maintenance on Aurizon Network’s Moura system, integrated possession number 75, between Graham and Dumgree (Figure 1).

Due to operational considerations, ballast undercutting work concluded early at about 2020, completing 554 m between 99.840 km and 99.286 km. The RM902 ballast cleaning machine departed the site at 2255.

On 28 October 2021, ballast resurfacing was conducted over the same section and was completed at 1140. Following this, local level crossings were re-established and, at 2245, the SW05 form (the authority for the work between Mount Rainbow and Dumgree) was provided to the integrated possession protection officer.

On 30 October 2021, at about 0847, the work between Graham and Dumgree was completed, and the track section was re-opened without speed restrictions.

Figure 1: Location of the track works Mount Rainbow – Dumgree, Queensland

Source: Aurizon, annotated by the ATSB

The occurrence

At about 1130 and 1215, 2 empty coal trains passed over the re-opened line, heading west, between Mount Rainbow and Dumgree without incident.

At about 1545, empty coal train 9QJ5 passed through Mount Rainbow heading west towards Moura Mine, travelling at about 64 km/h. The train gradually increased speed to a maximum of 77 km/h, before the driver applied dynamic brake to decrease speed for an approaching 60 km/h track speed limit.

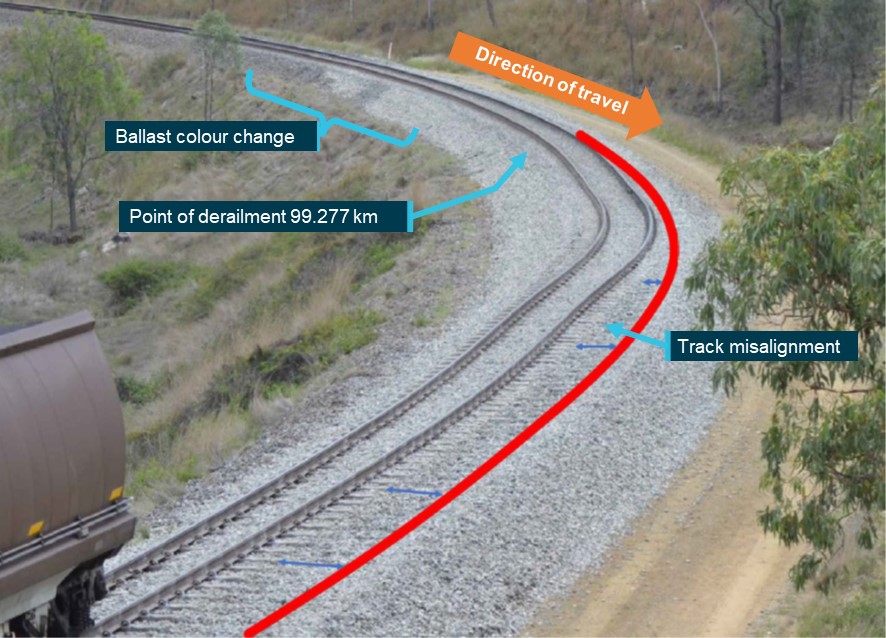

When approaching the 99 km, the rail traffic crew noticed a transition in ballast colour from dark to light (Figure 4). A short time later, at 1556:50, the recorded brake pipe pressure began to decrease in the remote distributed power locomotives. At 1556:57, travelling at 54 km/h, the emergency brake was activated (due to a loss of brake pipe air) in the leading locomotive, stopping the train about 160 m later at about 100.220 km. The in-cab telemetry between the leading locomotive and remote locomotives was broken.

After securing the train, one of the drivers walked back, discovered that the wagons had derailed (Figure 2), and reported the derailment to Aurizon network control.

Figure 2: Main wreckage site

Source: Aurizon, modified by the ATSB

Context

Train information

General

Train 9QJ5 consisted of 2 leading diesel electric locomotives, 50 empty coal wagons, 2 distributed power diesel electric locomotives, and another 50 empty coal wagons. The total length of the train was 1,714 m with a gross mass of 2,501 t. The train was operated by 2 appropriately qualified Aurizon drivers. Both drivers recalled during interview that the track was smooth as the leading locomotive passed over the recently ballasted track.

Recorded information

The locomotives were fitted with event data recorders. Data from the leading locomotive (4012) showed the train was operated consistent with the advertised track speeds. In addition, the emergency brake automatically activated as a direct result of the brake pipe loss of air due to the train separation.

At the time of derailment, the leading remote distributed power locomotive (4044) recorded a 4 kN tractive effort. The ATSB considered if this force contributed to the derailment through buff (compressive) forces in the couplings between the wagons. It was determined that the 4 kN was erroneous and did not contribute.

