Safety summary

What happened

On 2 December 2015, BHP Billiton (BHPB) train M03544 was loaded with iron ore at Yandi, Western Australia (WA). The train departed Yandi at about 2211 Western Standard Time (WST) and travelled north towards Port Hedland, WA, on the Newman main line.

At about 0530 on 3 December 2015, the train controller based in Perth was alerted to a dragging equipment detector (DED) alarm at the 67 km mark at Walla. Seven seconds later, train M03544 recorded a loss of brake pipe air pressure before the train came to a stop with the lead locomotive positioned near the 64.188 km mark, about 3 km from the DED.

The train controller contacted the train driver, advising that DED alarms had activated on both the east and west tracks. The train driver informed the controller that a loss of brake pipe air pressure had resulted in an uncommanded brake application bringing the train to a stop.

Shortly afterwards, as the driver walked towards the rear of the train to determine the cause of the loss of air pressure, he found that the train had separated and derailed.

What the ATSB found

The ATSB investigation identified that train M03544 derailed due to a broken rail. A fracture of the rail was probably initiated by the rapid growth of a detectable, yet unidentified, fatigue‑related transverse defect(s) in the west rail near the 67 km mark during the passage of the train.

The investigation also identified that the condition of the rail in the vicinity of the fracture contributed to relatively frequent failures in that area.

Finally, ultrasonic defect testing of the rail was undertaken in the heat of the day, potentially masking defects due to compressive forces in the rail.

What's been done as a result

In response to this occurrence, the operator of the train and track, BHP Billiton, took measures to improve track condition and reduce in-service rail defects by:

- accelerating the re-railing of 833 kilometres of track, including replacement of the track in the vicinity of the fracture

- the introduction of processes to:

- reduce the initiation of rolling contact fatigue cracks in rail track

- improve rail defect detection to prevent fatigue cracks from progressing to track failure.

Safety message

Early detection, assessment, and effective management of track defects is critical to minimising the risk of derailment and maintaining safe rail operations. Therefore, it is essential that track maintenance and infrastructure fault detection be of a high standard.

On 2 December 2015, BHP Billiton (BHPB) train M03544 was loaded with iron ore at Yandi, Western Australia (WA). The train departed Yandi at about 2211 Western Standard Time (WST) and travelled north towards Port Hedland, WA, on the Newman main line.

At the about 0221 the following morning, the train stopped for a driver changeover at the 199.447 km mark at Garden (Figure 1). The train resumed its travel to Port Hedland at about 0244.

Near Turner (Figure 1), at about the 119 km mark, the train driver of southbound train M03568 carried out a roll-by inspection as it crossed train M03544. The driver of train M03568 observed no defects on train M03544.

When the rear of the train had passed the 108 km mark, the train controller based in Perth observed that the track remained occupied. The controller contacted the train crew and issued an operational speed restriction of 60 km/h. The controller also requested maintenance staff to inspect the track infrastructure to determine the cause of the occupation.[1]

At about 0527, on approach to the 67 km mark, the train was travelling at a speed of about 61 km/h on a descending grade under dynamic brake.

At about 0528, the lead locomotives passed the dragging equipment detector (DED) located at the 67.01 km mark. About 2 minutes later, the train driver applied a brake command to manage train speed.

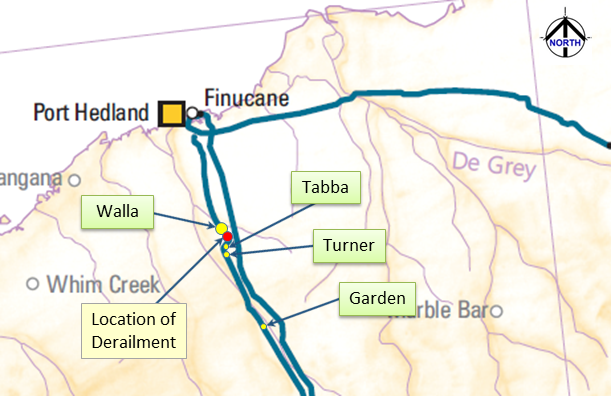

Figure 1: Map of the Pilbara region showing the derailment location

Source: Geoscience Australia annotated by ATSB

At 0530:29, the train controller was alerted to a DED alarm. At this time, the lead locomotives were about 2.35 km past the location of the DED detector (the train was 2.83 km in length).

About 7 seconds later, the train recorded a loss of brake pipe air pressure. As a result, the train came to a stop at 0531:24 with the lead locomotive positioned near the 64.188 km mark (about 3 km from the DED).

The train controller contacted the train driver advising that DED alarms had activated on both the east and west tracks. The train driver informed the controller that a loss of brake pipe air pressure had resulted in an uncommanded brake application bringing the train to a stop.

Shortly afterwards, the train driver began walking towards the rear of the train to determine the cause of the loss of brake pipe air pressure.

The train driver found that two ore cars located at positions 80 (OC 2266) and 81 (OC 6182) in the ‘B’ rake portion of the train had separated (Figure 2). The gap between the cars was about 350 m but they had not derailed. At position 85 (OC 8934), the driver found the trailing axle on the trailing bogie had derailed. The next four ore cars (that is, immediately trailing OC 8934) had derailed and overturned onto the west side of the track but had remained coupled.

