What happened

On the morning of 11 July 2013, a Sikorsky S-76C helicopter, registered VH-EXU, departed the heliport at Longford, Victoria on the first of a series of passenger ferry flights to a number of offshore platforms that were located throughout the Bass Strait oil and gas fields.

On departure from the Snapper platform for a return to Longford, the right engine failed. The helicopter descended rapidly toward the surface of the water.

The crew controlled the helicopter and secured the failed engine. In addition, in response to a right engine fire warning, the crew discharged fire extinguisher agent into the right engine compartment. A positive rate of climb was established and the helicopter was flown away before being escorted back to Longford by other company helicopters for a single-engine landing.

What the ATSB found

The engine failure was attributed to the fracture of a second-stage, high-pressure turbine blade. The liberated blade impacted and damaged adjacent blades with the resulting loss of power and associated increased vibration.

The engine and failed blade structure were inspected by the engine manufacturer. The manufacturer concluded that the failure was due to a combination of metal fatigue, blade creep and oxidation deposits. While a definitive cause for the blade fracture has yet to be determined, blade material, dimensional and quality assurance checks have ruled out any deficiencies.

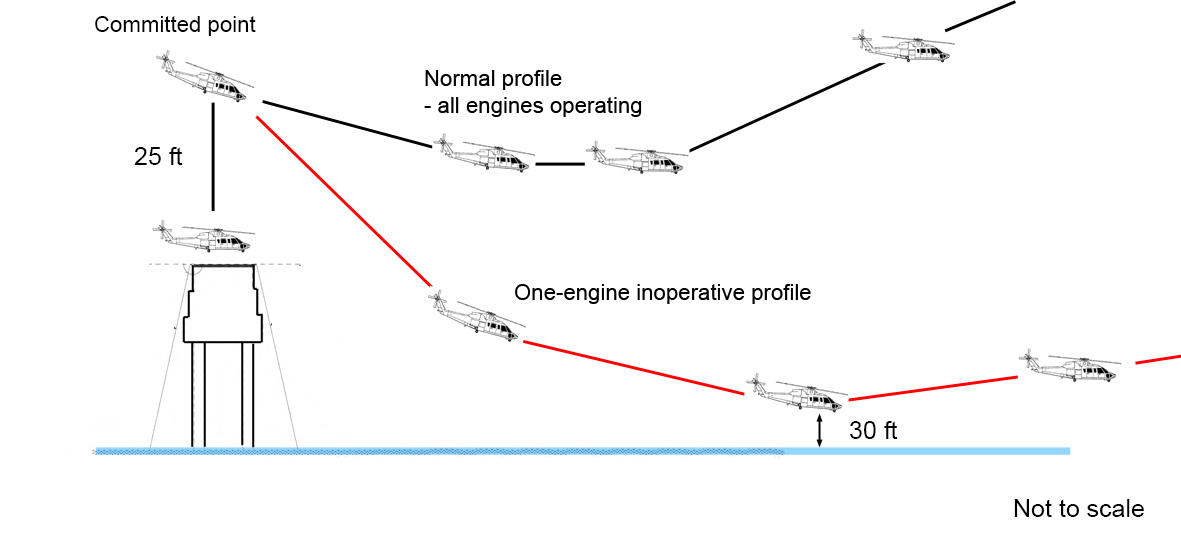

In the absence of published data from the helicopter manufacturer, the operator had established helideck flight departure and approach profiles consistent with the performance capabilities of the helicopter. In this case, the lift-off from the helideck followed the operator’s standard departure profile. Given this profile, the helicopter descended to within 30 ft (9 m) of the sea surface during the recovery to stabilised flight.

What's been done as a result

In the absence of a conclusive cause of the blade fracture and remedial information, the operator imposed a service life limitation on their helicopters’ engine turbine assemblies that were fitted with the same blades. In addition, the engine manufacturer issued notifications to operators and introduced specific inspection requirements relevant to potentially affected turbine assemblies.

At the time of writing, the engine manufacturer was continuing its investigation into the cause of the blade fracture.

Safety message

This occurrence highlights how a situation can quickly change from normal operations to one where the flight crew have to deal with an in-flight emergency. In this respect, effective crew interaction, thorough pre-briefing and anticipation of what can go wrong has been shown to increase the likelihood of a successful outcome. Recovery from the engine failure and potential ditching, and return of the helicopter to Longford, reaffirms the benefits of those preparatory actions.

Background

At 0730 Eastern Standard Time[1] on 11 July 2013, a Sikorsky S-76C helicopter, registered VH‑EXU (EXU), departed the operator’s heliport at Longford, Victoria on the first of a series of passenger ferry flights to a number of offshore platforms that were located throughout the Bass Strait oil and gas fields. This involved dropping off and picking up passengers at each stage. The flight duration between platforms was relatively short, ranging between 3 and 11 minutes.

At around 0835 the flight crew landed on Snapper platform for the final passenger drop-off/pick-up before returning to the Longford heliport. On board the helicopter for the flight to Longford were 10 passengers and two flight crew. The captain was the pilot monitoring and the copilot the pilot flying.[2]

After the passengers and their baggage were loaded, the flight crew completed their pre‑take‑off checks and commenced lift-off at around 0843. With all cockpit indications normal, the helicopter was established in a low hover above the helideck for final systems checks prior to departure. The copilot commenced a vertical climb from the hover and, after achieving the required rate of vertical climb and height above the helideck, reached the take-off ‘committed point’[3]. At this point, the copilot selected a nose-down attitude and commenced flying away in a standard, descending profile.