Track infrastructure

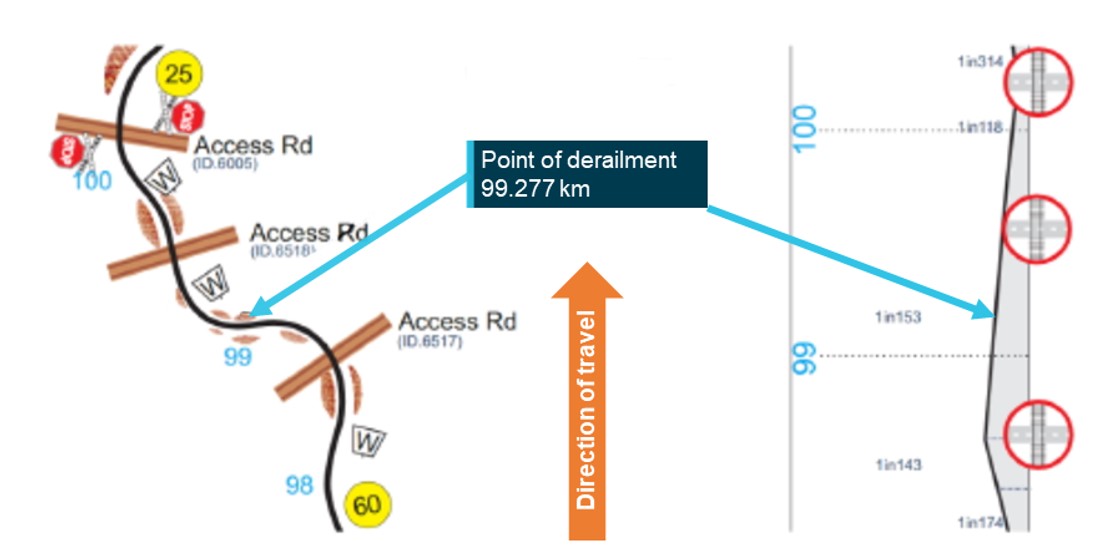

The narrow-gauge track[1] between Mount Rainbow and Dumgree consisted of 60 kg/m continuously welded rail fastened with resilient fasteners on concrete sleepers nominally spaced at 667 mm on ballast 250 mm deep. There was no overhead wiring electrical traction system or stanchions installed. The track consisted of undulating terrain with multiple tight radius[2] reverse curves (Figure 3 left). The point of derailment was located between 301 m radius reverse curves on a 1 in 153 downhill grade (Figure 3 right).

Figure 3: Track details at the point of derailment

Source: Aurizon, annotated by the ATSB

Site and wreckage information

Following the derailment, Aurizon inspected the derailment site and commenced an investigation. Based on the site evidence, Aurizon determined that the leading left wheel of the trailing rear axle of the 31st wagon (behind the 2 leading locomotives, VSAS 50930) climbed over the left rail (in the direction of travel) at 99.277 km (Figure 3). The wheel flange ran along the rail head for about 3.6 m then dropped off the field side.[3]

The following 20 wagons derailed (not including the 35th position wagon) and 2 remote distributed power locomotives derailed (located at position 51 and 52 in the consist). The train travelled about 400 m in a derailed condition. Aurizon specialists inspected the rolling stock in-field and found no pre-existing defects.

Aurizon found evidence of a track misalignment commencing at about 99.270 km, just prior to the point of derailment, where the concrete sleepers had begun to move both vertically and laterally (left and right). The track misalignment progressively worsened beyond the point of derailment (Figure 4). The ballast in the work location was also analysed. Although the ballast failed under 53 mm and 37.5 mm sieve tests,[4] Aurizon determined that the specification failure identified was not considered to have been contributory to the accident.[5]

Aurizon concluded that the recent track maintenance activity had a substantial impact on the compressive stress condition of the track leading up to the point of derailment in the heat of the day. This resulted in the track infrastructure becoming unstable and a flange climb derailment due to track misalignment.

Figure 4: Point of derailment and track misalignment

Note: The rear portion of wagons was removed from the site before the above photograph was taken. New ballast is lighter in colour.

Source: Aurizon, annotated by the ATSB

Stress-free temperature

Railway tracks are constructed of steel rails that expand and contract with changes in temperature. When the temperature increases, the rail expands and when the temperature decreases, the rail contracts. These changes in length can cause stresses and strains in the rail, which can lead to breaks, buckling, and other types of lateral instability. To prevent such instability, the rail is designed to have a stress-free temperature.

The design stress-free temperature refers to the temperature at which the rail is neither in compression nor in tension, and is established during track construction. However, this may change due to factors such as rail creep,[6] dynamic train forces (such as train acceleration and braking), and maintenance activities (such as tamping, destressing or ballast cleaning). Therefore, the actual stress-free temperature of the rail may not necessarily be the design temperature. Consequently, the actual temperature should be routinely measured to ensure it remains within the designed tolerances.

