Safety summary

What happened

At about 1050[1] on 31 October 2015, Genesee & Wyoming Australia train 6DA2 derailed near Marla, South Australia. The derailment resulted from a package bearing failure on wagon FQWY 12-F. The wagon and three other container wagons were significantly damaged and there was significant damage to the track. There were no injuries.

What the ATSB found

The ATSB found that the journal and bearing on wagon FQWY 12-F had seized and lost interference fit. The loss of interference fit generated high levels of frictional heating between the bearing and the axle journal, and the subsequent torsional shearing failure of the axle (commonly referred as a ‘screwed journal’). The axle failure caused the axle and wheels to stop rotating, resulting in one wheel skidding along the railhead for approximately 50 km, before derailing.

On the balance of the available evidence, the ATSB concluded that a loss of lubrication was the most likely contributor to the bearing breakdown and seizure. Evidence also suggested the breakdown developed relatively rapidly, given the absence of a positive fault detection from two bearing acoustic monitoring systems (RailBAM) passed on the previous day of the occurrence.

Safety message

Bearing failures leading to derailment continue to occur within the Australian rail network. Rail operators must continue to be vigilant and ensure axle bearings are correctly installed, maintained, and monitored throughout their life.

Screwed journal

__________

At about 0900[2] on 30 October 2015, Genesee & Wyoming Australia (GWA) train 6DA2 carrying containerised freight departed Berrimah (near Darwin, Northern Territory) bound for Adelaide Freight Terminal (AFT) (near Adelaide, South Australia). At Alice Springs, train 6DA2 stopped to off load and pick up containerised freight before continuing onto AFT the following day.

Prior to leaving Alice Springs, a full mechanical examination, including train brake test, and brake pipe leakage test (FX1) was completed. No issues were detected, and train 6DA2 departed at about 0555 bound for AFT in Adelaide.

Shortly after crossing the Northern Territory border into South Australia (at about the 1,001 km point[3] - Figure 1), a bearing journal separated from the lead axle of the trailing bogie 2 on the fourth-to-last wagon of the train. It is likely that as the right bogie side-frame collapsed, the additional load on the left caused the axle to tilt and jam the right wheel onto the wagon body. This subsequently caused the left side wheel to ‘lock up’ and slide along the railhead (flat spot shown in Figure 3).

At the time, train 6DA2 was travelling through a section of track with a speed restriction of 50 km/h. The crew however, did not notice any consequences related to the failed bearing journal.

The train continued travelling south for about 35 km and cleared a speed restriction at about the 965 km point. The driver then started to increase speed to the normal operating track speed of 110 km/h. The wheelset/bogie side-frame continued to slide, resulting in minor markings on some rail fastenings, scarring on the head of the rail, damage to a cattle grid and starting several small spot fires.

Figure 1: Map of locality of the occurrence, the journal, and the derailment site

Figure 1 illustrates the locality of the derailment in relation to Alice Springs. The callout box on the left illustrates where the journal was located. The callout box on the right illustrates where the train derailed. Source: Natmap annotated by the ATSB

Approximately 50 km after the journal separated from the axle, the wheelset climbed across the railhead and derailed (951 km point). The wheelset continued for an additional 11 km before the bogie completely dislodged from under the wagon body, resulting in significant damage to three following wagons and track (940 km point).

At about the same time (1153), the driver noticed a subtle pull on the train. The driver checked the gauges, looked in the locomotive rear-view mirrors, and noticed a small amount of dust at the rear of the train. The driver asked the observer (co-driver) if he could see any dust from his side of the train. Initially the observer reported nothing. However, shortly after the observer noticed some dust on his side of the train. The driver applied the brake, resulting in the train decelerating.

In the last few hundred meters of travel, after the brake application, the driver noted a further drop in brake pipe pressure, indicating a physical disruption in the brake system before the train came to a stand.

Figure 2 shows an illustration of the sequence of events.