Trailing the four derailed cars on the west side of the track, there was a gap of about 20 m. The next group of 21 ore cars (positions 90 to 110) had derailed in the vicinity of the 66.950 km mark. The first 10 of these ore cars were severely damaged and had concertinaed to both the west and east sides of the west track. Some of the cars had come to rest at 90° to the direction of travel. A number of the derailed ore cars pushed the east track laterally out of alignment for about 10 m in an easterly direction.

The remainder of the cars, from position 111 through to the end of the train (position 132), had remained on the track.

The derailment resulted in significant damage to 26 ore cars (Figure 3) but no one was injured.

Following the clean-up of iron ore, vehicles, wayside equipment and track materials, 50 m of the east track and 200 m of the west track was rebuilt. Operations on the Newman mainline east and west tracks recommenced on 5 December 2015.

Figure 2: Diagram of the ore cars near the 67.0 km mark

Source: BHP Billiton, annotated by ATSB

Figure 3: Derailed, loaded iron ore cars located in the rear portion of train M03544

Source: BHP Billiton

Source: BHP Billiton

__________

The Australian Transport Safety Bureau (ATSB) did not attend the incident site. The information presented in this section of the report and the analysis section that follows is principally based on information provided to the ATSB by BHP Billiton (BHPB), including reports commissioned by BHPB.

Location

Walla Siding is located on the Newman Railway in the Pilbara region of Western Australia (WA). The Newman Railway carries iron ore from seven inland mines to two port facilities at Port Hedland (Figure 1). The railway generally runs in a north-south alignment with the track kilometre distance starting at zero from Port Hedland and increasing as it runs south. Walla Siding is located about 60 km south of Port Hedland.

Weather

Weather conditions at the time of the derailment were fine and clear. The temperature ranged from a minimum of 23.0 °C to a maximum of 32.7 °C.

Train M03544 and its crew

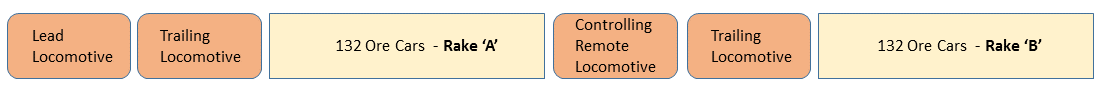

Train M03544 was a heavy haul, bulk iron ore service operated by BHPB. The train was 2.83 km in length and had a total weight of about 41,562 t. The train was hauled by four EMD SD70 ACe locomotives. There were two locomotives positioned at the front of the train, and a rake of 132 ore cars (‘A’ rake). Another two locomotives were positioned in the middle of the train, with a further 132 trailing ore cars (‘B’ rake) (Figure 4).

Figure 4: Typical arrangement of BHPB iron ore train consist

Source: ATSB

Source: ATSB

The crew consisted of two train drivers, one working the train and the other travelling passenger. The train driver commenced shift at 2200 on 2 December 2015. The driver had worked two shifts following a rest and recreation break and had had 8 hours rest before boarding the train at Garden (Figure 1). He had 30 years of train driving experience. He had been assessed and reaccredited as a mainline locomotive driver on 15 January 2015.

The driver was tested for the presence of alcohol and other drugs following the derailment, returning a negative result.

Locomotive data extracted after the derailment verified the train speed was 61 km/h through the point of derailment. The train driver had maintained the operational speed restriction of 60 km/h imposed by the train controller near the 108 km mark.

The investigation found that improper train handling or excessive speed did not contribute to the derailment.

Rolling stock

The BHPB ore trains are operated as unit trains using a variety of ore car types including A Goninan and Co/Lynx Engineering (GOLYNX), Qiqihar Railway Rolling Stock (Group) Company (QRRS) and Bradken. The typical arrangement of the ore car fleet comprises of rotary couplers on the ‘A’ end and a fixed coupler on the ‘B’ end (Figure 5). An electronically controlled pneumatic (ECP) braking system was fitted to these ore cars. The ore cars operating with isolated brakes in train M03544 was less than 1.5 per cent of the total braking capacity, and this proportion was within BHPB’s operating standard.

Figure 5: Typical BHPB ore car arrangement

Source: BHP Billiton, annotated by ATSB.

BHPB used a trip-based maintenance strategy where ore cars were serviced after 246 return trips from Port Hedland to the Newman mine sites. [2] This return trip interval between maintenance equated to the ore cars being serviced about every 210,000 km.

An assessment of maintenance records for the ore cars in train M03544 found that 21 cars in ‘A’ rake were due to be serviced. Two of these ore cars had maintenance requests as the return trip service interval had been exceeded. The majority of the cars in ‘B’ rake had completed 34 trips. In total, 7.9 per cent of ore cars had exceeded the maintenance interval.

An inspection of the derailed ore cars found no evidence of fractured wheels or failed axle bearings. Data extracted from the wayside hotbox detector (HBD) site located at the 84 km mark found no evidence of high bearing temperatures in train M03544 before it derailed.

