Safety summary

What happened

On 20 August 2019 a Regional Express, Saab Aircraft Company 340B, registration VH-ZLX, departed Adelaide, for a regular public transport flight to Port Lincoln, South Australia. During the post flight walk around, the first officer noted that the left main outboard landing gear tyre was deflated and that a piece of the wheel was missing.

Ground support personnel at Adelaide Airport subsequently located the missing section of wheel on the runway strip.

What the ATSB found

An area of fatigue cracking had initiated in the bead seat region of the wheel and progressed 86 mm around the circumference prior to final overstress fracture. Information obtained from the manufacturer and a previous ATSB investigation indicated that fatigue cracking of the bead seat area in this wheel type was a known issue with previously updated maintenance schedules and practices.

It was considered likely that the fatigue crack was present at the most recent maintenance visit, however, it had not been detected. Insufficient guidance in the operator’s maintenance procedures meant that inspections required by the component maintenance manual that might have identified the developing fatigue crack were not carried out.

What's been done as a result

The operator advised that, as a result of this incident, they have implemented new measures to prevent a recurrence. These include:

- Updating wheel maintenance procedures to ensure that non normal inspections are identified and carried out.

- Making the component maintenance manual for tyres more readily available to personnel by adding it to their engineering website.

- Providing additional advisory material to maintenance personnel on the requirements of completing unserviceable tags to ensure that other maintenance personnel performing subsequent work fully understand the defect.

- Providing additional training to personnel on wheel maintenance techniques.

Safety message

When situations or issues arise that do not fit into standard operating procedures, maintenance personnel should always be prepared to consult or request further guidance. This guidance can come from internal support materials, such as procedures, or external materials such as maintenance manuals or the manufacturer.

What happened

At approximately 1935 Central Standard Time[1] on 20 August 2019, a Regional Express, Saab Aircraft Company 340B, registration VH-ZLX (ZLX), departed Adelaide, South Australia for a regular public transport flight to Port Lincoln, South Australia. This was the last flight of the day for the aircraft and there were two flight crew, one cabin crew and 14 passengers on board. Following the landing in Port Lincoln, the first officer conducted an external inspection of the aircraft and noticed that the left main outboard landing gear tyre was deflated.

The crew reported no issues with aircraft handling during the take-off, landing or taxi phases of the flight. Additionally, none of the crew or passengers advised of any vibration or unusual noises during the flight.

On closer inspection of the wheel, the first officer noted that a piece of the wheel rim was missing (Figure 1). Ground staff were notified and the Port Lincoln aerodrome reporting officer (ARO) was contacted to conduct a runway inspection. The ARO’s inspection did not reveal any foreign object debris or damage to the runway.

The following morning, the operator dispatched engineers to replace the wheel and brake assembly. They informed the flight crew that the missing piece of wheel had been located on the runway strip at Adelaide Airport.

Context

Incident wheel history

The incident wheel was manufactured in 1995 and acquired by the operator in 2007. Since then, it had undergone 42 tyre changes, and 8 overhauls, the most recent of which was in October 2018. In the 10 months between this overhaul and the occurrence, it had accumulated 943 flight cycles on five different Saab 340B aircraft (Table 1).

The wheel’s removal from the first three aircraft was for routine tyre changes, with the tyres being worn to limit (WTL). Following its removal, the wheel was transported to the operator’s maintenance facility, inspected in accordance with the operator’s process, signed off as serviceable and returned to storage before transport and fitment to the next aircraft.

The removal from the fourth aircraft was due to a flat tyre. During a routine post flight inspection on 16 July 2019 the wheel was identified to be audibly leaking, maintenance personnel were notified and reported that when they arrived, the tyre was flat. As a result, both wheels in the set[2] were removed from the aircraft. The operator reported that prior to the occurrence flight the tyre pressure had been checked with a pressure gauge and was at the appropriate operating pressure before departure.

Table 1: Incident wheel maintenance history since previous overhaul

| Date | Aircraft | Reason for removal |

Cycles since wheel installation |

Cycles since wheel overhaul |

| 11-10-2018 | Wheel overhaul | N/A | 0 | |

| 21-12-2018 | VH-ZLJ | Tyre change (WTL) | 276 | 276 |

| 13-04-2019 | VH-OLL | Tyre change (WTL) | 230 | 506 |

| 21-06-2019 | VH-ZXQ | Tyre change (WTL) | 340 | 846 |

| 16-07-2019 | VH-ZXK | Flat tyre | 94 | 940 |

| 21-08-2019 (occurrence) |

VH-ZLX | Wheel failure | 3 | 943 |

Source: Operator

Following removal of the wheel in July 2019, an ‘unserviceable’ tag was attached, and the wheel was returned to the operator’s maintenance facility. A standard tyre change form with the word ‘Repair’ hand‑annotated at the top of the form was used to document the maintenance. The form indicated that the following items were completed.