Figure 2: Sequence of event against track speed

Figure 2 illustrates the position of key events leading up the derailment against the permitted track speeds (speed restrictions). The illustration is not scale. Source: ASTB

The observer was tasked to go and inspect the rear of the train. As he walked towards the rear of the train, he found that the rear bogie on wagon FQWY 12-F (fourth-to-last wagon) had dislodged from the platform and was located alongside the track approximately 500m from the rear of the train (Figure 3). The remaining three 2-pack wagons remained upright with all bogies derailed, with some completely removed from their associated platforms. Several containers from the derailed wagons had broken away from the train and landed in the rail corridor. The derailment had also caused significant damage to 12 km of track resulting in mostly cracked sleepers and damage to rail fasteners. There was no spillage of any dangerous goods.

Figure 3: Photo of derailment site with the screwed journal axle in the foreground

Figure 3 shows the derailment site. The axle in the foreground is the lead axle from the trailing bogie (refer to figure 2) of wagon FQWY12-F which was found to have the screwed journal. The callout box depicts the flat wheel due to the wheel jamming as a result of the screwed journal. Also pictured is the mated bearing on the journal. Obscured from view on the axle is the screwed journal. Source GWA

__________

Train information

Train 6DA2 was an intermodal freight service operated by Genesee & Wyoming Australia (GWA) between Darwin and Adelaide. On departure from Darwin, NT, the train consisted of three locomotives (GWU 6 leading, ALF 18 trailing and ALF 21 off line) hauling 29 wagons for a total length of 1,179 m and trailing mass of 2,016 t.

The 26th wagon behind the locomotives was FQWY 12-F, a 2-pack platform wagon (Figure 4) used to transport containers. The FQWY class wagons are rated at 43 t (tare), 184 t (gross) and operate at a maximum speed of 115 km/h.[4] The wagons ride on 70 t AAR three piece bogies. The wagons are owned and maintained by GWA.

Figure 4: Schematic of FQWY 12-F

The R2 axle bearing on platform two bogie D failed. The wheelset was the leading axle on bogie D in the direction of travel. Source: Genesee Wyoming Australia Pty Ltd and annotated by ATSB

The failed axle was the lead axle on the rear bogie (Bogie D). At the time of the derailment the train was traveling at approximately 82 km/h. A 6.45 t container was loaded on platform A and an 11.8 t container loaded on platform B.

Train crew

The train crew consisted of four drivers working the train in pairs on a rotating 8-hour relay shift. Two crew members would work the train while the remaining pair of drivers rested in the accommodation provided in the attached crew van.

Train handling

Analysis of the train data logger and found that train handling was consistent with the speed restrictions of the track.

Drugs and alcohol

Due to the remoteness of the site and time limitations, neither driver was tested for the presence of alcohol or drugs.

Track information

The track infrastructure was leased and maintained by GWA, with the movement of rail traffic managed from GWA’s Transport Control Centre located at Dry Creek (South Australia).

The standard gauge (1,435 mm) track was a mixture of 47 kg/m and 80 lb/yd rail fastened to concrete sleepers by resilient clips. The track formation comprised sand/clay based soil, topped with a capping layer and overlaid with ballast to a nominal design depth of 250 mm. The track bed supported prestressed concrete sleepers spaced at 667 mm centres.

Sections of track with 80 lb/yd rail had a speed restriction for freight trains of 50 km/h. Sections of track with a 47 kg/m had a limit of 110 km/h.

The rail size at the Point of Derailment (PoD) (approximately 951 km point) consisted of 47 kg/m. The rail size at the location where the journal separated (approximately 1,001 km point) was 80 lb/yd.

Wagon Maintenance

As per GWA Wagon Maintenance Instruction (WMI 01-01), all wagon maintenance was based on time or kilometres travelled. The inspection frequency was also dependant on the type of wagon. However, where a defect was detected either by a train examination or by condition monitoring equipment such as RailBAM, the wagon was scheduled for repairs.

For the FQWY class wagons, the maintenance instruction specified a time-based inspection period of five years from its last inspection date.[5] However, the maintenance instruction also stated the frequency of the examination is subject to duty cycle, and condition monitoring equipment available on the operational route.

The failed axle (numbered 45043), with bearing numbers 040321 and 00686 (left and right respectively), was installed under wagon FQWY 12-F in August 2014. The wagon’s most recent maintenance was completed in July 2015. While three wheelsets were changed on platform A, the wheelsets on platform B (including axle 45043) were within specification and returned to service.

