This investigation was conducted under the Transport Safety Investigation Act 2003 (Commonwealth) by the Office of Transport Safety Investigations (NSW) on behalf of the ATSB in accordance with the Collaboration Agreement. Released in accordance with section 25 of the Transport Safety Investigation Act 2003.

Safety summary

What happened

On Tuesday, 15 December 2020 at 0454, the crew of Qube loaded grain train 3966, consisting of 41 wagons and two CM class locomotives, reported a runaway on the descent of the Moss Vale to Unanderra rail line. The train reached speeds up to 100 km/h on a 30 km/h section of track before it derailed and separated at two points between Dombarton and Farmborough Heights, New South Wales (NSW). Shortly after, the train crew advised they had brought the two locomotives and the remaining two wagons to a stand at Farmborough Heights. The train crew were not physically injured.

What the ATSB found

The investigation identified that ineffective braking caused by several factors contributed to the runaway. The ineffective application of train braking systems was influenced by a heavily loaded train with some overloaded wagons, wagons with variable net brake ratio (NBR), reduced brake cylinder pressure through the train, and train handling and locomotive dynamic braking affected by low track adhesion conditions.

The weight of the train was near, but likely not over, the maximum allowable tonnage limit specified by the Australian Rail Track Corporation (ARTC)’s Train Operating Conditions (TOC) Waiver 16002. It was likely, however, that several individual wagons across the train consist were over the allowable limit for a single wagon.

Measurements of NBR at different times and on different wagons returned varying results ranging from 10.7% to 19.5%. The minimum required NBR for these wagons, specified by Australian Standards was 13%. While modifications were made to improve braking performance on the wagons, the NBR on some wagons continued to change over time. The wagon type test met the NBR requirement when introduced into service and met NBR requirements when tested post modifications, however there was no requirement for regular testing of NBR, which may have identified the changes in NBR.

The mix of wagons with variable NBRs and variability in loading likely reduced braking effort on some of the wagons during the steep descent along the rail line.

During the occurrence, the second automatic brake application made by the driver was made before the brake pipe had fully recharged. This resulted in a reduced amount of available brake cylinder pressure and lessened braking effort on the trailing wagons.

The driver's operation of the train and braking actions did not always conform to the operator (Qube)’s instructions, and it is likely some of the driver’s decisions on the morning of the accident were affected by fatigue.

Once control was lost, the driver elected not to use the emergency brake because they believed, in accordance with Qube’s procedures, that the locomotive braking would have been diminished. This in turn lessened the opportunity to regain control of the train.

Qube’s operational procedure for train management between Moss Vale and Inner Harbour did not consider locomotive configurations that maintained locomotive dynamic braking during emergency applications. This increased the risk of train drivers not applying the emergency brake during a runaway event. This assumption was also found to be embedded within other rolling stock operators’ procedures with similarly configured locomotives in NSW.

The conditions on the rail line from Summit Tank to Farmborough Heights on the morning of the incident included wet rail and track contaminant that likely contributed to low track adhesion and also reduced dynamic braking effort by the locomotives. The wheel slip/slide protection system worked as designed to maximise traction through the use of auto sanding to increase friction and derated the dynamic braking effort through the wheels to match the lower adhesion conditions.

Several rail flange lubricators, which provided lubrication to the down and up rail, were less than the 500 m minimum separation requirement specified in ARTC’s engineering practices manual RC2411. A review of these to ensure consistency with the engineering practice and to minimise the risk of excess track lubrication on a steep gradient was warranted.

Finally, the brake pipe charging flow indicator on CM class locomotives only provided a numerical display without any corresponding audio or visual warning system to alert the driver of its status. This limited the ability of the driver to detect derailment or train separation events and, as in this incident, effectively monitor recharge of main reservoir air into the brake pipe to ensure it was fully charged before making another brake application.

What has been done as a result

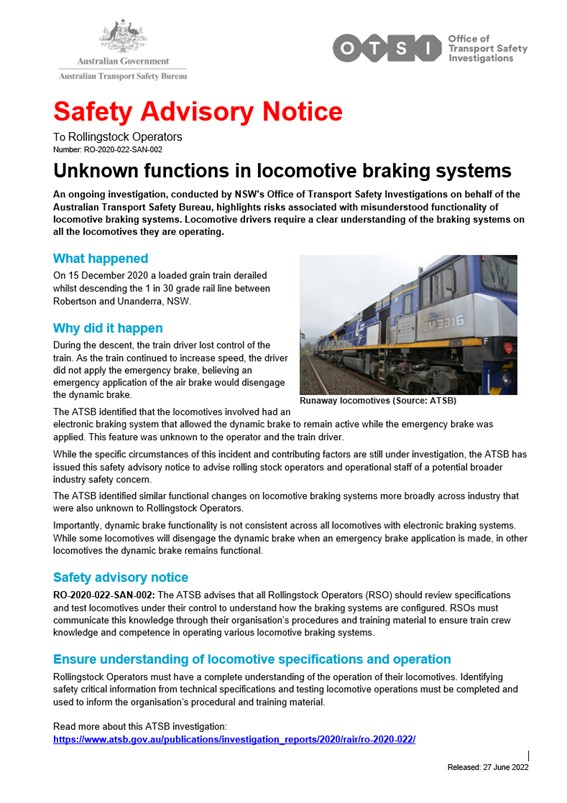

During the investigation, a Safety Advisory Notice was issued by the Office of Transport Safety Investigations (OTSI) in collaboration with the ATSB to the rail industry to raise awareness of variable locomotive braking system configurations on locomotives across Australia. Qube and other affected rollingstock operators took immediate actions to review their locomotive configurations, to ensure their locomotive drivers had a clear understanding of the braking systems on the locomotives they were operating.

A forum was chaired by the Office of the National Rail Safety Regulator (ONRSR) in March 2023 with Rail Infrastructure Managers (RIMs) and Rollingstock Operators (RSOs) that operated on the Moss Vale to Unanderra rail line. This provided an opportunity to discuss and communicate the risks of operating on the rail line and how to manage them to mitigate runaway events.

The two RIMs, Sydney Trains and ARTC conducted a review and alignment of Transport for NSW (TfNSW) TOC Manual Illawarra operations and the ARTC Route Access Standard - Section Page D52 Moss Vale - Unanderra. The focus of the review was on providing interoperable train configuration and operating conditions between the two RIM interfaces. Additionally, conditions for managing degraded dynamic brakes and hauling dead attached locomotives were developed. All changes were held in consultation with RSOs, ARTC operations and Network Control stakeholders.

In consultation with TfNSW, ARTC developed joint assessment criterion for Unanderra Trial train configurations, operating conditions, and implementation plans. The RSO will be required to submit supporting documentation as part of a variation to existing approved train configurations.

ARTC has updated NBRs for vehicle classes following physical testing and has worked with others in the rail industry to promote NBR testing as part of preventive maintenance.

Safety message

The rail line between Summit Tank and Unanderra is one of the steepest sections of rail line in NSW. To prevent runaway occurrences on this rail line, operators must regularly review the effectiveness of their risk controls and proactively manage conditions that present greater risk of runaway.

RSOs should ensure their trains have sufficient braking, are loaded within safe load limits and are operated in accordance with their procedures.

RSOs and RIMs should ensure that risk assessments identify critical operational requirements to safely run trains down such steep sections of track. They should also ensure that there is sufficient error tolerance to enable control of trains on sections of rail line that present increased risks from long and steep descents.

RSOs should review the locomotive specifications and test those locomotives under their control to understand how the braking systems are configured and the associated error tolerance. RSOs must communicate this information through their organisation’s procedures and training material to ensure train crew have knowledge of and competence in operating locomotive braking systems, including emergency braking in the event of a runaway.

The use of two-pipe wagon braking systems significantly reduces the recharge times for the brake pipe after a brake application, but the starting air pressure of a wagon’s auxiliary reservoir remains a critical consideration. For example, low auxiliary reservoir starting pressure at the beginning of an automatic brake application reduces the response of a wagon’s supplementary reservoir, resulting in lower wagon brake cylinder pressure and therefore less effective braking effort.

Finally, while a ‘full service’ automatic brake application typically provides the maximum pneumatic braking force available on a train, in the unique circumstance of a train with low auxiliary reservoir starting pressure, lowering the brake pipe pressure further through the application of the emergency brake, will result in an increase in the available braking force. However, this increased braking force will remain less than that which would have been available in full service had the auxiliary reservoir been fully charged at the time of the brake application.

The occurrence

Overview

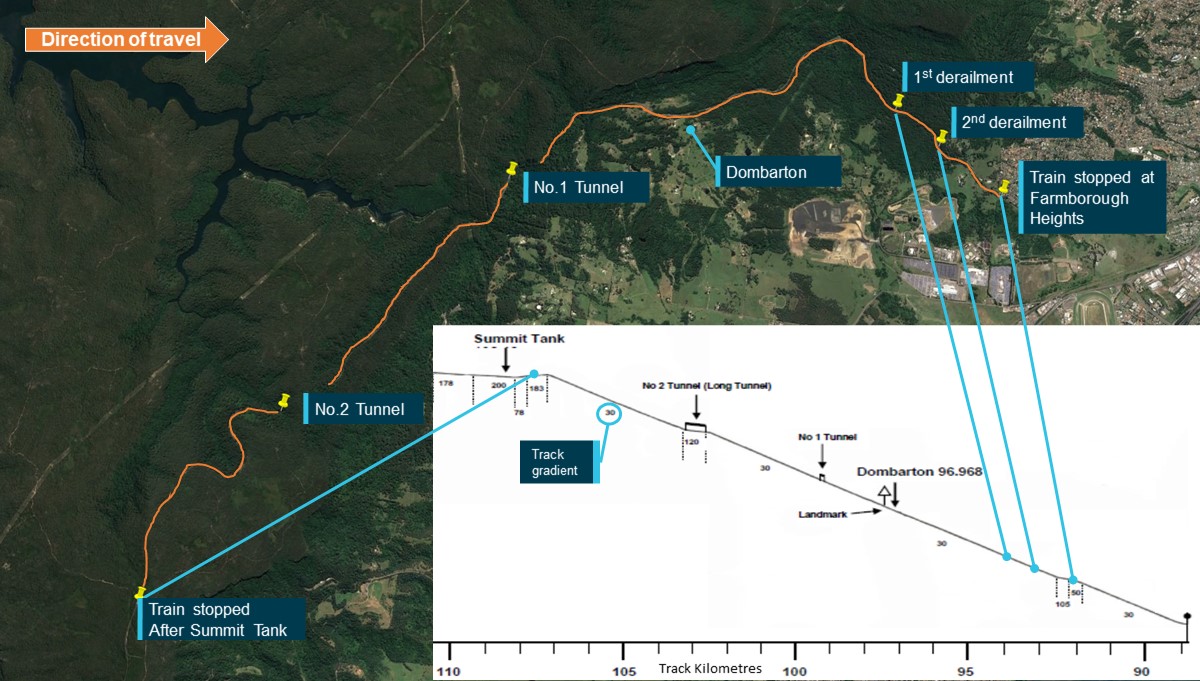

On 14 December 2020, at approximately 1815 Eastern Standard Time (EST),[1] Qube loaded grain train 3966 departed Temora, New South Wales (NSW) bound for Inner Harbour Port Kembla, NSW. The train travelled through the night and in the early hours of 15 December 2020 commenced the descent on the Moss Vale to Unanderra rail line. Between Summit Tank and Farmborough Heights, the train ran away,[2] derailed and separated at two locations. The 29th to 41st wagons derailed and separated at approximately 93.730 km from Sydney’s Central Station. Then the 3rd to the 28th wagons derailed and separated at approximately 93.220 km, before the locomotives and two remaining wagons came to a stop at Farmborough Heights (Figure 1).

Figure 1: Section of Moss Vale to Unanderra rail line between Summit Tank and Farmborough Heights

This image shows where the train stopped prior to descending the mountain, the points of derailment and where the train stopped. The inset is the track gradient diagram with corresponding stop points and derailments.

Source: Google Earth and QUBE, annotated by OTSI

Start of shift

On 14 December 2020, the train crew, consisting of a driver and driver’s assistant, signed on at 2000 at the Junee depot for an 11-hour shift. They were scheduled to start at 1430 but were laid back[3] to 2000. They travelled to Cootamundra and relieved the train crew on service 3966 at approximately 2110. They were rostered to work the train from Cootamundra to Port Kembla. The driver operated the train, for the near seven-hour journey, reporting at interview that the journey was uneventful with the train operating predictably to the start of the descent at Summit Tank.

