Executive summary

What happened

On the afternoon of 20 September 2023, the pilot of a Bell Helicopter Company 204B, registered VH‑EQW, was tasked with firefighting operations utilising a 1,230 L (Bambi Max) water bucket with a 5 m line. The helicopter departed on a 25-minute flight from a private property near Amberley, Queensland, and tracked to another property in Tarome, about 48 km to the south‑west.

While picking up a full bucket of water from the dam, the helicopter lost control, impacted the water, and subsequently sank to the bottom of the dam. The pilot extricated themselves with only minor injuries, however, the helicopter was destroyed.

What the ATSB found

The ATSB found that the Bambi Bucket suspension cables were caught over the left rear skid when the helicopter was on approach to the dam and during the water collection into the bucket. As the load of water was lifted, it was almost certain that the helicopter’s centre of gravity moved aft and left due to the tethered weight over the left rear skid. This resulted in asymmetric lift loads, loss of control and collision with water.

The ATSB’s examination of the wreckage did not identify any pre-impact defects with the helicopter. Also, the pilot had completed helicopter underwater escape training (HUET) about 2.5 years prior to the accident.

Safety message

Conducting helicopter external load operations over water is a complex task, with the risk of an accident shown to be over twice as high as private helicopter operations. There can be a lack of visual references, visual illusions over water, limited visibility and vertical reference of the hook and external load through mirrors and bubble windows.

As shown in this accident, fouling of external load suspension cable(s) on the airframe can lead to rapid changes in weight distribution, asymmetric lift and loss of control. This investigation reinforces that correct cable positioning is vital to the safety of external lift operations. Further, this accident highlights the importance of conducting HUET to increase the occupants’ chances of post-accident survival in the event of impact with water.

The investigation

The occurrence

Summary of events

On the afternoon of 20 September 2023, the pilot of a Bell Helicopter Company 204B, registered VH‑EQW, was tasked with firefighting operations utilising a 1,230 L water bucket (Bambi Max) with 5 m cables.

