Safety summary

What happened

On 30 May 2017, a twin‑engine Cessna 441 Conquest II (Cessna 441), registered VH-XMJ and operated by AE Charter (trading as Rossair) departed Adelaide Airport, South Australia for a return flight via Renmark Airport, South Australia.

On board the aircraft were:

- an inductee pilot undergoing a proficiency check, flying from the front left control seat

- the chief pilot conducting the proficiency check, and under assessment for the company training and checking role for Cessna 441 aircraft, seated in the front right control seat

- a Civil Aviation Safety Authority (CASA) flying operations inspector, observing and assessing the flight from the first passenger seat directly behind the inductee pilot.

Each pilot was qualified to operate the aircraft.

The flight departed Adelaide at about 1524 local time and flew to the Renmark area for exercises related to the check flight, followed by a landing at Renmark Airport. After a short period of time running on the ground, the aircraft departed from runway 25 at about 1614.

A distress beacon broadcast was subsequently received by the Joint Rescue Coordination Centre and passed on to air traffic services at 1625. Following an air and ground search the aircraft was located by a ground party at 1856 about 4 km west of Renmark Airport. All on board were fatally injured and the aircraft was destroyed.

What the ATSB found

The ATSB determined that, following a simulated failure of one of the aircraft’s engines at about 400 ft above the ground during the take‑off from Renmark, the aircraft did not achieve the expected single engine climb performance or target airspeed. As there were no technical defects identified, it is likely that the reduced aircraft performance was due to the method of simulating the engine failure, pilot control inputs or a combination of both.

It was also identified that normal power on both engines was not restored when the expected single engine performance and target airspeed were not attained. That was probably because the degraded aircraft performance, or the associated risk, were not recognised by the pilots occupying the control seats. Consequently, about 40 seconds after initiation of the simulated engine failure, the aircraft experienced an asymmetric loss of control.

The single engine failure after take‑off exercise was conducted at a significantly lower height above the ground than the 5,000 ft recommended in the Cessna 441 pilot’s operating handbook. This meant that there was insufficient height to recover from the loss of control before the aircraft impacted the ground.

While not necessarily contributory to the accident, the ATSB also identified that:

- The operator’s training and checking manual procedure for simulating an engine failure in a turboprop aircraft was inappropriate and increased the risk of asymmetric control loss.

- The CASA flying operations inspector was not in a control seat and was unable to share the headset system used by the inductee and chief pilot. Therefore, despite having significant experience in Cessna 441 operations, he had reduced ability to actively monitor the flight and communicate any identified problem.

- The inductee and chief pilot, while compliant with recency requirements, had limited recent experience in the Cessna 441 and that probably led to a degradation in the skills required to safely perform and monitor the simulated engine failure exercise.

- The chief pilot and other key operational managers within Rossair were experiencing high levels of workload and pressure during the months leading up to the accident.

- The Civil Aviation Safety Authority’s method of oversighting Rossair in the several years prior to the accident increased the risk that organisational issues would not be identified and addressed.

Finally, a lack of recorded data from this aircraft reduced the available evidence about pilot handling aspects and cockpit communications. This limited the extent to which potential factors contributing to the accident could be analysed.

What's been done as a result

Following the accident, CASA issued a temporary management instruction to provide higher risk protection around operations involving CASA flying operations inspectors. However, at the time of writing these instructions had not been permanently incorporated into regulation.

Safety message

Conducting a simulated engine failure after an actual take-off is a high-risk exercise with little margin for error. For that reason, Cessna recommended practicing this sequence in the 441 aircraft at a height of 5,000 ft above ground level to allow the opportunity for recovery in the event that control is lost.

A review of past accidents indicates that, while accidents associated with engine malfunctions are rare, training to manage one engine inoperative flight (OEI) after take‑off is important. The ATSB recommends that such training should follow the manufacturer’s guidance and, if possible, be conducted in an aircraft simulator. If the sequence is conducted in the aircraft close to the ground, then effective risk controls need to be in place to prevent a loss of control as recovery at low height will probably not be possible. Such defences include:

- defined OEI performance criteria that, if not met, require immediate restoration of normal power

- use of the appropriate handling techniques to correctly simulate the engine failure and ensure that aircraft drag is minimised/OEI performance is maximised

- ensuring that the involved pilots have the appropriate recency and skill to conduct the exercise and that any detrimental external factors, such as high workload or pressure, are minimised.

What happened

On 30 May 2017, a Cessna 441 Conquest II (Cessna 441), registered VH-XMJ (XMJ) and operated by AE Charter, trading as Rossair, departed Adelaide Airport, South Australia for a return flight via Renmark Airport, South Australia.

On board the aircraft were:

- an inductee pilot undergoing a proficiency check, flying from the front left control seat

- the chief pilot conducting the proficiency check, and under assessment for the company training and checking role for Cessna 441 aircraft, seated in the front right control seat

- a Civil Aviation Safety Authority flying operations inspector (FOI), observing and assessing the flight from the first passenger seat directly behind the left hand pilot seat.

Each pilot was qualified to operate the aircraft.

There were two purposes for the flight. The primary purpose was for the FOI to observe the chief pilot conducting an operational proficiency check (OPC), for the purposes of issuing him with a check pilot approval on the company’s Cessna 441 aircraft. The second purpose was for the inductee pilot, who had worked for Rossair previously, to complete an OPC as part of his return to line operations for the company.

The three pilots reportedly started their pre‑flight briefing at around 1300 Central Standard Time.[1] There were two parts of the briefing – the FOI’s briefing to the chief pilot, and the chief pilot’s briefing to the inductee pilot. As the FOI was not occupying a control seat, he was monitoring and assessing the performance of the chief pilot in the conduct of the OPC.

There were two distinct exercises listed for the flight (see the section titled Check flight sequences). Flight exercise 1 detailed that the inductee pilot was to conduct an instrument departure from Adelaide Airport, holding pattern and single engine RNAV[2] approach, go around and landing at Renmark Airport. Flight exercise 2 included a normal take‑off from Renmark Airport, simulated engine failure after take-off, and a two engine instrument approach on return to Adelaide.

The aircraft departed from Adelaide at 1524, climbed to an altitude about 17,000 ft above mean sea level, and was cleared by air traffic control (ATC) to track to waypoint RENWB, which was the commencement of the Renmark runway 07[3] RNAV-Z GNSS approach. The pilot of XMJ was then cleared to descend, and notified ATC that they intended to carry out airwork in the Renmark area. The pilot further advised that they would call ATC again on the completion of the airwork, or at the latest by 1615. No further transmissions from XMJ were recorded on the area frequency and the aircraft left surveillance coverage as it descended towards waypoint RENWB.

The common traffic advisory frequency used for air-to-air communications in the vicinity of Renmark Airport recorded several further transmissions from XMJ as the crew conducted practice holding patterns, and a practice runway 07 RNAV GNSS approach. Voice analysis confirmed that the inductee pilot made the radio transmissions, as expected for the check flight. At the completion of the approach, the aircraft circled for the opposite runway and landed on runway 25, before backtracking and lining up for departure. That sequence varied from the planned exercise in that no single-engine go-around was conducted prior to landing at Renmark.

At 1614, the common traffic advisory frequency recorded a transmission from the pilot of XMJ stating that they would shortly depart Renmark using runway 25 to conduct further airwork in the circuit area of the runway. A witness at the airport reported that, prior to the take‑off roll, the aircraft was briefly held stationary in the lined‑up position with the engines operating at significant power. The take-off roll was described as normal however, and the witness looked away before the aircraft became airborne.

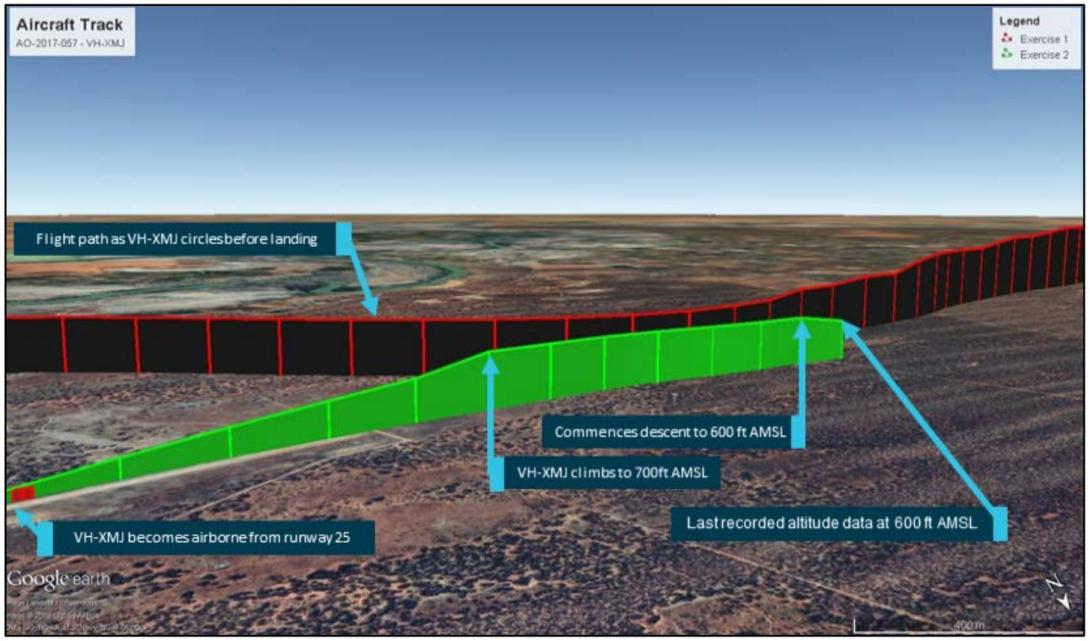

The aircraft maintained the runway heading until reaching a height of between 300‑400 ft above the ground (see the section titled Recorded flight data). At that point the aircraft began veering to the right of the extended runway centreline (Figures 1 and 15). The aircraft continued to climb to about 600 ft above the ground (700 ft altitude), and held this height for about 30 seconds, followed by a descent to about 500 ft (Figures 2 and 13). The information ceased 5 seconds later, which was about 60 seconds after take-off.