Start of the descent (~107.5 km)

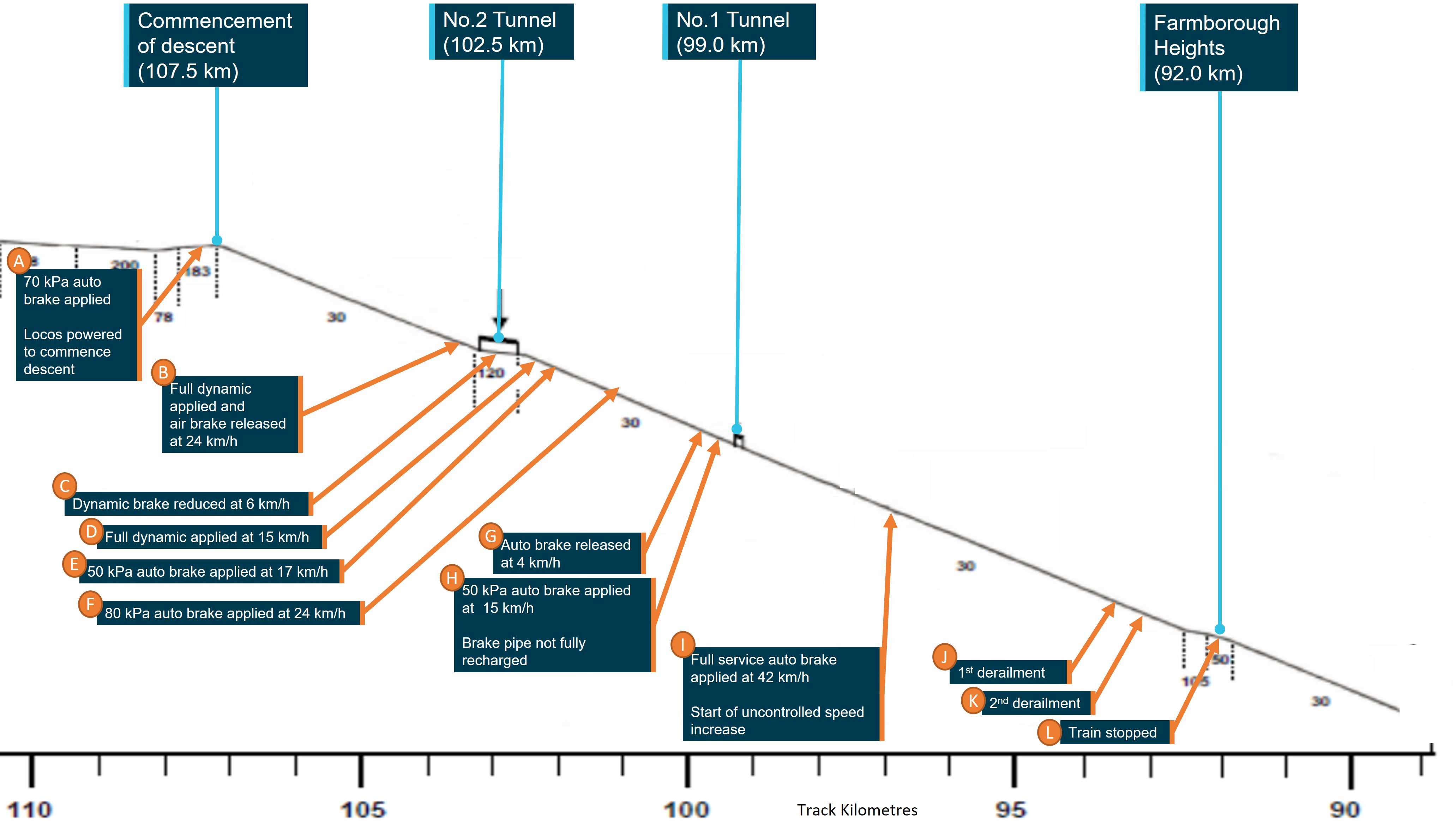

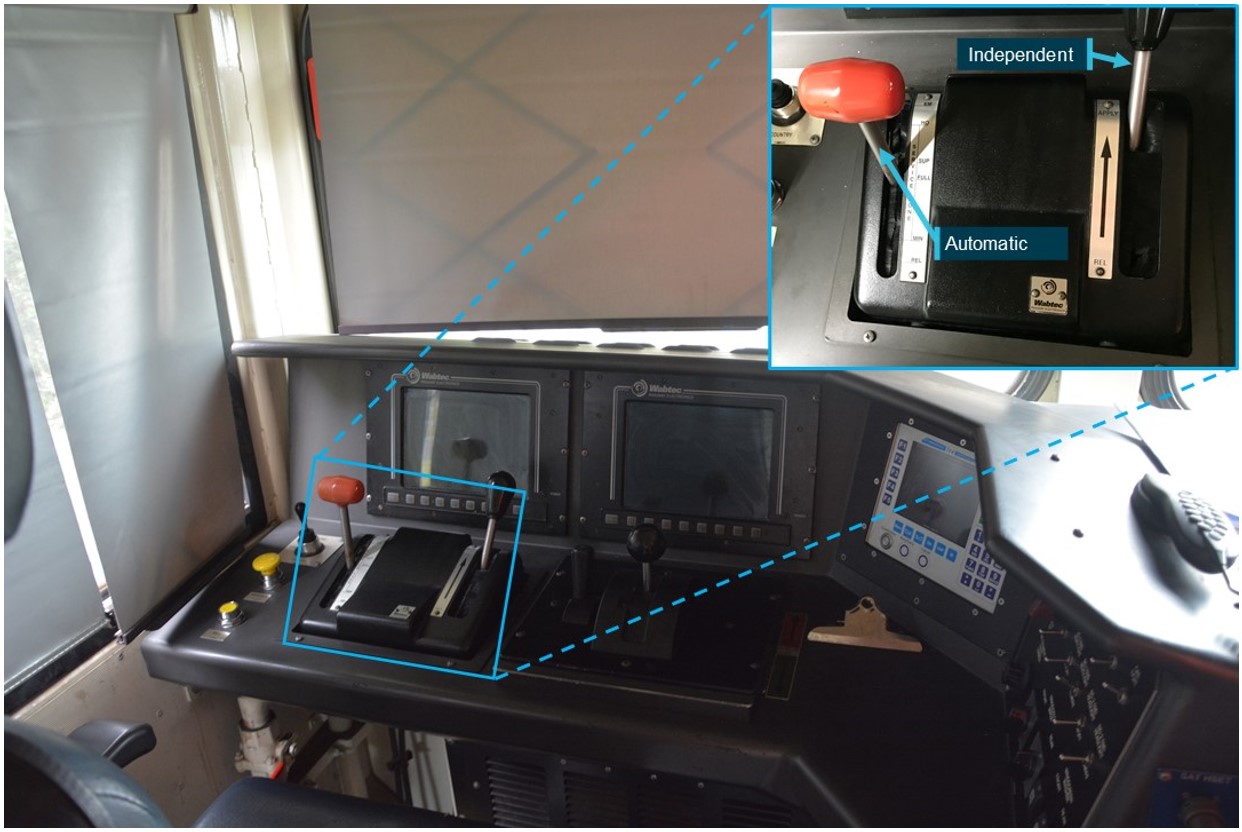

On 15 December 2020, at approximately 0415, the driver made an automatic brake[4] application (about 70 kPa reduction) and brought train 3966 to a stop at the level crossing just after Summit Tank (see A in Figure 2), as required by Qube’s operational procedure. Once stopped, the driver applied the independent brake.[5]

After a stop of approximately four minutes, the driver released the independent brake and with the automatic (train) brake still applied, powered the locomotives to commence movement against the still applied train brakes.

This stop and start process conducted by the driver at Summit Tank differed to Qube’s operational procedure, which stated that the train should be stopped using a 100 kPa brake pipe reduction (refer to Brake release rollaway time test for further information).

The driver then maintained the automatic brake at a 70 kPa brake pipe reduction and graduated the dynamic brake[6] to manage the speed of the train. This form of brake management was known as ‘balanced braking’.[7] The driver descended the rail line between Summit Tank and the No.2 Tunnel using this method of braking control.

Figure 2: Sequence of events

This image shows the sequence of events leading up to the loss of control and derailments.

Source: QUBE, annotated by OTSI

No.2 Tunnel (~102.5.0 km) to No.1 Tunnel (~99.0 km)

At 0436 the train entered No.2 Tunnel travelling at 24 km/h. The driver applied full dynamic brake and released the automatic brake (see B in Figure 2).

Releasing the automatic brake allowed the brake pipe to fully recharge[8] after about 50 seconds. The train slowed to approximately 6 km/h at this time (see C in Figure 2).

The driver then reduced the dynamic brake. Over the next minute, the train speed increased to about 15 km/h.

The driver applied the dynamic brake in full again (see D in Figure 2), then approximately 30 seconds later, with the train travelling at 17 km/h, the driver made a ‘minimum service’[9] automatic brake application (see E in Figure 2).

The train continued to increase speed over the next 30 seconds, with auto sanding[10] occurring three times as the train approached 18 km/h. The train then started to slow slightly over the next 45 seconds and auto sanding occurred another three times.

Over the next 2.5 minutes, without any further input from the driver, the train began to increase speed again. Auto sanding occurred 12 times, as the train speed reached 24 km/h. The driver increased the automatic brake application to about an 80 kPa brake pipe pressure reduction and the train started to slow (see F in Figure 2).

The frequent auto sanding on the descent from Summit Tank, in misty and wet weather conditions, indicated the locomotives' wheel slip/slide protection systems were working as designed to maintain dynamic braking under the adhesion conditions. The driver stated at interview that there were no wheel slip indications received on the locomotive to indicate reduced wheel-rail adhesion, and so they felt the dynamic brake was working effectively.[11]

The train speed reduced over the next 2.5 minutes to about 16 km/h, and auto sanding occurred 11 times. With the dynamic brake fully applied and the auto brake at 80 kPa reduction, the train speed continued to decrease over the next 2.25 minutes to 4 km/h, during which auto sanding occurred another four times (see G in Figure 2).

As the train slowed, the driver released the automatic brake and maintained the dynamic brake in full applied mode. The driver then managed the train speed using serial/cycling braking,[12] as per Qube work instruction WI-540 (Moss Vale to Inner Harbour Train Management). The braking instruction stated that if train speed could not be managed using a 75 kPa reduction and altering the dynamic braking to maintain speed, then the serial/cycle braking method must be used.

At 0448, at about 99.673 km,[13] with the train travelling at 15 km/h, the driver applied a minimum service brake application (see H in Figure 2). The automatic brake handle had been in the release position and charging for 43 seconds since the brakes were last applied.

Although the brake pipe pressure at the locomotive had, by this stage, recharged to 489 kPa on the cab gauge, the brake pipe charging flow indicator was still registering an air flow of 934 litres per minute. This meant that the brake pipe had not yet fully recharged throughout the length of the train (refer to Brake pipe charging flow indicator for further information). In interview, the driver recalled observing the flow meter indicating air flow of 934 litres per minute and judged the train brake pipe to be charged to about 90–95%.

The minimum reduction in brake pipe pressure did not appear to slow the train as the speed increased to 21 km/h over the following 14 seconds. The driver reduced the brake pipe by a further 14 kPa (425 kPa) but the speed continued to increase. The dynamic brake remained in the fully applied position and auto sanding was triggered regularly.

As the train’s speed reached the track section speed limit of 30 km/h, the driver reduced the brake pipe pressure by a further 7 kPa (418 kPa) and the train entered No.1 Tunnel.

No.1 Tunnel (~99.0) to Farmborough Heights (~92.0)

In interview the driver indicated that it was at this point they felt the train was behaving ‘unpredictably’, compared to its responsiveness to the two previous brake applications between Summit Tank and No.1 tunnel.

While in No.1 tunnel, the driver increased the automatic brake application, reducing the brake pipe pressure by a further 14 kPa (404 kPa). The train’s speed continued to increase to 32 km/h, just over the track speed limit of 30 km/h. The train passed through the tunnel and auto sanding was triggered eight times.

At 0450, at about 98.5 km, the driver increased the brake application again, reducing the brake pipe by another 7 kPa (397 kPa). The train was travelling at 34 km/h when the driver commented to the driver’s assistant, ‘I’m on the edge’. Auto sanding occurred two times.

Thirty seconds later, the driver increased the brake application. This reduced the brake pipe pressure by another 7 kPa, to 390 kPa. The train speed remained 34 km/h. Auto sanding occurred three times.

At this time, the head of the train was at about 98.2 km, entering a relatively straight section of track. The rear of the train was still passing through a series of 200 m curve radius left and right‑hand turns.

At about 98.0 km, the driver made another brake application (383 kPa). The train remained at 34 km/h.

As the head of the train reached 97.5 km, the speed increased from 34 km/h to 37 km/h over a 20 second period. At this point, the locomotives entered a 200m right hand curve with the full length of the trailing load on straight track behind it. This would have resulted in reduced dynamic locomotive braking and zero curve resistance on the wagons, which likely contributed to the acceleration. Although the driver made a further brake application (376 kPa), the train continued to increase speed over the next 15 seconds.

At 0453, at about 97.1 km, with the train speed at 42 km/h, the driver applied the automatic brake to ‘full service’[14] (see I in Figure 2). The train continued to increase speed up to 45 km/h over the next 20 seconds. The driver was heard on the in-cab recorder to say, ‘we’re not going to stop’, and then contacted Network Control. Over the next 90 seconds the speed increased to over 60 km/h.

The driver said to Network Control, ‘Can you guarantee me the road there at Unanderra, I’m having trouble stopping this train’. The network controller called Wollongong Panel and requested the rail line to be cleared at Unanderra and Wollongong Panel confirmed it would be done.

At 0455, the network controller called the driver of 3966 and confirmed the scale of the emergency. The driver said, ‘…I’m doing about 70 [km/h] and I’ve got it in full service, I don’t want to put it in emergency[15] because I’ll drop my dyno [dynamic brake] out.’ The network controller said, ‘so fairly dire then is it?’. The driver replied, ‘yeah I’m doing about 80 [km/h] now’.

The network controller kept the driver on the line while they called Wollongong Panel to confirm that the rail line was clear at Unanderra. Wollongong Panel confirmed it was, then the network controller asked the driver for an update. There was no response from the driver.

At 0456, the driver fully applied the independent brake with no apparent effect on reducing the speed of the train. The train was travelling at about 85 km/h, at track position 94.159 km. At this time wheel slide was recorded on the locomotives.

Seconds later, as the train passed the Dombarton distant signal WG1042U at 93.810 km, it went into a left-hand 200 m radius curve in the direction of travel, reaching a peak speed of about 100 km/h. The train was 70 km/h over the track speed limit of 30km/h. At this time, the 29th wagon and trailing wagons derailed and separated from the front part of the train (see J in Figure 2).

At 0457, with the front of the train at 93.100 km and travelling at about 98 km/h, the 3rd wagon up to the 28th wagon derailed and separated from the front part of the train. The train was on a right‑hand 200 m radius curve in the direction of travel (see K in Figure 2).

The train had started to slow after the first separation and at 0458, the two locomotives and remaining two wagons came to a stop at 92.040 km (see L in Figure 2).

As the train came to a stop, the driver advised Network Control ‘I’m at Farmborough Heights and all of a sudden it decided to grab [train started to slow]’.