- ‘General wheel check and inspection admin’

- valve subassembly reinstallation and the wheel inflation

- the post-inflation leak test[3], which found no evident leak.

Other items listed on the form, including visual inspection and non-destructive testing, were not performed as they were marked as ‘N/A’.

Following the leak check, the wheel was inflated to the recommended storage pressure and stored at the operator’s maintenance facility for approximately 1 month. On the day of the occurrence, the wheel was fitted to ZLX, and the aircraft conducted three flight cycles[4] before the rim section separated at Adelaide Airport.

Wheel examination

Following the incident, the wheel and tyre assembly, including the recovered segment, were provided to the ATSB for inspection.

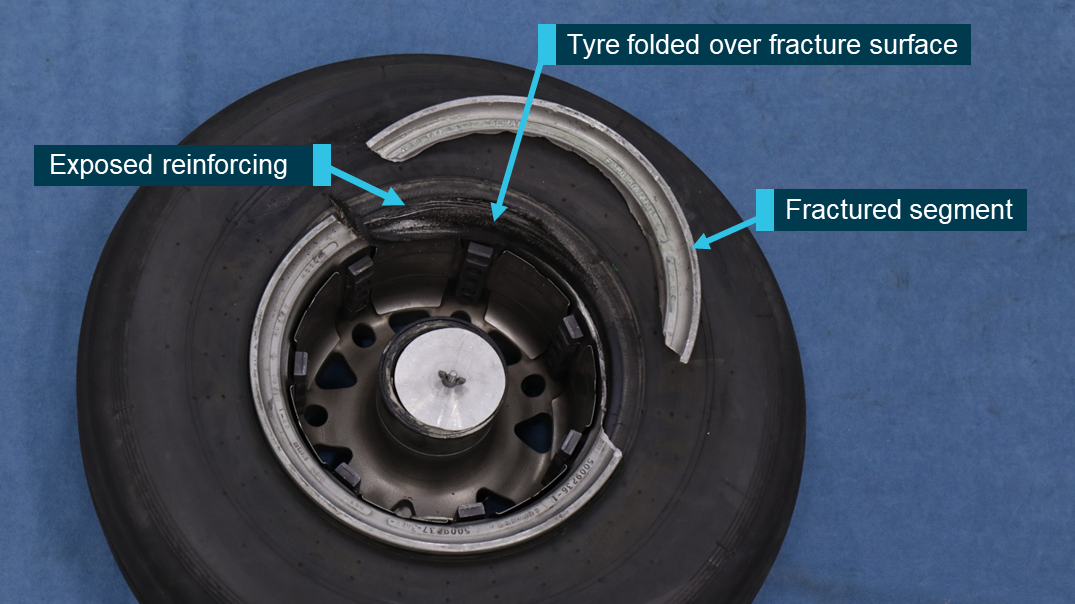

Initial inspections revealed that a section of the rim, comprising approximately one-half of the wheel’s circumference, had broken away with the fracture extending through the bead seat. The tyre had been damaged in the area of the fracture, with exposed steel reinforcing and some fractured wires. The tyre had folded over the fractured section of the rim and was caught on the edge of the rim (Figure 1).

Figure 1: Wheel in as-received condition

Source: ATSB

The tyre was removed, and the wheel disassembled to allow access to both sides of the fracture surface. The fracture followed a radial path through the wheel rim bead seat area (Figure 2).

Figure 2: Cross-section diagram of the wheel hub showing the location of the fracture

Source: Manufacturer, annotated by the ATSB

Beach‑marks consistent with fatigue crack progression were evident across both faces of the fracture surface (Figure 3 and 4). These markings extended radially from the internal bead seat radius surface towards the centre of the exposed fracture face. The beach-marks extended circumferentially around the rim for approximately 86 mm. While several potential fatigue initiation points were examined on both faces of the fracture, the exact origin could not be determined. The outer surfaces of the fracture, beyond the area of fatigue, were dull grey in colour and rough/fibrous in appearance. These features were consistent with a ductile overstress failure in a heat-treated aluminium alloy.

