Safety summary

What happened

In the early morning of 7 March 2020, a maintenance work group was undertaking work between Thorneside Station and Birkdale Station on the Cleveland rail corridor in Brisbane, Queensland. Queensland Rail (QR) was the rail infrastructure manager of the rail corridor. The work involved replacing a defective section of track.

A planned closure was due to commence at 0218, during which the replacement of the rail track would be done under a track occupancy authority (TOA) with in-field protection. Prior to the planned closure, the work group conducted preparatory work under a TOA which did not require in-field protection.

Soon after 0100, an excavator operator was directed by a member of the work group (the recipient) to access the running tracks. However, at that time the rail corridor was open for normal rail traffic activity.

At about 0108, a suburban passenger train was involved in a near collision with the excavator near Thorneside. With the train speed greater than 90 km/h, the driver of the suburban train noticed the excavator on the running tracks and applied the emergency brake. At about the same time, the excavator operator identified the oncoming train and initiated emergency measures, removing the machine from the running tracks as the train passed at a speed of about 61 km/h.

The train stopped 75 m past the incident site. The network control officer (NCO) subsequently approved the driver to continue after being informed that the excavator was clear of the tracks. However, the excavator was still within the (3 m) danger zone, less than 1 m from the nearest rail.

The excavator operator was directed by the work group supervisor to remove the excavator. As the excavator operator was about to do so, at 0137, there was a second near collision when another suburban passenger train passed through the incident site at 60 km/h (after applying emergency braking). The excavator operator had to jump clear down an embankment to escape danger as the train passed.

What the ATSB found

The network pre-start briefing for the work group was conducted at the Cannon Hill depot before the workers departed for the worksite. However, the ATSB found that the lead protection officer (PO), assistant PO and the excavator operator were not included in the briefing, which denied them and the work group of essential safety information applicable to their roles and responsibilities.

There were also limitations with a number of subsequent communications processes after the work group arrived at the worksite. The lead PO was not informed of or aware that the excavator had arrived at the worksite. Consequently, when the NCO notified the PO of a track fault indication (associated with the on-tracking of the excavator) and asked if there was any equipment on-track, the PO had an incomplete mental model of the work group and advised the NCO that there was no equipment on-track at that time.

In addition, without gaining the necessary permission, the recipient had directed the operator of the excavator to on-track under the incorrect assumption the planned closure had commenced, and the worksite was protected by a TOA with in-field protection and train activity on the rail corridor had ceased. The recipient had misinterpreted the situation due to misinterpreting an instruction from the team leader and a combination of other situational factors.

Following the first near collision, communications between the emergency hotline contact (in the network control centre) and the lead PO, and between the lead PO and the work group supervisor, did not clarify that, although the excavator was off the track, it was still in the danger zone. The supervisor also directed the excavator operator to remove the excavator from the danger zone without gaining the necessary authority from the NCO or confirming that rail traffic had been stopped. This omission contributed to the second near collision.

Some of these communication problems were associated with personnel not using appropriate rail terminology when conducting safety-critical communications. The ATSB found that the Queensland Network Rules and Procedures did not provide sufficient guidance for rail safety workers to ensure they used standardised rail-specific terminology when communicating safety‑critical information.

Network pre-start briefings are a critical control in place to manage the risk of collisions between rail traffic and workers and machinery, and Queensland Rail had undertaken significant work in recent years to improve these processes. However, the ATSB found that the design of the first-line assurance activities and the limited conduct of second-line and third-line assurance activities provided only limited assurance that the worksite protection aspects of the briefings were being conducted effectively.

What has been done as a result

Soon after the incident, on 10 March 2020, Queensland Rail (QR) issued a critical safety alert (CSA) directed to protection officers (POs) and their supervisors and managers, and all infrastructure workers and their supervisors and managers. The alert outlined a number of key actions, including that all workers must attend a prestart briefing prior to entering the rail corridor (and the briefing must include the PO giving the rail safety component of the briefing). In addition, all workers could not access the danger zone without being given permission by their supervisor, and the supervisor could not allow workers to enter the danger zone until they had received advice from the PO that required protocols were in place.

As a result of the incident, QR subsequently entered an enforceable voluntary undertaking (EVU) with the Office of the National Rail Safety Regulator (ONRSR). As part of the EVU, QR committed to 13 initiatives to improving planning processes for track access, the safeworking control framework, capability of safety-critical workers and effectiveness of safety assurance and performance. As of 1 November 2023, 12 of the 13 initiatives had been externally verified as closed and QR advised that the final initiative was on track for completion by 31 December 2023.

In addition to the EVU initiatives, QR has proactively introduced safety actions in response to this incident by:

- redeveloping the protection officer training package

- delivering communication training for all rail corridor workers

- implementing a first-line assurance activity focused on the effective use of rail-specific terminology and a range of other technical and non-technical skills when communicating safety-critical information

- developing targeted first and second-line assurance activities to measure the effectiveness of the improved pre-start briefing process.

Safety message

Substandard network pre-start briefings and communication irregularities have been identified as contributors to railway accidents in Australia and abroad. However, with this knowledge, rail infrastructure managers and track workers are still experiencing problems with the application of effective safety-critical communication, and assurance that network pre-start briefings are conducted in accordance with procedures designed to manage safety risks. It is essential that all workers attend a network pre-start briefing prior to entering the rail corridor and fully understand the worksite protection that is in place for their activities. It is also vital that workers use standardised railway terminology when conducting safety-critical communications to minimise the potential for misunderstanding.

In a safety-critical work environment that fundamentally relies on procedural controls, it is vital that first-line assurance activities are appropriately designed to provide an accurate account of key work practices being assessed, and that sufficient higher level assurance activities are conducted to provide confidence in the results of the first-line assurance activities. The absence of accurate information limits the ability of an organisation to learn and continuously improve safety.

The occurrence

Overview

In the early morning of 7 March 2020, a maintenance work group was undertaking work between Thorneside Station and Birkdale Station on the Cleveland rail corridor in Brisbane, Queensland. Queensland Rail (QR) was the rail infrastructure manager of the rail corridor.

At about 0108 local time, a QR suburban passenger train, with passengers on board, almost collided with an excavator while it travelled along the rail tracks near Thorneside. While personnel were attempting to remove the excavator from the danger zone[1] of the rail corridor, a second near collision occurred involving another suburban passenger train.

Pre-work arrangements

The maintenance work group was tasked with replacing a defective section of railway track located between Thorneside and Birkdale stations. The following personnel were involved in the maintenance work:

- a QR depot supervisor

- a QR work group team leader (acting as the supervisor of the maintenance task under the guidance of the depot supervisor)

- 4 QR maintenance personnel, including the operator of a front-end loader and one worker performing the role of the recipient.[2]

In addition, the following contractors were involved in the track maintenance work:

- a welder

- a labourer

- 2 protection officers[3] (POs), (lead PO and an assistant PO)

- an excavator operator.

The ‘planned closure’[4] was scheduled to start at 0218 on 7 March and involved the use of a track occupancy authority[5] (TOA) with in-field protection (sometimes known as a ‘protected TOA’).

At 2100 on 6 March 2020, the QR personnel, the labourer and the welder commenced their shift at the Cannon Hill depot in Brisbane. The supervisor and team leader discussed planning for the task and potential contingencies if there were delays. The team leader and members of the work group, who signed on at the depot, then prepared the work truck with the necessary tools for the worksite, while the supervisor planned the work schedule from their office.

At about 2130, the team leader gathered the work group members who were present for a network pre-start briefing[6] at the depot. The brief discussed the nature of the work task as well as the hazards and controls that would be applied. The work group was told that it was likely that preparation work at the worksite would occur prior to the planned closure using a TOA without in‑field protection (sometimes known as an ‘unprotected TOA’). The POs and the excavator operator were not involved in the pre-start briefing at the Cannon Hill depot.

After completing the network pre-start briefing, the team leader and members of the work group signed the relevant section of the Network Pre-Start Briefing form (MD-15-43), verifying they were present and that they understood the requirements of the briefing.