Post occurrence

With the train immobile, the driver’s assistant stepped off the lead locomotive to check the rest of the train and secure it. They reported back to the driver, via radio, that there were only two wagons attached to the two locomotives.

The driver conveyed this information to Network Control and the Qube Control Centre shortly after.

Recovery teams and emergency services were arranged to attend the site. Inspection of the rail track and rolling stock commenced at approximately 0700 and at 1140 recovery operations commenced.

The locomotives and two attached wagons were inspected by Qube and Chicago Freight Car Leasing Australia (CFLCA, the owner) before being transferred to Port Kembla.

At Port Kembla, the wagons were emptied, and grain weighed to confirm the weight of the remaining two wagons. The tonnage in the wagons was within load limits.

Context

Incident Location

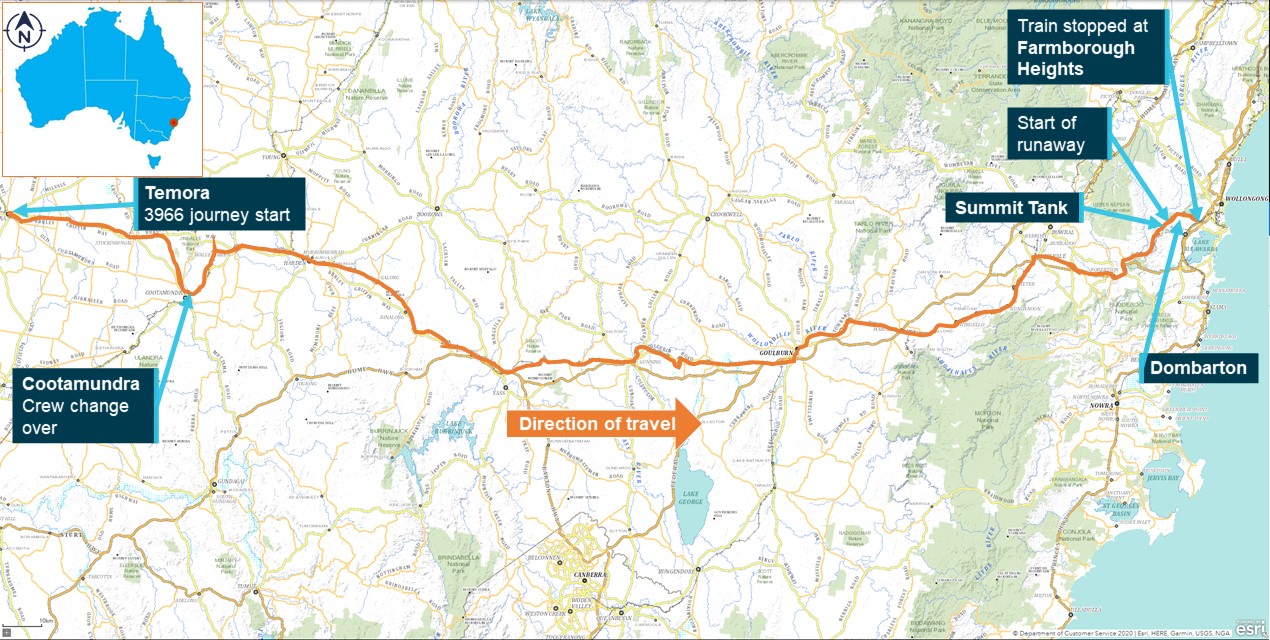

The runaway and derailment occurred between Summit Tank and Farmborough Heights on the Moss Vale to Unanderra rail line, near Dombarton, New South Wales (NSW). Dombarton is on the Illawarra Escarpment approximately 97 rail km south of Sydney Central Station. The train journey started in Temora and the train crew took control of the train at Jindalee (Cootamundra) (Figure 3).

Figure 3: Path of 3966

The orange line represents the rail route of 3966 from Temora to where it stopped at Farmborough Heights. Other key locations are identified.

Source: Google Maps, annotated by OTSI

Moss Vale to Unanderra rail line

The Moss Vale to Unanderra rail line is a 57 km section of track connecting the Main South rail line with the Illawarra rail line. The 20 kilometres of track between Summit Tank and Unanderra traverses down the Illawarra escarpment through multiple curves varying in radius between 185 m and 2020 m, transitions and straights. The grade[16] is primarily 1 in 30, other than small sections through No.2 tunnel and Farmborough Heights where the grades are 1 in 120 and 1 in 105 respectively (Figure 1). It is a single-track rail line at Summit Tank, mostly tree lined (Figure 4) and passes through two tunnels and a Rock Fall Shelter before reaching Dombarton where the rail line becomes double-track.

Figure 4: Front of train footage of track

Taken from 3966 front of train camera between 104.000 km and prior to entering No.2 tunnel. Tree foliage lines the track.

Taken from 3966 front of train camera between 104.000 km and prior to entering No.2 tunnel. Tree foliage lines the track.

Source: Qube

The rail line then remains double-track winding through more tree lined areas before reaching Farmborough Heights. At this location, the grade eases to 1 in 105 then changes back to 1 in 30 grade, winding down through more tree lined areas to Unanderra (see Figure 1 inset for track gradient).

Weather information

There were two Bureau of Meteorology weather stations in proximity to the occurrence: Moss Vale in the Southern Highlands, located at the top of the Illawarra escarpment, and Albion Park in the Illawarra region, located close to the bottom of the escarpment. The site of the incident was between these two locations.

The weather pattern recorded at both weather stations was similar. Recorded weather data logged light rain and moderate winds on the Moss Vale to Unanderra rail line (Table 1). In interview, the driver recalled the weather conditions on departure from Summit Tank to be that of ‘very misty rain’. The data logger also indicated the windscreen wipers of locomotive 3316 were activated between Tunnel 2 and Tunnel 1.

Table 1: Weather recorded at Moss Vale and Albion Park

| Place/Date | Temperature | Rainfall | Winds |

| Moss Vale/14 Dec 20 | 13.4 – 19.1 | 2.6 mm | ENE up to 41 km/h |

| Moss Vale/15 Dec 20 | 14.6 – 23.6 | 4.4 mm | NE up to 39 km/h |

| Albion Park/14 Dec 20 | 16.8 – 24.3 | 4.0 mm | NE up to 30 km/h |

| Albion Park/15 Dec 20 | 18.6 – 25.3 | 3.2 mm | NE up to 33 km/h |

Source: Bureau of Meteorology

Rail Transport Operators

Qube Holdings

Qube Holdings was a logistics and infrastructure company that provides import and export logistics services across Australia. Its rail logistics division, Qube Logistics (Rail) Pty Ltd (Qube), was accredited by the Office of the National Rail Safety Regulator (ONRSR) as a Rail Infrastructure Manager (RIM) and Rollingstock Operator (RSO) on the 20 January 2013, in the states of NSW, South Australia, Victoria, Western Australia and Queensland.

Qube was the RSO responsible for the operation of grain train 3966.

CFCL Australia Pty Ltd

Chicago Freight Car leasing Australia (CFCLA) was the owner and lessor of the locomotives and wagons. They were accredited as a RSO by ONRSR on 20 January 2013 and were primarily a locomotive and rollingstock leasing company providing assets to other RSOs in the Australian rail industry.

In January 2020, CFCLA was acquired by Anchorage Capital Partners and the company was rebranded as Rail First Asset Management in 2021.

Australian Rail Track Corporation

The Australian Rail Track Corporation (ARTC) manages and maintains approximately 8500 km of rail network across five states in Australia.

In NSW, ARTC leases the mainline interstate corridors from the NSW Government (Figure 5). ARTC is responsible for managing and maintaining these rail corridors in accordance with their accredited system standards.

Figure 5: ARTC leased rail network from NSW Government

Dark lines are the corridors managed and maintained by ARTC. The route of 3966 was between Cootamundra and PT (Port) Kembla

Source: ARTC

ARTC was accredited by ONRSR as a RIM and RSO on 20 January 2013 in the states of South Australia, New South Wales, Victoria, Western Australia and Queensland.

ARTC was the RIM responsible for the management and maintenance of the section of track between Summit Tank and Farmborough Heights on the rail line between Moss Vale and Unanderra. Slightly further down the rail line from Farmborough Heights, at 91.080 km, is the interface between ARTC and Sydney Trains rail networks. Above rail operators that use the Moss Vale to Unanderra rail line are required to operate their trains in accordance with the train operating conditions[17] of both RIMs.

Train Crew

The train crew consisted of a driver and driver’s assistant. Both were employed by Qube.

Driver

The driver started working for Qube in September 2012. They were qualified as a locomotive driver for 23 years.

Before working with Qube, the driver had operated train services on the Moss Vale to Unanderra rail line with another freight operator.

The driver was assessed and deemed competent to operate services on the Moss Vale to Unanderra line by Qube. The driver operated five other services on that line in the week prior to the incident train service on the 15 December 2020.

During post incident interview with the driver, they said (of the incident train, 3966) they had taken a mental note of the train weight and got a feel for the train as they operated the train from Cootamundra, but did not calculate the train’s tonnes per operated brake (TOB) as required in their procedure.

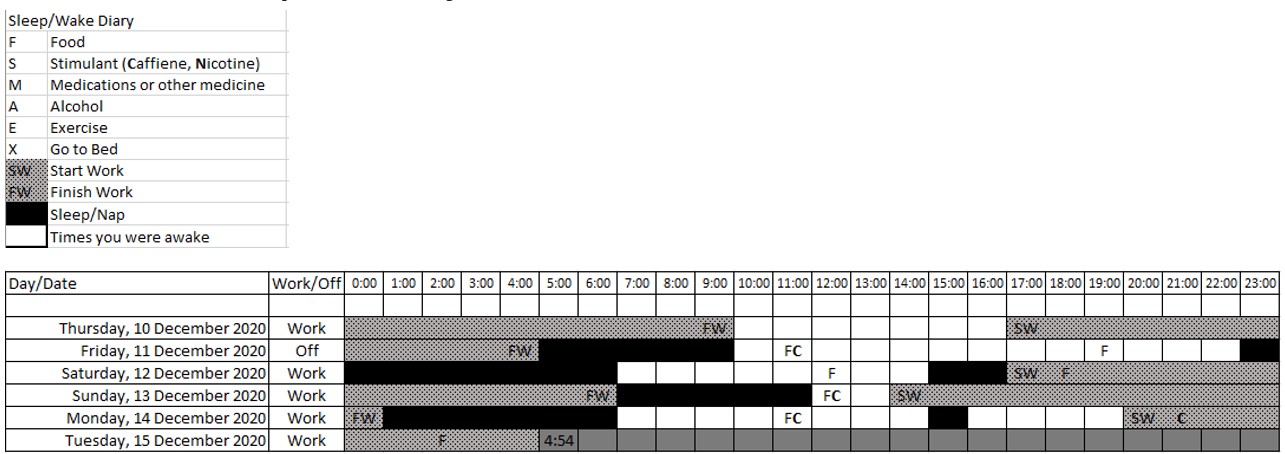

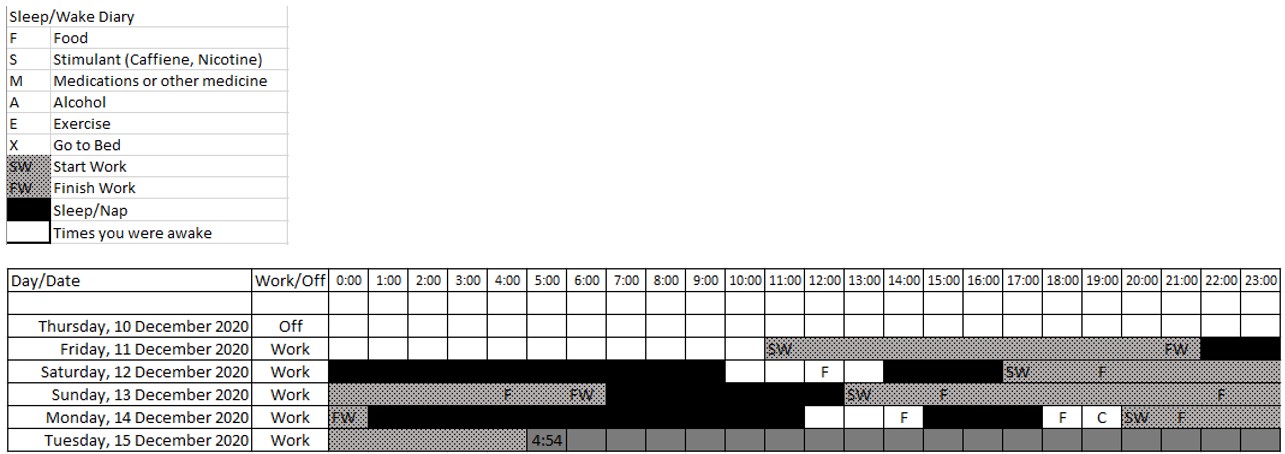

The driver’s sleep-wake activity in the days prior to the incident was also established (Table 2). The previous train service operated by the driver was an empty grain service from Port Kembla to Cootamundra that departed at 1315 on 13 December 2020. The driver completed this shift at approximately 0100 on 14 December 2020.

At interview, the driver indicated that they were not feeling fatigued at the time of the incident.

The front of train recordings also captured the time when the train passes Robertson station, near the start of the descent of the Illawarra Mountain. The driver was heard yawning, and shortly after the driver’s assistant starts a discussion about the use of ‘No Doz’[18] to keep you awake. The driver indicated they were not aware of the tablets.

Qube calculated the driver’s FAID[19] score at the time of the incident to be 82.99. Scores between 80 to 100 represented high fatigue likelihood.

Table 2: Driver sleep-wake diary

This is the driver’s account of fatigue related factors and activities in the week leading up to the incident. Actual work hours from Qube

Source: OTSI

According to Qube training records, the driver had current qualifications required to operate train services on the Moss Vale to Unanderra rail line. The relevant qualifications included:

- Level 5 – Driver Trainer[20]

- Driver competency against Work Instruction WI-540 (Train Management Moss Vale to Inner Harbour [Port Kembla]) was assessed as part of FM-781 (Train Driver Route Assessment Checklist). It was conducted on 28 and 29 November 2020. Competency was current.