Figure 1: Position information of VH-XMJ as the aircraft circled and landed on runway 25 (depicted in red), before backtracking and departing (depicted in green).

Source: Google and OzRunways, annotated by the ATSB

Figure 2: Altitude information of VH-XMJ (each vertical line represents 5 seconds)

Source: Google and OzRunways, annotated by the ATSB

A distress beacon broadcast was received by the Joint Rescue Coordination Centre and passed on to ATC at 1625. Following an air and ground search the aircraft was located by a ground party at 1856 about 4 km west of Renmark Airport. All on board were fatally injured and the aircraft was destroyed.

__________

- Central Standard Time (CST): Coordinated Universal Time (UTC) + 9.5 hours.

- An RNAV approach is a method of navigation utilising GPS that enables a pilot to guide his aircraft to a landing in low visibility situations. It is often practiced during check flights to ensure proficiency.

- Runway number: the number represents the magnetic heading of the runway.

Pilot information

There were three pilots on board VH-XMJ (XMJ). A summary of the role of each pilot, and their relevant training, qualifications and experience is provided below. The intention of the flight was to allow a Civil Aviation Safety Authority (CASA) flying operations inspector (FOI) to observe the Rossair chief pilot conduct an operator proficiency check (OPC), for the purposes of issuing him with a Conquest II (Cessna 441) check pilot approval (see the section titled Check pilot training). The pilot undertaking the OPC was being inducted into the company. The inductee pilot was seated in the left-hand control seat, the chief pilot in the right-hand control seat, and the CASA FOI in the first row passenger seat behind the left-hand seat pilot.

Inductee pilot

Flight role

The inductee pilot was the planned pilot flying. He was an experienced Cessna 441 pilot who had previously flown for Rossair from May 2010 to August 2014. Undertaking the OPC was part of his induction back into the company.

Qualifications and experience

The inductee pilot held an Air Transport Pilot (Aeroplane) Licence (ATPL), issued in December 1991, and Commercial Pilot (Aeroplane) Licence (CPL) issued in January 1979. He also held an ATPL from the Netherlands. He held a current class 1 aviation medical certificate (valid to 24 June 2017), which required reading correction to be available when flying, but placed no other restrictions on operation.

The pilot’s logbook showed a total flying experience of 14,751.1 hours, with 3,293.7 hours on single engine aircraft and 11,427.4 hours on a range of type-rated and class-rated multi-engine aircraft (see the section titled Pilot licencing). This included 987.7 hours on Cessna 441 aircraft. With the exception of the accident flight and an associated practice flight the week before, all of the inductee pilot’s Cessna 441 experience was gained prior to August 2014.

A review of the pilot’s licence and associated documentation identified that he held the relevant endorsements and ratings to fly the Cessna 441. In addition, he held a current grade 1 instructor rating for multi‑engine class rating training.

In the previous 90 days, the inductee pilot had logged 22.2 hours flying as pilot in command, all on multi-engine class rated aircraft, including 3.5 hours in XMJ the week prior to the accident.

Proficiency checks and flight reviews

The inductee pilot last completed an instrument rating proficiency check (IPC) during his multi‑engine class aircraft flight review in a Beechcraft Baron 95-B55 on 13 February 2017. This check required the pilot to demonstrate conducting a one-engine inoperative instrument departure, which was marked on his proficiency check form as completed satisfactorily. His IPC was valid at the time of the accident.

Chief pilot

Flight role

The pilot in the right-hand seat was appointed as the Rossair chief pilot in January 2016. On this flight, the chief pilot was being observed by the CASA FOI in order to assess his competence to perform operational proficiency checks on Rossair Cessna 441 pilots.

In accordance with the Rossair operations manual, as this was a checking flight, the chief pilot, in the check captain role, was the pilot in command (PIC) for the flight.

Based on the planned exercises for the flight the chief pilot’s role was to observe and monitor the inductee pilot’s proficiency. In addition, he was responsible for setting the power controls to simulate asymmetric flights when required and recover the aircraft if it deviated from safe flight.

Qualifications and experience

The chief pilot held an ATPL (Aeroplane), issued in June 2001, a CPL (Aeroplane) issued in August 1998, as well as an ATPL (Helicopter) issued in November 2013, and a CPL (Helicopter) issued in April 2007. He also held an ATPL (Aeroplane) from the United States of America. The pilot held a current class 1 aviation medical certificate, valid until 3 August 2017, which required reading correction to be available while flying, but placed no other restrictions on operation.

The chief pilot’s logbook history was sought by the ATSB, but the complete record could not be located. A review of available records for the pilot indicated the pilot had around 5,000 hours experience operating aeroplanes, including over 3,200 hours of turbine‑powered aeroplane experience. This included over 1,000 hours on a Cessna 441 aircraft, accumulated during the period between September 2001 and September 2004 and since March 2016. The pilot also had around 1,300 hours experience operating helicopters.

The pilot’s licence showed that the chief pilot held the ratings and endorsements required for the flight, as well as for operation of the company Embraer EMB 120 (EMB 120) aircraft. Additionally, he had previously held a grade 2 instructor rating for aeroplanes with night visual flight rules, design features (for example, retractable undercarriage and manual propeller pitch control), and single engine aircraft class rating endorsements.

In the previous 90 days, flight and duty records for the chief pilot recorded 128.1 hours of flight time, including 99.6 hours as a captain on the EMB 120 aircraft, and 16.6 hours in the Cessna 441, including a previous flight with the inductee pilot on 22 May 2017. The pilot’s flight and duty records had not been updated since 12 May 2017, so some of these times are based on planned flight times rather than actual flight times.

Proficiency checks and flight reviews

The chief pilot was inducted into Rossair Cessna 441 operations in April and May 2016 by the Cessna 441 fleet manager. The chief pilot successfully completed his line check and OPC on the Cessna 441 on 30 May 2016. As part of that flying, the chief pilot also completed training to become a check pilot on the aircraft. Following the flight on 30 May 2016, a recommendation was submitted to CASA that he be assessed as a Cessna 441 check pilot.

The chief pilot’s last IPC was completed as part of a type rating flight review in the EMB 120 simulator on 22 October 2016. Under CASA exemption 97/16 current at the time of the accident, this flight review conducted on a type‑rated aircraft, also satisfied the requirements of a flight review on the multi-engine class rated Cessna 441 aircraft.

The chief pilot had not completed an OPC or line check on the Cessna 441 aircraft since 30 May 2016. However, he had completed an OPC in the EMB 120 simulator on 1 February 2017, which was conducted under CASA observation. That 2017 check, although not conducted in the Cessna 441, met the required regulatory and operator proficiency checking requirements (see the section titled Operational proficiency check).

CASA flying operations inspector

Flight role

The CASA FOI was sitting in a non-control seat behind the inductee pilot, and therefore had no flying role on this flight. The role of the CASA FOI on the flight was to observe and assess the chief pilot’s skills in conducting an OPC on the inductee pilot.

Qualifications and experience

The CASA FOI held an ATPL (Aeroplane) issued in December 1990 and a CPL (Aeroplane) issued in February 1987. He also held a grade 1 instructor rating, with endorsements, among others, in instructor training, multi-engine class rating, and multi-engine aeroplane class rating instructor training. He held a class 1 aviation medical certificate, valid until 15 December 2017, which required reading correction to be available while flying, but placed no other restrictions on operation.

The CASA FOI had been in the role since 2008, and at the time of employment with CASA had 12,725 hours, including over 5,100 hours as a Cessna 441 pilot. The FOI role did not involve significant flying, but in the last 90 days he had completed 2.5 hours aircraft flight time, as well as simulator time.

Among a variety of flying and management roles prior to joining CASA, the FOI previously held chief pilot and head of training and checking roles at Rossair, with approval to conduct initial training on the Cessna 441.

Proficiency checks and flight reviews

The FOI completed a flight review and IPC in the Saab 340 simulator on 18 April 2017, and in the Bombardier Dash 8 simulator on 9 May 2017. He completed a flight proficiency check for his grade 1 instructor rating in a Beechcraft Baron 95-B55 on 24 May 2017. Additionally, the FOI had logged a 2.7 hour flight in the Cessna 441, with the FOI as PIC flying with the previous Rossair check pilot, in August 2016.

Aircraft information

General information

The Cessna 441 Conquest II is a pressurised, low‑wing, twin-engine turbopropeller (turboprop) aircraft with seating for up to 2 pilots and 9 passengers. Both pilot seats are equipped with flight controls however single‑pilot line operations are flown from the left seat. The right pilot seat would normally only be occupied by a second pilot for training and checking flights.

The accident aircraft, serial number 441‑0113, was manufactured in the United States by the Cessna Aircraft Company in 1980, and registered in Australia as XMJ in February 1989. The Cessna 441 is certified as a normal category[4] aircraft under the United States Federal Aviation Regulations Part 23, and issued with type certificate data sheet number A28CE by the United States Federal Aviation Administration in 1977. At the time of the accident, Textron Aviation Inc. was the Type Certificate holder[5] for the aircraft and as of March 2020, there were 39 Cessna 441 aircraft registered in Australia.

Notable modifications to the aircraft were the incorporation of supplemental type certificates to replace the three blade propellers with four blade propellers, replace the -8 engines with more powerful -10 engines and the installation of vortex generators[6] to increase the aircraft’s maximum take-off weight. Other than an associated increase in the aircraft’s maximum take-off weight, these modifications did not require any changes to the procedures and airspeed limitations in the aircraft’s pilot’s operating handbook (POH).