The engine failure and recovery

The crew recalled that immediately after setting the nose-down attitude, there was a loud bang accompanied by significant airframe vibration. The helicopter yawed about 5° to the right and descended toward the sea surface. Numerous lights illuminated on the master warning panel and an aural warning alerted the crew of a significant problem.

Coincident with the loud bang, the captain noted an immediate split in torque between the two engines and a decay in the main rotor speed. The captain identified that the right engine had failed and transmitted a MAYDAY[4] radio call to the operator’s search-and-rescue (SAR) service via the Longford flight following facility.

Following the engine failure, electrical power to the flight and navigation displays on each pilot’s instrument panel was disrupted, momentarily shutting down both primary electronic flight information system screens. Among other information, these screens display the attitude of the helicopter. The loss of attitude information required the copilot to revert to flying the helicopter with reference to the natural horizon.

The captain recalled that during the emergency the helicopter descended to around 30 ft (9 m) above the sea surface. Due to uncertainty of whether sufficient performance could be restored before an emergency ditching, the captain was ready to activate the emergency flotation system until the helicopter regained altitude and safe flight was assured.

The copilot recalled a positive airspeed trend through 45 kt and, at 60 kt, commenced a gradual climb with a recovery of the main rotor speed. Control of the aircraft was maintained and the crew were able to stabilise the main rotor speed at 107 per cent. The crew decided that the best option was to fly direct to the coastline.

After stabilising at 500 ft, the flight crew completed the engine failure checklist and secured the right engine. A follow-up radio call to the Longford flight following facility by the captain updated the operator on the situation. The crew elected to continue the climb to a target altitude of 1,000 ft.

During the climb, and despite the engine already being shut down, the crew were alerted to fire indications in the exhaust region of the right engine. The crew reported that the exhaust temperature increased rapidly until it was ‘off the scale’. In response, the crew carried out the engine fire checklist. This included activating the engine’s fire handle, which discharged fire‑extinguishing agent into the right engine compartment. The exhaust temperature reduced to zero. A third radio call to Longford advised of the engine fire and that it had been extinguished.

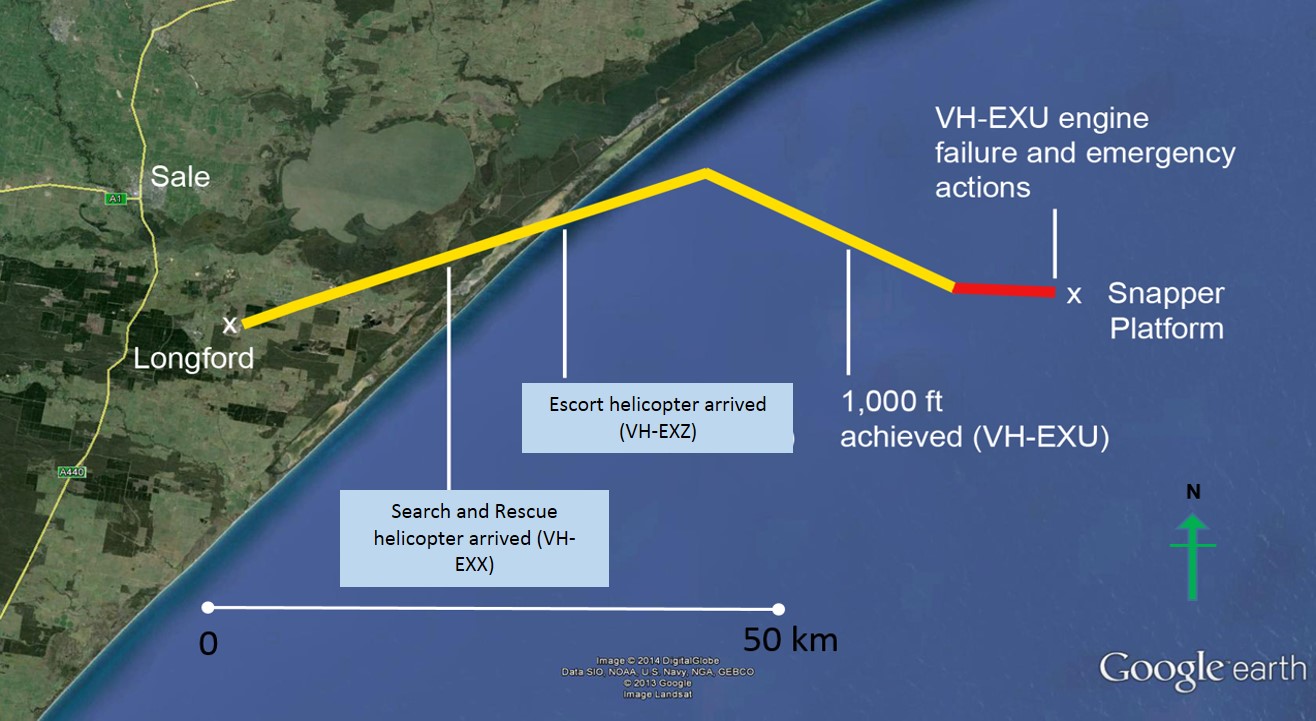

As part of their ongoing checks, the flight crew determined that the available fuel quantity in the tank that was feeding the left engine was approaching a low level as the helicopter approached the coastline. In response, the crew activated the cross-feed function to supply fuel from the right tank to the operating left engine. This ensured adequate reserves for the remainder of the flight to Longford. A depiction of the approximate flight track is provided in Figure 1.