- Rail Safety Worker medical last completed 28 July 2017, valid until 28 July 2022

- FM-780 (Train Operations Performance Checklist) last completed 11 February 2020, valid until 11 February 2023, and

- Qualified in CM locomotive operations on 11 April 2014 and competency was current.

Driver’s Assistant

The Driver’s Assistant started working for Qube in September 2020. They were qualified as a driver’s assistant and had no previous rail experience, prior to working for Qube.

According to Qube training records, the driver’s assistant had current qualifications required to assist train services on the Moss Vale to Unanderra rail line. Their relevant qualifications included:

- Level 2 – Second Person[21]

- Deemed competent to operate as an assistant under work instruction WI-540 (Train Management Moss Vale to Inner Harbour [Port Kembla], sign-off dated 9 October 2020 on Acknowledgement of Safety Critical Documents pro-forma. Competency was current, and

- Rail Safety Worker medical last completed 7 September 2020, valid until 7 September 2025.

Post incident interviews with the driver’s assistant established their sleep-wake activity in the days prior to the incident (see Table 3).

Qube calculated the driver’s assistant FAID score at the time of the incident to be 79.41.

Table 3: Driver’s Assistant sleep-wake diary

This is the driver’s assistant’s account of fatigue related factors and activities in the week leading up to the incident. Actual work hours from Qube.

Source: OTSI

|

Observation The train crew was working within the special fatigue management program requirements of the Rail Safety National Law National Regulations 2012. However, in high risk operations where train crew are required to descend long steep gradients, an operator’s fatigue management program should consider the additional demand this places on train drivers. |

Prior train services

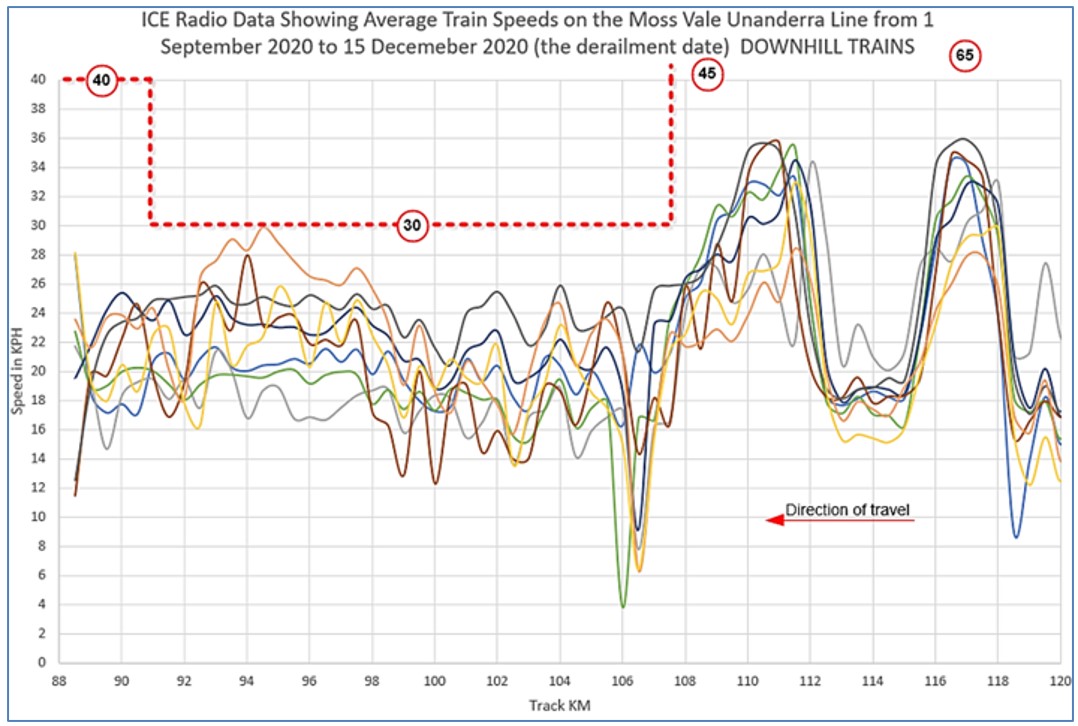

ARTC provided information from ICE train radio[22] data to establish the volume of rail traffic that had descended the Moss Vale to Unanderra rail line in the months leading up to the incident. The data set included the average train speed of all train operators travelling in the Up direction (downhill) between Summit Tank and Unanderra.

Between 1 September 2020 and 15 December 2020 there were 412 services. Each coloured line on Figure 6 represents an RSO and the average speed of their combined services.

ARTC also noted that there had not been any reports of Condition Affecting the Network (CAN)[23] from the drivers of these services specifically related to lack of adhesion. Further, there had not been any reports of CANs from services travelling in the down direction (Uphill) related to lack of adhesion or loss of traction.

Generally, a train travelling up a hill requires a higher coefficient of friction at the wheel rail interface for the wheels to maintain traction (before the wheels start to slip). The same train, coming down the same hill can maintain adhesion (before the wheels start to slide) at a lower coefficient of friction.

Figure 6: Average train speed all RSOs 1 September 2020 to 15 December 2020

Each coloured line represents a RSO and the average speed of all their train services that travelled down the mountain. The red dotted line indicates the speed limit in that section of track.

Source: ARTC

Track inspection and measurements

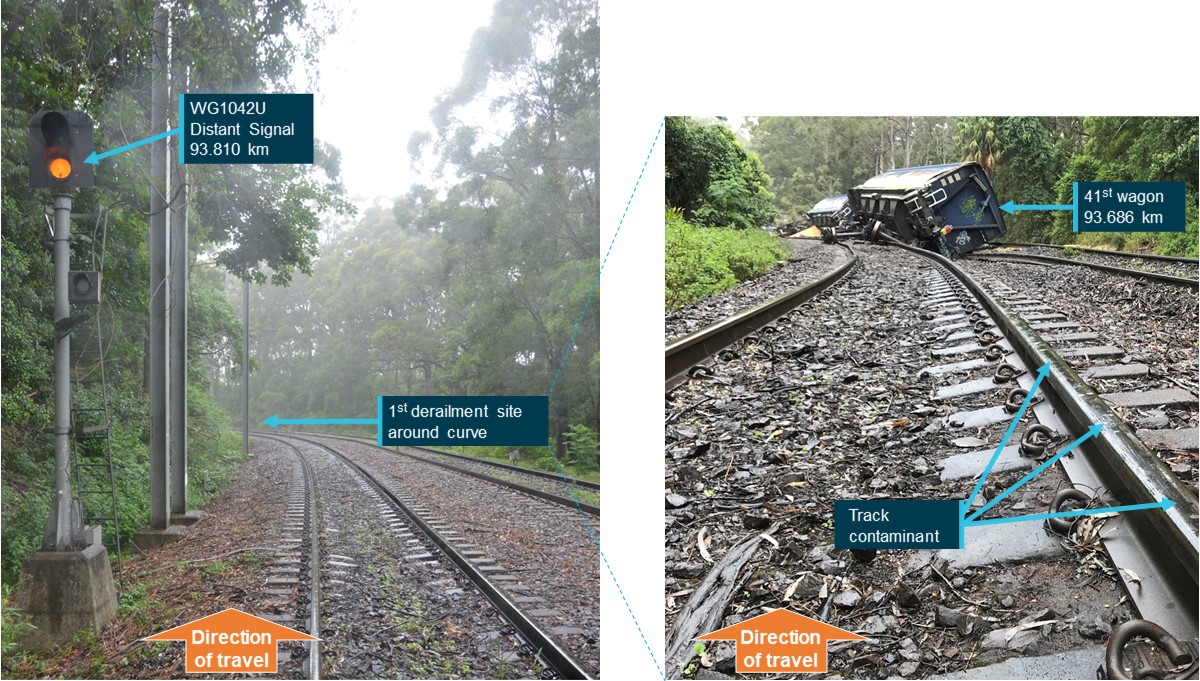

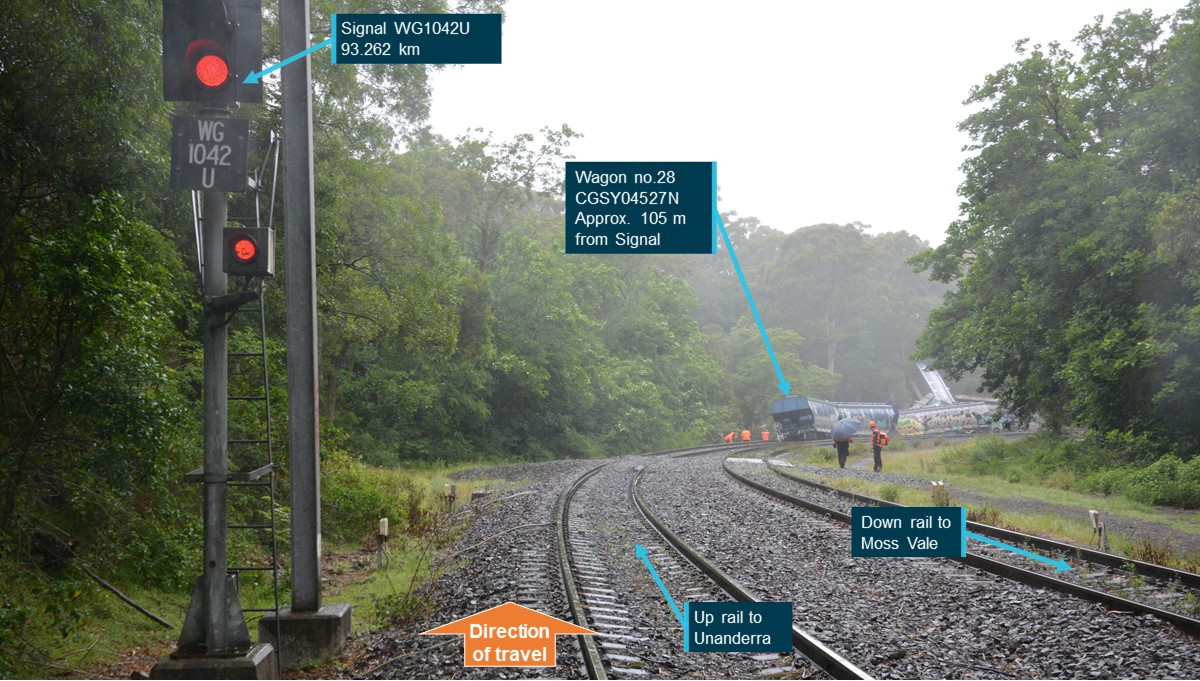

Transport safety investigators inspected the track on the day of the incident. The track area inspected extended from the stop point of the two locomotives and two wagons (approximately 92.000 km) up to 600 m prior to the first derailment site (approximately 94.300 km).

Observations of the track leading up to the first derailment site and the second derailment site were documented and photographs taken (Figures 7, 8 and 9). Initial assessment of the track condition was noted as not having any obvious defects that could be expected to increase the risk of derailment. Track measurements were taken by ARTC post incident. Superelevation[24] measurements were compared against design superelevation and short twist and long twist[25] were calculated.

The track leading up to the first derailment site, 93.810 km to 93.714 km was measured. ARTC had identified a point of first derailment at 93.710 km. The results of the track measurements at this location showed no exceedances of short or long twist.

Figure 7: Rail line leading to first derailment site

Facing Up direction (towards Unanderra and down the mountain)

Source: OTSI

Figure 8: Rail line between first derailment site and Signal WG1042U

Facing Down direction (towards Moss Vale and up the mountain)

Source: OTSI

Figure 9: Signal WG1042U to second derailment site

Facing Up direction (towards Unanderra and down the mountain)

Source: OTSI

Qube also contracted an engineering group to inspect the track post incident, who identified evidence of a derailment point, for the second derailment, at 93.220 km. However, the associated wagon and wheelset that made the markings could not be conclusively determined.

ARTC also took measurements of the rail track before and after the second derailment site. There were no exceedances of short or long twist found.

A contaminant was observed on the head of the rail lines across the area of track that was inspected. The contamination was more prominent in areas with more tree foliage. There was evidence of wheels rolling over and skidding through the contaminant at 94.000 km (Figure 10 and Figure 11).

Figure 10: Track contaminant at 94.000 km

Figure 11: Close up of track contaminant at 94.000 km

Pictures of the contaminant in Figures 10 and 11 were taken approximately 300 m prior to the first derailment, evidence of wheels rolling over and skidding through the contaminant

Source: OTSI

Investigators collected a sample of the track contaminant from the rail head, near the site of the second derailment (93.150 km), for testing at the ATSB laboratories.

The ATSB testing indicated the substance was leaf matter. There appeared to be a secondary substance which was described as balled up and highly compressed (dark and greasy) in appearance which was probably from the leaves but could not be ruled out as coming from another source.

Track maintenance

The preceding six months’ maintenance history for the Unanderra to Moss Vale rail line was reviewed. ARTC had undertaken inspections of the running line between 91.080 km (the ARTC rail network boundary with Sydney Trains Rail Network) and 150.600 km (Moss Vale Junction).

Inspections undertaken included track geometry, rail wear, front of train inspection, rail lubrication and rail lubrication devices.

The frequency of these inspections was specified in ETE-00-03 (Civil Technical Maintenance Plan (CTMP)) and ARTC records indicated these inspections had been completed as required.

However, the requested maintenance history records did not account for a rail lubrication device located at 97.030 km (Figure 12). This lubricator was located close to the Landmark and Dombarton (Figure 1 inset).

Following draft report feedback, ARTC produced a listing of all rail flange lubricators which included a rail flange lubricator at 97.030 km. ARTC also stated that this rail flange lubricator serviced trains travelling on the down (uphill) (Figure 12). No additional maintenance records were provided with the revised list.