Package bearings

The bearing that failed on wagon FQWY 12-F was a SKF 70t E-class package unit bearing. The mated bearing was a Timken 70t E-class package unit bearing.

Packaged bearings consist of two tapered roller bearing assemblies (rollers, cage and inner ring/raceway, sometimes referred to as a cone) mounted inside a common outer ring/raceway (sometimes referred to as the cup). During assembly, a spacer ring of specific width is placed between the two cones to ensure the correct pre-loading for the bearing assemblies. Outside each bearing assembly is a seal wear ring, over which the grease seal is positioned. When installed on the wheel-set, a backing ring is mounted on the in-board side of the axle journal and an end-cap is bolted onto the outer end of the bearing journal (Figure 5).

The manufacturers’ specification for the grease amount for the Timken bearing was approximately 400 grams (14 oz) and the SKF bearing at just over 450 grams (16 oz).

Figure 5: General arrangement of package bearing

The package bearing is assembled then press fitted onto the axle journal. As the bearing is completely sealed prior to being fitted there is no requirement to add any lubrication post fitting. Source: RISSB, coloured and annotated by ATSB

Maintenance

The Australian Rail Industry Safety and Standards Board (RISSB) is responsible for the development and management of rail industry standards, rules, codes of practice and guidelines, all of which have national application. Australian Standard AS7516 Railway Rolling Stock - Axle Bearings – Part 2: Freight Rolling Stock covers the maintenance of the various types of bearings used in the Australian railway industry, including package type bearings.

Section 3.2 of AS7516-2 states that package bearings should be of the No Field Lubrication (NFL) type, and that all components of the package assembly shall have the design capability of completing a service life without maintenance attention. Replacement of package bearing lubrication should occur not more than 8 years after assembly.

Bearing history

The failed bearing (00686) was manufactured in May 2005, with the first recorded fitting to an axle by Downer EDI occurring in February 2006. The bearing was subsequently inspected/remanufactured and re-fitted to different axles at irregular intervals until August 2014 when it was fitted to the axle subsequently used on FQWY 12-F. The fitting of the mated bearing was done concurrently.

Since its installation in August 2014, the wheel set (45043) has travelled over an estimated 335,000 km in a 13-month period.

During it’s in service life of over 10 years it is estimated that bearing would have travelled between 2,500,000 km and 3,000,000 km.

Bearing fatigue life

Bearing fatigue life is commonly referred to as the L10[6] life. This is a calculated prediction of bearing life in terms of stress cycles (related to revolutions) based on 10% of bearings showing the first evidence of fatigue. The first evidence of fatigue is defined as when one of the rolling contact surfaces develops a spall measuring approximately 6 square mm (refer to section - Contributors to bearing failure, Rolling surface damage).

Based on formulae contained in ISO281:2007, Roller bearings – Dynamic load ratings and rating life, the basic rating life of a roller bearing, in millions of revolutions (L10) is inversely proportional to the 10/3 power of the load applied. For example, if the bearing load is halved, the fatigue life will increase by a factor of about 10. Conversely, doubling the bearing load will result in a decrease in fatigue life by a factor of about 10.

The bearings used on the FQWY class wagon were ‘Class E’ tapered roller bearings and are commonly used on railway rolling stock throughout Australia. A typical fatigue life specification for a Class E bearing indicates that its L10 life is equivalent to about 2,600,000 km (wheel diameter of about 840 mm) when operating at maximum bearing load for 50% of its time. Tapered roller bearings are designed to support both radial loads (weight of wagon and other vertical forces) and thrust loads (cornering and other lateral forces). When considering bearing load, manufacturers sometimes provide both radial and thrust load ratings for their bearings. The rating is usually specified at a specific rotational speed of 500 revolutions per minute, which equates to about 80 km/h for wagons with a wheel diameter of 840 mm.

Records show that the bearing had been in service for just over ten years and travelled an estimated 3,000,000 km. However, its exact loading over this time could not be determined, as there are no accurate records kept over the life of the bearing.