Aurizon specified a rail design stress-free temperature of 38°C for the line between Mount Rainbow and Dumgree. Although the line had been regularly inspected and maintained, the actual stress-free temperature of the rail before the track disturbance work commenced was unknown.

Track standards

The track was to be maintained in accordance with Aurizon’s standards including the Civil Engineering Track Standards[7] and Track Stability Manual.[8]

Track consolidation

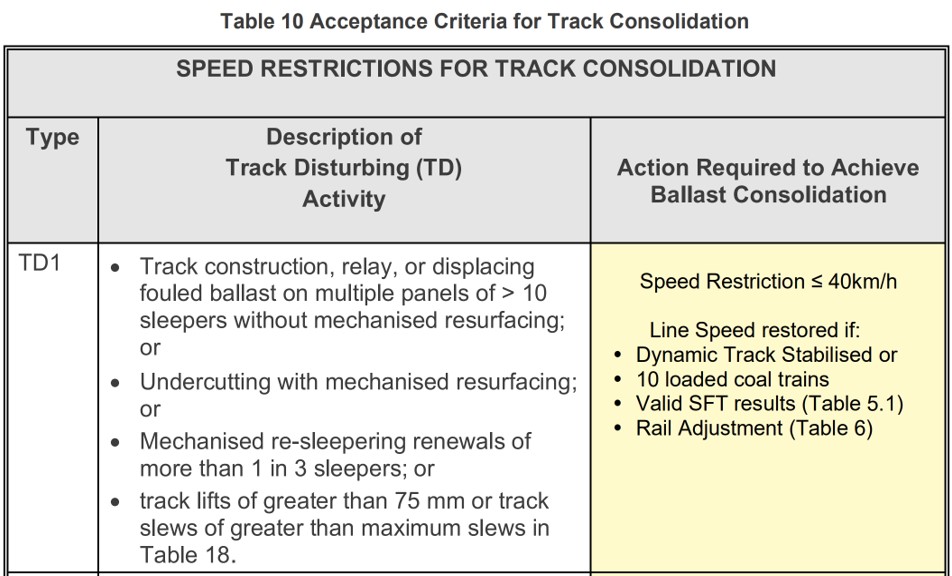

The Civil Engineering Track Standards stated:

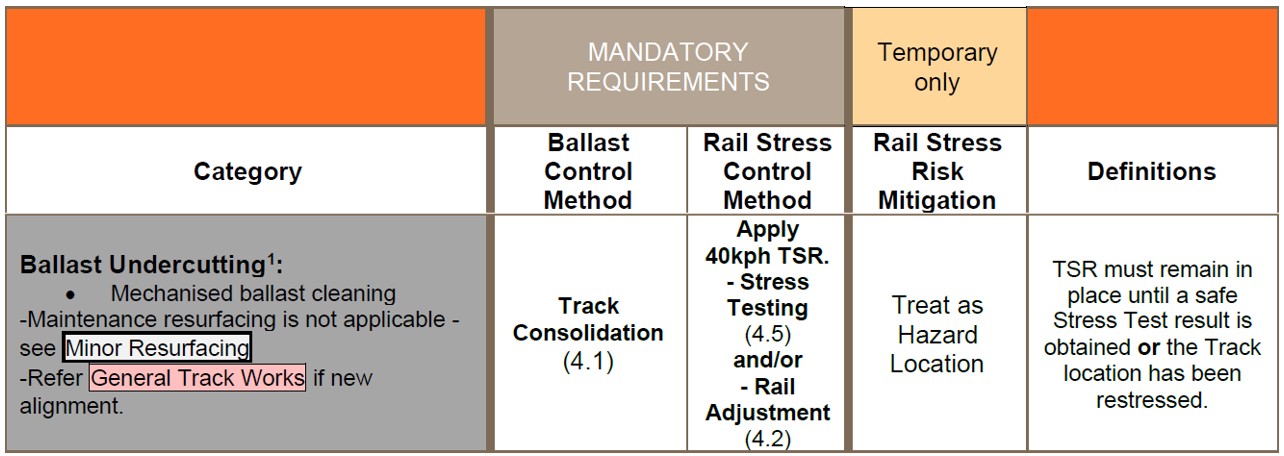

An excerpt of Table 10 is shown in Figure 5 indicating that a temporary speed restriction of 40 km/h or less was required after undercutting works until consolidation of the ballast[9] had occurred through either dynamic stabilisation or having 10 loaded coal trains pass over the track, establishing valid stress-free temperature results and making any rail adjustments.

Figure 5: Excerpt from the Civil Engineering Track Standards detailing the requirements for temporary speed restrictions for track disturbance works

Source: Aurizon, modified by the ATSB

Management of track stability

The Track Stability Manual described approved processes and procedures for the management of track stability on continuously welded rail by correct rail adjustment, and improving the track’s resistance to track buckles (compressive force) and breaks (tensile force). The management of track stability involved 2 separate processes:

- control of rail stress to reduce longitudinal forces in the rail that can lead to buckling

- maintenance of the ballast profile and condition to improve ability of track to resist these forces.