At about 2200, the work group members at the Cannon Hill depot travelled to the worksite at Thorneside, stopping briefly to purchase refreshments. At the same time, the POs arrived at the Cannon Hill depot to meet with the supervisor to discuss work arrangements, in particular the protection at the worksite. The supervisor communicated the potential for performing preparation work prior to the planned closure under the safeguard of a TOA without in-field protection,[7] which would require protection arrangements for the period of the preparation work in addition to those published in the train notice[8] for the planned track closure. Following the discussion between the supervisor and the POs, the team leader was provided with an overview of the proposed arrangements.

The lead PO contacted the network control officer (NCO) to discuss the proposed arrangements. The NCO checked their train diagram[9] and confirmed with the PO that there was availability to instate a TOA without in-field protection for the preparation work that allowed workers access to the track between trains for brief periods. As the NCO was nearing the end of their shift, they stated that they would inform the incoming NCO of the proposed work on track arrangement and the agreed protection for that work.

At about 2215, the team leader departed the Cannon Hill depot and travelled to the worksite at Thorneside. Shortly after, the POs and the supervisor also left the depot and travelled to the worksite in separate vehicles.

Preparation work

At about 2235, the team leader and members of the Cannon Hill work group arrived at the work group entrance gate to the rail corridor at Thorneside (located at the 23.645 km mark),[10] which was about 340 m east of the actual worksite (Figure 1). The team leader directed the recipient and the front-end loader operator to travel to Thorneside Station to collect the front-end loader that was required at the worksite.

At about 2245, the POs arrived at the work group entrance gate. The team leader and lead PO discussed the required protection arrangements for the preparation work, and the PO then briefed the work group members who were present about these arrangements.[11] The supervisor had not arrived at the worksite at this time. The PO explained that work in the danger zone would be for short periods, which would occur between train activity under the safeguard of a TOA without in‑field protection. The PO then contacted the NCO and the paperwork relevant to this TOA was completed. At about that time, the supervisor arrived at the entrance gate.

The TOA without in-field protection was issued to the lead PO at 2252 and it was suspended 10 minutes later at 2302. In that period, the PO, supervisor, and team leader entered the rail corridor through the entrance gate and walked to the worksite to evaluate the track defect and work requirements. While the TOA was suspended, they stood clear of the danger zone and 2 suburban passenger trains passed the site.

The TOA was reinstated at 2322 and suspended at 2333. In that period, at the request of the team leader, 4 members of the work group walked from the entrance gate to the worksite to perform preparation work, while the team leader returned to the entrance gate to measure a length of rail that had been placed in the rail corridor days earlier. The length of rail was to be cut to size in preparation for the replacement of the track defect at the worksite. The lead PO and supervisor remained at the worksite.

At 2325, the excavator operator, who was required for the planned closure (but not the preparation work) contacted the supervisor to obtain information about the location of the worksite. The supervisor directed the excavator operator to travel to the work group entrance gate and wait for instructions.

The excavator operator arrived at the entrance gate at about 2335, where they were met by the team leader and members of the work group. The excavator operator requested a worksite briefing but was told to wait until further notice as the excavator was not required until the planned closure and after the preparation work was finished. After completing several tasks, the team leader discussed the work arrangements with the excavator operator and requested the operator sign the network pre-start briefing form, which was signed. The excavator operator was not provided a formal network pre-start briefing and was not provided with any briefing about worksite protection arrangements by the lead PO. The PO was not informed or aware that an excavator had arrived at the worksite.

The team leader advised the excavator operator not to unload the excavator from the truck as passage through the work group entrance gate was not suitable for the excavator (as cement troughing was blocking its path). Consequently, the team leader directed the excavator operator to travel to another entrance gate further east, located at the 24.117 km mark (Figure 1), and wait for further instructions. In addition, the team leader advised the excavator operator to complete all documentation pertaining to the excavator accessing the rail corridor in readiness for the planned closure. The excavator operator then travelled to the next entrance gate, unloaded the excavator from the truck, and prepared the relevant paperwork.

Figure 1: Places of interest relevant to the worksite and the entrance gates

The image shows Thorneside Station, the worksite, entrance gates for the work group and the excavator and near collision location.

Source: Google earth, annotated by the ATSB

The TOA was reinstated at 0022 (on 7 March) and suspended at 0033. In that period, members of the work group walked from the worksite back to the work group entrance gate as preparation work at the worksite had been completed. The only remaining work activity prior to the planned closure was to load the bucket of the front-end loader with tools and equipment in readiness for transportation from the entrance gate to the worksite. At this time, the front-end loader was in the rail corridor near the entrance gate, but on the opposite side of the rail tracks to that of the entrance gate, work truck and work group.

While the TOA was suspended, the recipient, who had assisted in preparing the worksite, travelled by car to meet with the excavator operator at the other (excavator) entrance gate. The recipient and the excavator operator completed the necessary documentation in relation to the height limiter[12] on the excavator. The recipient advised the excavator operator that they required additional information on the state of the planned closure before they could grant access to the rail corridor. The recipient then travelled back to the work group entrance gate.

At 0051, as the recipient arrived back at the work group entrance gate, the TOA was reinstated. The team leader communicated an instruction to the work group ‘it’s on’, by which they meant the TOA had been reinstated and tools and equipment could be transferred from the work truck into the front-end loader.

On-tracking of the excavator

The recipient heard the team leader’s instruction and witnessed the work group loading the front‑end loader and assisted with the loading. Soon after, the operator of the front-end loader gave the recipient the height limiter key, which was a requirement before machinery could perform work on track under live overhead equipment. In interview, the recipient stated that the combination of these events gave them the impression that the planned closure was now in force.

In the belief that the planned closure was now active, the recipient contacted the electric control officer[13] (ECO), in accordance with procedures, to inform them about the location of the worksite and the number of machines (excavator and front-end loader) at the worksite.

Without seeking or receiving confirmation from the relevant personnel (team leader, supervisor, or PO) on the state of work and protection arrangements, the recipient travelled back to meet with the excavator operator at the (excavator) entrance gate. The recipient informed the excavator operator that the planned closure was active and that they could on-track the excavator, and the recipient unlocked the access gate.

Meanwhile, at the work group entrance gate, the team leader instructed all the workers there to stand down. At 0102, the lead PO, who was unaware that the recipient had directed the excavator operator to on-track the excavator, suspended the TOA and advised the NCO that preparation work was complete and there would be no further work until the planned closure at 0218. On receipt of the suspend code,[14] the NCO suspended the block,[15] and then set the signal path for a suburban passenger train (1898) to travel from Thorneside to Cleveland (eastward).

Shortly after the TOA for the preparation work was suspended, the excavator was driven into the rail corridor and, with the aid of its boom arm and bucket, the operator pulled the upper frame of the excavator onto the track and placed its guide wheels on the running tracks. The recipient advised the excavator operator to proceed towards Thorneside where they would be met. The recipient then returned to the work group entrance gate by car.

Track fault

At 0106:55, while train 1898 was stationary at Thorneside Station, the signalling system detected a track section between Thorneside and Birkdale was occupied. This detection momentarily generated a ‘failed track’ message on the monitor of the NCO’s workstation. At 0107:01 the track recovered, and at 0107:19[16] the passenger train departed the station.

As the indication of the failed track was in the vicinity of the work group, it prompted the NCO to contact the lead PO and question the whereabouts of the work group and machinery in relation to the running line. The NCO asked the PO if anyone in the work group had ‘gone on or near the track’, to which the PO replied ‘no’. The NCO further stated, ‘I’ve had a track fail and recover, which is most unusual, within the extremities of your TOA … which seems a bit odd’.

The lead PO ended the conversation by reassuring the NCO that everyone in the work group was off the track. At this time, the PO was unaware of the excavator’s movements and that it had on‑tracked as directed by the recipient.

First near collision

As train 1898 passed the work group entrance gate, it accelerated to above 90 km/h along the 100 km/h section of track (Figure 2). The recipient, who only minutes earlier directed the excavator operator to on-track the excavator, had just arrived back at the work group entrance gate as the train passed. On seeing the train, the recipient sounded the car horn in an attempt to warn the excavator operator of the approaching train, and they then proceeded in the car back towards the excavator.