Figure 1: Approximate flight track from Snapper platform to the operator’s heliport at Longford

Source: Google earth, modified by the ATSB

Operator’s SAR capability and response

The operator maintained a SAR capability at their Longford heliport that used a dedicated Sikorsky S-76C helicopter from within their fleet. A rostered crew remained prepared and on call during normal operations throughout the day.

Following the crew’s MAYDAY call the SAR helicopter was deployed to intercept EXU along its return track. Another of the operator’s helicopters that was en route to a nearby platform was contacted by the Longford flight following facility to divert and escort EXU for the return flight. The crew of this helicopter conducted a visual assessment of EXU and advised that no external damage was evident.

At 0913 the flight crew of EXU conducted a single-engine approach and landing at the Longford heliport.

__________

- Eastern Standard Time (EST) was Coordinated Universal Time (UTC) +10 hours.

- Pilot Flying (PF) and Pilot Monitoring (PM) are procedurally assigned roles with specifically assigned duties at specific stages of a flight. The PF does most of the flying, except in defined circumstances; such as planning for descent, approach and landing. The PM carries out support duties and monitors the PF’s actions and aircraft flight path.

- After this point during the departure, the flight crew were committed to flying the helicopter away from the offshore platform.

- MAYDAY is an internationally recognised radio call for urgent assistance.

Pilot information

Qualifications, experience and training

Both pilots held an Airline Transport Pilot Licence (Helicopter), an endorsement on the Sikorsky S‑76C (S-76C) helicopter and a valid Class 1 Aviation Medical Certificate. Both were designated by the operator as captains of the S76C helicopter type.

The captain of the helicopter, the more senior of the two pilots that day, was seated in the right seat. The copilot was seated in the left seat and maintained control of VH-EXU (EXU) throughout the emergency and return to the Longford heliport.

The operator maintained a training and checking organisation to manage aircrew flight competency with checks conducted on a 6-monthly basis. These checks included pilot response to a single-engine failure on reaching the take-off committed point. Examination of the pilots’ most recent training records showed that both had passed all of their competency checks.

The operator’s pilots were also required to complete S-76C simulator endorsement training. The copilot commented that the emergency training in the simulator and during their competency checks was invaluable in identifying and managing the engine failure on departure from Snapper platform.

The relevant aeronautical experience of the flight crew is outlined in Table 1 and Table 2.

Table 1: Copilot's aeronautical experience and relevant training

| Designation | Captain |

| Total flying hours | 6,100 |

| Total flying hours in the S-76C | 1,035 |

| Total flying hours in the last 90 days | 160.2 |

| Total flying hours in the last 30 days | 45.9 |

| Total flying hours in the last 24 hours | 6.4 |

| Last base[5] check | 16 June 2013 |

| Last S-76C simulator check | November 2011 (due again in October 2013) |

Table 2: Captain's aeronautical experience and relevant training

| Designation | Captain |

| Total flying hours | 11,050 |

| Total flying hours in the S-76C | 3,100 |

| Total flying hours in the last 90 days | 152 |

| Total flying hours in the last 30 days | 58.5 |

| Total flying hours in the last 24 hours | 3.1 |

| Last base check | 13 June 2012[6] |

| Last S-76C simulator check | November 2012 (due again in November 2014) |

Helicopter information

General information

The S-76C is a four-blade, twin-engine, transport category helicopter capable of carrying two flight crew and up to 12 passengers (Figure 2). It is often used for offshore oilfield support due to its long range.

EXU was manufactured in the United States in 1995 and first registered in Australia on 21 July 1995. It had accumulated 13,084 hours total time in service and 73,192 landings at the time of the engine failure. In the event of a ditching, EXU was equipped with:

- an emergency flotation system

- deployable life rafts

- passenger life jackets

- an emergency locator transmitter.[7]

As EXU was operated in the private category, a flight data recorder was not fitted, nor was it required by regulation. The operator had installed an aftermarket condition monitoring system that recorded vibration data of critical components including the main and tail rotors, rotor drive systems and engines.

Figure 2: Sikorsky S-76C

Source: Helicopter operator

Engine information

EXU was powered by two Safran SA Turbomeca (Turbomeca) Arriel 1S1 turboshaft engines located above and to the rear of the passenger compartment. These engines consist of five modules, with the gas generator (GG) turbine located in Module 3.

Examination of the engine records for the right engine in EXU showed that Module 3 had accumulated 2,275 hours in service and 2,664 cycles since the last overhaul.

Turbomeca service bulletin (SB) 292 72 0151 was issued in June 1992 and specified the incorporation of modification TU-204 across all variants of the Arriel engine. This modification involved corrosion and erosion protection of the second stage, GG high pressure (HP2) turbine blades via application of a low-pressure plasma coating. Modification TU-204 was incorporated in Arriel 1S1 engines at manufacture.

Following reports of several uncommanded in-flight engine shutdowns attributed to HP2 turbine blade failures, the engine manufacturer implemented internal documentation and procedures to remove all TU-204 HP2 turbine blades during overhaul of Module 3. Consequently, SB 292 72 0151 was amended on 18 August 2000, to recommend removal of all TU-204 modified blades.