Aircraft records

XMJ had a current Certificate of Registration, Certificate of Airworthiness and maintenance release, all of which were recovered from the accident site. The maintenance release was due to expire on 10 March 2018 or upon 13,859.0 hours total time-in-service, whichever came first. The maintenance release indicated that XMJ was equipped to be operated under the instrument flight rules and in the charter operational category. The maintenance release indicated that there was no maintenance due on the aircraft or open defects at the time of the accident. Prior to the departure from Adelaide, the aircraft had accumulated a total time in service of 13,845.3 flight hours.

Part 1 of the aircraft’s Logbook Statement specified that the aircraft was to be maintained in accordance with the AE Charter Services system of maintenance and all applicable airworthiness directives. The following summarises the maintenance activities conducted on XMJ leading up to the accident.

- On 31 August 2016 a number of parts, including both the left and right engines were removed for use on other company aircraft. These engines were reinstalled on 24 November 2016 and had operated for 385.2 hours on XMJ since this time.

- On 30 April 2017, the installed fuel control unit (FCU) from the aircraft’s left engine was replaced by an FCU borrowed from a third party maintenance organisation.

- On 4 May 2017, the aircraft was erroneously released to service prior to in-flight FCU set-ups having occurred, with an endorsement in the deferred defect list that the left engine had to be operated in manual mode until the FCU set-up had been completed but could continue in service until no later than 14 May 2017 without the set-up being completed.

- The Rossair chief pilot raised a concern on 8 May 2017 about the aircraft being released into service without the in-flight set-ups being completed, as the aircraft was more difficult than normal to operate with one engine in manual mode. Further maintenance work was performed on the aircraft, and, on 10 May, the aircraft was released into service, with both engines operating in normal (automatic) mode.

- The aircraft subsequently flew 28 flights, totalling 32.6 hours with no reported issues.

- On 26 May 2017, the original FCU that was removed on the 30 April 2017 was reinstalled onto the left engine of XMJ following removal, cleaning and reinstallation of the FCU’s manual mode control valve.

- A certification regarding a wing de-icing system unserviceability was made on 26 May 2017. It stated ‘No action was carried out at this time. Aircraft unavailable due to flying requirements. Customer notified.’ There was no entry in the defect field of the current maintenance release Part 3.

- Between 26 May and 30 May, the aircraft flew 6.9 hours without reported issue, including 4.5 hours across five sectors on the morning of the accident.

Aircraft systems information

Flight control overview

The Cessna 441 is fitted with conventional flight controls connected to the aircraft’s primary flight control surfaces. The primary flight controls consist of the rudder, elevators, and ailerons, which control the aircraft about the yaw, pitch and roll axes respectively.

The pilot controls an aircraft by manipulating the control wheel and rudder pedals, which deflect the ailerons, elevators and rudder. Deflection of an aircraft’s primary flight control surfaces changes the aerodynamic shape and therefore the amount of lift generated by the associated part of each wing, vertical stabiliser or horizontal stabiliser. These local variations in lift result in changes to the aircraft attitude and consequently flight path.

Any deflection of the primary flight control surfaces into the adjacent airflow produces aerodynamic forces on the surface and corresponding loads on the control wheel or rudder pedals. The magnitude of the aerodynamic force is principally related to the amount of flight control surface deflection, airspeed and trim tab deflection.

On the Cessna 441, adjustable trim tabs are attached to the trailing edge of the primary flight controls. These tabs are used to ‘trim’ or counteract the aerodynamic forces felt by the pilot on the control wheel or rudder pedals. During flight, deflection of an aircraft’s trim tab produces an aerodynamic force on the aft part of the associated primary surface. The tabs have the capacity, when adjusted in the opposite direction to the deflection of the primary control surface, to modify the aerodynamic force on the surface and correspondingly, reduce the load felt by the pilot on the control wheel or rudder pedals. The effectiveness of a trim tab is principally related to the amount of deflection and the aircraft’s airspeed.

Flap system description

The aircraft has four flaps, one inboard, and one outboard per wing. The flaps are normally in the fully retracted position. They are extended to slow the aircraft and allow it to land at a lower airspeed. They can also be used to improve take-off performance in the ‘T.O.’ position. The flaps are operated using a sliding selector. Flap travel is registered on an indicator adjacent to the selector. There are four detents in the selector assembly as follows:

- UP – fully retracted, 0⁰ of travel

- T.O. – 10° of flap down travel

- APPR – 20⁰ of flap down travel

- LAND – full extension, 30⁰ of flap down travel.

Engine and propeller controls

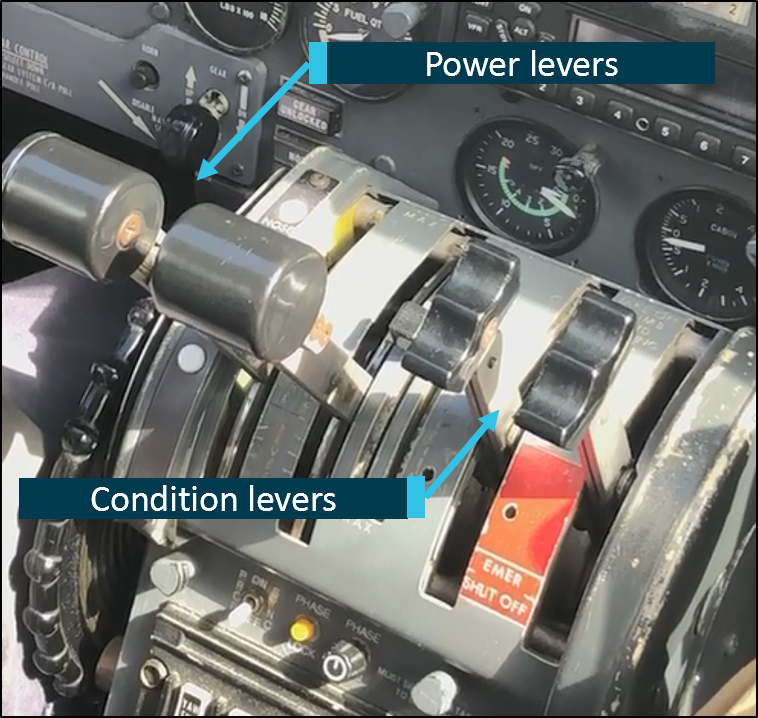

Each engine is controlled by two levers located in the engine controls section of the centre pedestal (Figure 3).

The power levers provide control input to the engine for the power necessary throughout the entire operational envelope. The power lever has the following positions:

- MAX

- AIR START

- FLIGHT IDLE

- GROUND IDLE

- REVERSE

The power levers can be moved freely forward of FLIGHT IDLE. A hard stop is provided at the FLIGHT IDLE position to prevent inadvertent selection of reverse thrust in flight (Figure 4). Finger latches located on each power lever must be pulled up to allow movement of the power levers rearward of the FLIGHT IDLE position.

The condition levers are used to set the engine revolutions per minute required for flight as well as acting as the control for propeller feathering and emergency fuel shut-off. The condition lever quadrant has the following positions:

- TAKEOFF, CLIMB and LANDING

- CRUISE

- START AND TAXI

- EMER SHUT-OFF

The condition levers can be moved freely forward of CRUISE. A hard stop is provided at the CRUISE position to prevent inadvertent selection of START AND TAXI speed in flight (Figure 5). Each condition lever must be pulled up to allow movement rear of the CRUISE stop. Another stop is provided at the START AND TAXI position. Rearward movement past this position allows the respective engine to be shut down and its propeller feathered.

Figure 3: Engine control levers

Source: ATSB

Figure 4: Power lever

Source: Textron Aviation Inc.

Figure 5: Condition lever

Source: Textron Aviation Inc.

Negative torque system

The aircraft’s engines are equipped with a negative torque sensing (NTS) system that activates under conditions of low propeller pitch (see the section titled Multi‑engine aeroplane propellers) when air loads drive the propeller instead of the engine. This can occur during normal operation at high airspeed and low power settings but will also happen following an engine failure. When NTS activates, the propeller blades are automatically driven towards the feathered[7] position to reduce both the air load and the significant associated drag. NTS will only activate while negative torque is detected so, unlike an auto‑feather system fitted to other aircraft, the blades will only automatically move to a high pitch position rather than fully feathered. Consequently, in the event of an engine failure the pilot is required to move the condition lever to the emergency shut off position to feather the propeller.

With regard to functioning of the NTS, the POH noted that:

NTS operation, as evidenced by a cycling sound of the engine(s) can occur at high airspeed with the power levers at FLIGHT IDLE; this is particularly true when operating in manual mode. NTS operation occurs when the propeller is driving the engine, rather than the engine driving the propeller. During normal mode operation, NTS can indicate the fuel flow is insufficient for existing conditions.

There is a POH requirement to confirm operation of the NTS prior to flight. Normal operation of the NTS on the ground is accompanied by illumination of an amber light on the cockpit annunciator panel for the respective engine being checked. The light was for check purposes only and would not illuminate during in‑flight activation of the NTS. Activation of the NTS on an operative engine in flight can be overcome by advancing the power levers slightly.

Manual mode operation

Manual mode refers to the engine power output being directly controlled by the power lever position rather than by a signal sent to the engine by the electronic engine control unit (EEC). The power system is designed so that fuel scheduling is lower in manual mode than it is in normal (automatic) mode.

Higher power lever positions are therefore required to maintain engine power when in manual mode compared to normal mode. This means that if a fault is detected in the EEC and the engine operation automatically reverts to manual mode the engine will have a reduction in power for that particular power lever setting. If that occurs the power can be restored by advancing the power lever as required.

Weight and balance

The ATSB determined the likely fuel on board at the time of the accident and the weight and location of people, baggage and ballast. From this information, it was calculated that the aircraft was within the weight and balance limitations specified in the aircraft’s POH and relevant supplements. The aircraft’s weight at the time of the accident was estimated to be about 3,950 kg. The aircraft’s maximum take-off weight was 4,690 kg.[8]

Meteorological information

The forecast weather conditions at Renmark Airport on the afternoon of the accident were benign with a southerly wind at 14 kt, visibility in excess of 10 km and scattered[9] cloud at 4,000 ft above the airport.