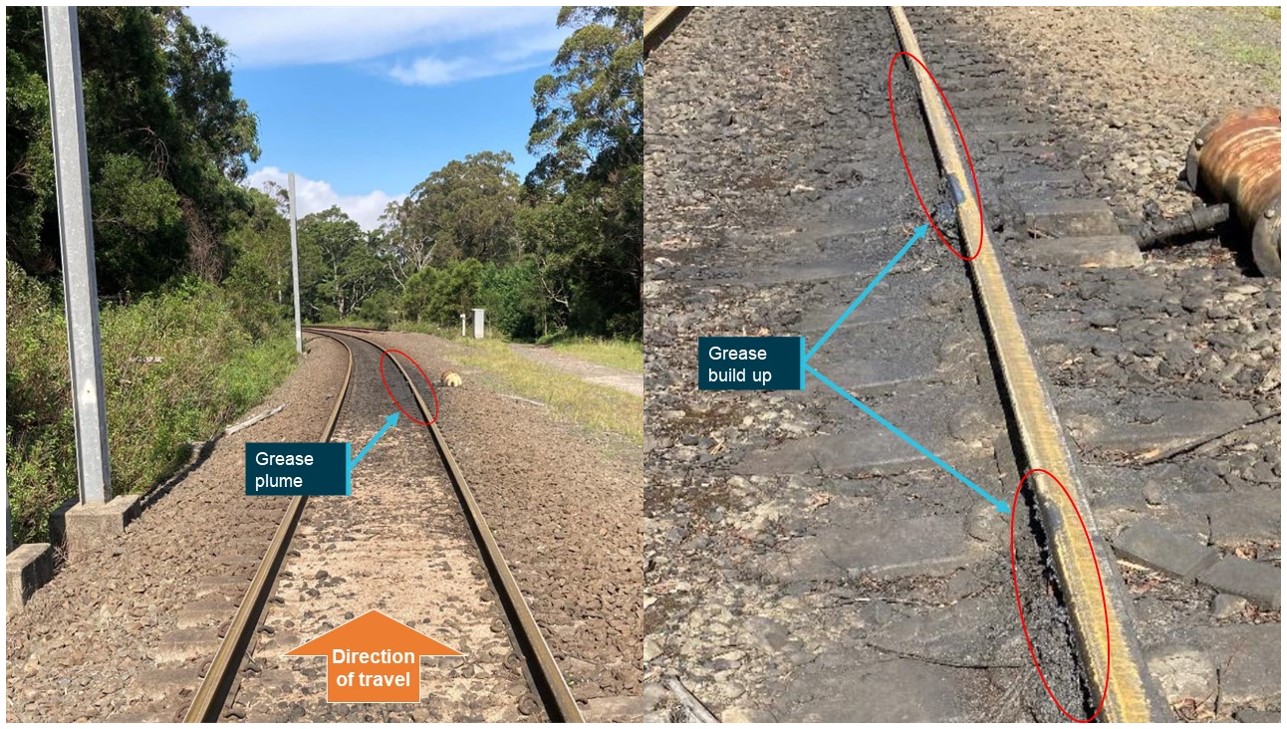

Figure 12: Rail flange lubrication device at 97.030 km and grease plume

Facing Up direction (towards Unanderra and down the mountain) device (left) and close up (right), this section of track was bi-directional

Source: Qube

General inspection of rail flange lubrication over this section of the rail line was last conducted between 96.893 km and 150.600 km on 14 June 2020, approximately six months prior to the incident.

The inspection intervals for rail flange lubricators were specified as once every 365 days. All rail flange lubrication devices listed in the maintenance records provided, from the ARTC boundary to Moss Vale Junction were inspected and deemed compliant on 30 August 2020, approximately 3.5 months prior to the incident.

The closest rail flange lubrication device to the one located at 97.030 km to have had a recorded general inspection was at 95.580 km on 30 August 2020.

Track Standards

ARTC’s Engineering Practices Manual, Civil Engineering, RC 2411 (Guidelines for Trackside Lubrication) stated on page 4:

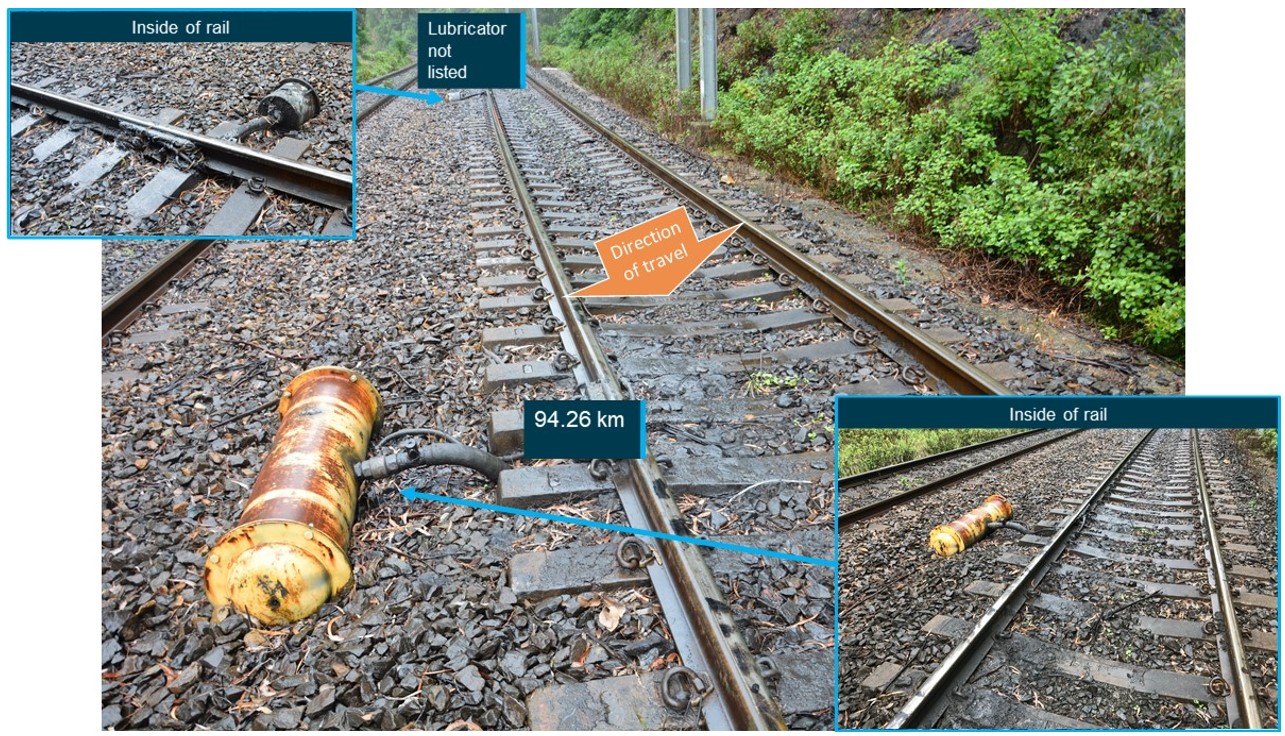

Approximately 1.2 km before the first derailment site, two rail flange lubricators providing lubrication for the down rail line (uphill) were located at 94.26 km and 94.30 km, 40 metres apart, the rail flange lubricator at 94.30 km was not listed on ARTC’s maintenance history records (see Figure 13).

Additionally, two rail flange lubricators listed in ARTC’s maintenance history records at 94.958 km and 94.535 km were less than the required 500 m separation stipulated in RC 2411.

Figure 13: Rail lubrication devices leading to left hand curve and site of first derailment

Facing Down direction (towards Moss Vale and up the mountain).

Source: OTSI

ARTC CoP (Code of Practice Rail) section 1.2.6.4 Performance Requirements stated:

ARTC was requested to provide results of any friction testing undertaken on the Moss Vale to Unanderra rail line between Summit Tank Service Crossing (100.222 km) and Dombarton Down Signal WG1043 (92.222km), in the period from 1 January 2017 to 31 December 2021. They did not provide any results from friction testing conducted, in the requested period and stated in feedback that the Code of Practice does not require on-going coefficient of friction measurements.

ARTC noted:

On 3 June 2021, 6 months post the incident, friction tests were conducted by Monash Institute of Railway Technology, commissioned by Qube. The testing was conducted between 97.580km (500 m before Dombarton in the direction of travel) and 95.461km (1.5 km after Dombarton in the direction of travel). The tests were undertaken using a push tribometer as required in the ARTC Code of Practice.

All tribometer measurements were performed under dry conditions and were conducted at four separate sites. The results are in Table 4.

Table 4: Tribometer measurements

| Site | Tribometer test/ Grease pot location | Friction coefficient top of rail (range) | Friction coefficient top of rail (average) |

| 1 | 97.4km to 97.2km |

Up rail – 0.17 to 0.22 Down rail – 0.17 to 0.35 |

0.2 0.26 |

| 2 | 97.11km to 97.078km |

Up rail – 0.24 to 0.37 Down rail – 0.19 to 0.24 |

0.32 0.2 |

| Lubricator @ 97.03km (Down rail) | |||

| 3 | 97.03km to 96.925km |

Up rail – 0.3 to 0.4 Down rail – 0.26 to 0.37 |

0.36 0.32 |

| 4 |

95.77km to 95.461km

|

Up rail – 0.16 to 0.29 Down rail – 0.2 to 0.33 |

0.23 0.26 |

| Lubricator @ 95.58km (Up rail) |

|

Observation Across the four sites tested relevant to this incident, the friction coefficient on the top of the up and down rails was lower than the design standard of 0.4 for grades steeper than 1 in 50. Also of note the friction coefficient in some locations under dry conditions was lower than the design standard of 0.3 for all other gradients. |

Rollingstock

The rollingstock was supplied to Qube by CFCLA under a lease agreement. The locomotives were maintained by CFCLA under its agreement with Qube. The wagons were primarily maintained by a contracted rollingstock maintainer to CFCLA and Qube in line with the lease agreement.

The rollingstock involved in the incident included:

- 2 CM Class Locomotives, CM3316 and CM3304

- 39 CGSY bottom dump grain hopper wagons

- 2 CGDY bottom dump grain hopper wagons.

The length of the train was 679.3 m.

CM class locomotives

The CM class locomotives were manufactured in 2012-13. They had a 22 t axle load and maximum gross power of 3300 hp (2460 kW). They were fitted with a Wabtec Fastbrake braking system and dynamic brake. They were also fitted with the Q-Tron QES-III locomotive control system that would provide an adhesion control function. The functional requirements for the adhesion control function as specified in Schedule 3 (Technical Specifications of MP33 Locomotive for CFCLA Rail JV) were:

The Locomotive Information Pack for the CM class locomotives[27] provided the operating conditions which included;

Maximum tractive effort – 414 kN, and continuous tractive effort – 363 kN, at a speed of 16 km/h

Peak dynamic braking effort – 244.6 kN, at a speed of 23.3 km/h.

The locomotive design fully provisioned mass at rail was 132 tonnes. The locomotive can carry 10000 litres of diesel fuel which would weigh 8500 kilograms and the weight of other provisions such as lube oil, water and sand, approximately 1 tonne. Therefore, the dry weight of the locomotive would be approximately 122.5 tonne.

Grain hopper wagons

There were two types of grain hopper wagons, making up the train consist of the grain train 3966. Thirty-nine wagons were CGSY type, brought into service on the NSW rail network in 2015. The other two wagons were CGDY type, brought into service on the NSW rail network in 2013. The grain hopper wagons were manufactured by China International Marine Containers Group Australia (CIMC), for CFCLA.

Before any rail vehicle was permitted to operate on a rail network, they were required to comply with the minimum operating standards of the rail network owner. The measurement of brake block forces was one of several vehicle compatibility tests conducted to ensure the vehicle complied with the minimum operating standards for rollingstock. Tests were conducted on one of every type of vehicle, prior to that type of vehicle operating on the rail network. This is known as the Type Test.

The average measured brake block force was used to calculate the net brake ratio (NBR). NBR is the sum of the measured forces applied by the brake blocks onto the wheels divided by the weight of the vehicle and is determined for both tare and gross (loaded) vehicle mass. For a loaded vehicle the minimum NBR specified by AS7510.2:2014 was 13% with a brake cylinder pressure of 350 kPa, for vehicles fitted with high friction composite brake blocks. ARTC’s standard WOS 01.400 also recommended an NBR of 13% in order to provide effective braking without skidding wheels. The brake blocks fitted to the CGSY and CGDY wagons were FIP HA30 high friction brake blocks.

The results of the type tests for the CGSY and CGDY wagons were provided by CFCLA. A brake block force test conducted on 13 September 2015, on wagon CGSY 4519A, achieved an NBR of 14.23% for the loaded vehicle. A brake force test conducted on CGDY 4027, on 14 September 2013, achieved an NBR of 15.79%.

Both wagon types had CIMC 120AK brake componentry, a two-pipe train braking system. The two pipes being a brake pipe and main reservoir. This system allowed for an improved recharge time of the brake pipe pressure and greater control of the train braking performance (see Means of operation – wagons).

Two-pipe braking systems on grain wagons was a requirement in ARTC’s Route Access Standard for the Moss Vale to Unanderra rail line, where the trailing tonnes was greater than 2400 t, as with 3966.

Inspection and maintenance of the brake blocks and brake adjustments were primarily completed by a contracted rollingstock maintainer, consistent with the lease agreement.

History of CGSY wagons

After delivery of the CGSY wagons into service, issues with the braking performance of the wagons were identified. CFCLA had investigated the issue and concluded the braking performance was unsatisfactory. As a result, CFCLA required the brake rigging ratio to be increased to improve the braking performance.