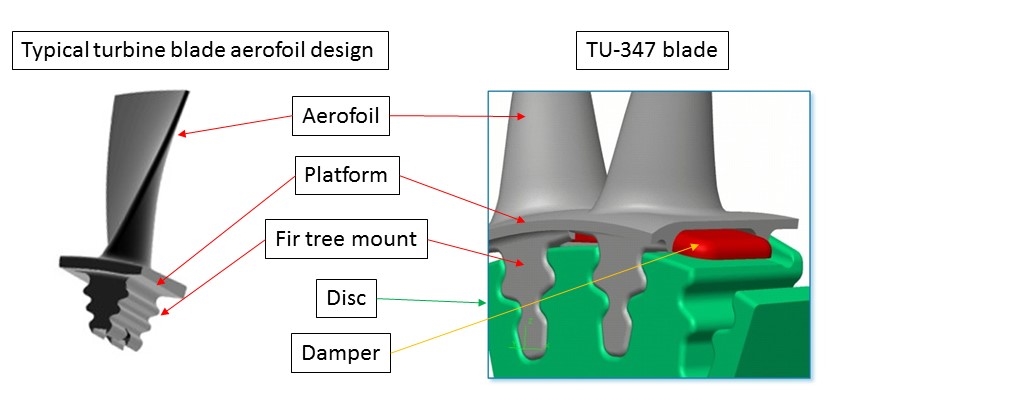

Subsequently, Turbomeca released SB 292 72 0347, effective from July 2008, which referenced the incorporation of modification TU‑347. This modification incorporated a redesigned HP2 turbine that was in accordance with the latest design standards.

The changes to the GG high pressure HP2 turbine as a result of the incorporation of TU-347 are illustrated in Figure 3 and include:

- an increased turbine disc thickness

- changes in the design of the blade locking system, fir tree root and blade

- changes in the turbine disc materials

- the addition of a damper device between the blade base and turbine disc.

Figure 3: TU-347 detail

Source: Turbomeca, modified by the ATSB

The HP2 turbine of the right engine in EXU had TU-347 incorporated when the Module 3 was last overhauled.

Airworthiness directive AD 2009-0236R1 was issued in November 2009 and required repetitive inspections to be carried out on the HP2 turbine in Arriel engines. Incorporation of SB 292 72 0347 terminated the requirements of the airworthiness directive.

Examination of the right (failed) engine

The failed right engine was removed from EXU and shipped to the engine manufacturer’s facility in Sydney, New South Wales where it was partially disassembled under the supervision of the ATSB. Module 3 of the engine and the oil pump assembly were subsequently transported to the engine manufacturer’s facilities in France. Here, the engine and oil pump were inspected under the supervision of the French aviation investigation agency, the Bureau d'Enquêtes et d'Analyses pour la sécurité de l'aviation civile.

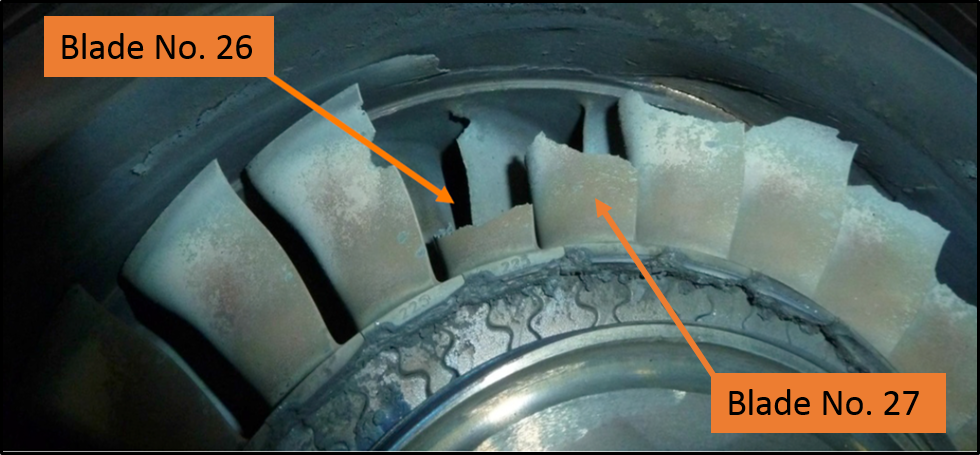

The examination of Module 3 revealed significant damage in the turbine area. This included fracture of the No. 26 blade of the GG high pressure turbine assembly second stage wheel (HP2) with resulting impact damage to, and loss of material from a number of adjacent blades. The GG turbine rear bearing also exhibited signs of significant damage associated with heavy rubbing on the races and flattening of the bearing rollers.

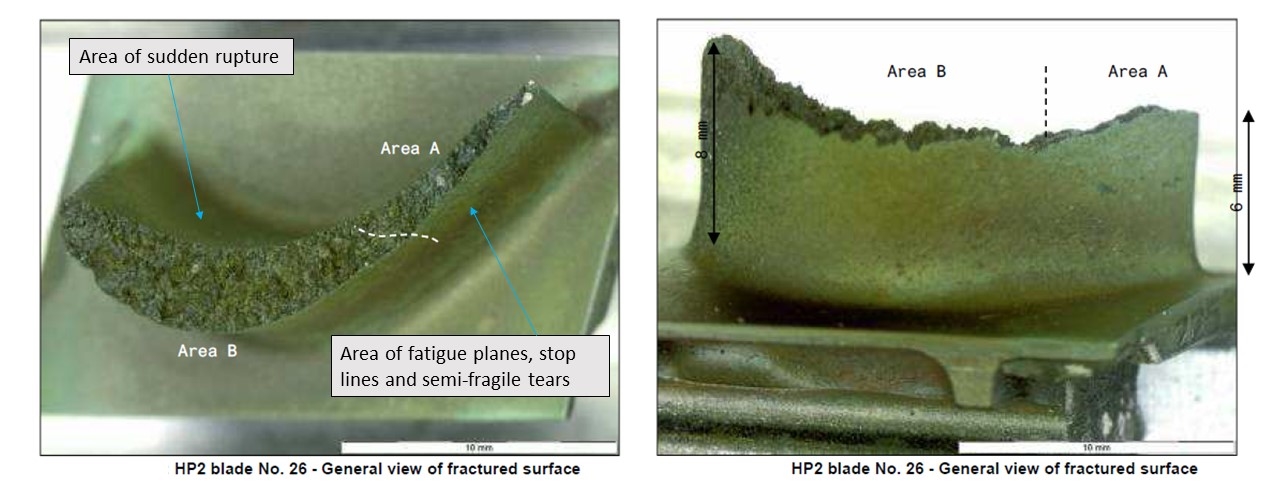

Examination of the failed blade by the engine manufacturer revealed a fracture resulting from a combination of static and dynamic stresses associated with bending loads during operation. The fracture occurred on the aerofoil section about 6 mm above the platform.