Wheel impact load detection (WILD)[3] sites on the Newman network recorded two ore cars in train M03544 with ‘severity 2’ (intermediate level) peak load impacts of 31 t and 31.2 t. These ore cars were located in ‘A’ rake at positions 31 and 37 respectively. Both ore cars had ‘cut-out requests’ noted on the wayside equipment alarm report, indicating that these vehicles were scheduled to be inspected and removed from service for repair.

There were no excessive wheel impact loads detected in ‘B’ rake of train M03544 and preceding train M0356.

There was no track defect recorded in the vicinity of the 67 km mark on the day of the derailment. The signalling system maintained a continuous track circuit before the arrival of train M03544.

A review of the train’s payloads found ore car 8667 at position 61 in ‘B’ rake was slightly heavier than the majority of other ore cars in the consist, with a gross weight of 162.7 t. Ore car 8667 was located 25 cars ahead of ore car 8934, the first car to derail near the 67 km mark. Although more heavily loaded, the loading on car 8667 conformed to BHPB transit mass standards.

Visual inspections of the rolling stock, reviews of maintenance records, wayside monitoring detection systems and data concluded it was unlikely that a significant rolling stock defect had initiated or contributed the derailment of train M03544.

Rail impacts on wheels

The four ore cars immediately ahead of the first derailed ore car, 8934 (Figure 22), were quarantined and transferred to Mooka where an inspection found rail impact marks on the left wheel tread surfaces. The ore cars were transferred to Port Hedland where the iron ore was dumped. The wheel sets were removed from ore cars 8819 and 3290 at the ore car repair shop where a detailed examination of the wheel tread surfaces was carried out. Single impact marks found on each left wheel of ore cars 8819 and 3290 were consistent with impacts with a broken rail head. The impact marks generally increased in magnitude relative to their trailing position and ore car 8934 (that is, the first derailed car).

Wheelset number 2L of ore car 8934 showed four wheel tread surface impact marks (Figure 6 & Figure 7). In the direction of wheel travel/rotation, the impact marks were intermittently spaced, generally oval-shaped about 45 mm long and angled at about 90° to the wheel flange.

Figure 6: Ore car 8934 - wheelset 2L impact marks from broken rail segments

The top photo shows the radial spacing of the rail impact marks viewed from the back of the wheel. The bottom photo shows three of four corresponding rail impacts looking from the front of the wheel. Enlarged details of the four rail impact marks are shown in Figure 7.

Source: BHP Billiton, annotated by ATSB.

Figure 7: Enlargements of the four rail impact marks ore car 8934 - wheelset number 2L

Numbered 1 – 4, corresponding rail impact bruises on the wheel tread surface (Figure 6) on ore car 8934 - wheelset #2L. All impact marks are transverse, angled about 90° across the tread surface.

Source: BHP Billiton.

Track infrastructure

The BHPB iron ore railway was a standard gauge track structure constructed with 68 kg/m rail fastened with resilient clips to concrete sleepers. The rails were continuously welded and joined with flash-butt[4] and aluminothermic[5] welds. The sleepers were contained in a crushed rock ballast and BHPB operated trains of 40 t axle loads over its track infrastructure.

In the direction of travel, the west track through the location of the derailment was tangent on a downhill gradient varying between -0.22 per cent and -0.8 per cent. Maximum track speed was prescribed at 75 km/h. The majority of loaded trains traverse the west track with empty trains returning via the east track.

The BHPB specification SPEC-073-C-12006 described the assessment and classification and response to rail defects with ratings for three levels of severity. A severity level 1 required more urgent attention than that of a severity level 3 (Table 1).

Table 1: Rail defect severity ratings

|

Severity rating |

Defect condition |

Corrective action |

Comments |

|

1 |

Immediate risk of broken rail or interruption to haulage operations |

Clamp and remove within 24hrs |

Track may be closed for some defect conditions |

|

2 |

Will not develop to Severity 1 before next scheduled inspection |

Clamp and remove within 1 week |

Corrective action period may be reduced in the event of increased haulage rates |

|

3 |

Will not develop to Severity 2 before next scheduled inspection |

Clamp and remove within 1 month |

Corrective action period may be reduced in the event of increased haulage rates |

Track geometry inspections

As part of the process in determining track condition, a series of track geometry parameters such as vertical and horizontal alignment, cross level variation, twist and gauge are considered. Potential track defects are examined and their severity determined with reference to defined defect limits for each track geometry parameter. The defined limits were documented in the BHPB standards.

A track geometry car is used to measure the track accurately and compare the results against a table of defect limits, which allows an appropriate response category to be allocated based also on rated track speed. Personnel conducting track patrols and unscheduled inspections also assess the severity of potential defects based on their knowledge and experience but do not normally take measurements.

On 27 November 2015, two severity 3 defects were found on the west track at the 67.052 km and 67.038 km locations. These were classified as severity 3 geometry defects requiring inspection within 28 days and repair within 12 weeks.

Rail and welded joint inspections

Patrol inspections were usually performed on the track between Port Hedland and Yandi while travelling in a road/rail vehicle at intervals not exceeding 2 days. Patrol inspections looked for visible rail defects such as broken rails, damaged rail surfaces or rail deformation. General inspections were performed for all new rail welds, and in response to previously identified defects or unusual rail conditions.