Figure 6 is an excerpt from the Track Stability Manual showing the track stability requirements for various disturbance works, including ballast undercutting. Ballast control through track consolidation, and rail stress control through stress testing or rail adjustment, were both mandatory requirements. The manual also noted that, as there were different mandatory requirements listed, there may be a situation where 2 or more speed restrictions may apply, and that the more ‘severe restriction’ should always apply. Following ballast undercutting works, in addition to the speed restriction required until ballast consolidation was completed (discussed above), a 40 km/h limit was to be put in place until a stress test with an adequate result or rail adjustment was performed.

Figure 6: Excerpt from the Track Stability Manual detailing the track stability requirements

Source: Aurizon, modified by the ATSB

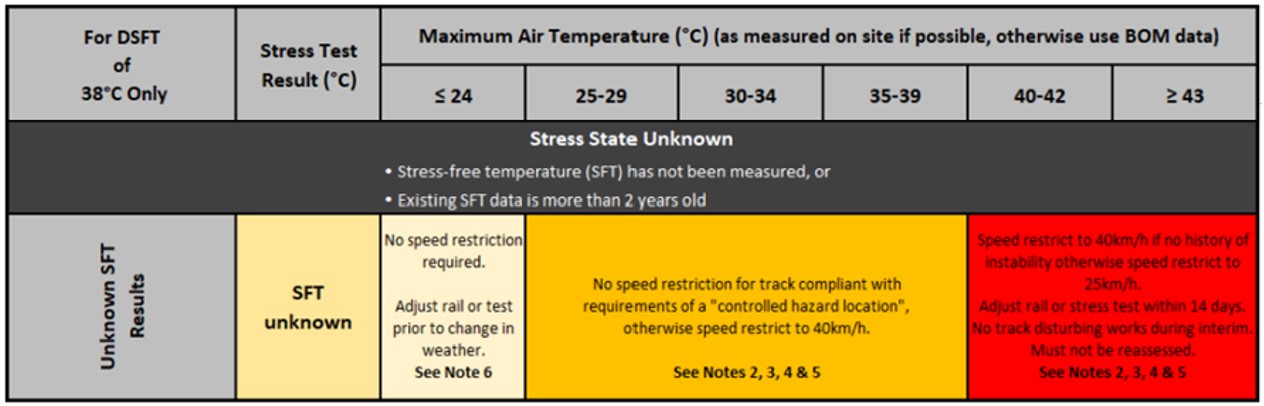

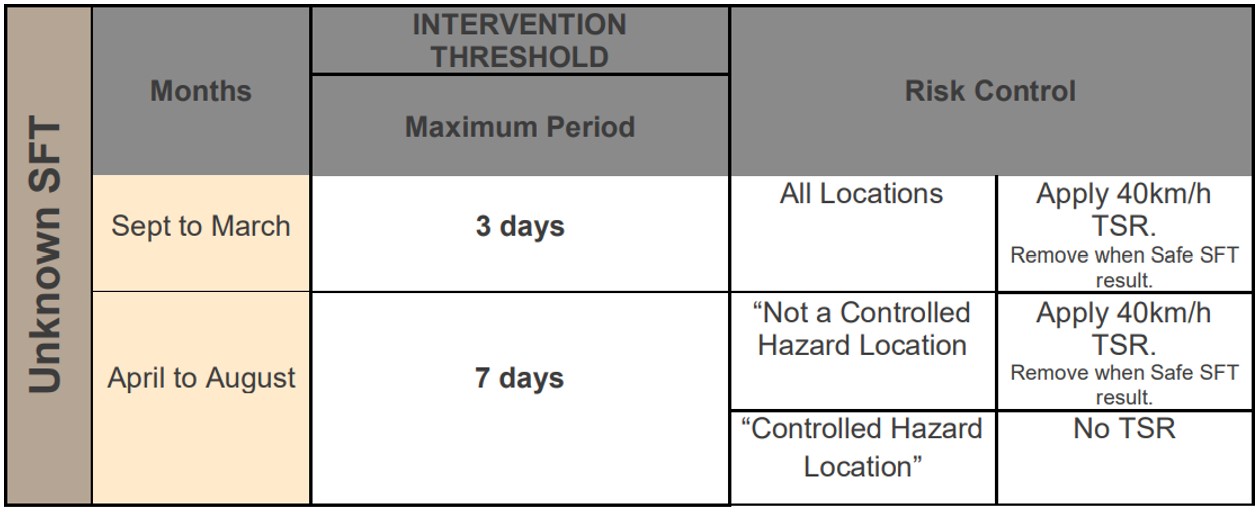

Figure 7 is an excerpt from the Track Stability Manual and shows the level of applied speed restriction based on the ambient air temperature and unknown status of the rail stress‑free temperature. In this instance, based on the unknown status of the rail stress-free temperature and ambient air temperature, a temporary speed restriction of 40 km/h was required until a rail adjustment was performed within the intervention threshold of 3 days (Figure 8).