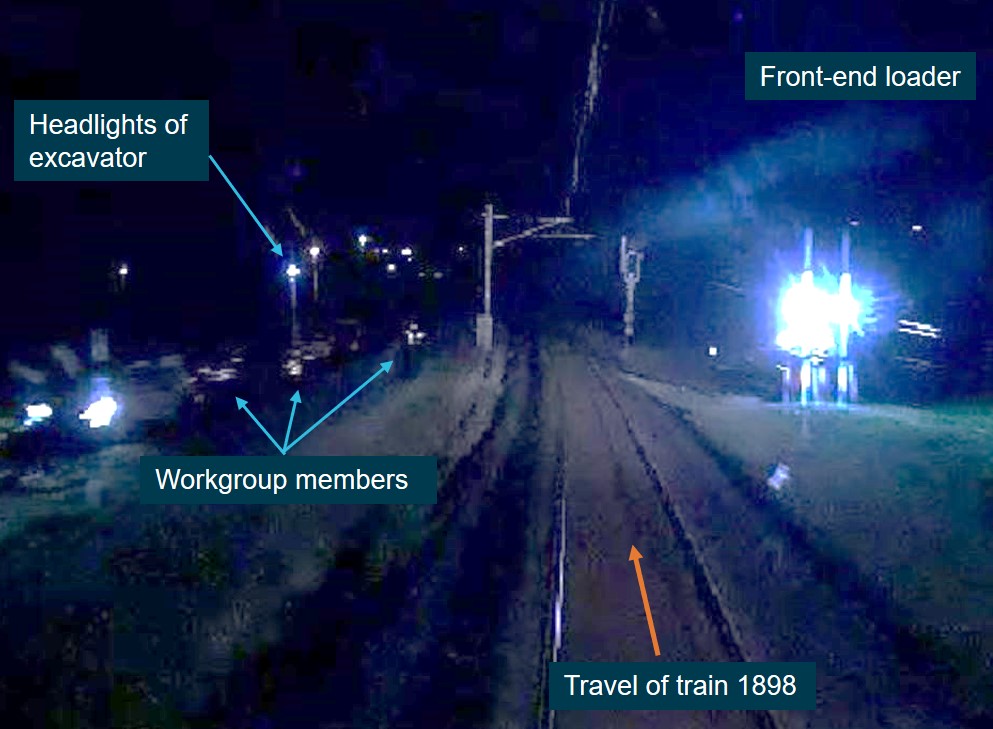

Figure 2: View from train 1898 showing the work group, front-end loader, and headlights of the excavator in the distance

The image is from the front-of-train camera in train 1898. The time is 0108:22, about 19 seconds prior to the near collision. In the distance, the headlights of the excavator can be seen as it travelled towards the worksite.

Source: Queensland Rail, annotated by the ATSB

The excavator operator first noticed the train’s headlights in the distance and assumed that they belonged to other machinery at the worksite. They had not heard the car horn.[17] At about the same time, the train driver observed the lights of the excavator, which they thought belonged to a car travelling on the road adjacent to the rail corridor.

As train 1898 traversed the sweeping left curve between the 2 entrance gates (Figure 1), both the train driver and the excavator operator realised that there was an imminent risk of collision. The train driver immediately applied the emergency brake, while the excavator operator swung the boom arm about 90° to the right of the excavator’s direction of travel, gouged the bucket into the ground and dragged the excavator from the rail tracks just prior to the train passing at about 61 km/h (Figure 3).

The excavator came to a stop clear of the running tracks. However, it was still in the (3 m) danger zone, less than 1 m from the nearest rail.

Figure 3: View from train 1898 showing the near collision

The images, from 1898’s front-of-train camera, are in sequential order and show the near collision between 1898 and the excavator. The rear of the excavator moved clear of the running line less than 1 second before the train’s arrival, with the train travelling at about 61 km/h.

Source: Queensland Rail, annotated by the ATSB

After stopping (about 75 m past the excavator), the driver of 1898 contacted the NCO and reported that they had almost collided with a ‘tractor or backhoe’ that was on the track.

The NCO then called the lead PO and described what the train driver had reported and made further inquiries as to whether a backhoe or loader was at the worksite. The PO advised the NCO that there was a front-end loader at the worksite, but it was well clear of the track when the train passed. The NCO then asked the PO if there was any other machinery at the worksite, to which the PO replied, ‘we only have one machine that’s it … and I’m standing right next to it’. Further discussion between the PO and NCO considered the possibility that another machine had on tracked near the worksite.

After finishing the call, the lead PO informed the depot supervisor of the situation. The supervisor stated that they had just received a call from the recipient explaining how they had directed the excavator operator to on-track as they thought that the planned closure was active and train activity had ceased.

At 0116, the lead PO contacted the QR ‘emergency hotline contact’ (located at the network control centre) and reported the near collision. As the PO was not located at the incident site, they provided details to the hotline contact as received from the supervisor, who was in direct communication with the recipient at the incident site.

The emergency hotline contact asked the lead PO ‘… has he moved away from the track’, referring to the excavator. The PO then relayed this question to the supervisor. The supervisor, after consulting with the recipient, confirmed that the excavator was away from the track, and this information was relayed on to the hotline contact. The emergency hotline contact then told the PO to leave the excavator where it was as the incident was going to be investigated. That message was then relayed to the depot supervisor, who passed it on to the recipient. During these communications, it was not made clear to any party that although the excavator was no longer on the track, it was still within the danger zone.

At the network control centre, the NCO was informed (by the emergency hotline contact) that the excavator had been moved away from the running tracks. After checking the welfare of the train driver, the NCO authorised the train’s movement from the incident site.

The depot supervisor, who had been in contact with their off-site manager regarding the incident, advised the lead PO that work was cancelled and that they were required to travel to the Cannon Hill depot for drug and alcohol testing. The depot supervisor then had another conversation with the recipient, who confirmed that the excavator was off track but may still be in the danger zone. The depot supervisor then travelled to the incident site to assess the situation (Figure 1). The PO discussed the supervisor’s directive with another member of the work group and then decided to travel to the incident site rather than returning to the Cannon Hill depot, as it was their role to oversee the protection of workers within the rail corridor.

Second near collision

When the depot supervisor arrived at the incident site, they noticed the excavator was still in the danger zone although they believed it was not within the profile of a train. The supervisor, without gaining the necessary authority from the NCO (via the PO), instructed the excavator operator to move the excavator from the danger zone. The supervisor later reported that they assumed that after a near collision, the NCO would have stopped all trains, but they did not confirm that this had occurred.

At 0136:22, the next suburban passenger train en route to Cleveland (18A0) departed Thorneside Station.

As the excavator operator moved towards the excavator, in accordance with the supervisor’s instruction, they heard a member of the work group call out ‘train on’. The excavator operator stated that, after seeing the train, they jumped down the embankment and clung to the fence as they thought the train may collide with the excavator. The train passed by the incident site at about 60 km/h.

At 0137, the driver of 18A0 contacted the NCO and reported ‘… the excavator was only just clear of the track, I thought I was going to clip it’.

After 18A0 had cleared the area, and without requesting the necessary protection, the excavator operator was again directed to remove the excavator. On this occasion, members of the work group cut a gap in the fence and the excavator was removed from the rail corridor.

After receiving advice of the second near collision, the NCO contacted the lead PO regarding the location of the excavator and its proximity to the running track. The PO advised the NCO that the excavator had been removed from the rail corridor and the work group were returning to the Cannon Hill depot for drug and alcohol testing.[18]

Context

General information of planned closure

Track defect

A track inspection in 2019 identified a track defect just east of Thorneside Station. Work to rectify the defect involved the replacement of a 5 m section of track, which involved cutting and welding. As dry weather restrictions were in place at the time, the work was deferred until the restrictions were lifted.

Train notice

On 28 February 2020, a train notice (TN20-02366) was issued that detailed the planned closure and work required to correct the track defect. The train notice included information such as:

- the date of the planned work – 7 March 2020

- the depot of the work group performing work – Cannon Hill

- the protection for the worksite – track occupancy authority (TOA) with in-field protection

- the extent of protection – main Cleveland line between signal L294 and signal TS9 Thorneside and No.2 road from signal TS11 to 656 points Thorneside (in effect from Thorneside Station east towards Birkdale Station)

- the name and contact details of the assigned protection officer (PO).