Continuous, detailed non-destructive test inspections (NDT) were carried out using vehicle-mounted and/or manual (handheld) ultrasonic test methods to detect internal and surface rail defects (See the section titled Ultrasonic tests – west track). Manual ultrasonic testing was used to verify the integrity of new aluminothermic and flash-butt welds and to confirm the size of suspected defects identified by continuous testing or visual inspection.

Identified rail defects were assessed within a series of defect categories such as transverse defect,[6] horizontal/vertical split or weld defect in the rail head, web, or foot.[7] The classification, position and size of defects were analysed with reference to a table of defect limits and associated severity codes. The severity codes defined the appropriate response required to control any risk to railway operational safety.

Rail defects were assessed within three levels, where a severity level 1 (red) broken weld defect must be removed before the passage of the next train. Severity level 2 defects (yellow) were to be generally actioned through regular reassessment or removed within 24 hours of discovery. A severity 3 level (blue) defect generally required a response time of 48 hours with daily reassessments and removal as soon as practically possible.

According to BHP Billiton Iron Ore, aluminothermic welds, and to a lesser extent flash-butt welds, were known to exhibit an increased frequency of defects and broken rails relative to those which occurred in parent rail. For this reason, all defects associated with welds may be classified separately to those in parent rail, or in cases where the generic defect types (for example, transverse defect) are identical, classified at a higher severity levels.

Welding records showed that the insulated rail joint[8] (IRJ) located at the 67 km mark was replaced on 5 September 2015 (Figure 8).

Figure 8: West track, location of repairs to rail sections near the 67 km mark

Video image capture of the west track showing the east and west rail near the insulated rail joints at the 67 km mark. There were a number of welds in close proximity (orange arrows).

Source: Rail Technology International, annotated by ATSB

Tamping

All BHPB track tamping was carried out based on data from the dynamic track recording vehicle and track geometry defect exceedance reports. Geometry defects exceeding thresholds over a longitudinal distance greater than 2 m contributed to increased maintenance and potentially a derailment.

A review of track maintenance records found that hand tamping was carried out at the 67.01 km mark on 30 September 2015. The records showed that about 1 month later (on 28 October 2015), the track was machine tamped on the west track between the 66.0 km to 66.9 km locations.

A track geometry report dated 24 November 2015 identified three defects located between the 65.5 km and 68.7 km locations on the west track. Low rail height was reported in this section but no significant anomalies were found.

A review of the track condition index[9] for 400 m north and south of the 67 km mark found no extraordinary geometry conditions.

Insulated rail joints

Records showed repairs on the west rail were carried out on 5 September 2015 to the broken IRJ at the 67.00 km mark. The most recent previous break of the IRJ at the same location had occurred on 25 June 2015.

The routine 3-monthly inspections of IRJs were found to have been carried out. On 20 November 2015, an inspection of the IRJs on the east and west tracks at the 67 km mark was carried out with no defects identified.

Rail height

The height of new rail was 185.7 mm. On tangent track, a minimum height wear limit of 166 mm was applied.

On the Newman west track for a distance of up to 10 m either side of the IRJ at the 67.0 km mark, rail height was measured at about 183 mm. The rail height on each side of those higher rail sections was about 11 mm lower at 172 mm (Figure 9).

Figure 9: Graph showing the variation in rail height near the IRJ at the 67 km mark

Source: Rail Technology International

Broken rails (west track)

An inspection of records listing broken rail defects for the period 1 January and 3 December 2015 showed three rail breaks on the west track between the 66 km and 68 km marks. On 2 November 2015, an aluminothermic weld repair was carried out on the west rail at the 67.27 km mark. Two other aluminothermic weld repairs to the east rail were made at the 67 km mark on 25 July 2015 and a second break on 24 September 2015 at the 67.01 km mark was recorded.

Rail grinding

Rail grinding is carried out to re-profile the rail head and in the process, removing small rolling contact fatigue (RCF) cracks. This grinding reduces the likelihood of RCF cracks developing into transverse defects deeper into the rail head, which can result in a rail break (usually under a loaded train).

A review of BHPB records showed that rail grinding on the west track through the location of the derailment was in accordance with the specification at the following locations:

- 2 October 2015 – 65.5 to 74.8 km

- 20 August 2015 – 64.6 to 67 km

- 26 May 2015 – 65.8 to 73.2 km.

Ultrasonic tests - west track

Ultrasonic rail testing involves passing sound waves into the rail and monitoring the echo returned by the sound waves reflecting off internal and external surfaces (reflectors). Defects within the rail (Figure 10) create reflectors which return unique echo patterns depending on their type, location and size. Examination of the echo patterns allows an operator to deduce the existence, type and size of suspected rail defects.

Figure 10: Rail defect types

Source: Australian Rail Track Corporation Non-Destructive Testing of Rail (for Internal & Surface Defects) ETE-01-03.

Ultrasonic inspections of rail on the BHPB network were carried out at intervals based on rail haulage rates measured in million gross tonnes (MGT). The minimum rail inspection frequency is 5 MGT and was conducted through the contracted services of Rail Technology International (RTI) using a road-rail vehicle.