Weather observations recorded at one‑minute intervals by an automatic weather station at the airport were obtained from the Bureau of Meteorology (BoM). Consistent with the forecast, in the 20 minutes preceding the accident the wind strength varied between 8‑13 knots, and the direction varied between 188‑205° magnetic. The cloud cover was consistently seven oktas at about 6,500 ft above the airport and the ambient temperature was 13°C.

The ATSB also sought the assistance of the BoM to assess the likely wind strength and direction at the operating altitude of the aircraft immediately prior to the loss of control. This was done to enable an assessment of the airspeed during the final flight segment using recorded groundspeed data (see the section titled Recorded flight data).

Airport information

Renmark Airport is at an elevation of 115 ft above mean sea level and has one sealed runway, 07/25, and one gravel runway, 18/36.3 As there is no air traffic control tower at the airport, traffic at the airport broadcast on a common traffic advisory frequency to advise intentions and arrange separation with other traffic.

The terrain west of the airport, along the extended runway centreline in XMJ’s departure direction, slopes upwards, with an elevation gain of about 60 ft between the runway and the accident site location.

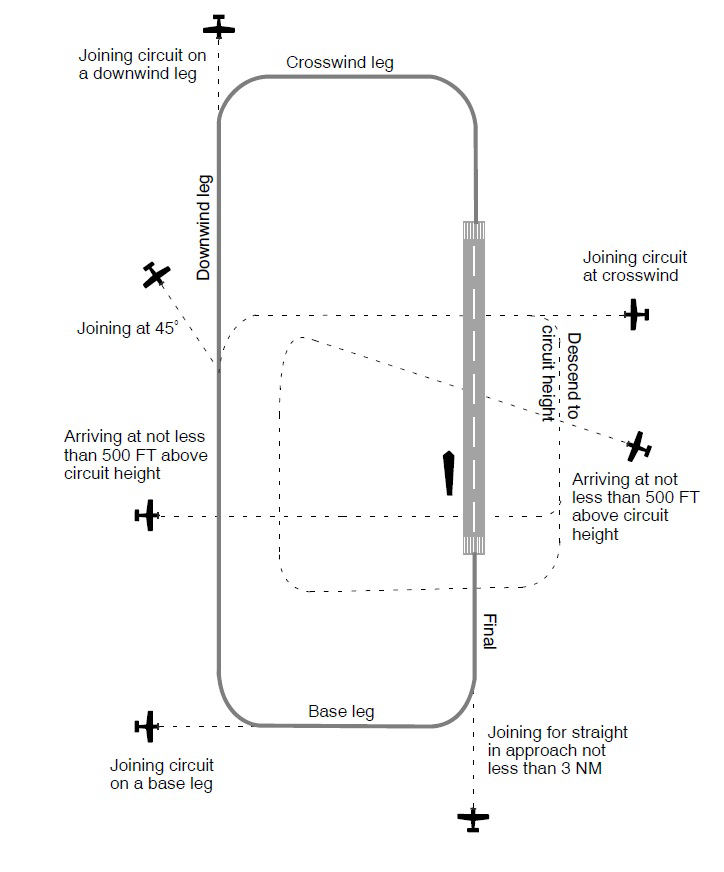

Circuit operations

In order to assure a safe and orderly traffic flow into and out of an airport, a standard circuit traffic pattern is used. The circuit consists of four legs: crosswind, downwind, base and final as shown in Figure 6, with standardised methods for joining the pattern to avoid traffic conflicts.

Figure 6: Standard circuit pattern

Source: Airservices Australia

Asymmetric flight

Multi-engine aeroplanes

In a discussion of small[10] multi-engine aeroplane operations, the United States Federal Aviation Administration (FAA) Airplane Flying Handbook FAA‑H‑8083‑3B, stated:[11]

The basic difference between operating a multiengine airplane and a single-engine airplane is the potential problem involving an engine failure. The penalties for loss of an engine are twofold: performance and control. The most obvious problem is the loss of 50 percent of power, which reduces climb performance 80 to 90 percent, sometimes even more. The other is the control problem caused by the remaining thrust, which is now asymmetrical. Attention to both these factors is crucial to safe OEI [one engine inoperative] flight. The performance and systems redundancy of a multiengine airplane is a safety advantage only to a trained and proficient pilot.

The importance of maintaining one engine inoperative performance and control was further emphasised in the handbook as follows:

In OEI flight at low altitudes and airspeeds such as the initial climb after takeoff, pilots must operate the airplane so as to guard against the three major accident factors: (1) loss of directional control, (2) loss of performance, and (3) loss of flying speed. All have equal potential to be lethal. Loss of flying speed is not a factor, however, when the airplane is operated with due regard for directional control and performance.

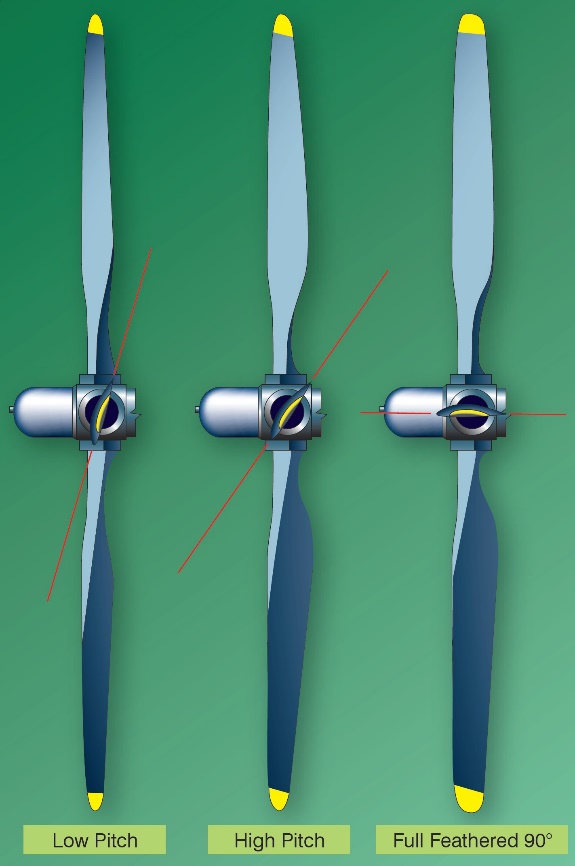

Multi-engine aeroplane propellers

In the event of an engine power loss, the inoperative engine may windmill - continue to rotate due to the airflow acting on the propeller. The FAA handbook described the hazard of a windmilling propeller as follows:

The propeller windmilling at high speed in the low range of blade angles can produce an increase in parasite drag, which may be as great as the parasite drag of the basic airplane.

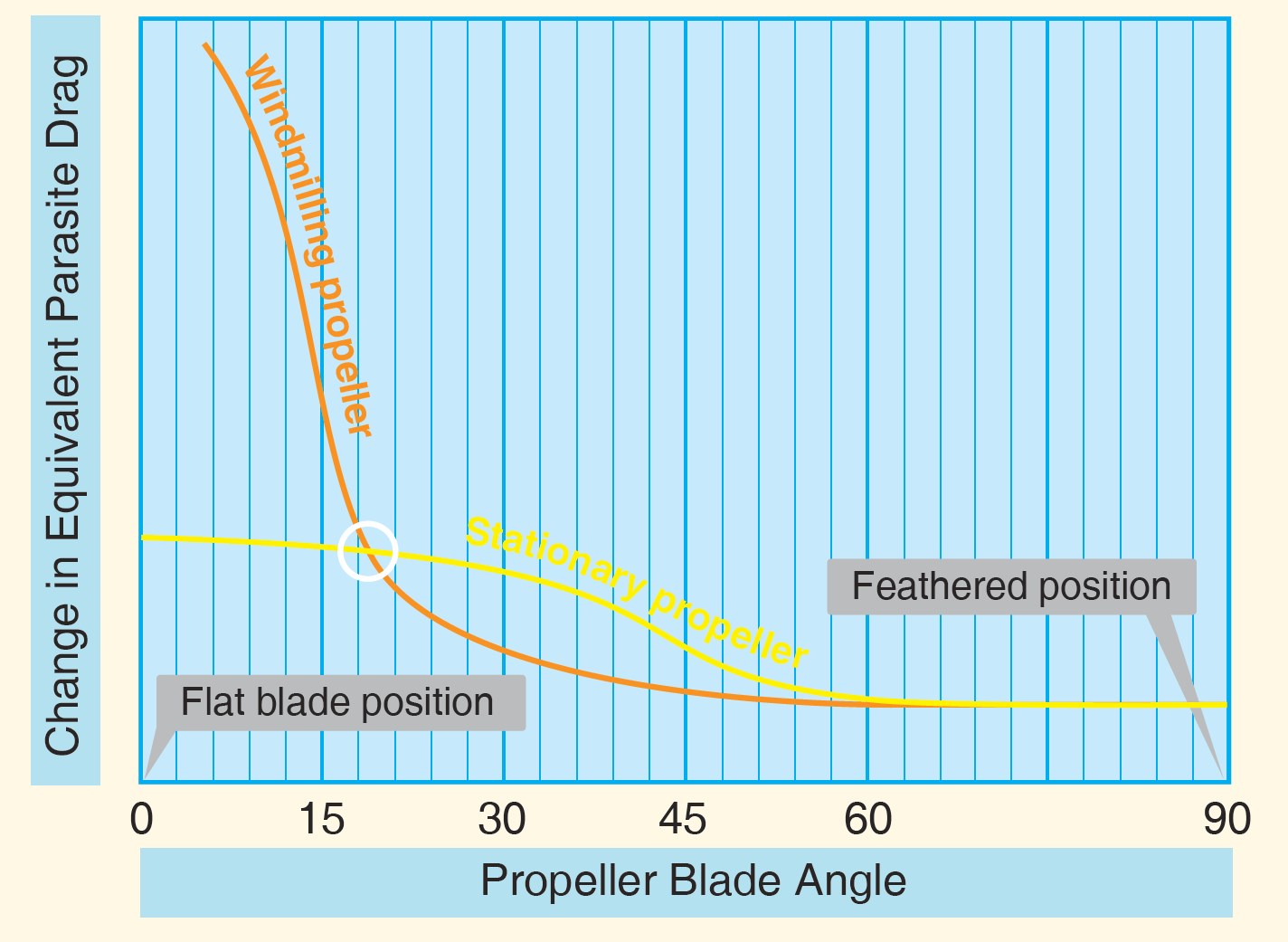

In order to minimise this significant source of drag on single engine controllability and climb performance, the propellers of multi-engine aeroplanes are capable of aligning the blades with the airflow (Figure 7).