When applying the L10 considered loading of 50% for the bearing, the bearing is determined to be in the 90% range of failure (developing rolling surface defects) at 10 years. However, when applying a more practical loading profile for FQWY 12-F of typically running to Darwin loaded and returning empty, the loading percentage is significantly reduced. As a result, the fatigue life for bearings operating from Adelaide to Darwin is likely to be much higher than the L10 life specified in the manufacturer’s documentation. Consequently, the fatigue life would likely increase beyond the 10 years/3,000,000 km travelled at the 50% loading.

It is considered typical of railway bearings, that their serviceable life is usually limited by factors other than simple bearing fatigue. While actual kilometres and loadings are not known for this bearing, it was considered unlikely that the bearing on wagon FQWY 12-F failed due to simple fatigue alone.

Bearing examination

GWA forwarded the recovered failed bearing components to Bureau Veritas for metallurgical examination. The Bureau Veritas also examined the mated bearing (opposite end of axle).

It was evident that a bearing on the wagon had failed and completely seized, causing the inner raceway to loose interference fit and spin on the axle journal. This generated and transferred sufficient heat into the journal to reduce its strength, make it ‘plastic’, and caused it to separate from the axle (an event commonly referred to as a screwed journal).

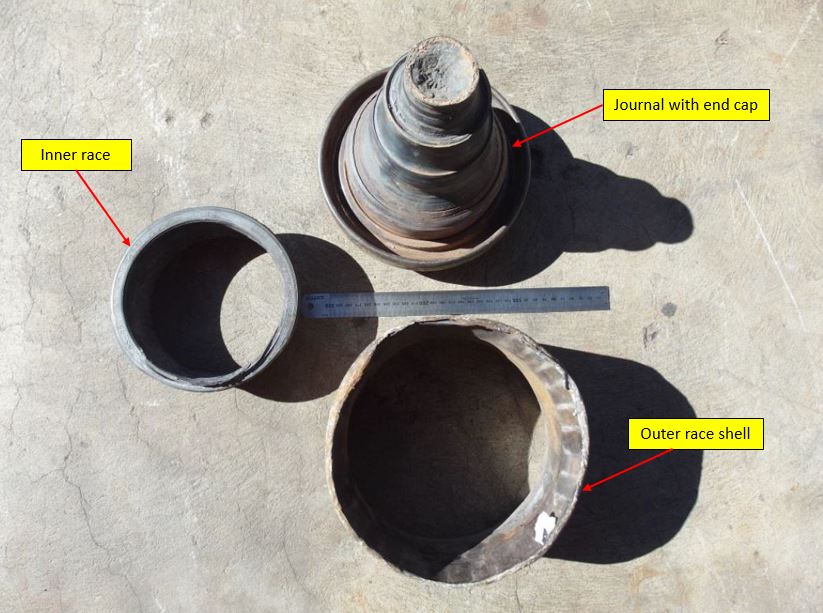

Post-derailment inspections were unable to locate any rolling elements or seals. The remaining components (Figure 6) consisted of the outer race shell (cup), a single inner race (cone) and the screwed off end of the axle with the bolted end cap.

Figure 6: Recovered components of failed bearing

The remaining components of the failed bearing above were retrieved from site and was inspected and analysed by the Bureau Veritas Source: Genesee & Wyoming Australia and annotated by ATSB.

Examination of the inner race of the failed bearing found stamping from SKF (Sweden). There was evidence of significant heat damage and significant amount of mill scale (flaky surface, often found on hot rolled steel), suggesting a long period of exposure to high temperatures.

Examination of the outer race was unable to identify any stamping. There was significant mechanical and thermal damage to the surfaces, as well as a build-up of mill scale. Marks found around the race suggested post incident false brinelling[7]. An area of spalling was also noted on the rolling surface of the outer race, though this was partially obscured by post failure surface damage.

There was no evidence of residual lubrication or grease on any of the bearing components.

The Bureau Veritas concluded that the most likely contributor to the bearing failure was a lubrication supply issue. This may have been due to either seal failure or inadequate lubrication at the time of assembly of the bearing package. The seal was not recovered so could not be examined to determine its condition and the possibility that it may have failed prior to the derailment.