Inspection of the fracture surface revealed two distinct regions nominated as area A and area B. Area B included the leading edge and accounted for approximately 83 per cent of the fracture surface. Area A included the trailing edge and covered the remaining 17 per cent of the fracture surface (Figure 4).

Figure 4: Blade No. 26 fracture surface examination

Source: Turbomeca, modified by the ATSB

The fracture surface was examined using a scanning electron microscope. In addition, metallurgical testing of blade No. 26 was conducted, along with blade No. 27 for comparative purposes.

The blade No. 26 area B fracture surface was typical of overstress and sudden fracture. Several isolated areas of fatigue crack propagation near the trailing edge of the blade (Area A) were noted; however, the origin could not be determined. There was no evidence of blade creep or sign of foreign object damage.

The blade No. 27 fracture surface was consistent with static overstress resulting from the impact of blade No. 26. This phenomenon also explained the damage observed on a number of the other blades. No significant metallurgical discrepancies were identified between the blades that were examined.

The fractured No. 26 blade and adjacent damaged blades are shown in Figure 5.

Figure 5: Blade No. 26 and damage to the adjacent blades

Source: Turbomeca, modified by the ATSB

Examination of the engine oil pump and apparent damage to the GG turbine rear bearing determined that any damage to those items was consistent with secondary damage associated with the blade fracture. The loss of the blade resulted in the unbalance and rapid deterioration in efficiency of the GG assembly, and a loss of engine power.

The internal rub marks on the rotating parts were a result of the unbalanced state combined with the natural modes of vibration encountered during the engine slowdown.

Right (failed) engine maintenance history

Aside from an early morning observation during the pre-take-off checks that the GG speeds were difficult to match for both engines, the crew reported that, up to the point when the right engine failed, there was no pre-indication of a significant abnormality. As was normal, an engine performance trend check was conducted prior to the first departure from Longford and no significant deviations were apparent.

Depending on the modification status of the engine, the manufacturer required the operator to perform a periodic inspection of the GG turbine rear bearing for clogging. The inspection involved measurement of the quantity of lubricating oil exiting from the rear bearing housing. If this quantity was less than the 50 ml specified in the maintenance manual, remedial action was necessary. Maintenance records for the right engine indicated that the oil flow checks were consistently within limits.

The operator’s system of maintenance for its Arriel engines specified that the measurement and recording of engine vibration data was to be conducted at 300- and 750-hour operating intervals. The data was recorded using an externally-mounted, calibrated instrument and sensor that recorded the vibration sample from the engine ‘rear point’, on the Module 3 external casing.

Examination of the rear point vibration recordings for the right engine found that they were below the maximum limits published by the engine manufacturer and were certified acceptable by the operator.

Due to the sampling rate periods of the aftermarket condition monitoring system, the engine operating parameters, including vibration levels, nearest to the time of the engine failure were not logged.

Recording and monitoring engine cycles

To ensure engine serviceability and monitor necessary service life limits of the engine’s rotating components, the engine manufacturer required operators to monitor and record engine operating cycles. The definition of a cycle varied with the rotating component and, in the case of the GG in the Arriel engine, complete[8] and partial[9] operating cycles were recorded.

The operator of EXU used a software program to record and monitor engine cycles. This required pilots to add relevant flight information based on sectors flown and their attendant engine power settings. The software program was designed to calculate the cycle particular to the rotating component and recorded the progressive cycle count. The results of the engine recording/monitoring were documented in the operator’s maintenance records.

An independent assessment of the operator’s methodology and cycle count totals was conducted by the engine manufacturer following the occurrence. The assessment concluded that the process and records were satisfactory.

Weight and balance

The S-76C has a maximum take-off weight of 5,307 kg (11,700 lb). The operator’s load sheets indicated that EXU had 590 kg (1,300 lb) of fuel on board at Longford prior to departure. With the weight of the fuel, the occupants and their equipment, the take-off weight at Longford was calculated to be 5,196 kg (11,455 lb), which was 111 kg (245 lb) below the maximum take-off weight.

The take-off weight of EXU at Snapper platform was estimated to be about 5,026 kg (11,080 lb), including about 286 kg (630 lb) of fuel for the flight back to Longford. The estimated take‑off weight was 281 kg (619 lb) below the maximum take-off weight and within the operator’s allowable weight restrictions given the ambient air temperature and pressure.

Meteorological information

The crew reported the conditions for the departure from Snapper platform as including a westerly wind of 5 kt (10 km/h), no visible cloud or adverse weather and an ambient temperature of 12 °C. The QNH[10] was reported as 1,034 hPa.

Platform/helideck operations

Snapper platform

Snapper platform is located approximately 40 NM (74 km) east of the Longford heliport and is one of a number of offshore oil and gas production platforms within the Bass Strait region.

Snapper platform was constructed with a helideck large enough to cater for two S-76C helicopters (Figure 6). The helideck is about 44 m (145 ft) above the sea surface and is constructed to provide an obstacle free zone when the correct take-off profile is flown.