Figure 7: Multiengine aeroplane propeller

Source: United States Federal Aviation Administration

This ‘feathered’ configuration stops the rotation of the engine and propeller and significantly reduces the parasite drag compared to that associated with a windmilling propeller (Figure 8).

Figure 8: Propeller drag

Source: United States Federal Aviation Administration

Asymmetric control

The majority of small, multi-engine aeroplanes like the Cessna 441 have two wing‑mounted engines that produce symmetrical propeller thrust during normal operation. One engine inoperative (OEI) flight in these aeroplanes results in asymmetric thrust and drag due to the offset position of the engines from the aeroplane’s centreline. The result is a tendency for the nose of the aeroplane to turn in the direction of the inoperative engine. The extent of the yaw may vary depending on which engine becomes inoperative, with the inoperative engine that produces the greatest degree of asymmetry being termed the ‘critical’ engine.[12]

The asymmetric yawing tendency may be countered through the application of rudder and aileron control inputs. As the effectiveness of an aircraft’s control surfaces generally decreases with decreasing airspeed, sufficient airspeed must be maintained while operating OEI to ensure that the rudder and aileron retain sufficient control authority to maintain directional control of the aeroplane.

The minimum control airspeed with the critical engine inoperative (VMCA) is established by test pilots during aircraft certification under a specific set of conditions, and is marked on the air speed indicators of most multi-engine aeroplanes with a red radial line. VMCA is influenced by a large number of factors, including an aircraft’s configuration/loading, operating altitude and pilot control inputs and is therefore likely to vary from the stated value.

The VMCA published in the Cessna 441 pilots operating handbook (POH) was 91 kt indicated airspeed. The POH further stated that:

The airplane must reach the air minimum control speed (VMCA) before full control deflections are able to counteract the roll and yaw tendencies associated with one engine inoperative and full power operation on the other engine. VMCA with wing flaps in take-off position is indicated by a red radial on the airspeed indicator. VMCA with wing flaps in the UP position and the airplane in an en-route climb configuration will be buffet limited and occur at a higher speed.

In addition to the published VMCA the POH also listed an ‘intentional one engine inoperative’ indicated airspeed of 98 kt with advice that:

Although the airplane is controllable at the air minimum control speed, the airplane performance is less than optimum. A more suitable speed with wing flaps positioned in take-off is 98 KIAS [kt indicated airspeed]. This speed is identical to the normal rotation speed, thus the pilot can direct more of this attention to determining and securing the inoperative engine than to achieving a speed not normally associated with take-off. This speed also provides additional safety for controllability and allows easier maintenance of altitude during the period of gear retraction and securing the inoperative engine.

As detailed in the FAA handbook, maintaining directional control following an engine failure during take‑off and initial climb is especially critical:

The first consideration following engine failure during takeoff is to maintain control of the airplane. Maintaining directional control with prompt and often aggressive rudder application and STOPPING THE YAW is critical to the safety of flight. Ensure that airspeed stays above VMC [VMCA]. If the yaw cannot be controlled with full rudder applied, reducing thrust on the operative engine is the only alternative. Attempting to correct the roll with aileron without first applying rudder increases drag and adverse yaw and further degrades directional control.

Asymmetric performance

Optimum single-engine climb performance is obtained by flying the aircraft at the published OEI best rate of climb speed (VYSE), 120 KIAS for the Cessna 441, with maximum available power and minimised drag. Minimum drag is achieved by:

- retracting the flaps and landing gear

- feathering the propeller of the inoperative engine

- minimising sideslip by presenting the smallest aircraft profile to the relative wind.

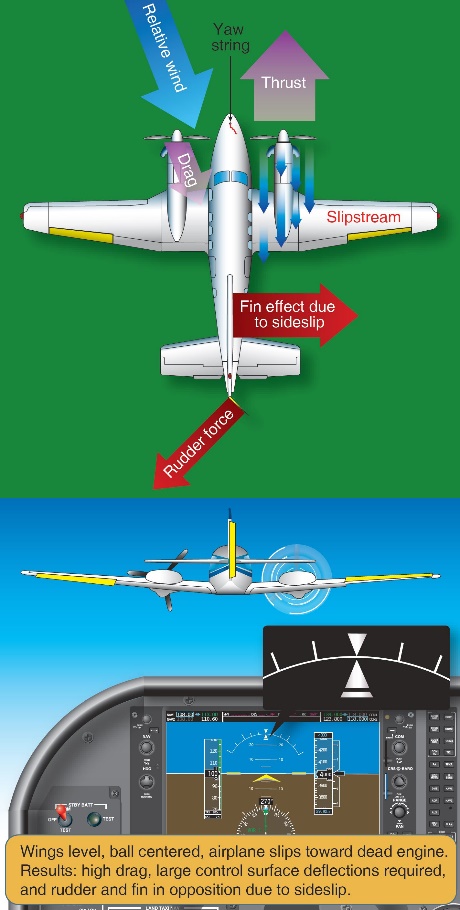

During symmetrical flight in a single-engine airplane, or a multiengine airplane with both engines operating, zero sideslip occurs when the balance ball[13] is centred. However, in the case of asymmetric thrust, zero sideslip requires a combination of bank angle and non‑centred ball position. That is, a combination of rudder and aileron inputs (Figure 9).

As it related to the Cessna 441, the POH provided the following information on the required combination of rudder and aileron inputs to minimise sideslip:

Best single-engine climb is attained with the wings banked approximately 3° to 4° and with a ⅔ to ¾ ball slip into the operative engine when the airplane is at low airspeed and heavy weight. As airspeed increases and/or airplane weight is significantly reduced, the ⅔ to ¾ ball slip becomes less important.

Figure 9: Zero sideslip

Source: United States Federal Aviation Administration

While it is possible to counteract asymmetric thrust using only rudder or only aileron, this results in significant performance and controllability penalties. Specifically, countering asymmetry with level wings and the ball centred (large rudder input towards the operative engine) results in moderate sideslip towards the inoperative engine that reduces climb performance (Figure 10). It also significantly increase VMCA as there is no horizontal component of lift to assist the rudder to counter the asymmetric thrust. In discussing this increase in minimum control speed as it related to the Cessna 441, the Civil Aviation Advisory Publication (CAAP) 5.23‑1(2) Multi-engine aeroplane operations and training stated:

…Flight tests in an instrumented Cessna Conquest showed that with a published VMCA [VMCA] of 91 kts, if the aircraft was flown in asymmetric flight with full power applied and the wings held level with the rudder balancing the aircraft, minimum control speed increased to 115 kts, an increase of 24 kts.

Figure 10: Rudder‑only input

Source: United States Federal Aviation Administration

Opposing asymmetric thrust using only aileron input results in a large sideslip towards the operative engine that also significantly reduces climb performance (Figure 11).

Figure 11: Aileron‑only input

Source: United States Federal Aviation Administration

OEI rate of climb performance for given operating conditions can be determined using data published in the POH/flight manual. Achieving the published performance relies on use of the zero sideslip technique and configuring the aircraft for minimum drag.

Considering the configuration and approximate weight of the aircraft at the time of the accident (see the section titled Weight and balance), the calculated OEI climb rate over a range of indicated airspeeds is shown in Table 1.

Table 1: One engine inoperative climb performance for Cessna 441 at 3,950 kg

| Indicated airspeed (kt) | Excess Thrust Horse Power (HP) | Calculated climb rate (ft/min) |

| 90 | 115.7 | 438 |

| 100 | 185.1 | 701 |

| 110 | 205.4 | 778 |

| 120 | 213.4 | 809 |

| 130 | 211.7 | 802 |

Source: ATSB analysis from aircraft certification data

The OEI performance data indicated that XMJ was capable of achieving a positive rate of climb following departure from Renmark if sideslip and other sources of drag were minimised.

Engine failure simulation

Zero thrust

Demonstration of OEI flight often involves simulating a failed engine by moving the power lever to a low power level rather than actually shutting down the engine and feathering the propeller. This method of simulation allows rapid normal power restoration. However, as detailed in the section titled Multi-engine aeroplane propellers, at low power settings the propeller will rotate due to the airflow rather than the engine, creating much higher drag than a feathered propeller. For that reason, a zero thrust power level is commonly set to overcome the drag associated with windmilling and more accurately simulate the low drag associated with a feathered propeller.

Zero thrust varies depending on the engine type, airspeed, altitude and temperature. In a piston engine aircraft zero thrust is normally achieved by setting a manifold pressure that results in a specific propeller rpm. In a turbine propeller engine zero thrust is expressed as an engine torque, and in some cases rpm, for a particular airspeed (normally VYSE).

Aircraft manufacturer’s procedures

The Cessna 441 POH detailed two procedures for simulating an engine failure, however neither procedure involved the use of a zero thrust power setting.