Partner bearing

The examination also included the partner bearing from the opposite end of the axle, and found it to be in good order. The amount of grease in the mated bearing was only a light application and contained small amounts of sand. The Bureau Veritas estimated conservatively that there was less than 200 grams of grease in the bearing as supplied (approximately 50% when compared to a newly packaged bearing). However, Downer EDI considered the grease levels to be relatively typical for in-service bearings. This was noted by ATSB investigators, during site visit to the Downer EDI workshops, in Port Augusta (February 2016). A collection of in service bearings, when examined, showed about 50% grease content, when compared to newly packaged bearings. There was no evidence of false brinelling or surface damage on the mated bearing.

Both grease seals were present and intact, though post derailment observations show the end seals of the bearing appearing to be ‘wet’ which indicates that some grease may have been liberated during the derailment. It could not be determined how much grease was installed in the bearing. However, it is likely that some grease from the mated bearing was lost as a result of the derailment.

Figure 7: Mated bearing with signs of grease leaking from end caps

Figure 7 shows that the end seals of the bearing appearing to be ‘wet’ which indicates that some grease may have been liberated during the derailment. This also indicates that there may have been a failure in the bearing seal. Source: Genesee & Wyoming Australia

Predictive monitoring

The RailBAM system is a predictive bearing condition monitoring system (Appendix A) used throughout Australia. The system listens for unique acoustic signatures known to be associated with specific defect conditions in bearings, such as rolling surface faults and looseness / fretting faults.

Rather than identifying imminent failure of a component, RailBAM facilitates the potential identification of defects as they develop. This is achieved through analysis of acoustic signature data and the identification of data trends from multiple passes. Rail vehicle operators may use this information for ongoing monitoring and/or scheduling for servicing and repairs.

RailBAM has proved reliable at detecting the acoustic signatures of developing surface faults such as spalling damage. However, it has proved more difficult to detect an acoustic signature that would suggest loss of lubrication.[8]

RailBAM data for 6DA2

A wayside RailBAM site is located near Berrimah. RailBAM data from that site for 6DA2 was examined. The data showed a single acoustic signature associated with the subsequently failed bearing (leading axle on the trailing bogie on wagon FQWY12-F). The signature was consistent with low-level rolling surface irregularity.

Since RailBAM is a predictive system for identifying data trends, it generally requires a series of consistent repeated detections to determine if the noise is erroneous or a true identification of a bearing fault. Consequently, a single low-level acoustic signature is considered more likely a false positive rather than a developing fault.

No alert or alarm condition was identified against wagon FQWY 12-F by the RailBAM system at Berrimah.

Similarly, there were no alarms or alert trends recorded against wagon FQWY 12-F for previous journeys through the condition monitoring stations at Berrimah, Port Germien (South Australia) or Northgate (South Australia).

It should be noted that GWA advised they no longer use RailBAM to track bearing looseness or fretting faults as it is considered to be unreliable.

Contributors to bearing failure

The failure process resulted in complete destruction of the bearing and much of the evidence that may have identified the cause of the failure. Consequently, the investigation looked at the common failure modes for railway bearings to identify the most probable cause.

The main contributors to rolling-stock axle bearing failure are:

- Rolling surface damage

Rolling surface damage (spalling) is a contact-fatigue mechanism and can result from lubrication supply or effectiveness issues, contaminants carried in the lubricant, or indentations due to impact loading. Spalling is where the bearing surfaces or rollers begin to break up, or flake. The material that has broken away then moves around inside the bearing, causing further damage to the rolling surfaces.

- Component failure

A common cause of bearing failure is failure of the cage. The cage maintains the roller bearings in the correct spacing and alignment. If the cage loses its ability to correctly align and guide the rollers, the resultant forces can lead to rapid deterioration and break-up of the cage. Under these conditions, broken cage material may become jammed in the rolling surfaces, with bearing seizure the likely result. Note that cage failure can also occur as a consequence of other failure modes, including rolling surface damage or lubrication failure.