Figure 6: Snapper platform and helideck, looking east

Source: Helicopter operator, modified by the ATSB

Helicopter performance

The operator’s fleet of S-76C helicopters was the primary means of transport for personnel working offshore, allowing the oilfield workforce to be ferried from Longford to the Bass Strait platforms, or transferred from one platform to another. The operator conducted over 4,000 S-76C flights per year in this role.

The operator conducted its flights in the S-76C in either of two multi‑engine helicopter performance categories:

- Category A operations were those where, in the event of an engine failure, the helicopter had adequate performance to safely continue or reject the take-off or landing. In order to meet these criteria, a reduced take-off weight may be required. However, Category A operations could not be conducted from elevated platforms due to performance limitations.

- Category B operations did not meet the operator’s Category A criteria. In the event of an engine failure during Category B operations, performance was available to enable the helicopter to safely continue the flight, except when the failure occured early in the take-off or late in the landing. In these cases, a forced landing may be required. The operator’s helicopter flights to the Bass Strait offshore platforms were conducted as Category B operations.

The operator’s Flying Operations Manual described a Category B departure profile employed for all helideck departures in the S-76C. In the course of the departure, a committed point is determined. This point is defined as the height above the helipad from which the helicopter can sustain an engine failure and continue the departure with one engine inoperative. If the take-off is rejected prior to the committed point, the helicopter is landed back on the platform.

The Category B departure profile requires the crew to establish the helicopter in a 5 ft (1.5 m) hover above the helideck before checking the available engine power. The pilot flying then climbs the helicopter vertically to at least 25 ft (7.5 m) above the helideck and confirms a minimum rate of climb of 200 ft/min passing through that height. The pilot flying makes a decision and ‘commits’ to continuing the departure. A rejected take-off will no longer be attempted. The pilot flying rotates the helicopter to a nose-down attitude of 15° and accelerates to the take-off safety speed while climbing to 250 ft above mean sea level. From this height, the helicopter is climbed at the best rate of climb speed.

In all cases, payload is offset against helicopter performance taking into account the ambient conditions and operational requirements.

Figure 7 provides a representation of the operator’s Category B departure from an offshore platform with all engines operating and an estimation of EXU’s profile following the engine failure.

Figure 7: Elevated helideck profile showing a representation of the operator’s Category B departure with all engines operating (in black) and an estimation of the departure profile for the occurrence flight (in red)

Source: ATSB

Operator activity

The operator’s activities were characterised by short-distance flights between offshore platforms and multiple flight sectors. Such operations result in engine cycle counts accumulating faster than operating hour limitations. An increased frequency of cycle-based maintenance results.

Engines are maintained in accordance with the engine manufacturer’s requirements with emphasis on engine operating cycle counting for service life tracking of critical rotating components. Engine rinsing was conducted at the end of the day’s flying, supplemented by periodic chemical cleaning of engine compressors and turbines as per the engine manufacturer’s requirements.

Related occurrences

Australian occurrences

The operator had three occurrences of HP2 blade failure between 1996 and 2001, all involving Arriel 1S1 engines. All were investigated by the ATSB and involved earlier-modification engines (pre TU-347) than those in EXU.

All of the ATSB investigation reports are available from the ATSB website.

Occurrence 199602839

On 9 September 1996, an S-76C helicopter experienced an in-flight engine failure of the right engine while taking off from an oil platform. A loud noise was heard before the engine failure. The right engine was shut down and the crew completed an uneventful single-engine return to the operator’s Longford base. There was no associated engine fire. The right engine was removed and sent to the manufacturer for disassembly and examination.

The manufacturer provided the operator with a final report noting the rupture (separation) of one GG turbine blade and subsequent rear bearing damage and GG seizure. The report stated that the separation was suspected to be the result of blade rubbing with the second stage nozzle guide vanes. There was no sign of fatigue as a factor, or abnormal over temperature operation of the engine.

Investigation 200100584

On 7 February 2001, an S-76C helicopter with two crew and 10 passengers on board, was in a hover as the flight crew completed their before take-off checklist. The pilot reported that while trimming the engines, a ‘pop’ was heard. The left engine turbine gas temperature was noted in excess of 1,000 °C. The helicopter was landed uneventfully. The flight crew reported that the only other cockpit indication of a problem was the almost simultaneous illumination of the left engine chip (magnetic particle) detector advisory.

The manufacturer's final report noted a separation of the No. 6 turbine blade of the GG second stage disc. The blade separated above the ‘fir tree’ attachment point but below the blade platform, before puncturing the second stage nozzle guide vane turbine ring.

Investigation 200103038

On 11 July 2001, an S-76C helicopter was in cruise flight with the automatic flight control system engaged, when the flight crew noted a loud noise and the helicopter yawed and rolled to the left and pitched nose-down. The right engine-out and fire‑warning annunciators illuminated and the engine-out aural warning sounded. The right engine GG RPM reduced to zero and extremely high turbine outlet temperature was indicated. The crew activated the right engine fire bottles and closed the fuel firewall shut-off valve before completing a single-engine landing at their base.

Disassembly and preliminary examination of the engine revealed the separation of one GG second stage turbine blade. Blade No. 16 was separated above the blade ‘fir tree’ attachment point but below the blade platform, and punctured the second stage nozzle guide vane turbine ring. The rear bearing of the GG had collapsed and was significantly damaged.

International occurrences

French Direction générale de l’aviation civile

The French Direction générale de l’aviation civile advised of a further three occurrences involving GG turbine blade failures. All occurred in earlier-modification engines (pre TU-347) than those in EXU.