Figure 7: Excerpt from the Track Stability Manual detailing speed restrictions based on ambient air temperature

Source: Aurizon, modified by the ATSB

Figure 8: Excerpt from the Track Stability Manual detailing the risk controls for an unknown rail stress-free temperature

Source: Aurizon, modified by the ATSB

Planned trackwork

Without dismantling the track, the ballast cleaning machine undercut the ballast bed with a moving chain beneath the rails and sleepers, removing contaminated and degraded ballast. The ballast was replaced with new ballast under the track, shown as the lighter colour in Figure 4.

Ballast undercutting track work, between Mount Rainbow and Dumgree, disrupted track stability between 99.840 and 99.286 km (554 m). This disruption potentially extended to include an influence zone up to 100 m either side of the work.[10] To mitigate the risks associated with track instability, the following key tasks were usually performed during and following disturbance work to assure track stability. They were, but not limited to:

- using track monuments[11] to measure offsets

- repositioning the track back to the original position based on the recorded offsets

- tamping[12] the track to the design curvature and superelevation[13]

- dynamic stabilisation[14]

- rail stress testing (if applicable) and subsequent adjustments to the rail

- using temporary speed restrictions until track stability was assured.

On 27 October 2021, following an initial delay, work commenced at about 1230 and about 350 m was completed before a shift handover. Following the handover to the afternoon shift, it was noted by the work supervisor that no temporary monuments had been installed. In preparation for continuation of the work, steel star pickets were hammered into the field-side of the track to create a temporary datum or monument points. The pickets were used at intervals of about 50 m to record track offsets, to ensure the track was returned to its original position following undercutting work. The afternoon shift completed about 200 m of undercutting work with monuments installed and track offsets recorded.

Following ballast replacement, the track was realigned using the previously recorded track offsets before design curvature and elevation corrections were made. The track was also dynamically stabilised to consolidate the ballast.

Generally, when ballast undercutting works was conducted, a stress test was completed following that works using a VERSE®[15] stress testing machine. The results of that test determined whether adjustments to the rail were required if found to be outside tolerances. In this case, as the curvature of the track was too tight to use this machine and receive accurate results, a re‑stress was planned to be completed. A re-stress (rail adjustment) involved cutting the rail, measuring the rail gap and temperature, calculating the rail stress-free temperature and required gap, then welding the rail together.

Prior to the work commencing, a rail stress plan was approved to begin following the work on 28 October 2021. Due to staff availability, the planned rail adjustment was not conducted on that date nor was there evidence provided to the ATSB that it had been rescheduled to occur within 72 hours, as specified in the Track Stability Manual (Figure 8). Following the work, a temporary speed restriction (TSR) board was not erected to cover the worksite. The site supervisor believed that other TSRs for the broader work covered that specific worksite.

Environmental information

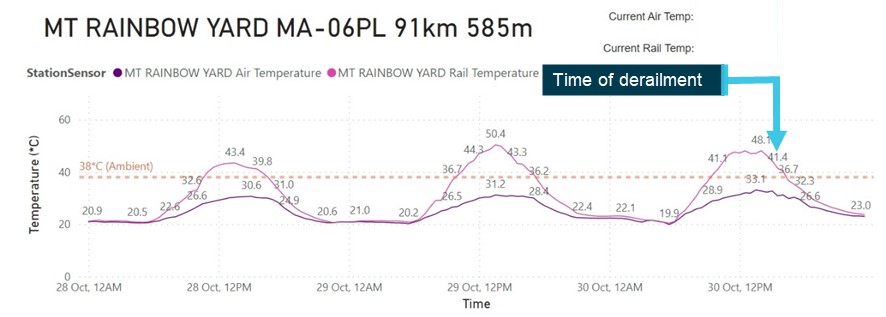

The closest Bureau of Meteorology weather monitoring station was at Thangool Airport, about 35 km south-south-west from the derailment site. The maximum outside air temperature recorded on 30 October 2021 was 34.2 °C.

Aurizon monitors air and rail temperatures at numerous locations on their network, including Mount Rainbow (7.7 km east) and Dumgree (10.4 km west). Table 1 shows the maximum air and rail temperatures, including near the time of derailment (at 1600).