The train notice also specified the type of plant (machinery) that was permitted to work within the TOA, which consisted of a front-end loader and an excavator. In addition, it noted that rail traffic would be suspended on the main line from Birkdale to Thorneside for maintenance work between 0218 to 0440. No trains would normally be running on the line during this period.

The purpose of the train notice was to inform relevant rail personnel of the details associated with the planned work and the impact that it would have on operations and advise those who needed to plan for the proposed closure.

The train notice did not mention that preparation work would be conducted under the protection of a TOA without in-field protection, as this arrangement was initiated after the train notice was published and as a result of some staff reporting sick during the day of 6 March.

Planned closure protection

In the scheduling phase of the planned closure, a TOA with in-field protection[19] was the chosen ‘work on track authority’[20] to protect workers within the worksite. It was selected because repairing the track defect involved breaking and obstructing[21] the track. In addition, machinery and members of the work group were required to work within the danger zone. This option was determined as an efficient and safe means of protecting the work group when performing such work.

To implement the TOA with in-field protection, the PO needed to coordinate with the network control officer (NCO) so that the NCO applied blocking facilities to prevent unauthorised rail traffic entering the portion of track within the TOA limits. Additionally, the PO or their delegate was to organise in-field protection at the limits of the TOA or at a defined distance from the worksite after blocking facilities were in place.

Two POs had been allocated to the planned work, with a QR employee assigned the role of lead PO and a contractor the role of assistant PO (to organise the in-field protection).

The protection arrangements (TOA with in-field protection) for the planned closure on 7 March was appropriate for the type of work involved in removing and replacing the section of track at Thorneside.

Preparation work prior to planned closure

Reason for preparation work

On 6 March, the day prior to the planned closure, the assigned lead PO and one of the 2 assigned welders reported sick. To fill the role of the lead PO, the contractor PO who had already been assigned the role of erecting in-field protection was elevated to the role of lead PO, and another contracted worker was engaged to erect the in-field protection for the planned closure. During the afternoon, both POs were advised to meet the QR depot supervisor at the Cannon Hill depot at 2200 to discuss protection arrangements for the worksite.

A replacement welder, however, could not be found at short notice, which placed pressure on the work group completing the work within the available timeframe. To remedy this problem, there was a proposal to start preparation work earlier than the scheduled start time listed on the train notice. This involved gaining access to the rail corridor, under the safeguard of a TOA without in-field protection, to perform the preparation work prior to the planned closure. The proposal required approval from the NCO overseeing the area where the preparation work was planned.

Preparation work protection

The QR document MD-12-189 (Queensland Network Rules and Procedures or QNRP) stated the safety requirements for all persons required to access and perform activities on QR’s rail corridor. The QNRP allowed for work within the danger zone under the safeguard of a TOA without in-field protection provided there was no requirement to break or obstruct the track. The preparation work prior to the planned closure did not require the track to be broken or obstructed.

At the worksite, and prior to requesting the TOA without in-field protection, the lead PO completed a ‘corridor safety planner and assessment form,’ which determined the protection was adequate for the proposed work arrangements. The PO contacted the NCO, who issued the TOA without in‑field protection to perform the preparation work between train movements prior to the planned closure.

During the preparation work, the lead PO and the NCO were suspending and re-instating the TOA without in-field protection as required between train movements. When the TOA was active:

- The NCO was applying blocking facilities to prevent unauthorised rail traffic entry into the portion of track within the limits of the worksite.

- The lead PO’s role was to inform the work group that protection was in place and work could be performed within the danger zone. Immediately prior to suspending the TOA, the PO’s role was to ensure workers were clear of the danger zone and in a safe place.

Under the requirements for a TOA without in-field protection, a ‘lookout’[22] was required if the track speed approaching the worksite was 100 km/h and there was less than 560 m minimum sighting distance. The track speed approaching the worksite from the west was 100 km/h and the sighting distance was about 350 m. Therefore, a lookout was required as an additional safety measure at the worksite. The ATSB identified that there was no ‘lookout’ in place at the worksite while the preparation work was conducted. Although this omission did not comply with the procedure, it did not contribute to the first near collision.

Worksite and rail corridor information

The worksite was about 500 m east of Thorneside Station, on the Cleveland rail corridor branch line (Figure 1). The branch line, which commenced at Park Road Station, serviced the south‑eastern suburbs of Brisbane. Between Park Road and Manly stations there were 2 suburban unidirectional running lines with some bi-directional signalling to facilitate the passing of trains. The main line east of Manly (which included Thorneside and Birkdale stations) had a single bi-directional running line that continued through to Cleveland Station.

Steep slopes on either side of the rail corridor prevented direct access to the worksite. To reach the worksite it was necessary for the work group to enter the rail corridor through the entrance gate about 340 m further east.

The excavator could not access the rail corridor through the same entrance gate as the work group, as cement troughing blocked its entry. Therefore, it was necessary to transport the excavator to the entrance gate about 470 m further east of the entrance gate used by the work group (Figure 1).

Rail network safety

Responsibilities of track workers

The QNRP referred to track workers as ‘Competent rail safety workers whose primary duties are associated with work on or around infrastructure in the Rail Corridor.’ It stated:

The QNRP also stated:

The deport supervisor, team leader, and recipient confirmed that prior to accessing the rail corridor under a TOA, the PO would obtain access authority and then inform the work group leader, who would then instruct other workers that they could access the rail corridor.

When dealing with a track vehicle needing to access or travel within a TOA, the QNRP stated:

Work group information

The QNRP defined a work group as:

Track workers must only perform work relevant to their competency qualifications. The work group assigned the task of repairing the track defect at Thorneside were appropriately qualified to perform relevant rail safety work applicable to their area of competence.

Supervisor information

The responsibility of a work group supervisor / team leader was to ensure there were sufficient qualified workers to complete the work within the time available. This included:

- ensuring workers were appropriately qualified and competent to perform work

- ensuring the necessary tools, equipment and machinery were available for workers to complete work tasks

- having contingency plans in place if the work could not be completed in the scheduled time

- ensuring that all work group members participated in the network pre-start briefing.

At a worksite, the supervisor / team leader was required to:

- actively oversee and communicate with work group members to ensure the work was progressing as planned

- communicate with the PO to ensure protection arrangements were adequate for the protection of the work group

- assist as required at the worksite and comply with the rules and procedures relevant to QNRP.

The supervisor of the work group involved in the near collision at Thorneside gained employment with QR in July 2012 and held positions in several roles, all within track maintenance operations. At the time of the incident, their role was acting supervisor at the Cannon Hill depot. Their role at the worksite was to oversee the work and supervise the team leader and others as required.

The supervisor attended training courses and successfully gained numerous rail safety qualifications applicable to rail safety work. Training and critical safety alerts relevant to this incident included:

- Communication protocols

- Communications (QNRP)

- Safely access the rail corridor (QNRP)

- Protection officer 1 (QNRP)

- Protection officer 2 TOA (QNRP)

- Critical safety alert: Follow instructions respond to emergency

- Critical safety alert: Entering the danger zone

- Critical safety alert: Communication safety critical information

- Emergency response

- Safety critical communications

- Delivering a pre-start briefing (network)

- Rail safety awareness

- Toolbox talk: Safeworking incidents

- Plan and organise work

- Operate under track protection

- Process workplace documentation

- Follow work health and safety

- Perform lookout duties

- Awareness safeworking rules.

- Safety comes first always workshop.

On the day of the near collisions, the supervisor was overseeing the team leader, who was acting as the supervisor in charge of the work group.

The supervisor had been working day shifts until 5 March and had over 30 hours free of duty prior to signing on for the overtime shift at 2100 on 6 March. They reported that they had a nap on the afternoon of 6 March before going to work, and they did not feel fatigued at the time of the incident.