Engine manufacturer

The engine manufacturer advised of four GG turbine blade failures in the second stage high pressure turbine of engines incorporating TU-347-modified turbine assemblies. This modification was incorporated in the engines in EXU.

The failures were attributed to foreign/domestic object damage[11] (two events) and an isolated failure associated with blade creep[12]. The fourth failure was attributed to a combination of blade creep and fatigue. Of the failures associated with blade creep or fatigue, oxidation was also present on the blade surfaces. All of the blade failures were isolated to individual blades with varying impact on engine operation. The blade failures did not result in in-flight engine shutdowns.

The engine manufacturer advised that since inception in July 2008, there were in excess of 2,400 modules in service with modification TU-347 incorporated and that the fleet had accumulated 4.1 million flight hours. Given the low number of failures, the risk of further failures can be considered to be low.

A review of a number of international accident databases was also conducted by the ATSB. This review showed no clear indication of TU-347-related engine issues or failures.

__________

- One of the operator’s competency assessments, a base check tests the pilot’s ability to operate the aircraft in normal and emergency situations.

- The operator’s Flying Operations Manual specified that a simulator check satisfied the requirements of a base check.

- Crash-activated radio beacon that transmits an emergency signal that may include the position of a crashed aircraft. Also able to be manually activated

- A complete GG operating cycle was defined by the engine manufacturer as an engine start, followed by an acceleration of the gas generator and then an engine shutdown.

- Between engine start-up and shutdown, a partial operating cycle of the GG was defined as whenever the gas generator is decelerated and then re-accelerated beyond a certain value.

- Altimeter barometric pressure subscale setting to provide altimeter indication of height above mean sea level in that area.

- Foreign object damage includes engine damage resulting from external objects entering the engine (for example paper, birds, rags or other objects blown about by the rotor wash). Domestic object damage includes engine damage resulting from objects originating from within the engine (for example, dislodged engine bolts or other objects).

- Blade creep is the permanent deformation over time of a turbine blade when subjected to constant stress and high operating temperatures.

Introduction

Flight operations to offshore platforms present unique challenges in terms of the physical environment, characteristics of the platform and helicopter performance. In addition, more involved and generally frequent maintenance is carried out on aircraft undertaking such operations. In this respect, no deficiencies in the operator’s maintenance practices were identified that may have contributed to the engine failure.

In this occurrence, the engine failure occurred at the most critical point during the departure from the platform, resulting in a significant loss of engine power and helicopter performance and the helicopter coming to within 30 ft (9 m) of the sea surface before flying away. This analysis will examine the nature of the engine failure and a number of operational aspects that increased the likelihood of a successful recovery from the failure.

Engine failure

Service Bulletin 292 72 0347 referenced the incorporation of modification TU‑347 in Arriel 1S1 engines. This modification, which incorporated a redesigned high pressure turbine assembly second stage (HP2) wheel that accorded with the latest design standards, had been incorporated in the engines in VH-EXU (EXU).

In an effort to understand the associated risk, the ATSB’s occurrence database and reports from the French Direction générale de l’aviation civile and the engine manufacturer were reviewed. This review indicated that, apart from an overseas engine failure involving a TU‑347‑modified engine that is still under investigation, the loss of the blade from the HP turbine and ensuing engine failure in EXU was the first involving a TU-347-modified Arriel 1S1 engine. The review also identified four previous occurrences that, while they did not result in engine failure or an in-flight shutdown, they did impact on engine operation. The manufacturer determined that in two of the events, creep/metal fatigue and oxidation deposits were factors.

The engine’s vibration monitoring system did not capture the engine vibration levels immediately preceding and after the blade fracture. This was a consequence of the system’s vibration sampling rate. The availability of vibration data closer to the blade fracture had the potential to better inform the investigation as to the nature of the fracture.

At the time of writing this investigation report, the engine manufacturer’s examination of Module 3 and the oil pump assembly from the right engine of EXU has identified no clear evidence of the cause of the blade fracture. The fatigue cracking to blade No. 26 was not discernible ahead of the blade fracture and assessment of the other blades in the affected engine did not reveal discernible defects.

In the absence of a conclusive cause, the engine manufacturer has continued its investigation into the blade fracture. This includes an examination of the manufacturing processes and a number of environmental and operational factors. Several potential contributing factors related to materials, dimensional and quality checks have been eliminated. The engine manufacturer acknowledged that the TU-347 blades were implicated in this occurrence, with the fracture being linked to the geometry of the aerofoil.

As of the date of this report, the engine manufacturer’s investigation concluded that the fracture occurred due to a combination of metal fatigue, blade material creep characteristics and oxidation origins. However, the definitive cause of the fracture remained unknown. The manufacturer reported that blades within excess of 2,000 operating hours or 2,300 cycles may be more susceptible to failure. The manufacturer is in the process of identifying potentially affected blades. Given the number of TU-347-modified modules in service and the amount of hours flown, the rate of failures is low. The associated safety risk is therefore considered to be low.

Aircraft operator

The operator’s Category B departure profile allowed crews to use their discretion and vary the committed point based on ambient conditions and aircraft payload. In this respect, the aircraft’s payload is adjusted to suit the characteristics of the specific platform.

In the event of an engine failure after passing the committed point, crews aim to convert height to speed while maintaining rotor RPM within limits using the available emergency power from the operative engine.

The operator’s Flying Operations Manual directed pilots to assess whether performance is improving or deteriorating during a one engine inoperative departure. In the case of a deteriorating situation, crews prepare for ditching. Where performance is improving or static, one engine inoperative power limits are observed and airspeed is monitored before being set at the best rate of climb speed with the landing gear retracted.