Figure 3: Excised portion of wheel rim with fatigue area highlighted

Source: ATSB

Figure 4: Magnified view of fatigue area showing crack progression along the bead seat and evidence of tyre contamination on the fracture surface

Source: ATSB

There was also black discolouration on the fracture surface. This was determined to be rubber debris from the tyre when it had been caught over the rim.

Scanning electron microscopy of the fracture surface revealed a relatively smooth fracture with evidence of non-uniform stepwise crack formation (Figure 5). This was further indication of a fatigue crack propagation through the material. Due to the non-uniform nature of the steps, it could not be determined how many cycles of fatigue had occurred before the overstress fracture.

Figure 5: Area of fatigue surface showing step-wise crack formation

Source: ATSB

The examinations did not locate any corrosion or pre-existing manufacturing defects. Externally, there was no significant surface or mechanical damage to the fractured rim.

Wheel design

The wheel, serial number AUG 95-1523, was a part number (P/N) 5010488 main wheel assembly manufactured by the Aircraft Braking Systems Corporation (ABSC), now Meggitt Aircraft Braking Systems (MABS) in August 1995. The wheels were for use on a range of fixed and rotary wing aircraft including the Saab 340B.

Following a number of in‑service failures, in August 1994 ABSC identified an issue with the design of these wheels. These failures were attributed to fatigue crack development in the bead seat region of the wheel.

In order to ensure that cracks were detected prior to wheel failure, the manufacturer issued a service bulletin SF340-32-24, ‘SAAB 340 Main Wheel Sub Assembly 5009327 and 5009327-1’, which revised the required inspection and maintenance procedures for this wheel-type. The changes included non-destructive inspection, either eddy current or ultrasonic, at a series of locations around the wheel at each tyre change.

The inspection schedule for these wheels was introduced by service letter (SL) SL-GS-36.[5] The SL indicated that overhauls should be performed at maximum intervals of five tyre changes, or 1,500 flight cycles, whichever occurred first, nominally introducing an interval of approximately 300 flight cycles between each eddy current inspection. That interval was consistent with the maintenance history of the failed wheel.

In December 1995, the manufacturer released an updated design (P/N 5010488-1) that included additional reinforcement in the bead seat region. Figure 6 and 7 show the differences between the two designs. The new design could not be retrofitted to existing wheels. The manufacturer’s advice to operators in the service bulletin that introduced the new design (Saab 340-32-41) was that the older wheels (serial number OCT95-1606 and earlier) could be used until stock depletion, provided the necessary maintenance and inspection standards detailed in SL‑GS‑36 were maintained.

Figure 6: Diagrams showing the difference in the original and revised wheel designs

Source: Manufacturer modified by the ATSB

Figure 7: Example of the difference between the old and new wheel designs

Source: ATSB

The manufacturer advised that they were not aware of any in service failures in the last 10 years and could not determine how many of the older wheel designs remained active, as they were not alerted to removal of wheels from service. The ATSB also reviewed defect reporting service (or equivalent) databases of the Civil Aviation Safety Authority, the United States Federal Aviation Administration and Transport Canada (Canadian Regulatory Authority) for reports of wheel failures. The jurisdiction of these agencies covers the majority of the aircraft with this wheel type. That review identified four reported wheel failures in the last 20 years and none in the last 10 years.

A search of the operator’s engineering database showed 38 wheels of the older design remained active in their fleet. In the 10 years prior to this occurrence, the operator has experienced one other in-service failure on their aircraft (see the section titled Previous occurrence) and 69 wheels of this type have been removed from service. It could not be determined if the removal of these wheels from service was due to the presence of fatigue cracks, as this level of detail was not recorded in the engineering database.

Component maintenance procedures

The component maintenance manual (CMM) outlined a range of different maintenance tasks that were to be carried out on this type of wheel (both the original and updated designs). It stated that, with the exception of the overhaul requirements already outlined, wheels were an ‘on condition’[6] part.

Three key procedures given in the CMM were for tyre change, overhaul and special cases.

Tyre change

The tyre change procedure was carried out when a tyre was worn to its tread limit. This involved recording the details about the wheel, dismantling the removable flange, removing the worn tyre, conducting a detailed visual inspection of the whole wheel assembly and non-destructive (eddy current or ultrasonic) inspection of specific areas.

Overhaul

At an overhaul, wheels had to undergo a full tyre change inspection plus eddy current, ultrasonic or fluorescent penetrant inspection of the whole wheel.

Special cases

‘Special cases’ inspections were required when the tyre had been operated with a flat or damaged tyre, or when the mating wheel[7] has been operated with a flat tyre.