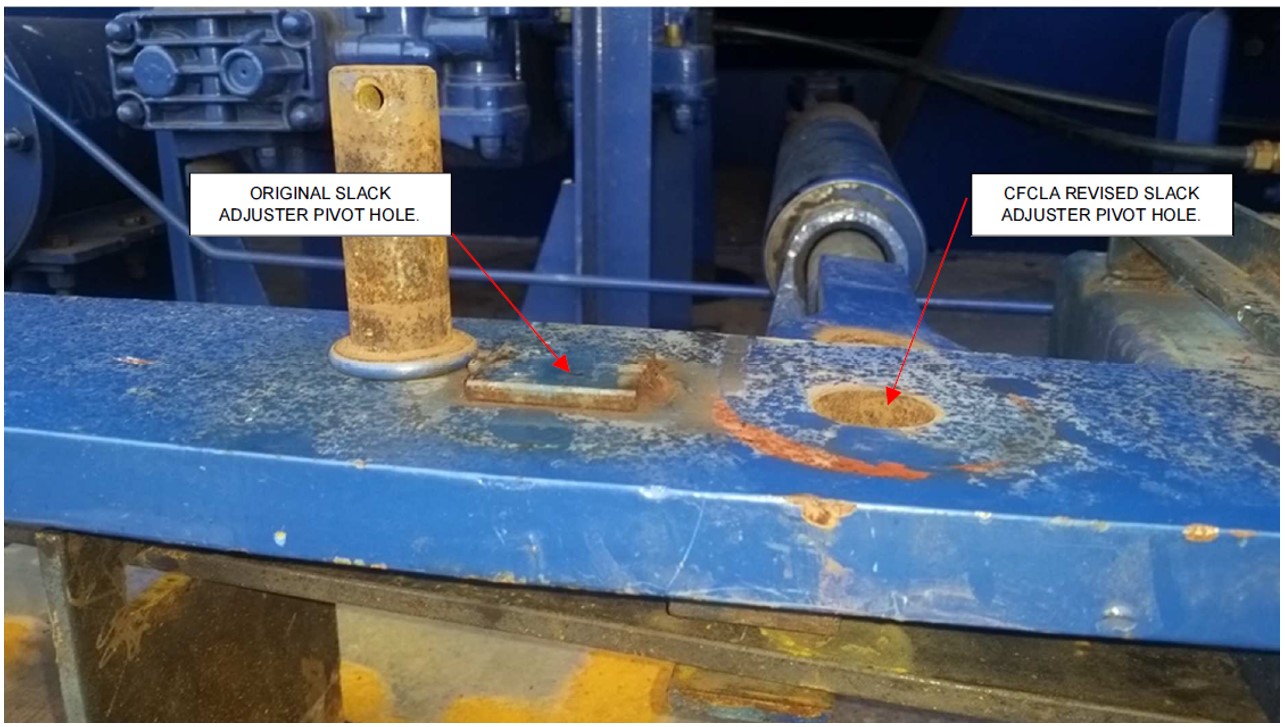

To achieve this, slack adjuster pivot holes were re-drilled in the brake lever (Figure 14).

Following this modification to the brake lever, CFCLA found that the braking performance of the wagons had not improved and advised the original engineering manufacturer (OEM) CIMC that they had undertaken modifications to the brake lever ratio to improve brake performance which was not successful and requested advice from CIMC on a possible fix. The detail of the modifications made by CFCLA was not provided to CIMC.

|

Observation The configuration and change management processes employed to manage this modification to the wagons was not effective. |

CIMC’s review of the wagon’s design identified an error in the brake rigging system, in the setup of the control rod on the slack adjuster. The control rod on the slack adjuster had been fixed to the wagon structure. This did not permit the slack adjuster to perform its primary function of reducing the slack in the brake system. This resulted in the brake cylinder piston travel increasing as brake blocks wear, with an eventual reduction in brake block forces on the wheels.

CIMC revised the design to incorporate a control lever.

Figure 14: Revised slack adjuster pivot holes

Source: Wayne Clift Consulting

When the revised control lever design was fitted by CFCLA to a trial wagon, they found there was no change to the operation of the brakes. The slack adjuster was still unable to reduce the slack in the brake rigging.

In March 2017, an independent subject matter expert (SME) was engaged by CIMC, to assess and determine the root cause of the braking issue on the CGSY wagons.

Conclusions and recommendations from the SME were as follows:

On 20 April 2017, the same SME was engaged by CFCLA to conduct the first article compliance inspection and testing sign-off and to provide a report on the revised control lever design. The SME conducted testing on CGSY 4542H and found and recommended the following:

On 22 April 2017, a train consisting of 40 CGSY wagons was involved in a runaway down the Illawarra Mountain (see Related Occurrences).

On 18 May 2017, as a result of the runaway on 22 April 2017, the NBR was tested on CGSY 4502V and found to be 13.9%. This wagon was the 38th wagon in the train consist and was randomly chosen for testing.

On 10 July 2017, the CGSY wagons were returned to CFCLA and taken to Goulburn for care and maintenance. During this time, the CGSY wagons were modified with the slack adjuster control lever. They were returned to service on 3 April 2018, to service other bulk grain contracts.

On 16 November 2020, the CGSY wagons recommenced operation on the Moss Vale to Unanderra rail line. Qube provided information to confirm the wagons had received a 28 day periodical maintenance on 5 November 2020 and assurance FX exam brake tests had been conducted post return of the wagons to Qube.

The wagons completed 12 journeys on the Moss Vale to Unanderra rail corridor, including a trip two days prior to this incident journey on 15December 2020.

Train weight

There were several sources of data providing varying values of the weight of the train.

The load out tonnes[28] from Temora BFB[29] was 2703.9 t in 40 wagons + 1 empty wagon. This equated to a trailing tonnage of (39 x 23.2 t + 2 x 22.7 t + 2703.9 t) = 3654.1 t.

The train driver’s hand-written train consist stated the trailing tonnage was 3690 t. However, each loaded wagon was noted as 90 t which equated to a trailing tonnage of (40 x 90 t + 22.7 t) = 3622.7 t.

Qube’s computer printed train consist, provided when requested for copies of the train consist, had loaded wagons weighing 89 t each which equated to a trailing tonnage of (40 x 89 t + 1 x 22.7 t) = 3582.7 t.

The train consist provided to ARTC, from Qube, had a declared weight of the train of 3198 t, which included a declared weight of the locomotives at 123 t each. The trailing tonnage, according to this train consist, was (41 x 72 t) = 2952 t. The 41st wagon was indicating it was loaded which was incorrect. This declared weight was significantly lower (by 456.1 t) than the weight of the train calculated on the Temora BFB load out tonnes. This was a 12.5% difference.

The two remaining wagons from the derailment were taken to Port Kembla for unloading and weighing. CGSY 4516T and 4518Y total grain weight was 134.385 t, as observed on the belt weigh system at Port Kembla. The average weight for each wagon was therefore (67.2 t + 23.2 t) = 90.4 t.

Using this figure to estimate the trailing tonnage equated to (40 x 90.4 t + 22.7 t) = 3638.7 t.

This weight was greater than the declared weight to ARTC, the driver’s hand-written train consist and Qube’s computer printed train consist, but less than the trailing weight calculated using the load out tonnes from Temora BFB and below the maximum allowable trailing weight (3680 t) as per ARTC TOC Waiver 16002[30].

It was noted that the train journey required 3966 to traverse the TfNSW rail network[31]. As per the TfNSW TOC Manual (TS TOC.2.2020 Issue 2 v19.0 2 September 2020), the load tones for freight trains travelling on the rail line from 91.080 km to Unanderra was a maximum of 3300 t for locomotives of class L3, as the CM locomotives were. Based on this, the train weight was greater than the allowable tonnage (on the TfNSW rail network) on all records of the train weight, other than the train consist provided by Qube to ARTC and TfNSW, which had a declared weight of 3198 t.

The trailing load was also measured by ARTC’s Exeter wayside detector at 0248 hrs, 15 December 2020. The wayside detector calculates a weight in motion and uses specific locomotive classes as weight references to conduct an automatic calibration at every pass of one of the reference locomotives. ARTC stated the wayside was not a certified weighbridge but achieved a +/- 3% accuracy.

It was noted that the weight of the locomotives provided by the wayside detector were within 1% of the calculated weight of the locomotives, accounting for indicative fuel levels in the locomotives (taken from the data logger) and their tare weight.

It was also noted the wayside detector recorded the last wagon in the consist CGDY 4026 at 27.67 t, approximately 4.5 t higher than its documented tare weight. ARTC provided data from the wayside of the previous two tare weights taken of CGDY 4026, which indicated the tare weight as 25.53 t on 5 December 2020, and 26.0 t on 21 October 2020. The tare weights of other CGDY wagons taken by the wayside monitor on 21 October 2020 indicated the average tare weight of the CGDY wagons was 27.5 t.

These readings indicated the tare weight of the CGDY class wagon was not the documented 22.7 t as registered with the infrastructure manager.

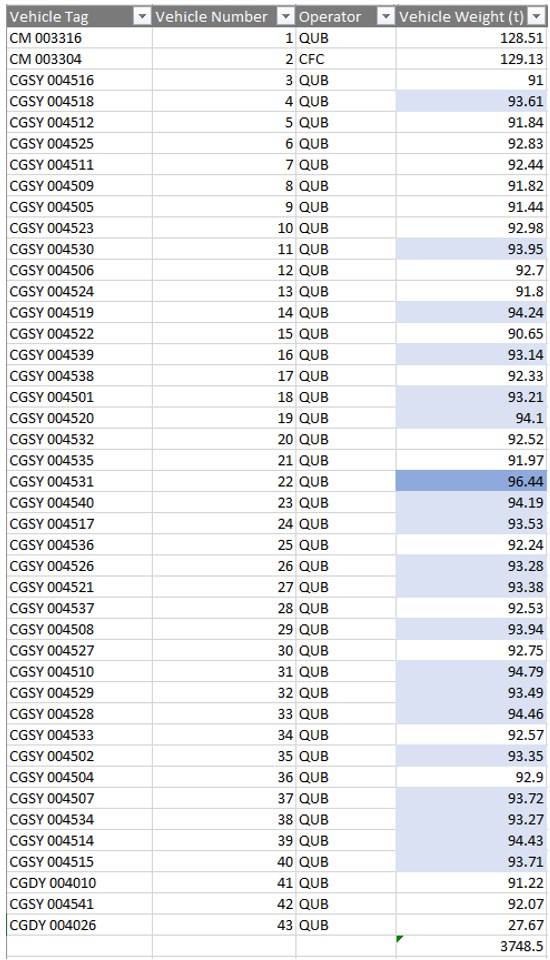

The total trailing weight measured was 3748.5 t. With consideration of the +/-3% accuracy, the train was between 3636.045 t and 3860.95 t (Figure 15). This indicated the train may have been running heavier than allowable tonnage limit of 3680 t.

There was also variability in wagon weights of approximately 7%, ranging from 90.65 t to 96.44 t. The wayside data indicated 20 of the 41 wagons were over the allowable loaded wagon weight limit of 92 t.

Figure 15: Exeter wayside detector read out

Source: ARTC

While it could not be established with 100% certainty what the trailing weight of the train was, the total load out tonnes from Temora BFB plus the tare weight of the wagons was considered most representative as all other sources were only estimates of the grain weight in the wagons.

ARTC’s wayside detector at Exeter was considered an indicative source of weight in each wagon, which highlighted a 7% degree of variability in the amount of grain loaded in each wagon across the train consist. It also highlighted specific wagons were likely overloaded.

These combined indicated the weight of the train was near maximum allowable tonnage and probably under the 3680 t limit for the train. However, it was likely a number of these wagons were over the allowable limit for a single wagon and there was variation in loading across the train consist.

|

Observation Inaccurate reporting of train weights presents an increased risk to operations, particularly when trains are operating heavier than expected. |

Rollingstock inspections

Prior inspections

The most recent wagon periodical maintenance (28 day) inspection was conducted in Goulburn by a contracted wagon maintainer and signed off for release back into service on 25 November 2020, 20 days prior to the incident.

Post-incident inspections

Transport safety investigators’ observations of the rollingstock on the day of the incident included the portion of the train which had not derailed, the locomotives and two wagons (Figure 16), and both sites where rollingstock had derailed.

Figure 16: Stop point of runaway train 3966

Source: OTSI

On arrival at the locomotives and two wagons it was observed that the coupler knuckle was closed and locked on the back of the second wagon CGSY 04518Y and that both main reservoir (MR) and brake pipe (BP) isolation cocks were closed. It was later confirmed that the driver’s assistant had isolated the cocks post derailment to stop air leaking from the main reservoir and brake pipe.

The locomotives were shut down because noise from the running engines was disturbing nearby residents. Isolation cocks for the locomotive’s bogies and brake equipment appeared to be in the correct orientation when inspected.

The wheels on the remaining connected wagons showed some signs of heat (see Figure 17). There were no visual signs of flat spots on the wheels. This was later confirmed when the rolling stock was tested on 17 December 2020, prior to moving to Port Kembla to unload the wagons. Sand was also evident on the rail head located under the wagons and locomotives.

Figure 17: Back of 2nd wagon CGSY 04518Y

Source: OTSI

The brake shoes were in contact with the wheels across both locomotives and wagons. The contact patch of the brake shoes was not aligned with the wheel diameter on some wagons (Figure 18).

Figure 18: Side of 1st wagon CGSY 04516T brake shoe

Source: OTSI

On 17 December 2020, two days after the incident, testing on the rollingstock that had not derailed was conducted, to ensure the braking systems were operating to standard. The wagons were tested for brake pipe leakage rate (5 kPa/min) and given a brake holding test (13 mins). These were within specified limits.

The lead locomotive CM3316 had a functional brake test conducted by CFCLA and was given a Locomotive Ready to Go Certificate prior to the locomotives and two wagons being driven down to Port Kembla to unload and weigh the grain.

The trailing locomotive CM3304 brake function test was not conducted post incident. The locomotive event logger data for CM3304 indicated the control system acted as designed, with the air brake system and dynamic brake system performance recorded.

Net braking ratio tests

The NBR is the ratio of the sum of the measured actual brake block forces in kilograms divided by the total vehicle mass, in kilograms, at rail.