- Lack of (or faulty) lubrication

The purpose of a lubricant is to reduce friction by separating the rolling surfaces at the points of high-pressure contact. Contamination of the lubricant by foreign materials such as metal flakes, filings and dirt reduces the effectiveness of the lubricant, and often causes accelerated wear of the components. A lack (or loss) of lubricant, through failed seals or poor maintenance, can result in elevated levels of frictional heating at the contact surfaces – leading to the eventual overheating of the bearing. This can cause components within the bearing to fail, such as the roller bearing cage.

Examination of the failed bearing found evidence of rolling surface damage. However, the absence of repeat acoustic signatures from the various RailBAM sites suggests the bearing condition on FQWY 12-F had deteriorated relatively quickly.

Failure of the cage (component failure) may have contributed to the failure of the bearing, however the cage could not be located so this mode of failure could not be confirmed.

Considering the available evidence and in the absence of any evidence to the contrary, a loss of lubrication was considered the most likely contributor to the failure and seizure of the bearing, resulting in a catastrophic failure with minimal (if any) warning signs.

__________

- All weights and lengths for FQWY wagons refer to the total weight and/or length of the two platforms combined.

- With a tolerance of 6 months before or after the due date

- L10 is the life expectancy of a bearing in kilometres before the likelihood of rolling surface defects increases.

- Brinelling is the imprint on a hard surface, such as raceways of a bearing, which can lead to spalling. False brinelling is indent damage caused by reasons other than fretting as is normally associated with this type of damage.

- Southern,C., Rennison,D & Kopke,U (2004). RailBAM - An advanced bearing acoustic monitor – initial operational results RTSA – Conference on Railway Engineering,

Bearing remanufacturing process

Package bearings used within Australia require minimal in service maintenance, generally limited to visual inspections. When a package bearing is identified as requiring service, either through visual detection of a fault or through predictive monitoring systems such as RailBAM, the axle with the two package bearings is sent for bearing replacement.

The bearing packages are removed from the axle, stripped and cleaned before being sent for inspection. All components of the stripped package bearing are kept together (cup, cone, bearings, and spacers) excluding the seal, which is disposed of. The inspection and remanufacturing area then receives the components.

At the commencement of each shift the remanufacturing staff verify the operation of all equipment, including the grease applicator. The grease injection system has seven settings for delivering a pre-determined amount of grease for the various areas of a packaged bearing, such as the rollers/cage. The operator checks a test application using calibrated scales to ensure the correct amount of grease is delivered for each setting. The results are recorded on a daily test sheet.

An initial examination of the bearing components is carried out prior to a detailed review. If any damage or corrosion is detected the bearing is scrapped. The more detailed inspection examines the bearing for any marks or damage to the rolling surfaces. The internal and external diameters are checked and the bearing endplay (movement) tested before the bearing is reassembled and packed with grease.

The grease injection system delivers a pre-determined amount of grease to the various areas of the bearing. The operator selects the appropriate grease delivering option for each component and manufacturer of the bearing (Rollers, Spacer ring). The selections are clearly marked and numbered one through seven, each number showing the amount of grease delivered in ounces and grams.

After each phase, the bearing package is visually inspected to confirm the correct amount of grease has been applied. Once the bearing has been fully greased the final seal is pressed onto the package and the bearing history sheet updated.

Whilst the most likely contributor for the bearing failure was a lack of lubrication and the observation suggesting approximately 50% lack of grease in the partner bearing, the ATSB could not substantiate any failure in EDI Downers remanufacturing. In general, the axle bearings on FQWY 12-F were maintained in accordance with GWA and rail industry standards.

From the evidence available, the following findings are made with respect to the derailment of train 6DA2 near Marla on bearing failure on 31 October 2015. These findings should not be read as apportioning blame or liability to any particular organisation or individual.

Safety issues, or system problems, are highlighted in bold to emphasise their importance. A safety issue is an event or condition that increases safety risk and (a) can reasonably be regarded as having the potential to adversely affect the safety of future operations, and (b) is a characteristic of an organisation or a system, rather than a characteristic of a specific individual, or characteristic of an operating environment at a specific point in time.

Contributing factors

- Freight train 6DA2 derailed due to a failed axle on wagon FQWY 12F.

- The axle failed when the bearing seized, generating enough heat for the bearing journal to go ‘plastic’ and separate from the axle, a condition referred to as a ‘screwed journal’.