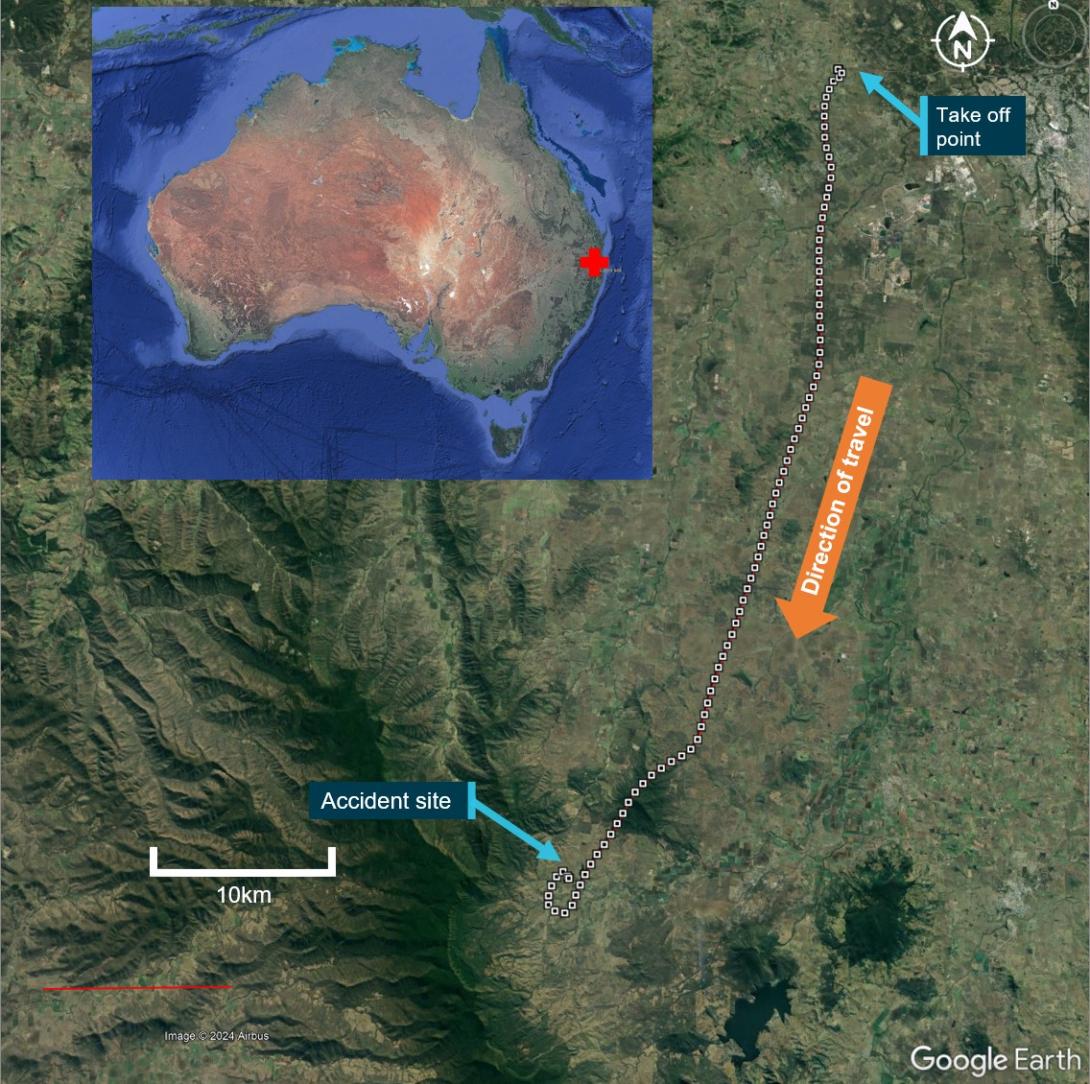

The helicopter departed from a private property near Amberley, Queensland, on a 25-minute flight to another property near Tarome, about 48 km away (Figure 1) with the intention of uplifting water from a dam (dip site) with the water bucket slung under the helicopter for firefighting operations. The flight track data indicated that the helicopter had an average cruise ground speed of about 85 kt (78 kt indicated airspeed (IAS)), with a maximum of 93 kt (85 kt IAS).[1]

After arriving overhead the property, the pilot aligned the helicopter with the dam, descended over the water to the dip site and submerged the bucket. As the pilot began to initiate the bucket lift, control of the helicopter was lost, and it impacted the water surface and sank. The pilot sustained minor injuries, but exited and swam to shore, and the helicopter was destroyed.

Figure 1: VH-EQW flight track from the take-off point to the accident site

Source: Google Earth, modified by the ATSB

Pilot account of events

The pilot was operating the helicopter from the left seat for increased visibility from the bubble window while conducting the external load operation. The pilot recalled that, after arriving at the property at Tarome, they commenced filling their first load of water from a dam. The pilot reported that, during water collection, they heard an unusual noise and that the helicopter ‘kicked a bit’. Remaining in the hover, the pilot checked that all engine indications were normal and that the bucket and line were in the appropriate place. However, the pilot reported that something still did not feel right. As a result, they elected to dump the water from the bucket and initiate a climb out. The pilot stated that, within about 10–15 seconds, as engine power was being applied and the water was being released (dumped) from the bucket, the pilot heard what they described as a ‘loud roaring’ sound and the helicopter pitched up, yawed, rolled left, and impacted the water at low speed.

Witness observations

The accident was observed by 2 witnesses (Figure 2). Witness 1 observed the helicopter circle, move towards the dam on their property to collect water, and observed the entire accident sequence. They also photographed and videoed the helicopter’s movements up until moments before the accident. The witness did not see or hear anything unusual before the helicopter impacted the water. Witness 2 was on an adjacent property; they noted a definitive increase in what they thought may have been engine noise just before the accident occurred.

Figure 2: VH-EQW flight track with accident site and witness locations

Source: Google Earth, modified by the ATSB

Witness video

Recorded video taken by witness 1 just prior to the accident showed the helicopter on approach to the dam. It captured the water bucket suspension cable caught over the rear of the left skid when on the approach (from the start of the video – Figure 3 top) until the helicopter was initiating lift‑off with the external load of water (Figure 3 lower). The video ended as the helicopter started to take the weight of the bucket, which contained a large quantity of water. The helicopter was recorded starting to pitch up and roll left before the video stopped. There was no discernible change in sounds emanating from the helicopter for the duration of the video.

Figure 3: Sequence of water pickup from dam showing bucket cable position from approach (top) to lifting off (lower)

Source: Still photographs taken from witness video, annotated by the ATSB

Pilot egress

The pilot recalled that, after the surface impact, the helicopter almost immediately became inverted, filled with water, and sank to the bottom of the dam. The pilot stated that they removed their seatbelt and helmet and attempted to open the front left door but could not open it with either the normal or emergency release handles. The helicopter was almost fully submerged when the pilot swam to the rear of the cabin and tried to open the rear right door. They made further unsuccessful attempts to egress by kicking the helicopter windows.

The pilot then moved to the rear left door, and applying considerable force, was able to successfully open it. The pilot recalled that, when they initially attempted to open the emergency exits, they may have been trying to operate the door handles in the incorrect (opposite) direction due to the helicopter being inverted.

The pilot escaped the sinking helicopter and swam a few metres to the surface and then to the side of the dam.

Context

Pilot information

The pilot held a Commercial Pilot Licence (Helicopter) with ratings for single and gas turbine engine helicopters. Prior to the accident flight, the pilot had accumulated 2,599.4 hours of total flying experience. They had 220.8 hours total on the Bell 204/205/UH-1 helicopter. Of this, 22.8 hours was pilot in command of the Bell 204, which was accrued in the 2 months prior.