The first POH procedure was designed to practice management of an engine failure during the cruise phase of flight. The procedure involved retarding the power lever to the AIRSTART position and then shutting the engine down. In discussing the AIRSTART power lever position, the POH stated:

The AIRSTART position does provide some forward thrust. This position is recommended as it allows the best exhaust gas temperature stabilization before shutdown and it is the lowest position which will prevent the fuel computer from tripping to manual mode during an airstart.

If the power lever is retarded below the AIRSTART position and the fuel computer trips to manual mode, normal mode may be regained by advancing the power lever slightly and cycling the fuel computer switch to OFF then back to ON.

The second procedure was designed to train pilots to handle an engine failure in the take-off configuration. This involved using a fuel interruption process to actually shut the engine down. This was achieved by momentary selection of the engine stop button which activated a solenoid within the fuel control unit and cut off the fuel supply to the engine. In order to also simulate representative control forces during the exercise, the set up for the sequence involved:

- extending the landing gear

- extending the wing flaps to the take‑off position

- trimming the aircraft for a speed greater than the intentional one engine inoperative speed of 98 kt.

This procedure directly referenced related guidance in the POH, applicable to the demonstration of VMCA, which stated:

One engine inoperative procedures should be practiced in anticipation of an emergency. This practice should be conducted at a safe altitude (5000 ft AGL), with full power on both engines, and should be started at a safe speed of at least 98 KIAS. As recovery ability is gained with practice, the starting speed may be lowered in small increments until the feel of the airplane in emergency conductions is well known. It should be noted that as the speed is reduced, directional control becomes more difficult. Emphasis should be placed on stopping the initial large yaw angles by the IMMEDIATE application of rudder supplements by banking slightly away from the yaw. Practice should be continued until: (1) an instinctive corrective reaction is developed and the corrective procedure is automatic, and (2) airspeed, altitude and heading can be maintained easily while the airplane is being prepared for a climb.

The POH did not contain any procedure relating to simulation of an engine failure during the actual take‑off phase.

Additionally, for Cessna 441 aircraft with the serial number 0173 onwards (not applicable to VH‑XMJ) the POH, in reference to the ‘engine shutdown to simulate engine failure in takeoff configuration’ procedure (second procedure), explicitly stated

“This procedure must not be practiced at an altitude below 5,000 ft AGL”

Some of Rossair’s other Cessna 441 aircraft operated under this later POH, but the operators manual did not note a difference between the two handbooks.

With respect to the change in the POH procedures applicable to serial number 0173 and onwards, the aircraft manufacturer advised that:

- there was no material difference between the aircraft from serial numbers 0173 and onwards and the earlier serial numbers (0172 and prior) that necessitated a different method of simulating an engine failure in the take-off configuration

- the statements in the earlier POH procedure that referenced the demonstration of VMCA have the same intent as the warning note in the POH for aircraft with serial numbers 0173 and onwards, which states this procedure must not be practiced at an altitude below 5,000 feet above ground level.

Operator’s procedures

Rossair’s operations manual contained information relating to simulated engine failures in both Part A (general operations) and Part C (training and checking). Part A of the manual stated:

Simulated asymmetric flight is not to be carried out unless specifically authorised, and then only when accompanied by an authorised person. Asymmetric flight shall not be carried out when passengers are being carried and shall only be conducted on a designated training flight.

Any engine failure simulation shall be conducted by closing the power lever to a position equivalent to zero thrust (Turbine) in accordance with Part C, or moving the mixture lever to the idle cut off position (Piston).

For the purpose of training, simulated engine failures and the feathering of aircraft propellers shall only be conducted in VMC conditions. In addition, the aircraft shall be operating above 3000 ft AGL, unless the simulation or feather practice is specifically required during the approach and landing phase.

Following any practice engine shut-down in flight, the engine controls must be set for an immediate restart.

At no time are stalling or Vmca demonstrations to be made with the aircraft propeller feathered.

Part C contained detailed information on the procedure for simulating engine failures in the Cessna 441 (Figure 12). However, the procedure varied from that outlined in Part A with regard to initial power settings and the height at which the simulation could be initiated.

Part A detailed that engine failure simulation for training purposes was to occur above 3,000 ft above ground level unless specifically required during the approach and landing phase. Part C permitted the simulation of engine failure ‘After attaining the higher of 400’ or acceleration altitude’. The reference to ‘acceleration altitude’ was not applicable to the Cessna 441.

Figure 12: Rossair training and checking manual

Source: AE Charter/Rossair

The Part C procedure involved retarding power to flight idle (power level to minimum) and then advancing the power to zero thrust (to represent a feathered propeller) on completion of the engine failure drills. This is the normal technique used for simulating the failure of a piston engine aircraft, where the pilot must manually feather the propeller.

It is not necessary to select less than a zero thrust setting to simulate failure of a turboprop engine equipped with auto feather or negative torque sensing systems (such as the Cessna 441). More importantly, setting the power lever below the zero thrust setting will increase propeller drag. As detailed previously, selection of less than the AIRSTART power lever position in the Cessna 441 can also affect automatic operation of the fuel computer.

An earlier version of the company operations manual detailed simulation of a failed engine on a turboprop engine by only moving the power lever to zero thrust. The ATSB could not determine how the procedure involving moving the power to below zero thrust was introduced into the 2016 version of the manual (in use at the time of the accident). However it may have occurred during the merger of Rossair with another company (see section titled Overview of the operator). Additionally, this section of the operations manual was approved by the Civil Aviation Safety Authority without detection of the error (see section titled Regulatory services processes).

Finally, the propeller manufacturer advised that for the four‑bladed propellers fitted to XMJ, the required zero thrust setting was about 234 ft.lbs of engine torque, 116 ft.lbs less than stated in Part C of the operations manual.

Regulatory guidance

CAAP 5.23‑1(2) Multi-engine aeroplane operations and training, provided comprehensive guidance on the operation of multiengine aeroplanes. With regard to the simulation of engine failures, it stated:

Before simulating engine failures in multi-engine aircraft, instructors must be aware of the implications and be sure of their actions. Consult the aircraft flight manual or POH for the manufacturer’s recommended method of simulating an engine failure.

The CAAP also provided guidance on setting power to simulate a failed engine. Specifically, it was recommended to initially close the throttle of a piston engine to replicate a windmilling propeller and then set zero thrust once the trainee had simulated propeller feathering. In the case of a turboprop engine, replication of an engine failure only required selection of zero thrust. Guidance was also provided on a method to establish zero thrust if it was not specified.

The CAAP also detailed a number of risks associated with multi-engine training, including:

- inappropriate management of complex aircraft systems

- conducting flight operations at low level (engine failures after take-off)

- conducting operations at or near VMCA or VSO [stall speed with undercarriage and flap selected] with an engine inoperative

- asymmetric operations.

With regard to flight operations at low level, the CAAP further stated:

Any flight operation at low altitude has potential dangers. Trainers have debated over the decades on the value of practicing engine failures after an actual take-off, near the ground. The general consensus is that despite the risks, pilots must be trained to manage these situations in multi-engine aircraft.

…Instructors should consider not simulating engine failures below 400 ft above ground level (AGL) to provide a reasonable safety margin.

Accident flight procedure

There was insufficient information and recording devices to determine the specific procedure used to simulate the engine failure after take‑off from Renmark Airport. However, the electronic briefing developed by the chief pilot in preparation for the occurrence check flight provided specific guidance on how engine failures were to be simulated as follows:

All failures will be preceded by the phrase “simulated”

• Once the memory items have been carried out, zero thrust will be set

• The instructor will handle the ‘failed’ engine

• Pilot is to use other power lever as required

• When landing, pilot may retard both levers as required

Any failure not preceded with the phrase “simulated” is real and shall be treated as such.

In preparation for the occurrence check flight, a practice flight covering similar sequences was conducted in XMJ the week before with the chief pilot and inductee pilot. That flight also had an observer on board with extensive Cessna 441 check pilot experience. The practice flight was not conducted as a training flight, but rather a private flight with two licenced and experienced pilots on board, preparing for their respective roles during the CASA check flight.

The observer advised that during the practice flight, the engine failure was simulated by the chief pilot reducing the power lever but not all the way to the flight idle stop. He further recalled that once the inductee pilot completed the initial response actions, the chief pilot partially advanced the power lever. The observer stated that, based on his experience, zero thrust in the occurrence aircraft was about 150 ft.lbs of torque and lower than other company Cessna 441 aircraft. He also recalled that the chief pilot set a power lever position at or slightly above that torque value during the simulation.

Stall speed

The calculated stall speed depends on the weight of the aircraft, as well as the gear and flap configurations, and the angle of bank. For XMJ, at the ATSB calculated take-off weight from Renmark Airport (3,950 kg), with:

- gear and flap retracted

- power at the flight idle,

the calculated stall speed with wings level was 85 KIAS. At 20° angle of bank, the stall speed increased to approximately 88 KIAS.

Flight recorders

XMJ was not equipped with a flight data recorder or cockpit voice recorder. Requirements relating to the fitment of flight recorders is detailed in Civil Aviation Order (CAO) 20.18 as follows:

An aircraft of maximum take-off weight:

a) In excess of 5,700 kg and which is:

i. turbine powered; or

ii. of a type first certificated in its country of manufacture on or after 1 July 1965;

shall not be flown (except in agricultural operations) unless it is equipped with an approved flight data recorder and an approved cockpit voice recorder system;

b) Less than or equal to 5,700 kg and which is:

i. pressurised; and

ii. turbine powered by more than one engine; and

iii . of a type certificated in its country of manufacture for operation with more than eleven places; and

iv. issued with its initial Australian Certificate of airworthiness after 1 January 1988;

shall not be flown unless it is equipped with an approved cockpit voice recorder system.

The Cessna 441 has a maximum take‑off weight of 4,468 kg so CAO 20.18(a) was not applicable. Additionally, although meeting a number of the criteria detailed in CAO 20.18(b), the Cessna 441 is certified for a maximum of eleven seats (two crew and nine passengers). The aircraft was therefore not required to be fitted with either a flight data recorder or a cockpit voice recorder.