Other findings

- A loss of lubrication most likely contributed to the relatively quick deterioration and seizure of the bearing, resulting in a catastrophic failure of the bearing with minimal (if any) warning signs.

- The axle bearings on FQWY 12-F were maintained in accordance with GWA and rail industry standards.

- It was considered unlikely that the bearing on wagon FQWY 12F failed due to simple fatigue alone.

Sources of information

The sources of information during the investigation included the:

- The Australian Rail Track Corporation (ARTC)

- Railway Industry Safety and Standards Board (RISSB)

- Genesee & Wyoming Australia (GWA)

References

- ATSB Transport Safety Report, Rail Occurrence Investigation RO-2008-010

- ATSB Transport Safety Report, Rail Occurrence Investigation RO-2010-011

- SKF, Product Information 401, Bearing failures and their causes 1994

- Bureau Veritas, Metallurgical report, 11 December 2015

- Genesee & Wyoming Australia Wagon Maintenance Instruction WMI 01-01

Submissions

Under Part 4, Division 2 (Investigation Reports), Section 26 of the Transport Safety Investigation Act 2003 (the Act), the Australian Transport Safety Bureau (ATSB) may provide a draft report, on a confidential basis, to any person whom the ATSB considers appropriate. Section 26 (1) (a) of the Act allows a person receiving a draft report to make submissions to the ATSB about the draft report.

A draft of this report was provided to Genesee Wyoming Australia, the drivers of train 6DA2, EDI Downer, and the Office of the National Rail Safety Regulator.

Submissions were received from Genesee Wyoming Australia, a driver of train 6DA2, EDI Downer, and the Office of the National Rail Safety Regulator. The submissions were reviewed and where considered appropriate, the text of the report was amended accordingly.

Appendix A – Condition monitoring systems

Hot-box detectors

Hotbox detectors are a reactive method of condition monitoring. They usually detect the infrared signature of bearing components and alarm if the temperature exceeds a predetermined setting. However, there are a number of variables that can affect their performance on a mixed freight/passenger rail corridor. These variables include but are not limited to:

- train loading

- train speed

- weather conditions.

Consequently, hotbox detection is usually used as a ‘last line of defence’ to protect railway infrastructure assets critical to production processes such as coal and ore carrying railways.

Due to the potentially unreliable performance of hotbox detectors under mixed freight/passenger conditions, more effort has been directed towards predictive condition monitoring of railway rolling stock travelling on the interstate main lines.

Bearing Acoustic Monitoring

Bearing Acoustic Monitoring (BAM) is a predictive condition monitoring system that ‘listens’ to the acoustic signature of bearings and can detect faults as they develop. It is the primary method for detecting potential bearing faults on rolling-stock travelling on the interstate main line. Recorded data from each train is stored in a database allowing evaluation, trending, and maintenance scheduling of rolling-stock based on predicted bearing condition.

BAM uses sensitive acoustic arrays to record the sounds emanating from wheels and bearings passing through the monitoring site. The recordings are processed for the sound characteristics that are unique to specific types of bearing faults. BAM is best at detecting faults on rolling surfaces such as the inner and outer raceways, and rollers in rolling-stock bearings. BAM can also detect looseness or fretting faults and ‘noisy’ wheels (flanging and wheel flats).

BAM systems are usually installed and maintained by infrastructure managers. However, the data is made available to rolling stock operators through a web interface. The BAM database categorises potential bearing faults in the form of levels of severity (1, 2, and 3 with level 1 being the most critical). The database allows operators to analyse bearing fault history and trends in order to plan their preventative maintenance strategies.

As for any monitoring system, there are some limitations. For example, BAM is a system that ‘listens’ for bearing noises, and under some conditions, other noises (rubbing equipment, tread defects or flanging wheels) may affect the results. However, being a predictive condition monitoring system, multiple passes of potentially defective bearings allows true fault trends to be clearly identified and actioned before a defect reaches a critical level.