Team leader information

The team leader worked as a track maintainer with a rail contract company for about 3 years prior to gaining employment with QR in September 2016. Through internal training, the team leader acquired rail safety qualifications appropriate to their employment in network maintenance operations. They had recently undertaken the role of acting team leader. Training relevant to this incident included:

- Safely access the rail corridor (QNRP)

- Communications (QNRP)

- Protection officer 2 TOA (QNRP)

- Protection officer 1 (QNRP)

- Network lockout workshop

- Toolbox talk: First worker at emergency site

- Delivering a pre-start briefing (network)

- Toolbox talk: Post incident management guideline

- Rail safety awareness

- Follow occupational health and safety

- Process workplace documentation

- Lead a work team or group

- Perform lookout duties

- Safety comes first always workshop.

On the day of the incident, the team leader was acting as the supervisor under the guidance of the depot supervisor. The team leader delivered the network pre-start briefing at Cannon Hill depot and oversaw the work group and work activities associated with the replacement of the defective section of track.

The team leader had been working day shifts until 5 March and had over 30 hours free of duty prior to signing on for the overtime shift at 2100. They reported that they had a normal sleep on the night of 5 March and a nap on the afternoon of 6 March before going to work, and they did not feel fatigued at the time of the incident.

Protection officer information

The QNRP stated that the primary duty and responsibility of the PO was to manage the rail safety component of a worksite, and that the PO must be satisfied other work will not interfere with their primary duties. A worksite in the danger zone, or a worksite with potential to intrude into the danger zone, was required to have a PO for the duration of the work.

Specific planning duties of a PO included:

- investigating the location of the worksite

- having a detailed work plan

- completing a safety assessment to determine the work on track authority, means of protection[23] or safety measures[24] needed to protect workers

- meeting with the supervisor of the work group to discuss safety and protection arrangements

- providing worksite protection details for the worksite safety briefing

- participating in the network pre-start briefing

- contacting the NCO if necessary.

Specific duties at the worksite included:

- communicating with the NCO about the work

- ensuring the appropriate protection had been selected to protect the work group at the worksite

- identifying the safe place (for workers at the worksite)

- advising the supervisor / work group when it is safe to enter the rail corridor / danger zone

- immediately prior to suspending a TOA ensuring workers cease work and remain clear of the danger zone

- keeping records about the work on track method and protection arrangements.

The lead PO involved with the track work near Thorneside held the appropriate competencies to administer TOA protection. The PO had worked for contract providers while performing the role as a PO for more than 3 years. They had worked on the QR network many times but had not previously worked at Thorneside. On the day prior to the planned closure, the PO was advised by a QR representative that they would be the lead PO and to meet the depot supervisor at Cannon Hill depot at 2200 to discuss protection arrangements for the planned work at Thorneside.

The assistant PO was not involved in any work activity related to the preparation work. Their role was to place in-field protection after the preparation work was completed and prior to the commencement of the planned closure.

Excavator operator information

The role of the excavator operator during the planned closure was to move the replacement piece of rail from within the rail corridor to the worksite. At the worksite, they were required to remove the defective rail and fit the replacement rail into place so it could be welded. In addition, they were required to comply with rules and procedures applicable to working safely within the rail corridor.

The excavator operator was employed by an external provider as a sub-contractor providing services to QR as required. They were advised to meet a QR representative at Thorneside Station at 2230 on 6 November, who would direct them to the worksite.

The excavator operator was qualified to operate the excavator and held the relevant competencies to work within the rail corridor and danger zone. They had worked in the earthmoving industry for many years and owned an earthmoving business for 11 years. The excavator operator stated that they had worked excavators at QR worksites on multiple occasions but had not previously worked at Thorneside.

Recipient information

The role of ‘recipient’ was previously known as ‘authorised person’ until a recent name change. Although the title of the role had changed, the responsibilities remained the same.

In accordance with QR’s authorised person [recipient] facilitator guide (FG-STD-141-01), the authorised person [recipient], working in QR’s 25,000 volts electrified area, was a qualified and competent worker who:

On the day of the incident, the recipient’s role was to ensure the excavator and the front-end loader did not encroach into the electrical exclusion zone while working under the overhead line equipment at the worksite. This involved completing the relevant documentation with the machine operators and ensuring the height limiter on each machine was engaged prior to working under the overhead line equipment.

As required, the recipient was to interact with and discuss relevant information with the PO at the network pre-start briefing and at the worksite to ensure safety. The recipient could also perform other work tasks at the worksite, providing they were qualified to do so and that the work did not interfere with their primary duties and responsibilities. During the planned closure on 7 March, the recipient was also required to act as the mobile plant spotter,[25] which involved separating the excavator and front-end loader from workers at the worksite.

According to QR’s safe work method statement (SWMS) work activity MD-13-268 (Operation of height limited plant), the recipient was required to establish communication processes with machine operators and these processes had to be incorporated in the network pre-start briefing. The recipient was to observe and supervise the plant operations with full visibility and communication. To ensure this means of communication was operating as intended, they were required to confirm the radio channel and test the radios with each mobile plant operator.

On the day of the incident, the recipient (acting as the mobile plant spotter) was not in possession of a radio when they directed the excavator operator to on-track the excavator and therefore was not able to contact and alert the excavator operator of the approaching train. Channel 15 was recorded in documentation associated with the network pre-start briefing as the radio channel for machine operators to use. However, the recipient did not advise the excavator operator of which channel to use. The excavator operator had set their radio to channel 15 as this was the preferred channel when working on QR worksites (Excavator information).

The recipient had worked in rail maintenance operations as a QR employee for about 3 years. Prior to working for QR, they were employed by a railway construction contractor performing rail safety work. The recipient had gained numerous rail safety qualifications and attended operational training courses that enabled them to perform rail safety work. Training relevant to this incident included:

- Safely access the rail corridor (QNRP)

- Communications (QNRP)

- Safety comes first always workshop

- Delivering a pre-start network briefing

- Rail safety awareness

- Authorised person

- Working in the electrified territory

- Process workplace documentation

- Operate under track protection

- Follow work health and safety

- Lead a work team or group

- Perform lookout duties

- Protection officer 1 (QNRP)

- Safety comes first always workshop.

Two days prior to the incident, the recipient attended a training course that provided them with recipient qualifications. The recipient attended the course on 4 and 5 March (0800–1600), before having 31 hours free of duty and signing on for work at 2100 on 6 March. The maintenance work at Thorneside on 6–7 March was the first time they had acted in the role of recipient since gaining the qualification. They had previously performed the role of mobile plant spotter.

The recipient noted that normally they would seek confirmation from the team leader / supervisor before directing a vehicle to on-track but on this occasion, they did not do so because they thought they had understood the situation. The recipient also noted that normally all the workers accessed the rail corridor from the same location, whereas on this occasion the excavator being at a different location added some complexity. The recipient also noted that in their experience it was normal for all the workers (including the POs) to be at the same briefing whereas on this occasion the briefings were distributed.

Network pre-start briefing

The QR procedure Network Pre-Start Briefing (MD-12-87) defined a network pre-start briefing as:

The purpose of a network pre-work briefing was to provide an opportunity for the work group to gain an understanding of the work, roles, and responsibilities of individuals, and provide an environment where questions relating to the work and worksite protection could be asked and answered. The briefing, and its associated form (MD-15-43), provided the framework to ensure hazards were identified, risks were managed, and relevant personnel at the worksite had the appropriate delegation to authorise safeworking decisions.

The QNRP and QR guidelines required the nominated person[26] (in this case the team leader) to deliver the network pre-start briefing before starting work (with a briefing to be conducted for each work activity). MD-12-87 stated the nominated person was to ‘gather all workers and contractors involved in the work to be undertaken’ and explain the activities that were to be completed and how it would be undertaken. Where safeworking requirements existed (for work in the rail corridor), these were to be discussed by the PO.

The nominated person was also required to compile and complete the appropriate network pre‑start briefing form. In addition, they were required to ensure that all identified workplace health and safety and rail safety hazards associated with the work and equipment had appropriate controls in place to manage and or eliminate risk. Each worker / contractor was to have the opportunity to identify any additional hazards or controls, and each worker and contractor was required to sign the briefing form.

The PO’s role at the network pre-start briefing was to inform all workers about the protection in place at the worksite and the limits of the protection. In addition, they were to answer any questions related to protection and worksite arrangements.