In the case of a wheel operated with a flat tyre, the CMM required that the wheel undergo a careful visual inspection for damage, and a roundness check to ensure that the wheel was still circular. If the wheel was out of a specific tolerance, then it was to be replaced. There was no requirement for the wheel to undergo any non-destructive inspection in this process.

Operator’s maintenance process

The operator provided maintenance personnel with two different forms for carrying out the routine maintenance on wheels of this type, one for overhaul and another for tyre changes. The two forms specified the required tasks (as detailed in the CMM), and a location for each task to be signed off.

At the time of the occurrence, neither of these forms required personnel to confirm the reason for the tyre removal or if any additional maintenance actions, such as those outlined in the ‘special cases’ section, were required. There was no form for the special cases procedures.

A review of maintenance documentation indicated that non‑destructive inspections were carried out during the last overhaul of the occurrence wheel and during each subsequent tyre change conducted prior to the wheel failure. No cracking was identified during any of those inspections.

Previous occurrence

ATSB Investigation AO-2009-006

On 6 February 2009, a Regional Express Saab340B aircraft, registered VH-KDQ, landed at Sydney Airport following a regular public transport flight from Orange, New South Wales. During the post-flight inspection, the crew noted that that the aircraft’s left main outboard landing gear wheel was deflated and had sustained damage. Closer inspection by maintenance personnel revealed that a section of the wheel had fractured but remained attached to the wheel assembly.

The ATSB’s examination of the wheel found that it had failed due to a fatigue crack that had developed within the bead seat after initiating in the transition radius.

The failed wheel was a part 5010488 main wheel assembly manufactured by ABSC, serial number SEP92-0621 and, as discussed in the Wheel Design section, was more susceptible to this type of failure. The investigation reviewed the safety actions that had previously been put in place by both the manufacturer and the operator, finding them to be satisfactory.

Safety analysis

Component failure

Failure of the left main outboard landing gear wheel from Saab 340B aircraft, VH-ZLX, was a result of the fracture and separation of a section of the inner wheel rim adjacent to the tyre bead seat. The cracking and fracture was typical of a progressive fatigue cracking mechanism, which had initiated on the internal bead seat transition radius. In conventional pneumatically pressured wheel designs, the internal bead seat radius is typically a region of high bending stresses. As such, it is pre-disposed to the initiation and growth of fatigue cracking. Operational stresses arising from tyre flexure during taxi and landing can further contribute to this failure mechanism.

The bead seat radius fatigue cracking was a known issue with wheels of the original ABSC P/N 5010488. To improve the reliability of these wheel assemblies, the wheel manufacturer introduced updated inspection methods and tyre change or cycle limits between overhauls. To further address the issue, a revised wheel design (P/N 5010488-1) with features that strengthened the bead seat region of the wheel aimed at preventing fatigue failures was introduced. The failed wheel from VH-ZLX was of the original design.

Wheel inspection and crack development

Each time the non-destructive testing was conducted at a tyre change, no cracks were identified, and the wheel remained in service. Two scenarios were identified that could have accounted for the presence of the fatigue crack that initiated the failure:

- the initiation and growth of the crack occurred rapidly, with the crack developing in the time since the last non-destructive inspection was carried out, or

- a crack had initiated at the time of the last non-destructive inspection and was not detected.

The ATSB was not able to determine the crack growth rate that occurred in the wheel rim from the fracture surfaces. While rapid crack development could not be conclusively ruled out, for the following reasons the ATSB considered it probable that a crack had been present at the time of the last non‑destructive inspection but had not been detected:

- The relatively large size of the fatigue area (86mm), compared to the relatively low number of flight cycles that had occurred (97) since the last eddy current inspection.

- The nominal interval between eddy current inspections was 300 flight cycles, however, this failure occurred well before the next inspection was due. The very small number of reported failures in this wheel type in last 10 years indicated that the inspection interval generally appears adequate to capture cracks before they progressed to failure in service.

- While it was possible that the wheel was operated for a short time with lower than recommended tyre pressure which could have influenced the crack growth rate, it was considered unlikely that it increased the growth rate enough to cause failure at one third of the nominal inspection interval.

Available forms

When the wheel was presented to the wheel bay following its removal from VH-ZXK, the personnel involved utilised the standard tyre change form to complete the inspection, noting on the form that this was not a standard tyre change, rather a ‘Repair’. Utilising the tyre change form, personnel signed for the ‘general wheel check and inspection admin’ task. This task did not include a visual inspection, as it was listed as a separate item on the form. When reinflated, the tyre retained pressure for the required 24 hours and so the tyre was not changed. As a result, a complete tyre change inspection, including non‑destructive inspection, was not performed.