It is evident that predictive condition monitoring and a pro-active approach by train operators has become an integral tool for managing the risk of bearing defects on freight rolling stock, especially in relation to rolling surface defects. For example, the ARTC BAM site at Nectar Brook showed a reduction in the number of level 1 rolling surface faults from about 0.5% in 2002 to about 0.05% in 2010. However, Level 1 looseness or fretting (LF1) faults have not experienced the same improvement. In 2002, LF1 faults were about 1.2%, reducing down to about 0.6% in 2005 before rising back to 1.0% in 2009 and 2010.

On-board condition monitoring

In the past, condition monitoring of rolling-stock has been the realm of trackside equipment (Hotbox, RailBAM, etc.), usually fixed at a specific geographical location. While predictive systems may provide a broader level of protection, reactive systems are limited to protection of equipment and infrastructure in the immediate vicinity.

The next evolution of condition monitoring would be one that continuously monitored each wagon for developing faults (predictive) and immediately communicated any critical conditions to the train drivers (reactive). This type of system is referred to as an on-board condition monitoring system. While various limitations (functional and economic) have prevented these systems being widely used on railway freight operations in the past, recent technological developments have now made the concept more attractive. However, at the time of this incident, only limited developmental work had been started within Australia.

Purpose of safety investigationsThe objective of a safety investigation is to enhance transport safety. This is done through:

It is not a function of the ATSB to apportion blame or provide a means for determining liability. At the same time, an investigation report must include factual material of sufficient weight to support the analysis and findings. At all times the ATSB endeavours to balance the use of material that could imply adverse comment with the need to properly explain what happened, and why, in a fair and unbiased manner. The ATSB does not investigate for the purpose of taking administrative, regulatory or criminal action. TerminologyAn explanation of terminology used in ATSB investigation reports is available here. This includes terms such as occurrence, contributing factor, other factor that increased risk, and safety issue. Publishing informationReleased in accordance with section 25 of the Transport Safety Investigation Act 2003 Published by: Australian Transport Safety Bureau © Commonwealth of Australia 2017

Ownership of intellectual property rights in this publication Unless otherwise noted, copyright (and any other intellectual property rights, if any) in this report publication is owned by the Commonwealth of Australia. Creative Commons licence With the exception of the Coat of Arms, ATSB logo, and photos and graphics in which a third party holds copyright, this publication is licensed under a Creative Commons Attribution 3.0 Australia licence. Creative Commons Attribution 3.0 Australia Licence is a standard form licence agreement that allows you to copy, distribute, transmit and adapt this publication provided that you attribute the work. The ATSB’s preference is that you attribute this publication (and any material sourced from it) using the following wording: Source: Australian Transport Safety Bureau Copyright in material obtained from other agencies, private individuals or organisations, belongs to those agencies, individuals or organisations. Where you wish to use their material, you will need to contact them directly. |

Whether or not the ATSB identifies safety issues in the course of an investigation, relevant organisations may proactively initiate safety action in order to reduce their safety risk. The ATSB has been advised of the following proactive safety action in response to this occurrence.

Genesee Wyoming Australia

GWA have investigated and implemented the following short-term actions:

- Investigate imposing a life limit on bearings, either by years or by overhauled cycles (i.e. bearings greater than 8 years old and/or greater than 8 rebuilds to be scraped when the wheelsets is next machined).

- Investigate the use of polymer cage in all new bearings.

- Investigate recent development relating to bearing seals.

- Develop a process for examining bearings and for providing important feedback from the bearing maintainer on the analysis of bearings that have been identified as faulty by wagon condition monitoring systems.

- Review the preferred bearing supplier/maintainers unit overhaul quality processes and subject bearing to random inspections at various stages of their lifecycles.

- Consider utilising alternative bearing suppliers.

- Conduct a gap analysis between Pacific Nationals wheel bearing standards used by Downer EDI and the RISSB Wheel Bearing Standards, December 2015.

- Consult with other rolling stock operators on the methods they use in an effort to increase best practice.

- Conduct an audit of the EDI Downer workshops in Port Augusta.

- Complete a quality examination of bearings recently overhauled by Downer EDI.

GWA have investigated and implemented the following long-term actions:

- Consider the installation of Hotbox detectors on the Northgate BP-Berrimah corridor.

- Investigate the use of ‘on wagon’ bearing condition monitoring.