In combination, the operator’s focus on crew and simulator training in the management of single‑engine emergencies, and the crew’s actions in response to the engine failure in EXU, increased the likelihood of a successful outcome.

From the evidence available, the following findings are made with respect to the engine failure sustained by Sikorsky S-76C helicopter, registered VH-EXU, near Snapper Platform helicopter landing site, Bass Strait, Victoria on 11 July 2013. These findings should not be read as apportioning blame or liability to any particular organisation or individual.

Contributing factors

- The No. 26 blade separated from the right engine high pressure turbine assembly second stage wheel, impacting adjacent blades and resulting in a significent loss of engine power.

- The significant power loss of the right engine considerably reduced the helicopter’s performance during a critical phase of flight.

Other factors that increased risk

- While the engine manufacturer identified that the No. 26 blade of the high-pressure turbine assembly second stage wheel fractured due to a combination of fatigue, creep and oxidation, the specific factor leading to the fracture has yet to be determined.

Other findings

- In combination, the operator’s focus on crew and simulator training in the management of single engine emergencies, and the crew’s actions in response to the engine failure in VH‑EXU, increased the likelihood of a successful outcome.

The ATSB did not identify any organisational or systemic issues that might adversely affect the future safety of aircraft operations. However, whether or not the ATSB identifies safety issues in the course of an investigation, relevant organisations may proactively initiate safety action in order to reduce their safety risk. The ATSB has been advised of the following proactive safety action in response to this occurrence.

Proactive safety action taken by the helicopter operator

The helicopter operator advised that, in response to this occurrence, they reviewed the reliability of the Arriel 1S1 engine second stage, gas generator high-pressure turbine blades in their fleet of Sikorsky S-76C helicopters. In particular, the operator examined those turbine blades that have been modified in accordance with the engine manufacturer’s service bulletin SB 292 72 0347. As a result of that examination, while the manufacturer’s published service life for the turbine blades is 6,000 hours, the helicopter operator has imposed its own life limit of 2,000 hours.

Proactive safety action taken by the engine manufacturer

The engine manufacturer initiated a series of actions in response to the engine failure, including:

- issuing Service Letter No. 2888/13/AR1S in July 2013, which advised operators of the occurrence and the manufacturer’s preliminary lines of enquiry

- issuing Information Letter Arriel1/002/14 in November 2014, which advised field technicians and maintenance centres to pay close attention to TU-347 blades for damage and report the results (at the time of this report, the manufacturer had received no reports of damaged TU‑347 blades)

- issuing Service Bulletin 292 72 0845 on 19 January 2015, which required a one-off visual inspection of the free (power) turbine blades in Arriel 1 series engine variants

- amendment of the Arriel 1 series engine Repair Manual, effective mid-2015, to specify a dye penetrant inspection of TU-347 blades whenever an engine was returned for repair.

In addition, the engine manufacturer advised that it was in the process of developing a service bulletin for distribution to operators once any potentially affected TU-347 blades were identified.

Sources of information

The sources of information during the investigation included:

- the flight crew of VH-EXU

- the helicopter operator

- Safran SA Turbomeca

- the Bureau d'Enquêtes et d'Analyses pour la sécurité de l'aviation civile.

Submissions

Under Part 4, Division 2 (Investigation Reports), Section 26 of the Transport Safety Investigation Act 2003, the ATSB may provide a draft report, on a confidential basis, to any person whom the ATSB considers appropriate. Section 26 (1) (a) of the Act allows a person receiving a draft report to make submissions to the ATSB about the draft report.

A draft of this report was provided to the flight crew of VH-EXU, the helicopter operator, Safran SA Turbomeca, the Bureau d'Enquêtes et d'Analyses pour la sécurité de l'aviation civile and the Civil Aviation Safety Authority.

Submissions were received from the helicopter operator, Safran SA Turbomeca and the Civil Aviation Safety Authority. The submissions were reviewed and where considered appropriate, the text of the report was amended accordingly.

Purpose of safety investigationsThe objective of a safety investigation is to enhance transport safety. This is done through:

It is not a function of the ATSB to apportion blame or provide a means for determining liability. At the same time, an investigation report must include factual material of sufficient weight to support the analysis and findings. At all times the ATSB endeavours to balance the use of material that could imply adverse comment with the need to properly explain what happened, and why, in a fair and unbiased manner. The ATSB does not investigate for the purpose of taking administrative, regulatory or criminal action. TerminologyAn explanation of terminology used in ATSB investigation reports is available here. This includes terms such as occurrence, contributing factor, other factor that increased risk, and safety issue. Publishing informationReleased in accordance with section 25 of the Transport Safety Investigation Act 2003 Published by: Australian Transport Safety Bureau © Commonwealth of Australia 2016

Ownership of intellectual property rights in this publication Unless otherwise noted, copyright (and any other intellectual property rights, if any) in this report publication is owned by the Commonwealth of Australia. Creative Commons licence With the exception of the Coat of Arms, ATSB logo, and photos and graphics in which a third party holds copyright, this publication is licensed under a Creative Commons Attribution 3.0 Australia licence. Creative Commons Attribution 3.0 Australia Licence is a standard form licence agreement that allows you to copy, distribute, transmit and adapt this publication provided that you attribute the work. The ATSB’s preference is that you attribute this publication (and any material sourced from it) using the following wording: Source: Australian Transport Safety Bureau Copyright in material obtained from other agencies, private individuals or organisations, belongs to those agencies, individuals or organisations. Where you wish to use their material, you will need to contact them directly. |