Limitations of ultrasonic testing

Ultrasonic rail testing relies on detecting an echo from sound waves reflecting off internal and external surfaces (reflectors). Detection of defects using this method requires skilled operators and the ability of the equipment to detect a clear echo reliably is dependent on a number of factors, such as:

- Grease, dirt or uneven rail surfaces (due to shelling, pitting and/or worn rail profiles) can reduce the quality of the interface between the ultrasonic probe wheels and the rail surface.

- The geometry of the defect may reflect the sound waves away from the probe wheels thereby attenuating the echo signal received by the ultrasonic test equipment.

- Low reflectivity of the defect surfaces may result in greater attenuation of the reflected sound waves than those of a surface with high reflectivity.

- Equipment calibration.

- Compressive forces within the rail (due to high rail temperature) may push the surfaces of a defect together such that the sound waves are transmitted through the defect rather than reflecting off the surfaces of the defect.

A review of one of BHPB’s internal investigation reports[10] for this occurrence noted that ‘small transverse defects are easier to detect when the track is cooler’. The review also noted that:

…previous ultrasonic inspections of track were only carried out at night, where the advantage of ultrasonic testing, when the rail is cool and with reduced thermal stress, allowed for greater detection of transverse defects. The night inspections were carried out on the Mt Newman railway, however this practice ceased many years ago for non-technical reasons...

This review recommended that consideration should be given to reintroducing the practice of night inspections.

Assessment of data

The last ultrasonic test carried out on 29 November 2015, four days before the derailment, found a severity 1 transverse defect at the 67.280 km mark on the west rail. The defect was located in the rail head at an aluminothermic weld joint. The defect was removed 2 days later with replacement rail aluminothermically welded in-situ.

Between 1 January and 28 November 2015, two other severity 1 defects (Table 1) were detected on the west track between the 66 km and 68 km marks on the Port Hedland to Yandi line. These defects were also removed. In this period, one severity 3 defect was found on the west rail at the 68.197 km mark, about 1.2 km from the location of the derailment.

__________

- Ore cars with higher trips were allowed to operate with asset protection and condition monitoring systems where the wheel condition permitted (i.e. where flange, and tread condition remained within prescribed tolerances).

- Wheel Impact Load Detector (WILD) is a safety system used to identify defective wheels by measuring the dynamic impact on railway track.

- The fusion welding of rail ends by electric arc heating and contact under high pressure.

- A welding process in which an aluminothermic reaction takes place within a crucible and the resultant metal flows into a mould enclosing the rail ends that are to be joined.

- Transverse defects are progressive fractures that spread across the width of the rail.

- Not all under-foot defects are detectable by ultrasonic or visible inspections.

- A rail joint manufactured and assembled such that the joined rails are electrically insulated from each other.

- Track Condition Index (TCI) is a single unit of measurement of track condition in any one 100 m segment of track. This value is calculated through the application of weightings to returned geometrical measurements. Geometrical parameter weightings have been defined based on their influence to track performance. (BHP Billiton Track Engineering CoP v2.1)

- NTS Ultrasonics Pty Ltd REVIEW: DERAILMENT INVESTIGATION REPORT: WALLA 67 KM. 3/12/2015.

Broken rail section

Following derailment of train M03544, BHP Billiton (BHPB) commissioned a series of investigations into the incident. The investigations concluded that the derailment most likely occurred due to a broken rail on the west track near the 67 km location. The cause of the broken rail was attributed to an undetected transverse defect that likely resulted from rolling contact fatigue (RCF). The defect was found in a 1.1 m length of rail retrieved from the derailment site (Figure 11).

Figure 11: Broken rail with fatigue cracks

Source: BHP Billiton

The provider of ultrasonic rail testing for the occurrence track, Rail Technology International (RTI), disagreed with BHPB’s finding as they concluded that that 1.1 m length of rail was ‘highly unlikely’ to have been in service at the time of the derailment. This conclusion was based on a number of factors such as weld finish, appearance/condition of the fracture surface, and size and number of defects. The ATSB conducted a review of the evidence and concluded:

- The weld finish in the 1.1 m section was consistent with welds in the vicinity of the 67 km mark.

- The oxidised appearance/condition of the fracture surfaces resulted from water being used onsite to wash the surface in preparation for detailed photography.

- Specialist metallurgical examination of the section concluded that the fracture surfaces were only lightly corroded. That was consistent with a relatively recent failure.

Additionally, the rail height on the west track was about 172 mm, except for a 20 m section of 183 mm height rail in the vicinity of the 67 km mark. The height of the recovered length of rail was consistent with the rail height west track near the 67 km mark.

Finally, there were four welds at about 5 m intervals in each rail of the west track near the 67 km mark. The welds closest to the insulated rail joint (IRJ) joined rail of similar height, whereas the outer welds joined rail of different heights. The weld in the recovered section of rail indicated joints of similar height rail.

Considering all of the above, the ATSB concluded that the 1.1m broken section of rail was probably in service immediately prior to the derailment and not from a previous rail failure.