Table 1: Aurizon recorded temperatures

| Location | Maximum temperature °C | Time of derailment temperature °C | Train at 1130 (°C) | Train at 1215 (°C) | |

| Mount Rainbow |

Air Rail |

33.1 at 1330 hrs 48.1 at 1400 hrs |

31.1 40.1 |

30.9 47.6 |

32 48 |

| Dumgree |

Air Rail |

35.7 at 1445 hrs 51.6 at 1315 hrs |

35.3 49 |

32.3 48.1 |

33.8 50.8 |

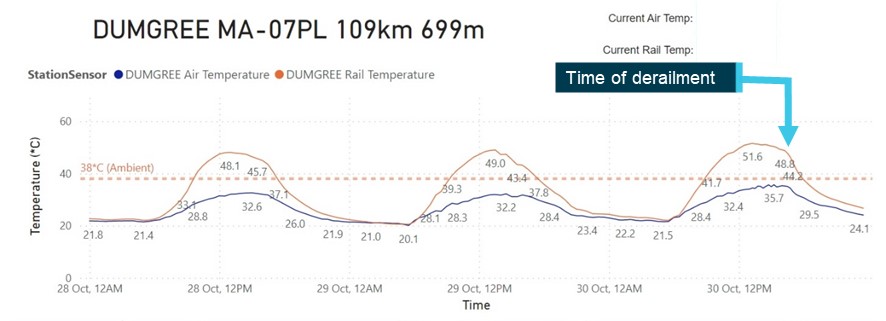

Figure 9 and Figure 10 show Aurizon recorded air and rail temperatures at Mount Rainbow and Dumgree between 28 October 2021 and 30 October 2021. The maximum air temperatures on each day were below the design stress-free temperature of 38°Cfor the rails. However, at the time of the derailment, the rail temperature was decreasing and was about 40.1 °C at Mount Rainbow and 49 °C at Dumgree.

Figure 9: Mount Rainbow air and rail temperatures

Source: Aurizon, annotated by the ATSB

Figure 10: Dumgree air and rail temperatures

Source: Aurizon, annotated by the ATSB

Similar occurrence

ATSB investigation (RO-2018-005)

On 24 January 2018, at about 1347 local time, loaded Aurizon coal train EF01 encountered a track buckle at Duaringa, on Aurizon Network’s Blackwater System between Emerald and Rockhampton, Queensland. The buckle resulted in 17 wagons in the train consist derailing (Figure 11), damaging 502 m of track on the down line and 54 m of track on the adjacent up line, with rails, sleepers and overhead line equipment requiring replacement.

Figure 11: Duaringa derailment site

Source: ATSB

The ATSB found that the track buckle had formed on a falling 1 in 50 grade at the point of the track where ballast cleaning and track stabilisation work had been completed less than 12 hours earlier. The ballast cleaning operational plan did not consider compressive stress in the continuous welded rail as a risk at this location.

The compressive stress, steep grade, proximity to a turnout and high ambient temperature meant the track structure had a limited capacity to constrain lateral forces. While the ballast cleaning, track resurfacing and dynamic track stabilisation work met Aurizon Network’s civil engineering track standards, negative operational outcomes were not anticipated when a risk assessment was done for the site.

Following this occurrence, Aurizon changed its procedures to ensure a temporary speed restriction was applied to all work sites on which ballast undercutting had been performed. The restriction was to remain in place until rail adjustment or stress testing had been completed and it had been determined that the rail stresses were within accepted limits. In addition, sites with a high risk of compressive rail stress would be identified and added to the site hazard map before conducting ballast cleaning.

Safety actions implemented by Aurizon following the Duaringa derailment had not been applied as part of the planned track work between Mount Rainbow and Dungree and are discussed in the Safety analysis below.

Safety analysis

On 30 October 2021, Aurizon empty coal train 9QJ5, derailed while traversing a section of track following disturbance work 7.7 km west of Mount Rainbow, Queensland. This analysis will discuss the track disturbance work and associated requirements following that work.

Track irregularity and derailment

The on-site examination identified wheel flange climb on the outside of the curved section of track between Mount Rainbow and Dumgree, indicating the point of derailment. Once the wheel climbed and dropped off the rail head, it created further damage, which led to further following wagons derailing. At the time, the train was travelling at 56 km/h.

The track in the vicinity of the derailment had been disturbed during ballast undercutting work, which was completed 2 days prior to the accident. This work destabilised the track until such time that it was realigned/tamped, stabilised, and the rail adjusted.

Further, it was established that the track immediately prior to the point of derailment near where the ballast undercutting transitioned to the original track (within the influence zone) was misaligned. Therefore, as there was no evidence to indicate that any issues with the rollingstock or train handling contributed, it was likely that the derailment occurred as a result of a track irregularity following the recent works.

Rail adjustment

To reduce the risk of lateral instability due to rail stress-free temperature being outside design tolerances, the Aurizon Track Stability Manual relied on the track being placed back into the same position following disturbance work. The stability manual also relied on a rail adjustment or stress test to confirm the rail stress-free temperature before a temporary speed restriction, protecting the area, was removed.