Recorded flight data

As part of the investigation, data broadcast by the automatic dependent surveillance broadcast (ADS-B) equipment fitted to the aircraft was obtained from various web-based providers. Depending on the provider, this data recorded the following parameters at intervals of either 6 or 15 seconds:

- latitude and longitude

- time of the logged position

- pressure altitude

- groundspeed

- track.

A review of the data identified that the aircraft descended outside ADS-B coverage as it approached the circuit area at Renmark Airport. Consequently, no ADS-B flight data was available for the departure of XMJ from Renmark.

However, GPS data transmitted from an on board mobile device with the OzRunways application installed was able to be sourced. This data was available at 5 second intervals with the GPS altitude truncated to the nearest 100 ft and accurate to about -30/+130 ft of the recorded value. The OzRunways data parameters were compared with ADS‑B information from earlier stages of the flight and was found to be consistent. That provided assurance that the OzRunways data was valid and could be relied upon for analysis of the final flight segment. Although the recorded parameters were considered representative of the actual flight profile, it was not possible to determine how they varied between sample points.

Using the GPS groundspeed, and wind information obtained from the BoM, the aircraft’s true airspeed (TAS) was calculated. The TAS values were then converted to a calculated indicated airspeed (IAS) using altitude and temperature data. Given the relatively low operating altitude, the IAS varied only slightly from the calculated TAS. The airspeed and height above the ground variation over the final 1 minute of the flight, referenced to the elapsed time from take‑off, is shown in Figure 13.

Figure 13: Indicated airspeed and altitude variation over the final minute of flight

Source: ATSB

The data showed a steady increase in airspeed up to about 132 kt, followed by loss of airspeed, brief stabilisation around 110‑115 kt, then a further decrease to about 107 kt before the data ended. The maximum recorded airspeed was about 10 kt higher than published OEI best rate of climb speed VYSE (120 kt, see the section titled Asymmetric performance) and occurred at a height of about 300 ft above ground level.

That height was derived from the recorded GPS altitude of 400 ft less 100 ft for the approximate runway elevation (see the section titled Airport information). Noting that the GPS altitude was truncated to the nearest 100 ft and had an accuracy of about ‑30/+130 ft, a height of 300 ft above the ground was indicative of an actual height range between 270‑420 ft above the ground.

Analysis of the indicated airspeed and height profiles indicated that, on attaining the minimum operator‑specified conditions for initiation of a simulated engine failure, the variation in airspeed and altitude was consistent with a reduction in performance associated with OEI flight.

The airspeed subsequently decreased below the target airspeed of VYSE and remained below that airspeed for the final 35 seconds of the data. The final airspeed value of 107 kt was above both the calculated stall speed (see the section titled Stall speed) and the published minimum control airspeed VMCA. However, it was below the VMCA range established during flight testing in the Cessna 441 (see the section titled Asymmetric performance).

Figure 14 illustrates the difference in the calculated IAS and height (above ground level) profiles between the departure from Renmark Airport and the earlier departure from Adelaide Airport.

Figure 14: Departure profile comparison

Source: ATSB

In addition to the airspeed variation, the aircraft’s rate of climb was derived from the GPS altitude data and is shown, together with the aircraft’s track deviation from the runway heading in Figure 15. The data indicated that the aircraft initially climbed at greater than the expected OEI rate of climb before levelling and maintaining approximately level flight for 30 seconds until the data ended. A review of the airspeed over the same time period identified that it reduced during the peak increase in the rate of climb, suggesting that the aircraft was pitched up to reduce airspeed.

Analysis of the track variation identified that the aircraft deviated to the right of the runway centreline during the final minute of the flight. That movement was consistent with both the prevailing left crosswind component during the departure and a reduction in power on the right engine.

Figure 15: Rate of climb and track variation over the final minute of flight

Source: ATSB

Operational information

Pilot licencing

Each of the three pilots on board held a Civil Aviation Safety Regulations 1998 (CASR) Part 61 licence. CASR Subpart 61E requires that pilots meet a series of ongoing requirements in order to exercise the privileges of their licence. Relevant requirements are discussed below.

Pilot recency requirements for carriage of passengers

CASR Part 61.395 outlines the recent experience requirements that pilots must have in order to carry passengers. By day, this includes at least three take-offs and three landings within 90 days in the aircraft. A pass in a flight check meets this requirement.

The Rossair operations manual (Part A) reflected the Part 61 requirements for landings and included the company recency requirements for conducting instrument approaches.

Both of the pilots in the control seats met the recency requirements for the flight they were conducting.

Class and type rated aircraft

Under the regulations prior to CASR Part 61, particular aircraft required a pilot to be trained, endorsed and checked on that aircraft type in order to operate that specific type. Under Part 61, there are still some aircraft which come under this requirement (‘type rated aircraft’), such as the Embraer EMB 120, but other aircraft are included in a class rating (‘class rated aircraft’). This means that a check on any aircraft in the class rating covers all other aircraft in that class rating. Pilots must complete a flight review for the class rating every two years to continue operating aircraft in that class.

The Cessna 441 is in the multi-engine class rating. However, the complexity of the aircraft is recognised by CASA, who requires that pilots that wish to operate the Cessna 441 first complete flight training and a flight review in this aircraft type, before it becomes covered by the class rating in subsequent years. Other complex twin aircraft covered by this legislation include the Beechcraft King Air C90, King Air B200 and the de Havilland DHC-6 Twin Otter.

As discussed previously (see the section titled Pilot licencing), the CASA FOI renewed his class rating in a Rossair Cessna 441 with the Cessna 441 fleet manager in late 2016. The inductee pilot completed his multi-engine class rating renewal along with his instrument proficiency check in a Beechcraft Baron 95-B55 in February 2017.

The chief pilot had not been checked on a class rated aircraft, since his check pilot training was completed in the Cessna 441 (see the section titled Pilot licencing). In October 2016 he completed his instrument proficiency check (IPC) and type rating renewal in the EMB 120 simulator, which, at that time, under CASA exemption 97/16 satisfied the requirements for the multi-engine class rating renewal. Despite the EMB 120 being a two crew aircraft, and the Cessna 441 being a single pilot operation, the chief pilot was not required to demonstrate on‑going competency in the Cessna 441, as long as he continued to be checked in the EMB 120.

General competency

CASR Part 61.385 ‘Limitations on exercise of privileges of pilots licences – general competency requirement’ states:

1) The holder of a pilot licence is authorised to exercise the privileges of the licence in an aircraft only if the holder is competent in operating the aircraft to the standards mentioned in the Part 61 Manual of standards for the class or type to which the aircraft belongs, including in all of the following areas:

• Operating the aircraft’s navigation and operating systems;

• Conducting all normal, abnormal and emergency flight procedures for the aircraft;

• Applying operating limitations;

• Weight and balance requirements;

• Applying aircraft performance data, including take-off and landing performance data, for the aircraft.

(1A) Subregulation (1B) applies if the holder of a pilot licence also hold an operational rating or endorsement

(1B) The holder is authorised to exercise the privileges of his or her pilot licence in an activity in an aircraft under the rating or endorsement only if the holder is competent in operating the aircraft in the activity to the standards mentioned in the Part 61 Manual of standards (if any) for:

a) The class or type to which the aircraft belongs; and

b) The activity.

In assessing personal competency under this regulation, CASA recommended that ‘pilots should seek advice and consider refresher training or practice before commencing an operation they haven’t carried out for a while’. Although the pilot is already licenced and current on the class of aircraft, training for general competency can only be given by a pilot who holds an instructor rating and appropriate training endorsements.

The check flight briefing (see the section titled Check flight sequences) prepared for the flight had a series of questions at the end of the briefing for the inductee pilot to answer, consistent with the areas of competency identified above. Additionally, the practice flight conducted by the two pilots the week prior was an opportunity to practice the handling skills in this aircraft rather than other aircraft flown by each of the pilots.

Operational proficiency check

A proficiency check is ‘an assessment of your skills and knowledge in a particular operational area. Pilots are required to undertake proficiency checks to ensure they continue to be competent conducting particular kinds of operations’ (CASA Proficiency checks information sheet, 2018). CASA recognises that skill decay occurs over time, and that these checks are an on-going measure to ensure that the licence competencies specified in the CASR Part 61 Manual of Standards continue to be met (see the section titled Skill decay).

Operational proficiency checks are carried out by an operator and may also include the elements required for an instrument proficiency check (IPC), provided the check pilot is authorised to conduct both types of check. The chief pilot in this case was being checked only for approval to conduct OPCs. Operational proficiency checks can only be conducted on pilots employed by that company.

Operating under Civil Aviation Regulations 1988 (CAR) Regulation 217 (see the section titled Organisational structure) Rossair pilots had to pass two proficiency checks per year (listed in the operations manual as alternating between an IPC and OPC), with at least four months between checks, in order to exercise the associated privilege. As the inductee pilot was re-joining the operator, this was his first OPC in the Cessna 441 in over three years. The chief pilot had completed an:

- OPC in the Cessna 441 in April 2016 in the left seat, and in May 2016 from the right seat, as part of his Cessna 441 check pilot training

- IPC in the EMB 120 in October 2016, and an OPC in the EMB 120 simulator in February 2017.

This met the regulatory and operator requirements for proficiency checking, but did not permit assessment of the chief pilot’s on-going competency in the particular area of single pilot operations.

Practice engine failure after take‑off check requirements

The chief pilot was the pilot primarily being checked during the flight and he had to conduct the inductee pilot’s operational proficiency check in line with the company procedure to be approved as a check pilot.

When a proficiency check is conducted under a CAR 217 approval, the exercises conducted are set by the CAR 217 holder rather than CASA. The Rossair operations manual Part C stated that proficiency checks were to be conducted in accordance with their own check assessment form and the CASA instrument proficiency check form. The company guidance was for check pilots to reference the section of the CASR Part 61 manual of standards for the instrument rating flight test.