While the RTI report suggested the more likely cause of the derailment ‘would be a failure of wheel, bogie or axle’, no specific evidence was provided to support that conclusion. Furthermore, there was no evidence of rolling stock failure found onsite (both rolling stock and prior track scarring) that contributed to the derailment and the general disposition of the derailed cars was consistent with failure of the track rather than rolling components of the train. However, there were contact marks on the wheels consistent with track discontinuity. It was considered most likely the witness marks on the wheel occurred as the west rail suffered multiple fractures near the 67 km mark under the passage of ore cars.

The ATSB considered the potential influence of the higher than normal forces on the rail recorded by the wheel impact load detector during the passage of train M03544, as well as the preceding train. The magnitude of the impact forces, were not considered sufficient to initiate derailment but may have contributed to rapid failure of a weakened section of rail.

Specialist analysis of the recovered rail found that the fracture initiated at two fatigue‑related transverse defects (Figure 12), with the remainder of the fracture occurring relatively quickly due to overload associated with passage of train M03544.

Figure 12: Large fatigue crack in rail section

Source: BHP Billiton

Rail stress-free (neutral) temperature

The area surrounding the 67 km point had been subjected to several maintenance activities, including a few days before the derailment. The records showed that a length of rail was installed at about the 67.150 km mark when the rail temperature was about 65 °C. That, along with other activities, would most likely increase the stress-free temperature of the track in that area. An increase in stress-free temperature had the effect of shifting the effective operating envelope of track structure.

According to BHPB, the stress-free track temperature was 40 °C. This specification was based on midpoint average minimum and maximum temperatures expected for that time of year (summer). If the stress-free temperature of rail is too low, there is a higher risk of track buckling in warmer weather. Conversely, if the stress-free temperature is too high, there is a higher risk of rail breaks in cooler weather. Given the time of the derailment (about 0530) and higher stress-free temperature, it was most likely that the track temperature was lower than the stress-free temperature. This meant that the rail was most likely in a state of tensile force (that is stretched), excluding track buckle as a cause for the derailment.

Rail at a temperature 20 °C below stress-free temperature is unlikely to cause a catastrophic failure in itself. The dynamic nature of a passing loaded train (high load, high cycle) could expose a weakness in the track or rail structure under tensile stress. This weakness could lead to a rail break. A rail break allows the rail to separate, and the separation depends on how much below stress-free temperature the rail temperature is. The greater the difference between these temperatures, the greater will be the separation.

The wider the gap on the rail running surface, the more passing wheels will pound the opening. Successive wheel impacts lead to further deformation, increased running surface discontinuity, and increased risk of derailment.

The most recent rail breaks (25 July and 24 September 2015) had a recorded gap of 60 mm and 90 mm respectively, a significant discontinuity of the running surface increasing the risk of derailment.

The BHPB investigation report noted that broken rails in the recent past had not led to derailment. The following from a report authored by the Institute of Railway Technology at Monash University for BHPB is also relevant.

Straight breaks or vertical fractures, for example from a single isolated transverse defect or a defective weld, generally present a very low risk of derailment, and to the author’s knowledge, none have occurred despite a considerable increase in the incidence of broken rails since 2012.

Therefore, derailment risk is greatly increased with incorrectly stressed rail. In the event of a broken rail, the gap will widen increasing the running surface discontinuity.

Track condition

The ATSB reviewed the BHPB-commissioned specialist reports that it used to determine the findings of its investigation.

One of the BHBP reports, in discussing the scoping of track locations for re-railing, revealed that the section between 60 km and 73 km locations of the west track was in poor condition, noting that:

… extensive areas where the rail asset integrity was less than adequate (ballast condition, head height, numerous aluminothermic welds, rolling contact fatigue (RCF) developing into TD due to grinding debt[11] etc.).

According to BHPB, delays and changing priorities resulted in the section of track between 66 km and 69.5 km being deferred from the re-rail plans until April 2016.

The BHPB report concluded:

The general condition of the rail was such that failures occurred frequently and further rail failure could be expected unless the asset integrity is improved. Rail failure may lead to derailment if circumstances reinforce each other resulting in cascading failures culminating in derailment. At the time of derailment the following rail related factors resulted in a high risk of rail failure:

- the existence of a grinding debt resulting in an increased risk that RCF cracks become TD’s;

- extensive areas where the rail head height is of concern; and

- a high number of aluminothermic welds.

The rail condition, high axle loads combined with wheel impact loads exacerbate the rate of rail failure. Some “wheel impact breeding hot spots” initiate the development of high impact wheels which spread defects through the weakened rail network.

The rail failure KPI set during the FY 16 budgeting process is one failure per week. This KPI benchmarks poorly against heavy haul rail industry. The setting of a KPI at this level indicates a lack of knowledge of what best in class should or could be. A benchmarking review performed in September / October 2015 has identified this as something to be addressed and consequently the KPI is (as of February 2016) being reconsidered to drive improvements.

There is history of over reliance on aluminothermic welding with knowledge that such welds will generate more failures.

The finding and conclusions of BHPB’s reports indicated that the general condition of the rail on the west track in the vicinity of the rail fracture was poor and contributed to relatively frequent failures in that region.