In this instance, a rail adjustment was planned (due to track curvature) as part of the work. However, due to resourcing issues, this was not performed before the track was returned to service as planned. In addition, there was no evidence provided to the ATSB indicating that the rail adjustment was rescheduled to be completed within the 72-hour requirement specified in the manual.

Consequently, the actual stress condition of the track was unknown when the track was returned to service. However, while the 2 other trains had passed over the disturbed track earlier in the day at normal speed without issue, the operator concluded that the track would have been in a compressive state following the works. Therefore, it was likely that the track was likely left in a stressed condition following the disturbance works and the track irregularity developed under train 9QJ5.

Temporary track monuments

Track monuments are used as datum points for the positioning of track within the rail corridor. Based on the records provided, the initial 350 m of work had not been monumented and the offsets not recorded. However, temporary monuments were regularly installed and used for about the final 200 m of the ballast undercutting, near the point of derailment. This meant that the final section of work had likely been realigned/tamped and stabilised in, or very near the original position. Therefore, the lack of track monuments for the earlier works was not considered to be a contributing factor in the derailment.

Irrespective, where permanent track monuments are not installed, the regular installation and use of temporary monuments ensures accurate track offsets are taken and the track is restored to the original position following any track disturbance works. This reduces the risk of affecting the rail stress-free temperature due to incorrect track alignment.

Temporary speed restriction

Following track disturbance work, Aurizon specified the requirements for temporary speed restrictions. In this instance, the track disturbance works required a 40 km/h temporary speed restriction to be applied, covering the works area and influence zones either side. Based on Aurizon requirements, the restriction was required pending the rail adjustment. Although it was not required for ballast consolidation as it had been dynamically stabilised during the restoration process.

However, following the work, a temporary speed restriction was not implemented. Potentially, a broader temporary speed restriction related to other work may have been mistaken as applying to the ballast undercutting area. Furthermore, the missing temporary speed restriction was not detected during the track hand back process to the integrated possession protection officer.

Considering 2 previous trains had passed over the site, in the heat of the day, and at normal track speed (up to 60 km/h) without incident, the contribution of the missing temporary speed restriction was unable to be established. Despite this, Aurizon mandated the implementation of temporary speed restrictions following track disturbance work. This is important to manage the risk of lateral track instability due to unconsolidated ballast and/or incorrect or unknown rail stress-free temperature.

Findings

|

ATSB investigation report findings focus on safety factors (that is, events and conditions that increase risk). Safety factors include ‘contributing factors’ and ‘other factors that increased risk’ (that is, factors that did not meet the definition of a contributing factor for this occurrence but were still considered important to include in the report for the purpose of increasing awareness and enhancing safety). In addition ‘other findings’ may be included to provide important information about topics other than safety factors. These findings should not be read as apportioning blame or liability to any particular organisation or individual. |

From the evidence available, the following findings are made with respect to the derailment of coal train 9QJ5 near Mount Rainbow, Queensland, 30 October 2021.

Contributing factors

- As 9QJ5 travelled between Mount Rainbow and Dumgree at 56 km/h on a curved section of track, the train derailed likely due to a track irregularity following track disturbance works.

- The track near the point of derailment was not re-stressed (adjusted) following the track work, as planned. Consequently, the track was likely left in a stressed condition when the track was handed back fit for service.

Other factors that increased risk

- Temporary track monuments had not been regularly placed throughout the worksite, increasing the risk of the track not being returned to the correct position following track disturbance work.

- After the track disturbance works had been completed, a temporary speed restriction of 40 km/h was not applied to assure safe passage over that section of track, which had not yet been cleared for operating at the normal speed of 60 km/h.

Safety actions

| Whether or not the ATSB identifies safety issues in the course of an investigation, relevant organisations may proactively initiate safety action in order to reduce their safety risk. The ATSB has been advised of the following proactive safety action in response to this occurrence. |

Safety action by Aurizon

Aurizon advised the ATSB of the following safety actions:

- A rail stress worker course was developed and rolled out to relevant roles.

- Roadshows were conducted in all districts, where network asset leaders discussed the intent and application of the Track Stability Manual.

- The Track Stability Manual was reviewed and updated.

- A rail stress appreciation course was created and attended by civil supervisors and civil superintendents across the Aurizon network.

- Site assessment walkout templates were updated to include relevant rail stress related information.

- A toolbox talk was created and issued to all infrastructure workers, reinforcing procedural requirements when performing track disturbing work to maintain track stability.

Sources and submissions

Sources of information

The sources of information during the investigation included:

- the train crew

- Aurizon

References

Office of the National Rail Safety Regulator. (2019). Guideline - Road Rail Vehicle Management and Operations, Version 1.0. Adelaide, SA: Office of the National Rail Safety Regulator.