When an operator proficiency check is conducted without an instrument proficiency check, there is no CASA requirement for the candidate to demonstrate management of a simulated engine failure after take-off. The Rossair check assessment form however, had a required flight component to ’deal with a simulated engine emergency after take-off requiring an immediate re-landing’.

There are a number of CASA checks which require demonstration of an engine failure after take‑off in a multi-engine aircraft, both for initial issue of a licence or endorsement and during specific types of proficiency checks. The wording of the specified activity varies slightly between checks, for example ’conduct instrument departure (one engine inoperative)’ for the multi-engine class rating; or ’manage an engine failure after take-off (simulated)’ in the multi-engine class rating.

While the wording varied, the competencies are all similar in intent: requiring the pilot to manage the simulated failure while maintaining the aircraft within specified tolerances; and configuring and flying the aircraft to achieve the best performance.

While the manual of standards does not specify a height at which these activities should be conducted, CAAP guidance stated that they should not be conducted below 400 ft above ground level. The requirement of managing an engine failure during an instrument departure or after take‑off, could be interpreted as meaning that these activities should to be conducted at low altitude. However, there was no direct comment in any CASA guidance that this is required.

The flight

Background

The chief pilot’s approval instrument had a conditional requirement that an additional pilot had to be either employed or contracted to Rossair as a fleet manager on the Cessna 441 (see the section titled Organisational structure). Due to an unexpected temporary loss of his medical approval, the fleet manager became unable to conduct flying duties for Rossair, and was therefore unable to fulfil the full fleet manager role, which included check flight responsibilities.

To resolve this issue, the chief pilot wrote to CASA to request a variation to his chief pilot instrument of approval, to remove the requirement for a Cessna 441 fleet manager. It was intended that the fleet manager would continue in an administrative fleet manager role, and a contract Cessna 441 pilot would be used for on-going check and training responsibilities, with the chief pilot maintaining oversight responsibilities only. The proposed contract pilot was known to CASA, and had been given permission to carry out two OPC checks for Rossair in April 2017 while there was no company check pilot.

In response to this request, CASA proposed that the chief pilot should be checked in the aircraft conducting an OPC on a company pilot. This check would give the chief pilot approval to conduct OPCs and line checks. The approval would then allow him to undertake the Rossair induction process with the contract Cessna 441 pilot, before the contract pilot began all checks on company pilots.

Check flight sequences

The chief pilot developed an electronic briefing, in preparation for the occurrence check flight, which included specific detail of the ground and flight components to be conducted. The briefing detailed the following two flight exercises:

Flight exercise #1

• Normal departure via SID [standard instrument departure from Adelaide Airport]

• Fly to

• Holding pattern, engine failure

- Conduct memory items then checklist

- Radio calls, passenger brief

• RNAV approach

- Single engine

• Visual then go around on final

- Single engine

• Single engine circuit and landing

Flight exercise #2

• Normal take-off [from Renmark Airport]

- Engine failure above 400’

› Conduct memory items and checklists

› On base,[14] engine will be restored

- Climb to 8000’

- Steep turns

- Partial panel

- Stall

› Clean

› Approach configuration

- Two engine instrument approach at Adelaide.

While the pre-check briefing was not witnessed by anyone other than the participants, surveillance data and radio transmissions indicated the accident flight was conducted as per the briefed flight exercises, except that no single‑engine go around was performed on arrival at Renmark. An observer on board the aircraft during the preparatory practice flight the week before reported that the briefed sequences, including a practice engine failure after take‑off from Renmark Airport, were undertaken.

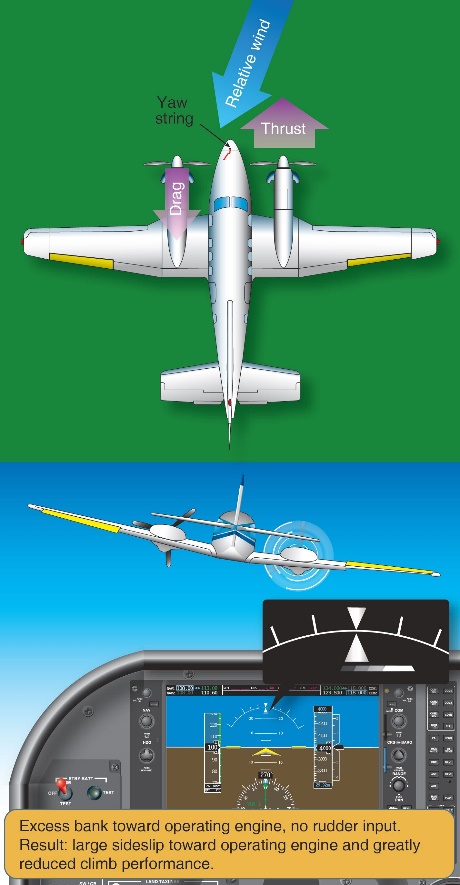

With regard to that sequence, the second flight exercise detailed that following a normal take‑off and simulated engine failure above 400 ft above ground level, ‘memory items and checklists’ were to be conducted. These memory items, also known as ‘phase one’ checks, were detailed in the company operations manual for the Cessna 441 as follows:

| 1. Engine power | ADJUST as required |

| 2. Inoperative engine | DETERMINE |

| a. Condition lever | EMERGENCY SHUT OFF |

| b. Firewall shut of | PUSH to close |

| 3. Landing gear | UP |

| 4. Flaps | UP above 115 knots |

The memory checks duplicated the initial response actions detailed in the POH checklist for an engine failure above the minimum control airspeed, VMCA (see the section titled Asymmetric flight) (Figure 16).

Figure 16: POH engine failure checklist

Source: Cessna 441 Pilot’s operating handbook

In the event of an actual engine failure, the briefing detailed that the ‘[inductee] Pilot is to continue operating the aircraft unless the instructor [check pilot] elects to take over with the phrase “Taking Over”.’ and that the check would then be terminated and the aircraft landed at an appropriate airport.

The briefing also outlined the following process for transitioning control of the aircraft between the chief pilot and inductee pilot:

• Control over aircraft is to be conducted with the “handing over, taking over” phrase.

• If at any time, the instructor announces “taking over”, the pilot shall:

- Remove hands and feet from all controls’

- Respond “handing over”.

• To pass control of aircraft to pilot, instructor shall announce “handing over”. The pilot shall:

- Place hands and feet on the controls,

- Respond “taking over”,

- Be responsible for operation of the aircraft.

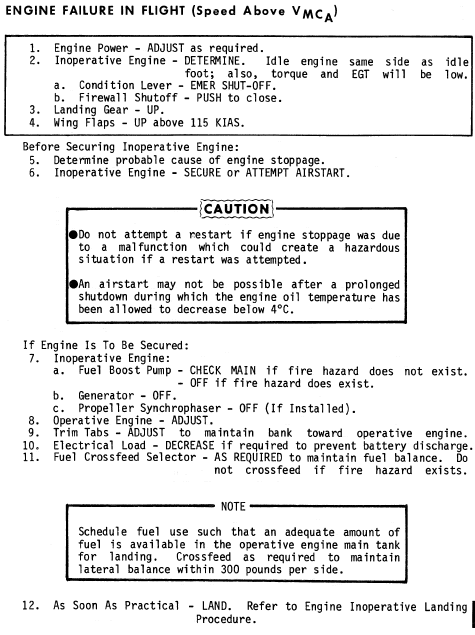

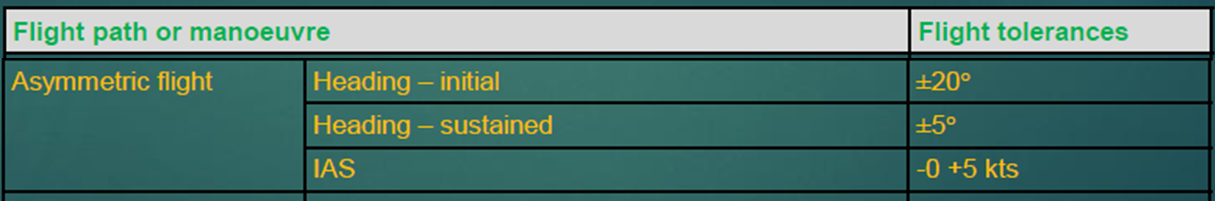

The briefing also specified the required test flight tolerances from the Civil Aviation Safety Regulations 1998 Part 61 Manual of Standards, including for asymmetric flight (Figure 17). In detailing the objectives of the proficiency check, with regard to flight tolerances the briefing also stated:

“a sustained deviation outside of the applicable flight tolerance is not permitted”.

Figure 17: Required flight accuracy tolerances

Source: Rossair

Carriage of passengers during practice emergency procedures

Regulation 249 of the Civil Aviation Regulations 1988 prohibited the carriage of passengers on board an aircraft during the practice of emergency procedures, such as simulated engine failures. CASA issued exemption EX74/15 which, under certain circumstances, permitted a passenger to be carried if the pilot in command - being either a check pilot, approved testing officer of flight examiner - carried out a proficiency check or flight test on another pilot. This exemption permitted the chief pilot to be carried as an observer on three check flights during his Cessna 441 check pilot training (see the section titled Check pilot training).

The exemption at the time did not explicitly refer to carriage of CASA FOIs, outside permitting them to be carried during their training in connection to become a flight examiner or inspector. Following this accident, CASA issued exemption EX58/19 – Carriage of passengers on proficiency check and flight test flight instrument 2019 - which clarified the previous exemption, clearly stating that a CASA officer could be carried as a passenger for duties directly relating to the conduct of the flight test or proficiency check. The explanatory statement for this exemption stated ’the pilot in command must ensure that the passenger does not interfere with the conduct of the proficiency check of flight test. The passenger must not occupy a control seat’.

Flying operations inspector seated in non-control seat