Ultrasonic testing

The 1.1 m section of fractured rail found onsite (Figure 11) contained one large and two small areas of fatigue cracking. Initially, BHPB assessed that the rail defect that led to the fracture was not detected during RTI’s last ultrasonic rail inspection on 29 November 2015.

However, after analysis of the RTI data, BHPB concluded that a large transverse defect was detectable but not identified by the individual operator conducting the inspection. That conclusion was disputed by RTI on the basis that BHPB had misinterpreted the ultrasonic signature of a weld in that location as being that of a transverse defect.

The ATSB reviewed RTI ultrasonic recordings from the 29 November inspection (RTI replayed the data via proprietary software and captured the information in a video file). The ATSB viewed the video file 50 m on either side of the IRJ at the 67 km mark (see Figure 8). Approaching the area of interest (in the direction of travel in Figure 8), ultrasonic signatures were evident about 5 m from the IRJ. No other significant signatures were identified.

The ATSB also reviewed previous ultrasonic recordings for the same location on 15 and 25 November and compared them with those of 29 November. No ultrasonic indication was recorded on 15 November and a small indication was recorded on 25 November (Figure 13). Ultrasonic indications from the nearby IRJ at the 67 km mark where also compared for those three dates and found to be largely consistent. The consistency of the IRJ ultrasonic signatures supported a conclusion that the signals for the rail position shown in Figure 13 were indicative of a developing rail defect.

Figure 13: Ultrasonic indications

(left – 15 November, centre – 25 November, right – 29 November)

Source: Rail Technology International

Specialist reports commissioned by BHPB, and authored by NTS Ultrasonics and Aben Technical Services, also assessed the variations in signatures at that location across the three dates in November 2015. Those reports both supported a conclusion that the signals were indicative of a developing transverse defect, with the NTS Ultrasonics report stating that:

…From these data traces it seems that the transverse defect has grown very quickly between 25/11 and 29/11.

Based on signal variations, the NTS report also stated that the accuracy of some of the data across these three runs may have been affected by ultrasonic probe positioning and calibration issues. Neither of these reports discussed differences between ultrasonic signatures associated with welds compared to transverse rail defects. The Aben report did however discuss interpretation of the 29 November 2015 signature as follows:

The indication as seen on 29-11-2015 run bears a marked resemblance to the end of rail head indications as seen in the IRJs... A large vertical TD [transverse defect] is geometrically very similar to the rail end in an IRJ, and the lack of any indications from areas below the head of the rail once again points to a head only discontinuity.

Based on a review of the ultrasonic data in the area of the rail failure, and all of the available specialist reviews, the ATSB concluded that the developing defect transverse defect was probably detectable.

Finally, the NTS Ultrasonics report, in discussing factors that can adversely affect the identification of defects, stated:

… Rail flaw detection is one of those occupations where the operator must be fully alert all the time, not unlike air traffic control and other high attention occupations. In some circumstances operators can be distracted from monitoring the system, and sometimes overloaded with data from the system. As highlighted in the Aben report, when a lot of data is coming in (from many closely spaced welds, for example), the operator may feel under pressure to move through the data quickly and perhaps not giving each data set the attention it warrants. Misclassification is a possibility, and the successful performance of these systems must depend on the experience of the operators.

Crossing train control area boundaries requires radio contact with track controllers, and this may be distracting. Apparently the 67 km mark is close to such a boundary.

Ultrasonic testing of the tracks was conducted during hours most likely when the rail temperature was higher than the stress‑free temperature of 40 °C. Rails at a higher temperature are subjected to compressive forces. These compressive forces may mask certain rail defects, such as transverse cracks. It was noted by staff onsite that the grind markings were on the rail head. Data from the most recent RTI inspection did not appear to be affected by the grind markings on the rail head.

The RTI report (in response to the initial BHPB report) commented that since the start of 2015, RTI had reported 247 transverse defects in parent rail and 131 transverse defects in welds.

The specialist report authored by NTS Ultrasonics stated:

The advantages of testing rail at night when the track is cooler (lower thermal stresses) was established many years ago on the Mt Newman line, but the practice was dropped for non-technical reasons.

Consideration should be given to reintroducing this practice.

In its recommendations, the BHPB derailment investigation report stated that:

BHPBIO should obtain clarification from RTI on how the following factors affect detection of rail defects including details on mitigating controls that address the variability of these factors:

- Calibration of equipment;

- Rail stresses;

- Probe contact;

- Gain settings;

- Rail crown conditions including wear and foreign contamination like oils;

- Noise filtering;

- Rail profile; and

- Track geometry.

The following from the NTS report is relevant to the limitations of ultrasonic testing:

To a large extent, the basic principles of ultrasonic rail flaw detection were established by the mid-1980s and have not changed much since. The use of digital technology has made data presentations, data storage, and instrument control better, but the underlying ultrasonic technology has barely changed in over 30 years. Other inspection technologies such as eddy current and ACFM have seen recent development for rail, but are not complete inspection technologies. Perhaps a review of the current “state of the art” in rail flaw detection could recommend useful combinations of technology to be considered for future inspection contracts as well as setting useful directions for research and development. It is possible that rail flaw detection will develop in useful ways if the end users of the services are more pro-active in asking for reasonable improvements and helping provide the resources to make it happen.