Qube conducted NBR tests on the two remaining CGSY wagons (4516T and 4518Y) that did not derail in the incident. The testing was conducted at Junee on 9 February 2021 by a qualified rollingstock engineer, under the observation of representatives from CFCLA.

The NBR test results were:

- CGSY 4516T was 12.45%

- CGSY 4518Y was 10.7%.

These results did not meet the minimum design standard net braking ratio for vehicles fitted with high friction composition brake blocks. Noting that the standard applied to new vehicles only and there was no requirement to test NBR on an ongoing basis.

The RISSB Standard AS 7510.2: 2014 Braking Systems – Part 2 – Hauled Rolling Stock stated:

As per ARTC’s WOS 01.400 Freight Vehicle Specific Interface Requirements Issue 1.0 Dec 2005, the NBR for vehicles fitted with high friction brake blocks, fully loaded, recommended 13% to provide effective braking without skidding wheels.

Transport for NSW RSU 400 Series – Minimum Operating Standards for Rolling Stock – Freight Vehicle Specific Interface Requirements V2.0, issued 24 August 2017 required 16% NBR to be used as a minimum for all new rollingstock and provided the conditions when the net braking ratio was lower than 16% but higher than 13% (for existing rollingstock):

As mentioned in Grain hopper wagons, the type test for the CGSY wagons was found to be greater than 13% but lower than 16%. The type test conducted on CGSY 4519A confirmed the NBR for the wagon was 14.23%.

It was understood by CFCLA at the time that the requirement for all new bulk commodity type wagons became effective as of 1 January 2018. The CGSY wagon type was published in the ASA Train Operating Conditions (TOC) Manual version 11.0 on 15 December 2017 with unrestricted operating conditions.

The two NBR tests on the remaining wagons could not statistically be considered representative of the entire consist. However, the NBR on a freight wagon should not be significantly different to other wagons of the same design assuming they are all built to the same drawings. The CGSY wagons had varying measured NBRs from 19.5% down to 10.7%, as seen from the various tests conducted on different CGSY wagons over their service life.

Post this incident on 15 December 2020, there remained five CGSY wagons in the fleet.

As noted in Net braking ratio tests, the NBR tests conducted on 9 February 2021 returned 12.45% and 10.7%.

The other three CGSY wagons not involved in the incident were tested on the 12 May 2021 and results were, CGSY 4542H – 12%; CGSY 4503H – 19.5%; CGSY 4513P – 14.5%.

It was noted that CGSY 4542H was modified by the SME to improve its brake performance. The NBR of this wagon when tested on 20 April 2017, post modifications, was 15.0% (see History of CGSY wagons).

Wagon brake pipe continuity

The ‘brake pipe’ is critical to the functionality of a train’s braking system. This pipe, which runs along the length of the train, provides the means through changes in air pressure to effect application and release of the train’s brakes (see Means of operation – wagons). A disruption in the continuity of this pipe, such as a brake pipe tap closed between wagons, will result in less wagons providing braking force.

To ensure brake pipe continuity and the correct functionality of a train’s brakes throughout the consist, the brake system is tested prior to commencement of a train’s journey. For the accident train, these tests were performed the previous day, with one wagon (of the 41 attached to the train) identified as having its brake components isolated.

In addition, Qube undertook a comparison of the time taken to recharge the brake pipe on the day of the accident (15 December 2020), against that of the train’s previous journey on 12 December 2020.

Qube found that there was no appreciable difference in the time taken to recharge the brake pipe between the two services, supporting the brake pipe was fully connected and continuous throughout the train consist on the day of the accident.

Contact patch of brake blocks

It was observed in the post incident inspection that some of the brake blocks on the wagons were not in contact with the wheel on the leading edge of the brake block. Qube also found this during their inspections and considered the gap at the outer edge of the brake blocks a contributor to lowered coefficient of friction[32] at the brake block/wheel interface. The reduced contact area between block and wheel also results in higher heat in the block contact area, which increases the risk of brake fade.

The manufacturer of the brake blocks had conducted tests of the high friction brake blocks in 2017. The testing indicated that brake block friction generally reduced as speed increased; and when the brake blocks were wet. Additionally, brake blocks were more susceptible to reduced friction with the wheel when the block had a gap at the leading edge of the brake block.

Of the 41 wagons attached to the accident train, the two remaining upright wagons with brakes applied were observable and found with gaps at the outer edge of the brake block.

There was evidence of a heat stripe (blue discolouration on metal occurs at approximately 300 degrees Celsius) on the left rear wheel of wagon CGSY 04518Y (see Figure 17). This indicated the contact patch from the brake block to the wheel was not consistent and evenly applied across the wheel. The corresponding right wheel did not show signs of heat build-up (no blue discolouration) to the same extent as found on the left wheel.

The wheels on CGSY 04516T and on the Locomotives showed very little signs of heat (no blue discolouration was present).

Train braking system

General description

There are three braking systems fitted to the CM class locomotive in addition to the parking brake. These comprise of two types of air operated (pneumatic) brake, that is, the automatic and independent, and an electrical dynamic brake. The use of each of the three braking systems is dependent on the circumstance during which braking effort is required.

Automatic brake

Introduction

The ‘automatic brake’ controls the brakes on the entire train, including the wagons and locomotive/s. Central to this system is the brake pipe, which runs along the length of the train. Changes to air pressure within the brake pipe regulate the application and release of the train’s brakes. When fully charged (that is, brakes released), the brake pipe pressure is about 500 kPa. Reduction of this pressure by the driver results in application of the train’s brakes.

The driver regulates the pressure within the brake pipe through operation of the automatic brake handle (see Figure 19). The brake handle positions on the CM class locomotive are:

- Release – brake pipe charging or charged up to 500 kPa, which releases any automatic brake applied to the locomotive/s and wagons.

- Minimum service – reduces the brake pipe pressure to 450 kPa which initiates a minimum application of the brakes on the locomotive/s and wagons.

- Service zone – a graduated reduction of the brake pipe pressure from 450 kPa to 350 kPa, which correspondingly increases the braking forces at a graduated rate.

- Full service – reduces the brake pipe pressure to 350 kPa which fully applies the brakes on the locomotive/s and wagons.

- Suppression – reduces the brake pipe pressure to 350 kPa for the purposes of penalty brake[33] suppression and reset.

- Handle off – reduces the brake pipe pressure to 0 kPa. This handle position configures the locomotive such that it cannot be used for initiating braking commands.

- Emergency – rapidly reduces the brake pipe pressure to 0 kPa which quickly provides a full service brake application to the locomotive and wagons (see Means of operation – wagons).

Figure 19: Automatic and independent brake handles

Source: OTSI

Means of operation – wagons

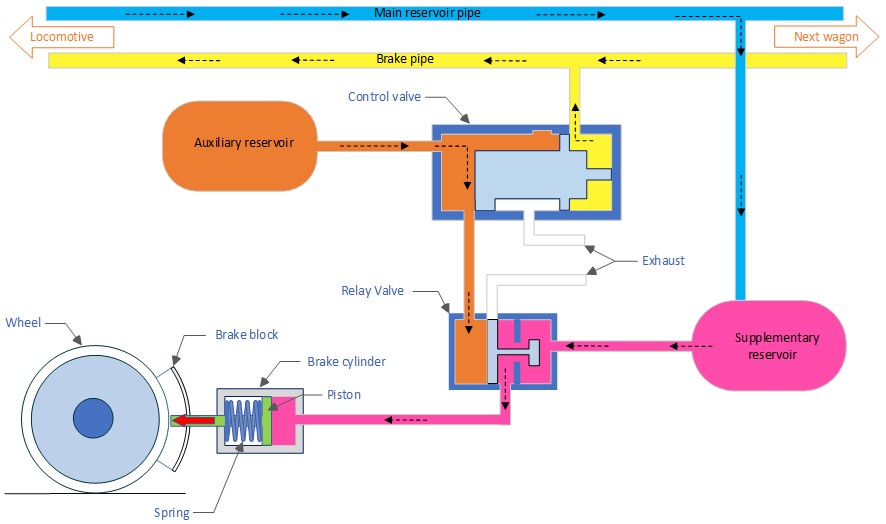

In addition to the brake pipe, each CGDY and CGSY wagon was fitted with a pneumatic control valve, auxiliary reservoir, relay valve, supplementary reservoir and brake cylinders. The control valve responded to changes in pressure within the brake pipe. On sensing a reduction in brake pipe air pressure, the control valve would reduce the auxiliary reservoir air pressure by an equal amount. This auxiliary reservoir air would supply reference (signal) air to a relay valve, in-turn permitting air from the supplementary reservoir (continuously supplied by main reservoir air from the locomotive)[34] to enter the brake cylinder. A piston within the brake cylinder would then push the brake blocks against the wagon wheels, causing friction and slowing of the train (see Figure 20).

Figure 20: Wagon airbrake application process

The image is a simplified representation of an airbrake application on a wagon. The control and relay valves consist of rubber diaphragms, springs and ports that respond to air pressure differences to perform their functions.

Source: OTSI

In effect, on two-pipe trains (as with the CGDY and CGSY wagons) the pressure in the brake cylinder is directly proportional to the air pressure reduction in the auxiliary reservoir. Maximum braking effort is achieved when brake pipe pressure is reduced to 350 kPa, known as a ‘full service’ brake application. At this point the brake pipe, auxiliary reservoir and brake cylinder pressures equalise with each other at about 350 kPa. Therefore, further reductions in brake pipe pressure do not result in increased braking effort. Table 5 provides an overview of braking system pressures in response to various brake pipe pressures.

Table 5: Automatic brake pressure equalisations for a 500 kPa brake pipe[35]

| Automatic brake handle position | Brake pipe (kPa) | Auxiliary reservoir (kPa) | Brake cylinder (kPa) | |

| Release | 500 | 500 | 0 | |

| Minimum service | 450 | 450[1] | 118[2] | |

| Service zone (example pressure) | 400 | 400[1] | 235[2] | |

| Full service | 350 | 350[3] | 350[2] | |

| Emergency | 0 | 350[4] | 350 |

[1] Auxiliary reservoir equalises with the brake pipe.

[2] Brake cylinder pressure equates to about 235% of the pressure loss in the auxiliary reservoir.

[3] Auxiliary reservoir equalises with both the brake pipe and brake cylinder.

[4] Auxiliary reservoir equalises with the brake cylinder, preventing further equalisation with the brake pipe.

In a similar manner to the wagons, a reduction in brake pipe pressure also applies the brakes on the hauling locomotives. For a CM class locomotive, the maximum automatic brake applied locomotive brake cylinder pressure attainable is also 350 kPa.

Once the required speed reduction has taken effect, the driver places the automatic brake handle in the ‘release’ position which restores the brake pipe pressure to 500 kPa. On sensing an increase in brake pipe air pressure, the control valve allows air from the brake pipe to recharge the auxiliary reservoir to 500 kPa.[36] In addition, brake cylinder air pressure is vented to atmosphere allowing a spring within the brake cylinder to force the piston to retract, thereby removing the friction force of the brake blocks from the wagon wheels (see Figure 21).

Figure 21: Wagon airbrake release process

The image is a simplified representation of an airbrake release on a wagon. The control and relay valves consist of rubber diaphragms, springs and ports that respond to air pressure differences to perform their functions.

Source: OTSI

With brake pipe operated pneumatic braking systems, the brakes on the train do not apply simultaneously. As brake pipe pressure is vented from the lead locomotive, the brakes on the leading wagon apply first, followed sequentially by the other wagons towards the rear of the train.

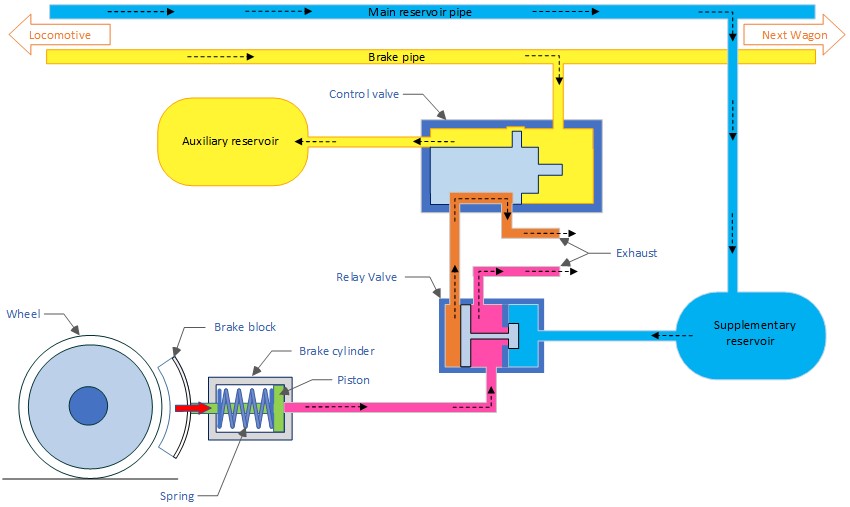

Brake pipe charging flow indicator

During an automatic brake release, main reservoir air, produced by the main compressor on the locomotives, recharges the brake pipe to 500 kPa. Although brake pipe pressure is restored relatively quickly at the front of the train, this does not accurately reflect brake pipe pressure along the length of the train. To assist the driver in determining whether the brake pipe is fully recharged in readiness for another brake application, a brake pipe charging flow indicator is provided.

Due to the sensitivity of the brake pipe charging flow indicator, it is possible to detect small losses in brake pipe pressure. This is particularly useful in alerting the driver to a derailment or train separation[37] event towards the rear of the train, whereas the brake pipe pressure on the locomotive may indicate little or no pressure loss.

On the CM class locomotive, the brake pipe charging flow indicator is on a computer display unit (CDU) on the driver’s control station. The indicator consists of a numeric value of main reservoir to brake pipe air flow expressed in litres per minute. It is located at the bottom of a bank of similar numeric displays including the brake pipe, main reservoir and locomotive brake cylinder pressures (see Figure 22). There is no accompanying visual annunciator tile or audible alarm to draw the driver’s attention to the activation of the brake pipe charging flow indicator.