Although a planned network pre-start briefing occurred at the Cannon Hill depot on 6 March 2021, delivered by the team leader, the POs and the excavator operator were not invited to the briefing and therefore did not participate in the briefing.

In interview, the recipient stated that a second network pre-start briefing occurred at the worksite prior to entering the rail corridor at Thorneside. This however was not a network pre-start briefing, but rather a briefing to advise the work group that protection was in place for the preparation work and when they could enter the rail corridor and the danger zone. The team leader confirmed that a network pre-start brief did not take place at the worksite.

To assist the investigation, the ATSB interviewed a QR subject matter expert who designed and delivered training for track workers, including POs. In relation to the planned track maintenance work at Thorneside, it was their view that all members of the work group, including the lead PO, assistant PO, and excavator operator, should have attended the network pre-start briefing at the Cannon Hill depot.

Network pre-start briefing form

After a fatal accident in Brisbane in May 2017 (see Previous network occurrences), QR revised and developed a new network pre-start briefing form (MD-15-43) specifically for staff who delivered and participated in network pre-start briefings. The form contained 6 sections that had to be completed by the nominated person before work commenced at a worksite.

The purpose of the revised network pre-start briefing form was to establish a consistent process for the delivery of a network pre-start briefing and provide a workplace focus on the identification, treatment and communication of both task and site-specific risks. QR developed a facilitator’s guide for trainers, and specific training was provided to rail safety workers who had a responsibility to deliver network pre-start briefings.

The network pre-start briefing form for the work at Thorneside on 6–7 March 2020 was completed by the team leader. Content in the form relevant to this incident included:

- Section 1 – This section briefly required details for the work group, the person in charge (in this case the team leader), and the work task (requiring a clear description, SWMSs and permits used). The completed form listed 3 SMWSs but no description of the work task was provided.

- Section 2 – This section listed several specific items and sought brief information regarding the process in place for each item.

- In response to the question ‘Is the work occurring within the Rail Corridor?’, a box was ticked for the answer ‘Yes – Protection Officer to provide a brief on the track protection requirements’.

- In response to the question ‘Is there potential for mobile plant or equipment (including vehicles) to contact people, infrastructure or other plant?’, a box was ticked for ‘Yes – detail the site plan for the separation of people and plant in your briefing…’.

- Section 3 – With regards to a site sketch, a train signal diagram for Thorneside with annotations was appended to the form. The diagram showed (in broad terms) the area of the worksite and the travel path that machinery would be using. The travel path did not explicitly indicate that different machinery would be using different access gates (as that had not been determined prior to or during the briefing). The type of machinery using the travel path was not noted.

- Section 4 – The form required a list of site-specific hazards and controls. The completed form included several hazards and controls, including:

- With regard to the hazard ‘Trains’, it listed ‘Blocks, Lookout’ as the applicable controls. There was no record in the briefing form that there would be 2 phases of work (preparation work and the planned closure work), each with different protection arrangements.

- With regard to the hazard ‘Machinery’, it listed ‘Separation, spotters’ as the applicable controls. There was no indication on the form of the types of machinery that would be used (and no mention that an excavator would be used).

- Section 5 – This section contained details of what needed to be done if something changed. It included instructions for a ‘Pause and Re-start’ in the event of workers being unprotected, there was a change to the condition / task or a new hazard / risk was identified. Details of any debrief could be included on the form (and in this case it was blank). The instructions for a pause and re-start included:

- Immediately pause the work we are doing;

- Move to a safe place, and ensure any plant or equipment is moved clear of the Danger Zone and is protected;

- Document the new hazard / risk and list the controls (using Section 4); and

- Communicate the controls to everyone onsite by conducting a ‘Restart Briefing’.

- Section 6 – This section (titled ‘Commitment to work safely’) asked workers to sign the form as acknowledgement that they had ‘taken the opportunity to ask questions and thoroughly discuss this briefing, so you can implement the controls agreed to protect you and your co-workers’. With regard to the completed form:

- The work group members who attended the briefing at the depot signed the form at the depot.

- The 2 POs and the excavator operator did not attend the briefing at the depot, however their signatures were recorded on the form. The excavator operator signed the form at the worksite at the request of the team leader. Both POs signed the form after returning to the Cannon Hill depot after work at the worksite had been cancelled as a result of the near collisions.

- The supervisor’s signature on the network pre-start briefing form was listed after the excavator operator and the lead PO. The supervisor (and another worker) confirmed they were at the briefing at the depot, but the supervisor did not sign the form at that stage.

Network communication

QNRP rule 2007 (Network communications) and QNRP procedure 2008 (Spoken and written communication) provided information for rail safety workers relevant to safeworking communication, general communication protocols and communication equipment.

Rule 2007 referred to effective communication as the ability to successfully send, receive and understand information. It stated that communication in the network must be:

- clear, brief and unambiguous, and

- relevant to the task at hand, and

- agreed as to its meaning before being acted upon.

In general, the rule provided information on the principles, fundamentals, and protocols of network communication. It noted that emergency communications needed to commence with the phrase ‘emergency, emergency, emergency’. It also detailed specifics relevant to spoken and written communication in the context of electronic transmissions. However, it did not specify the requirement to use rail industry specific terminology when communicating safety-critical information, either electronically or face-to-face.

QNRP procedure 2008 provided standard terms to be used in radio communications, including using the term ‘out’ when the transition was complete and the term ‘roger’ meaning the information had been received and understood. Like the rule however, there was no guidance to rail safety workers on the use of rail-specific terminology when communicating safety-critical information, either via electronic devices or face-to-face.

In the context of the work and near collisions at Thorneside, rail-specific terminology used in communication should have included terms such as:

- danger zone

- foul[27]

- obstruction[28]

- safe place[29]

- access[30]

- obstruction[31]

- issued

- suspended

- reinstated.

Conversely, the Rail Industry Safety and Standards Board’s (RISSB’s) Safety critical communications guideline (2018) stated in a section on fundamentals of communication:

The guideline noted such principles should be applied to all communications, safety critical or not.

The RISSB guideline also stated:

Train and excavator information

Trains 1898 and 18A0 information

Both trains (1898 and 18A0) were scheduled suburban passenger services travelling between Shorncliffe and Cleveland via Central Station. Train 1898 consisted of suburban multiple units (SMUs) 227 and 229, and 18A0 consisted of an interurban multiple unit (IMU) 166 and SMU 285. Both trains were crewed by a driver and guard and had passengers on board.

Trains 1898 and 18A0 were fitted with event recorders and front-of-train cameras. Relevant information from these recordings has been included in other sections of this report.

Excavator information

The excavator involved in the near collisions was a Kubota CRV032 (Figure 4). It had an operating weight of 5 t and was fitted with small, retractable rail wheels enabling it to mount and operate on the running tracks.

The maximum speed of the excavator while on track was 4 km/h. It had an R3[32] detection rating, which meant the vehicle did not reliably operate track circuits; as a result, the vehicle was not detected by the signalling system and was not visible on the NCO’s workstation monitor. The boom arm was fitted with a height limiter allowing it to work under live overhead line equipment.

According to QR standard MD-14-575 (Road Rail Vehicles), the excavator was classified as a ‘road rail vehicle’ and was only allowed to operate within track closures. The QNRP categorised a road rail vehicle as a track vehicle. In accordance with the QNRP, permission had to be obtained from the PO before a track vehicle could enter a work on track authority (such as a TOA) or traverse a worksite within a work on track authority. On the day of the incident, the excavator was on-tracked at Thorneside without the permission of the PO.

Australian Standard (AS) 7502:2016 (Road Rail Vehicle) stated that a flashing beacon light shall be mounted on the top of the vehicle, or in a suitable location(s), so that the light is visible to a person standing 4 m in any direction from the vehicle on level ground. In addition, the flashing beacon light was required to be activated while the vehicle was operating on-track in rail mode. Although the excavator involved in the near collisions was fitted with a beacon capable of flashing, video footage showed that it was not active at the time of the near collisions.