As the wheel had been operated with a flat tyre, even if for a short time, it should have undergone the additional inspections outlined in the ‘Special cases’ section of the CMM. However, the documentation that maintenance personnel used did not identify this as a requirement, nor did it direct them to the CMM for further guidance in non-standard cases.

The ‘Special cases’ section of the CMM required a detailed visual inspection and roundness check to be carried out. The ATSB was unable to determine whether either of these inspections could have identified the crack. However, they would have been opportunities to determine that something was out of place and prompt further investigations. Although not required as part of the ‘Special cases’ section, had the wheel been subject to non-destructive inspection, the crack would have almost certainly been detected.

Findings

These findings, related to the landing gear wheel failure of Regional Express Saab 340B VH-ZLX, should not be read as apportioning blame or liability to any particular organisation or individual.

- A fatigue crack initiated at the bead seat and led to the failure of the left outboard main landing gear wheel.

- This wheel design was susceptible to fatigue cracking in the bead seat region.

- It is probable that a fatigue crack was present at the time of the last non-destructive eddy current inspection but not detected.

- The operator’s wheel maintenance forms did not adequately convey the inspection requirements for wheels operated with flat tyres. Subsequently, when the flat tyre was detected and the wheel brought in for maintenance, inspections that may have detected the crack were not carried out.

Safety action

Whether or not the ATSB identifies safety issues in the course of an investigation, relevant organisations may proactively initiate safety action in order to reduce their safety risk. The ATSB has been advised of the following proactive safety action.

Aircraft operator

The aircraft operator has advised the ATSB that in response to this incident they have updated several of the forms used for carrying out wheel maintenance. The forms now include additional steps to identify and treat wheels that fall into the ‘Special cases’ categories of the CMM and to ensure that all wheels in these categories undergo non-destructive inspection.

Additionally, they have made the tyre CMM more readily accessible to maintenance personnel, and disseminated advisory materials to ensure that the reason wheels are removed from service is correctly annotated on the unserviceable documentation. They have also provided retraining for a number of their staff in the correct wheel maintenance procedures.

Purpose of safety investigationsThe objective of a safety investigation is to enhance transport safety. This is done through:

It is not a function of the ATSB to apportion blame or provide a means for determining liability. At the same time, an investigation report must include factual material of sufficient weight to support the analysis and findings. At all times the ATSB endeavours to balance the use of material that could imply adverse comment with the need to properly explain what happened, and why, in a fair and unbiased manner. The ATSB does not investigate for the purpose of taking administrative, regulatory or criminal action. TerminologyAn explanation of terminology used in ATSB investigation reports is available here. This includes terms such as occurrence, contributing factor, other factor that increased risk, and safety issue. Publishing informationReleased in accordance with section 25 of the Transport Safety Investigation Act 2003 Published by: Australian Transport Safety Bureau © Commonwealth of Australia 2020

Ownership of intellectual property rights in this publication Unless otherwise noted, copyright (and any other intellectual property rights, if any) in this report publication is owned by the Commonwealth of Australia. Creative Commons licence With the exception of the Coat of Arms, ATSB logo, and photos and graphics in which a third party holds copyright, this publication is licensed under a Creative Commons Attribution 3.0 Australia licence. Creative Commons Attribution 3.0 Australia Licence is a standard form licence agreement that allows you to copy, distribute, transmit and adapt this publication provided that you attribute the work. The ATSB’s preference is that you attribute this publication (and any material sourced from it) using the following wording: Source: Australian Transport Safety Bureau Copyright in material obtained from other agencies, private individuals or organisations, belongs to those agencies, individuals or organisations. Where you wish to use their material, you will need to contact them directly. |

__________

- Central Standard Time (CST): Coordinated Universal Time (UTC) + 9.5 hours.

- The component maintenance manual stated that when one wheel in a dual wheel set was operated with a flat or damaged tyre, the other mating wheel must also undergo an inspection for damage due to potential for overload or other damage.

- Post-inflation leak check required the tyre to be inflated to operating pressure for 24 hours. The tyre was then pressure-tested and the pressure reduction was not permitted to exceed 10 per cent.

- Flight cycle: a completed takeoff and landing sequence.

- SL-GS-36 was first issued in July 1993. The most recent revision, version seven, was issued in January 2006.

- For ‘on condition’ components, maintenance is carried out as required rather than on a fixed schedule of flight cycles, time or operational hours.

- Mating wheel: the other wheel on the same part of the landing gear