Figure 22: Driver’s computer display unit

Source: OTSI

As depicted in Table 5, a full service application of brake cylinder pressure (350 kPa) is achieved when the driver reduces the brake pipe pressure to 350 kPa. However, this is dependent on the auxiliary reservoirs on each wagon being fully charged to 500 kPa at the time the brake application is made.

Where the brake pipe has not been given a sufficient opportunity after an automatic brake application to recharge the brake pipe across the entire length of the train prior to the reapplication of the automatic brake, it will result in a lower auxiliary reservoir starting pressure, particularly on wagons at the rear of the train. As a result, there is a reduced pressure drop in the auxiliary reservoir when equalising with the brake pipe on the subsequent brake application. In response, the relay valve and supplementary reservoir provide less pressurised air to the brake cylinders, resulting in a reduced braking force than would be achieved if the auxiliary reservoir starting pressure is 500 kPa. Table 6 provides an example of this reduced brake cylinder pressure where an auxiliary reservoir has recharged to only 450 kPa prior to the reapplication of the automatic brake.

Table 6: Brake pressure equalisations from 450 kPa auxiliary reservoir starting pressure[38]

| Brake pipe (kPa) | Auxiliary reservoir (kPa) | Brake cylinder (kPa) | |

| ~500 | 450[1] | 0 | |

| 450 | 450[2] | 0 | |

| 425 | 425[3] | 59[4] | |

| 400 | 400[3] | 118[4] | |

| 350 | 350[3] | 235[4] |

[1] Note: Braking system still in release mode, with the brake pipe in the process of recharging the auxiliary reservoirs.

[2] Auxiliary reservoir remains equalised with the brake pipe, no brake cylinder pressure effected.

[3] Auxiliary reservoir equalises with the brake pipe.

[4] Brake cylinder pressure equates to about 235% of the pressure loss in the auxiliary reservoir.

This phenomenon of reduced available braking force due to low starting auxiliary reservoir pressure is termed ‘running out of air’. In summary, the lower the starting pressure of the auxiliary reservoir at commencement of an automatic brake application, the lower the braking force available.

Partial braking force recovery when running out of air

As explained in Means of operation – wagons, the maximum braking effort achievable is a full service brake application, due to the concurrent equalisation of the brake pipe, auxiliary reservoir and brake cylinder pressures. That is, further reductions in brake pipe pressure below 350 kPa do not result in increased braking effort. The only exception is when the train’s braking system is running out of air.

In this unique scenario a further reduction in brake pipe pressure will result in increased brake cylinder pressure. By lowering the auxiliary reservoir pressure below 350 kPa, it is possible to force an equalisation of the brake cylinder pressure at a higher rate than is by then achievable in full service. For example, as discussed in Running out of air, where an auxiliary reservoir is only recharged to 450 kPa prior to the reapplication of the automatic brake, the maximum brake cylinder pressure available in full service will be about 235 kPa. However, by reducing the brake pipe pressure further, an equalisation between the auxiliary reservoir and brake cylinder pressures will occur at about 314 kPa (see Table 7).

As described in Driver controls, it is not possible for the driver to graduate the brake pipe below 350kPa, for example, to 314 kPa as noted above. The next available command after full service is either ‘handle off’ or ‘emergency’, both of which result in 0 kPa brake pipe pressure, at a service (controlled) rate for the former and at a rapid rate for the latter.

Table 7 summarises various scenarios of reduced auxiliary reservoir starting pressures. This is then compared to the maximum brake cylinder pressures available in full service, versus the maximum brake cylinder pressures available with the brake pipe pressure reduced to 0 kPa.

Table 7: Approximate maximum brake cylinder pressures from auxiliary reservoir starting pressure[39], [40]

| Auxiliary reservoir starting pressure (kPa) | Maximum achievable brake cylinder pressure (kPa)[2] in ‘full service’[3] | Maximum achievable brake cylinder pressure (kPa)[2] with brake pipe at 0 kPa | |

| 500[1] | 350 | 350 | |

| 490 | 329 | 343 | |

| 480 | 306 | 336 | |

| 470 | 282 | 329 | |

| 460 | 259 | 321 | |

| 450 | 235 | 314 | |

| 440 | 212 | 307 | |

| 430 | 188 | 300 | |

| 420 | 165 | 293 | |

| 410 | 141 | 286 | |

| 400 | 118 | 278 | |

| 390 | 94 | 271 | |

| 380 | 71 | 264 | |

| 370 | 47 | 257 | |

| 360 | 24 | 250 | |

| 350 | 0 | 243 |

[1] Fully charged auxiliary reservoir, with expected starting pressure during normal operations.

[2] Brake cylinder pressure equates to about 235% of the pressure loss in the auxiliary reservoir.

[3] Brake pipe reduced to 350 kPa.

Importantly, despite the ability to increase available brake cylinder pressure with the brake pipe reduced to 0 kPa in instances of running out of air, it is not possible to again obtain the maximum braking force available as would be provided by full service with a fully charged auxiliary reservoir starting pressure.

|

Observation While ordinarily a ‘full service’ automatic brake application provides the maximum pneumatic braking force available on a train, in the unique circumstance of a train ‘running out of air’, a lower brake pipe pressure results in an increase in the available braking force. However, this increased braking force would still be less than that available in full service had the auxiliary reservoir been fully charged at the time of the automatic brake application. This option was available to the driver. |

Independent brake

The ‘independent brake’ applies pneumatic brakes to the locomotive/s only, independently of any trailing wagons. It is operated by the driver using the independent brake handle on the driver’s control station (see Figure 19). On the CM class locomotive, it has two positions: ‘release’ and ‘apply’, with an intermediate graduated service zone. The independent brake can be graduated in both application and release. In the fully applied position, the locomotive brake cylinder pressure is about 500 kPa.

Dynamic brake

The electrical dynamic brake is designed to reduce locomotive fuel usage and wear on wagon componentry as occurs with pneumatically operated friction brakes. It provides a supplementary means of train-speed control that complements the train’s pneumatic automatic brake.

When dynamic brake is selected, it alters the locomotive’s traction motor fields from a tractive power to a generator configuration. The subsequent power generated by the rotating locomotive wheels is fed to resistor grids and dissipated as heat, resulting in a retarding force. This retarding force is limited to the locomotive wheelsets only, rather than dispersed across the entire train. Increasing or decreasing the amount of electrical resistance varies the braking effort on the rotating locomotive wheels.

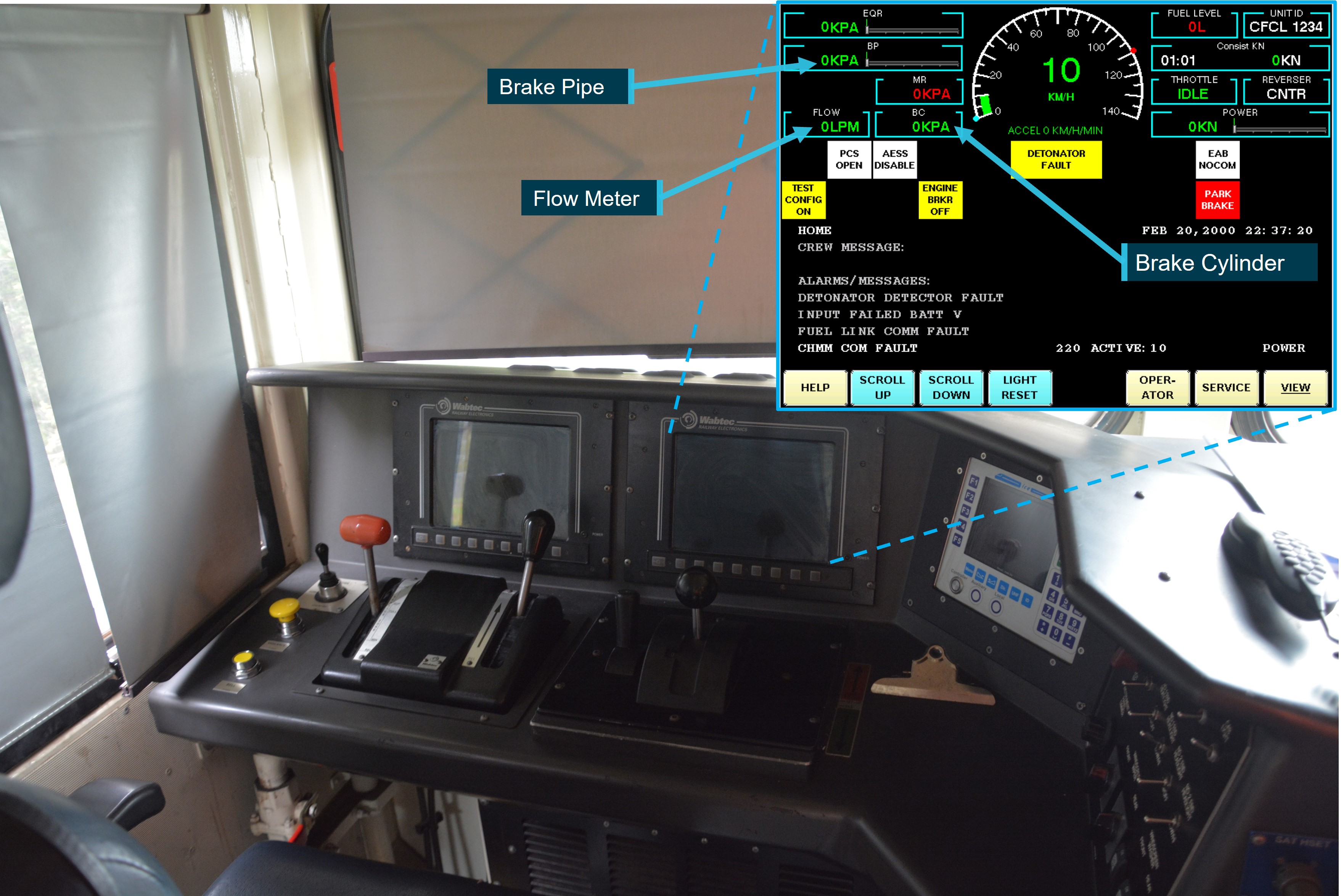

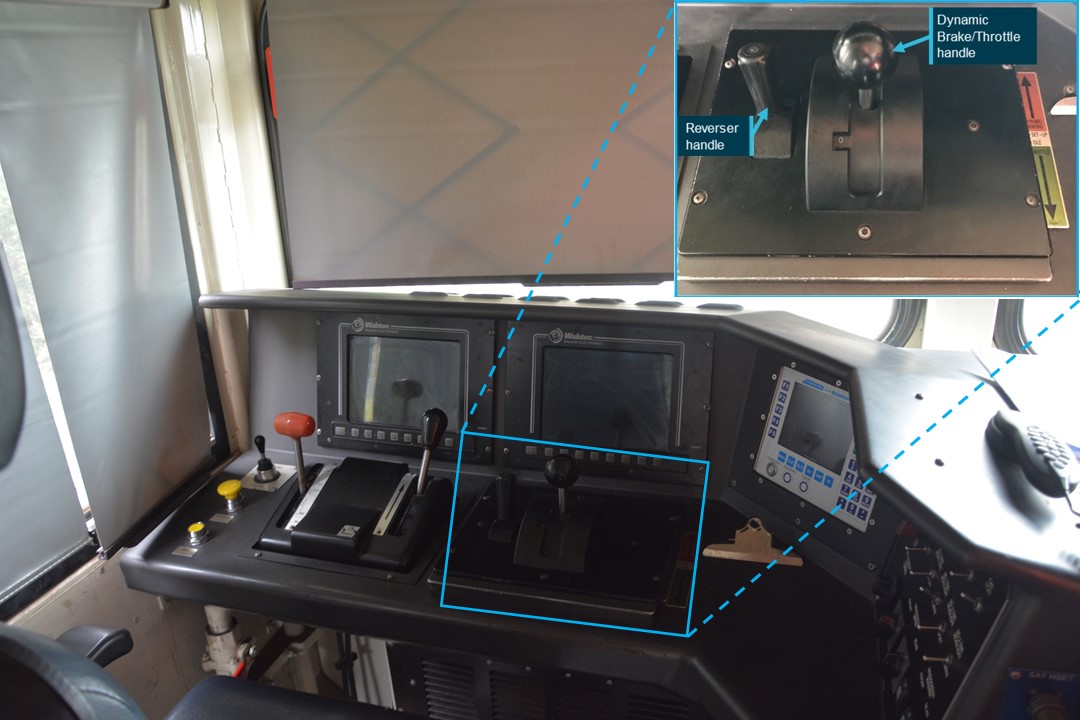

On the CM class locomotive, the dynamic brake is selected by the driver moving the throttle/dynamic brake handle on the driver’s control station into the dynamic braking zone (see Figure 23).

Figure 23: Dynamic brake / throttle handle

Source: OTSI

Automatic brake relationship with dynamic brake

As described in Means of operation – wagons, when the automatic brake is applied air pressure develops in the locomotive’s brake cylinders. Simultaneous application of both the dynamic brake and locomotive brake cylinder pressure can result in potential wheel lock-up and wheel slide. To prevent this, a dynamic brake inhibit (DBI) function[41] is supplied as part of the Fastbrake air brake system. The DBI automatically releases any automatic brake applied locomotive brake cylinder pressure whilst dynamic brake is in use. Independent brake applied locomotive brake cylinder pressure is not affected by the DBI.[42]

The Fastbrake system provides the option for the owner/operator to specify during the locomotive design the activation of the dynamic brake knockout (DKO) function during an emergency brake application. When activated, the DKO causes the locomotive’s dynamic brake to disengage, and the automatic brake applied locomotive brake cylinder pressure to be restored. Wabtec advised, that where the optional DKO function is not fitted, the dynamic brake is retained during an emergency brake application, resulting in extra available braking effort.

CM class locomotive braking systems

General