In general, where people and mobile plant (machinery) share the same worksite, there should be radio communication between the plant operator and the mobile plant spotter / supervisor. The excavator was fitted with a UHF radio, which was set to channel 15 when it was placed on-track. The excavator operator said that channel 15 was QR’s preferred channel for maintenance work communication and they had been told to use this channel at other QR worksites.

In interview, the excavator operator stated that after the first near collision they transmitted a call over the radio but communication with the work group was unsuccessful. The team leader reported that they heard a radio call on channel 15 including the word ‘train’ but did not know who had made the call and the call did not make sense (as they were not aware that the excavator operator had on-tracked). They asked the person to repeat the message but heard no reply.

Figure 4: Excavator involved in the near collisions

Source: Queensland Rail

Related occurrences

Introduction

This section provides information about a selection of rail occurrences that involve problems with the briefing of rail workers prior to them undertaking work on track. The list is not exhaustive. Each of the occurrences involved a range of different factors, and the descriptions below focus only on aspects that have some relevance to the incident at Thorneside on 7 March 2020.

Mindi, Queensland, 2007

On 7 December 2007, 2 QR workers were fatally injured as a result of being struck by a track machine when carrying out their duties at Mindi, Queensland. The Queensland Transport Rail Safety Investigation (QT2140) stated that worksite safety briefings [network pre-start briefings] were not performed prior to starting work. It also noted that work group members did not challenge the absence of a worksite safety briefing.

One of the recommended safety actions from the investigation noted:

A coronial inquest into the Mindi accident noted that the absence of a worksite safety brief [network pre-start briefing] was most likely a contributing factor to the death of the 2 workers.

Newbridge, New South Wales, 2010[33]

At about 1116 on 5 May 2010 a collision occurred between an XPT passenger train and a track‑mounted excavator near Newbridge, New South Wales. The operator of the track-mounted excavator was fatally injured.

The PO had conducted a pre-work brief involving the excavator operator and a hot-work labourer, during which a TOA was identified as the control in place for rail traffic. After obtaining a TOA from the NCO, the PO then advised the excavator operator and the hot-work labourer that the TOA had been obtained and that they could prepare for work while the PO put the site protection in place. A short time later both the hot-work labourer and excavator operator entered the danger zone before the worksite protection arrangements (detonators and flags) had been put in place.

An examination of the pre-work briefs found that the identified hazards were mostly related to general issues (for example, slips trips and falls and hazards associated with work equipment such as the excavator or oxyacetylene cutting). The only mention regarding the hazard of potential rail traffic identified the TOA as the relevant risk control. There was no mention of unexpected approaches of other rail vehicles and the use of additional site protection.

The excavator operator and hot-work labourer were relatively inexperienced. The ATSB found that, although the PO had told the excavator operator and hot-work labourer that the PO had received the TOA, they did not explicitly communicate to the workers that they should not occupy the danger zone until all site protection measures were put in place.

Jaurdi, Western Australia, 2011[34]

On 28 March 2011, a freight train 7SP3 collided with a track mounted excavator between Jaurdi and Darrine, Western Australia. The train driver sustained a minor injury. There was significant damage to the lead locomotive and the excavator, and minor damage to the track as a result of the accident.

The ATSB found that 2 track mounted excavators had been placed back on the track without permission of the authorised employee responsible for the coordination of track side safeworking activities between Jaurdi and Darrine. Another finding was that, although separate pre-work briefings were conducted, there was no discussion about train running information and site protection between the supervisor of the excavators and the authorised employee (who was the supervisor of the track machines at another location).

Laverton, Victoria, 2015[35]

On 2 October 2015, a train departing Laverton Station approached a worksite where a supervisor was marking a track to identify dog spikes to be removed, with a lookout for their protection. The lookout observed the train, warned workers of its approach, and signalled to the driver that the track was clear. However, as the train took the crossover, the supervisor was foul of the track, and was struck by the train that was travelling at about 59 km/h. The supervisor suffered serious injuries.

The ATSB found that the pre-work briefing was not conducted. As a result, the supervisor and lookout (and others in the work group) did not receive the benefits of a safety briefing that would have informed them of the outcomes of the worksite hazard assessment, train running, and the designated position of safety.

Clyde, New South Wales, 2016[36]

On 18 June 2016, a signal maintenance team (SMT) worker was fatally injured by a train at Clyde, New South Wales, while working in the rail corridor. The ATSB investigation (conducted by the NSW Office of Transport Safety Investigations) identified a number of contributing factors and other factors that increased risk. Safety factors related to pre-start briefings included:

- The PO had briefed the civil team, however they did not brief the signal team, and the signal team did not seek a pre-work briefing before commencing work on-track.

- The signal team assumed their workplace was within the limits of the TOA and did not plan their own worksite protection…

- The Sydney Trains worksite briefing process did not compel a new work group to seek a worksite protection pre-work briefing when accessing an existing worksite. The safety message from the ATSB report noted:

The investigation report also included a finding relating to network communications between multiple parties not being ‘clear, brief and unambiguous.’

Petrie, Queensland, 2017[37]

In May 2017, a QR protection officer (PO) was fatally injured after being struck by a suburban passenger train at Petrie, Queensland.

Four POs were assigned to the maintenance task, including 3 POs at Petrie Station. The lead PO participated in the briefing of the maintenance workers, and the 3 POs then undertook a pre-start brief for the implementation of the protection (stop signs and railway track signals), which the other 2 POs then started implementing. It was one of these POs who was fatally injured.

The ATSB found that the POs were not familiar with the new rail infrastructure and uncommon site layout at Petrie Station. The POs were not advised of an early work shift start requirement, which resulted in them having insufficient time to prepare for the task, and they experienced pressure to complete the task within the scheduled time. In addition, QR had no process for ensuring the provision of adequate time for the POs to familiarise themselves with new or changed worksites.

The train notice diagram had been incorrectly marked with the open and closed rail lines by a different PO, and the POs’ pre-start briefing was limited to about 90 seconds. In addition to this, the recorded pre-start briefing forms contained errors and inconsistent sign-off entries; it is possible that the recording of the pre-start brief had been rushed.

Following the accident, QR undertook a number of safety actions. The QR investigation had found that the ‘pre-start briefing process on the night was not effective in ensuring the risks of individual live tracks and site-specific hazards and risks were understood and controlled by the Protection Officers’. A subsequent review of the task distribution for POs noted that the pre-start safety briefings often lacked planning and were delivered spontaneously, and it recommended a review of the effectiveness and improve the delivery of the pre-start safety briefings. The network pre‑start briefing procedure and form were subsequently revised with briefings provided to relevant workers.

Training and qualification records showed that the supervisor, team leader and recipient involved in the occurrence at Thorneside, had attended training in delivering the revised network pre-start briefing procedure and form, and the revised form was used during the pre-start briefing on 6 March 2020. QR also re-enforced the message of ‘the right to stop work and getting safety right before commencing’ as part of its ongoing network pre-start brief project.

In addition, QR organised the development of a consistent process for marking up train notice diagrams.

Margam, United Kingdom, 2019[38]

On 3 July 2019, at Margam East Junction in South Wales, United Kingdom, 2 track workers were struck and fatally injured by a passenger train. A third track worker came close to being struck.

The group of 6 track workers were assigned a safe work pack (SWP) that included 3 tasks to be completed, and another task was added on the morning of the accident that was not included in the SWP. The SWP stated the work would be conducted between 1230 and 1530, with 2 types of protection included for this period (line blockages and lookout warning), although which tasks were to be protected by which method was not clearly articulated.

The workers commenced the tasks soon after 0800 using a lookout, but there were problems with its implementation when the workers spilt into 2 groups doing different tasks with only 1 designated lookout between them. The workers who were struck were performing a noisy task (maintaining a set of points) that should only have been undertaken with the line blocked. The controller of site safety (PO) and the lookout were with the other group when the accident occurred.

Overall, the system of work that was proposed was not adopted, and an alternative arrangement became progressively less safe as the work proceeded, which created conditions that made an accident much more likely. The SWP was developed without the involvement of any of the workers involved, and there was no challenge by the workers to the way the work was being conducted.