__________

From the evidence available, the following findings are made with respect to the derailment of the loaded BHP Billiton iron ore train M03544 near Walla, Western Australia on 4 December 2015.

These findings should not be read as apportioning blame or liability to any particular organisation or individual.

Safety issues, or system problems, are highlighted in bold to emphasise their importance. A safety issue is an event or condition that increases safety risk and (a) can reasonably be regarded as having the potential to adversely affect the safety of future operations, and (b) is a characteristic of an organisation or a system, rather than a characteristic of a specific individual, or characteristic of an operating environment at a specific point in time.

Contributing factors

- Train M03544 most likely derailed as a result of passing over a fractured section of rail.

- The fracture of the rail probably resulted from rapid growth of undetected fatigue‑related transverse defect(s) in the west rail near the 67 km mark during the passage of train M03544.

- The fatigue‑related transverse defect was probably detectable, but not identified during ultrasonic testing of the rail.

- The general condition of the rail on the west track, in the vicinity of the rail fracture, contributed to relatively frequent failures in that area. [Safety issue]

Other factors that increased risk

- Ultrasonic testing was undertaken in the heat of the day when rail temperatures were high, potentially masking defects due to compressive forces in the rail.

The safety issue identified during this investigation is listed in the Findings and Safety issues and actions sections of this report. The Australian Transport Safety Bureau (ATSB) expects that all safety issues identified by the investigation should be addressed by the relevant organisation(s). In addressing those issues, the ATSB prefers to encourage relevant organisation(s) to proactively initiate safety action, rather than to issue formal safety recommendations or safety advisory notices.

All of the directly involved parties were provided with a draft report and invited to provide submissions. As part of that process, each organisation was asked to communicate what safety actions, if any, they had carried out or were planning to carry out in relation to each safety issue relevant to their organisation.

The initial public version of these safety issues and actions are repeated separately on the ATSB website to facilitate monitoring by interested parties. Where relevant the safety issues and actions will be updated on the ATSB website as information comes to hand.

Rail condition

The general condition of the rail on the west track, in the vicinity of the rail fracture, contributed to relatively frequent failures in that area.

Safety Issue: RO-2015-023-SI-01

Sources of information

The sources of information during the investigation included the:

- BHP Billiton ICAM investigation report (rev 4)

- ALS Global Examination of failed rail section ex – Newman Main Line (91HM0474 Rev 1)

- ABEN Technical Services W15-0109 - Derailment Review - Rail Testing Aspects

- Rail Technology International 67km Derailment Response

- NTS Ultrasonics Review: Derailment Investigation Report

- Institute of Railway Technology Review of Investigation Reports (Monash/RT/2016/1140)

- International Heavy Haul Association 2015 Managing the Transition from Rail Wear to Rolling Contact Fatigue in a Heavy Haul Environment

- BHP Billiton Standard - Code of Practice Track Engineering - Number: 0002664 Version: 2.1

Submissions

Under Part 4, Division 2 (Investigation Reports), Section 26 of the Transport Safety Investigation Act 2003 (the Act), the Australian Transport Safety Bureau (ATSB) may provide a draft report, on a confidential basis, to any person whom the ATSB considers appropriate. Section 26 (1) (a) of the Act allows a person receiving a draft report to make submissions to the ATSB about the draft report.

A draft of this report was provided to BHP Billiton, Office of the National Rail Safety Regulator, and Rail Technology International.

Submissions were received from BHP Billiton and the Office of the National Rail Safety Regulator. The submissions were reviewed and where considered appropriate, the text of the report was amended accordingly.

Purpose of safety investigationsThe objective of a safety investigation is to enhance transport safety. This is done through:

It is not a function of the ATSB to apportion blame or provide a means for determining liability. At the same time, an investigation report must include factual material of sufficient weight to support the analysis and findings. At all times the ATSB endeavours to balance the use of material that could imply adverse comment with the need to properly explain what happened, and why, in a fair and unbiased manner. The ATSB does not investigate for the purpose of taking administrative, regulatory or criminal action. TerminologyAn explanation of terminology used in ATSB investigation reports is available here. This includes terms such as occurrence, contributing factor, other factor that increased risk, and safety issue. Publishing informationReleased in accordance with section 25 of the Transport Safety Investigation Act 2003 Published by: Australian Transport Safety Bureau © Commonwealth of Australia 2018

Ownership of intellectual property rights in this publication Unless otherwise noted, copyright (and any other intellectual property rights, if any) in this report publication is owned by the Commonwealth of Australia. Creative Commons licence With the exception of the Coat of Arms, ATSB logo, and photos and graphics in which a third party holds copyright, this publication is licensed under a Creative Commons Attribution 3.0 Australia licence. Creative Commons Attribution 3.0 Australia Licence is a standard form licence agreement that allows you to copy, distribute, transmit and adapt this publication provided that you attribute the work. The ATSB’s preference is that you attribute this publication (and any material sourced from it) using the following wording: Source: Australian Transport Safety Bureau Copyright in material obtained from other agencies, private individuals or organisations, belongs to those agencies, individuals or organisations. Where you wish to use their material, you will need to contact them directly. |