Rail Industry Safety and Standards Board. (n.d.). Glossary of Terms. Retrieved from https://www.rissb.com.au/glossary/

Rail Industry Safety and Standards Board. (2018). Track stability (AS7643: 2018). Retrieved from https://www.rissb.com.au/products/as-7643-track-stability/

Submissions

Under section 26 of the Transport Safety Investigation Act 2003, the ATSB may provide a draft report, on a confidential basis, to any person whom the ATSB considers appropriate. That section allows a person receiving a draft report to make submissions to the ATSB about the draft report.

A draft of this report was provided to the following directly involved parties:

- train crew

- Aurizon

- Office of the National Rail Safety Regulator.

Submissions were received from:

- Aurizon

- Office of the National Rail Safety Regulator.

The submissions were reviewed and, where considered appropriate, the text of the report was amended accordingly.

Purpose of safety investigationsThe objective of a safety investigation is to enhance transport safety. This is done through:

It is not a function of the ATSB to apportion blame or provide a means for determining liability. At the same time, an investigation report must include factual material of sufficient weight to support the analysis and findings. At all times the ATSB endeavours to balance the use of material that could imply adverse comment with the need to properly explain what happened, and why, in a fair and unbiased manner. The ATSB does not investigate for the purpose of taking administrative, regulatory or criminal action. Terminology An explanation of terminology used in ATSB investigation reports is available here. This includes terms such as occurrence, contributing factor, other factor that increased risk, and safety issue. Publishing informationReleased in accordance with section 25 of the Transport Safety Investigation Act 2003 Published by: Australian Transport Safety Bureau © Commonwealth of Australia 2024

Ownership of intellectual property rights in this publication Unless otherwise noted, copyright (and any other intellectual property rights, if any) in this report publication is owned by the Commonwealth of Australia. Creative Commons licence With the exception of the Coat of Arms, ATSB logo, and photos and graphics in which a third party holds copyright, this publication is licensed under a Creative Commons Attribution 3.0 Australia licence. Creative Commons Attribution 3.0 Australia Licence is a standard form licence agreement that allows you to copy, distribute, transmit and adapt this publication provided that you attribute the work. The ATSB’s preference is that you attribute this publication (and any material sourced from it) using the following wording: Source: Australian Transport Safety Bureau Copyright in material obtained from other agencies, private individuals or organisations, belongs to those agencies, individuals or organisations. Where you wish to use their material, you will need to contact them directly. |

[1] Narrow gauge is nominally 1,067 mm.

[2] Aurizon defined a tight radius curve as a 300 m radius.

[3] The side of the rail opposite the gauge face (the inner side of the running rail head).

[4] New ballast contains approximately 40-45% voids and has the size, shape, density, and grading requirements specified to suit the operational requirements and environment. However, although all Australian railway systems have differing grading requirements, all have a maximum size of 53 or 63 mm and are limited to approximately 0.7% of dust passing a 75 μm sieve.

[5] Aurizon Category A investigation report of derailment of 9QJ5.

[6] The permanent or progressive longitudinal movement of rails in track caused by expansion or contraction of the rail or the action of rail traffic.

[7] SAF-STD-0077-CIV-NET Module 10 Civil Engineering Track Standards – Track Stability and Hot Weather Precautions, Ver 1.0, 11/01/2021.

[8] AZN.NA.MAN.12.6170.005 HWD Track Stability Manual – Network, Ver 2.0, 04/01/2021.

[9] The process of recompacting the ballast after track disturbance works, achieved through either the action of loaded trains or mechanical means.

[10] Any rail adjustment or speed restriction resulting from track disturbance works must cover the extent of the site, and an additional length of track beyond the immediately affected area. This is known as the influence zone as defined by Aurizon (Track Stability Manual). For rail adjustments, the influence zone extended 100 m at each end of the affected work area.

[11] A permanent monument located at the side of the track to facilitate the accurate measurement of rail creep. Measurements were taken between a marker on the monument and punch marks made on the side of the rail head. Where no permanent monuments were installed, it was best practice to install and use temporary monuments, such as steel star pickets.

[12] The process by which ballast is packed around the sleepers of a track to ensure the correct alignment for the location, speed and curvature of the line.

[13] Generally, the term superelevation (or cant) is used for intended height difference in the rails (that is, where the track is inclined in a curve), and the term 'cross-level' is used for unintended height difference (that is, due to track irregularity).

[14] Dynamic track stabilisation is a track maintenance technique that uses controlled vibrations to improve the stability of the ballast bed. This is done by applying horizontal vibrations to the track while simultaneously applying a vertical load. The vibrations cause the ballast stones to re-arrange themselves in a denser and more homogeneous structure, which improves the track's resistance to lateral displacement and settlement.

[15] The vertical rail stress equipment (VERSE®) machine is a scientific instrument used to non-destructively measure the stress-free temperature of continuously welded rail.