The investigation by the UK Rail Accident Investigation Branch (RAIB) found that local management/supervisors were not actively monitoring, and had not identified and managed, non‑compliant safety behaviors at the depot. The investigation also considered why Network Rail (the rail infrastructure manager) had not created the conditions that were needed to achieve a significant and sustained improvement in track worker safety. Relevant underlying factors were identified:

In terms of safety assurance, frontline management/supervisors were required to undertake planned ‘Level 1’ (first-line) assurance activities, which included worksite inspections to review the effectiveness of the planning process, competence of staff, and unsafe behaviours and activities/ conditions, including corrective actions as required. Regarding worksite inspections, the investigation identified that managers may have been relying on submitted paperwork rather than undertaking observations of work on site. In addition, there was a self-assurance process where front-line management was required to formally check compliance with procedures by responding to a series of subject-related questions. These questions were designed to monitor the managers’ own compliance and that of their staff.

The evidence obtained by RAIB suggested that the underlying weaknesses in the design of the level 1 assurance processes included:

The investigation also found multiple problems with the design and execution of this process and noted that it was frequently referred to by managers and staff as a ‘tick box’ exercise. Overall, for a variety of reasons, the audits were not effective in detecting a range of problems with planning paperwork, procedural non-compliance, and unsafe working practices, and did not trigger the higher-level management actions needed to address them.

In contrast, level 2 audits (conducted by persons independent from those with the responsibility to implement the risk controls) detected numerous examples of non-compliance in work practices. Over a 3-year period (June 2016–July 2019), 30 level 2 audits were undertaken. These identified 36 non-compliance reports (NCRs) and 8 repeat NCRs. Most NCRs contained multiple instances of non-compliance of various types and 10 NCRs included non-compliances that were considered by the auditor to be ‘systemic’ in nature. The RAIB noted that the NCRs confirmed evidence that the management self-assurance (level 1) process was an unreliable mechanism. The RAIB also noted these level 2 audits, although reasonably thorough, were heavily based on reviews of paperwork.

Other incidents

Track worker safety has been a significant concern for the rail industry for many years, and at the time of the Thorneside incident track work safeworking was listed by the Office of the National Rail Safety Regulator (ONRSR) as one of its safety priorities. For the calendar year 2020 it reported that there were 458 track work safeworking rule and procedure breaches.

During the investigation, QR was requested to provide records and brief descriptions of notifiable safety incidents relevant to work on track safety breaches between 1 March 2018 and 29 February 2020. QR provided details of 24 incidents that occurred on its south-east Queensland network. Limited details were provided for some incidents. However, the available information indicated at least 3 notifications had some similarities with the incident at Thorneside:

- One notification in which a PO advised that an excavator operator had on-tracked an excavator without permission.

- One incident in which a welding crew had accessed a rail corridor and commenced work. The welding crew had not contacted the PO to sign on to the multiple workgroup register. A subsequent internal investigation identified a number of ‘absent or failed defences’, including the ineffective use of the pre-start briefing.

- One incident involving a near collision between the tilt train[39] and a work group, where the PO suspended the TOA unaware that there was a work group working on-track.

Management oversight of network safety

Overview of risk management and assurance process

QR had documented standards and procedures for risk management and assurance. The standard MD-11-1338 (Risk management) stated:

In a section titled ‘Monitor and review, the standard stated:

The standard also stated:

QR standard MD-16-24 (Assurance) expanded on the monitor and review concepts. It stated that in order for risk management to be effective, QR should comply with a set of assurance principles, which included:

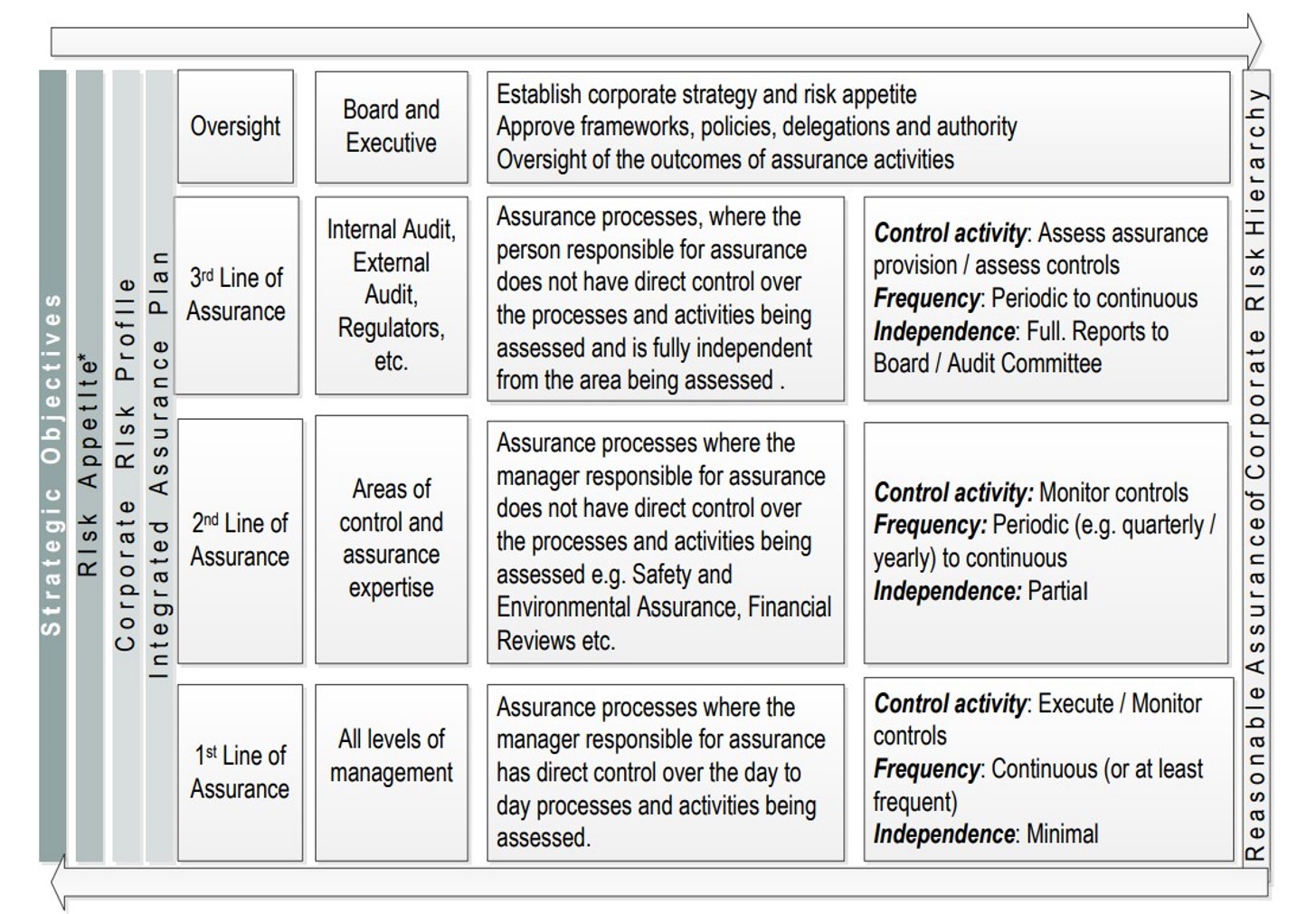

QR’s 3 lines of defence assurance model was summarised in a diagram, as shown in Figure 5.

Figure 5: QR’s 3 lines of defence assurance model

Source: Queensland Rail

In line with QR’s procedure MD-12-27 (Assurance), QR was to develop an integrated assurance plan (IAP) focussing on second-line and third-line assurance activities through an assurance mapping exercise to provide a holistic view of all assurance activities in relation to the corporate risk hierarchy. The assurance procedure also stated that the planning of second-line and third-line assurance activities would be based on matters such as:

QR’s corporate risk register regarded the safeguard of its workforce as one of its major priorities. One of the risks identified was:

As part of the investigation process, QR was asked to provide its integrated assurance plans[40] for financial years 2017–18, 2018–19, 2019–20 and 2020–21. In addition, the ATSB requested first‑line, second-line and third-line assurance activities over a predetermined period related to network pre-start briefings and related matters.

First-line assurance activities