The pilot was qualified to conduct helicopter firefighting operations and had low‑level and sling operation ratings. The pilot last completed an aerial application proficiency check on 29 June 2023, which was valid until 20 June 2024, and a low-level helicopter flight review on 12 August 2023.

The pilot held a Class 1 Aviation Medical Certificate, valid to 12 June 2024, with no restrictions.

Helicopter information

General information

The Bell Helicopter Company 204B (and 205) is the civilian version of the UH-1 Iroquois. It was designed in the mid‑1950’s as a utility helicopter. The helicopter had a 2-blade main rotor and 2‑blade tail rotor and was powered by an Ozark Aeroworks T53-L-13B turboshaft engine. The helicopter was manufactured in the United States in 1965 and first registered in Australia in 2014 as VH-EQW. It had accumulated about 23,515 flight hours total time in service and had a current certificate of airworthiness and registration. The helicopter’s technical log had no outstanding defects at the time of the accident.

VH-EQW was fitted with an external load hook located directly underneath the main rotor transmission, in line with the helicopter’s centre of lift.

Bucket and suspension cable information

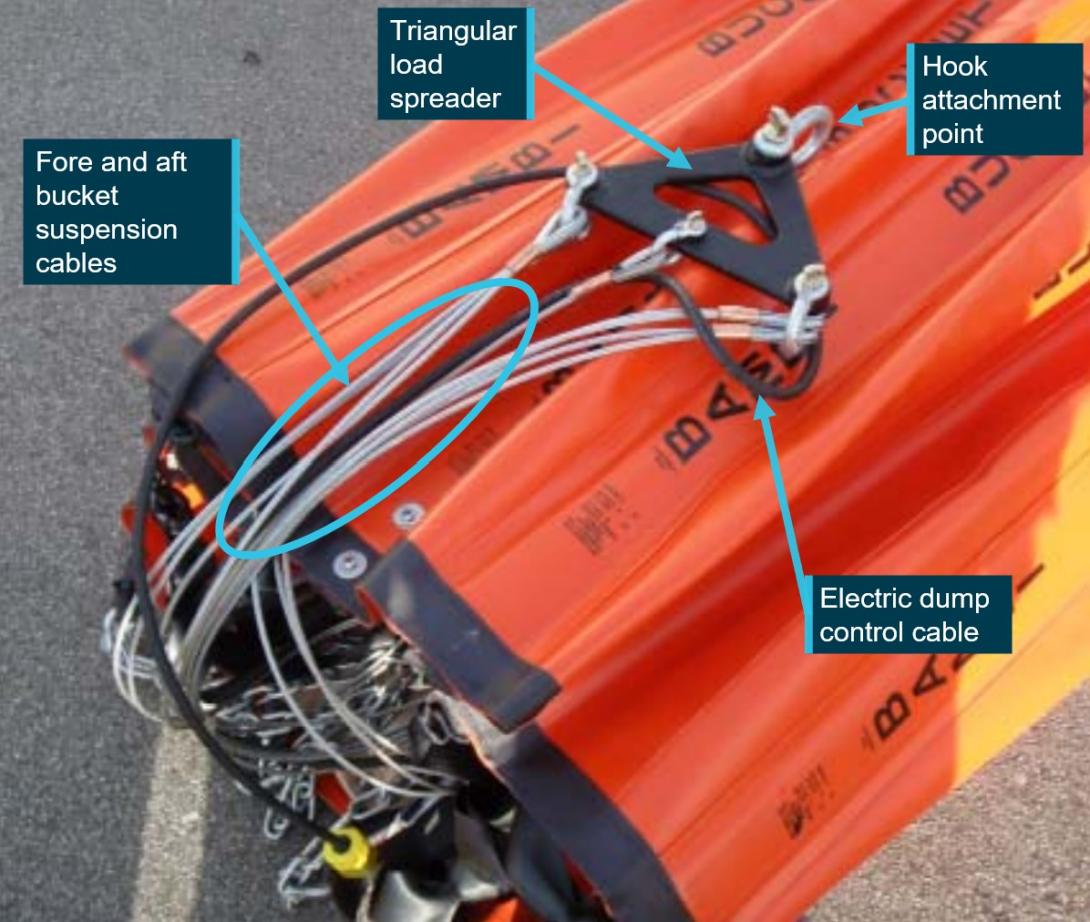

The Bambi Max water bucket fitted to VH-EQW was manufactured by SEI industries and weighed 67 kg empty and 1,300 kg when full, with a capacity of 1,230 L. The bucket was connected to the helicopter’s external load hook by several stainless steel suspension cables, separated fore and aft by a triangular spreader bar (Figure 4). A dump switch on the collective[2] was connected through a black electrical cable to control the dump valve located in the base of the bucket. The suspension cables used on the day had a length of 5.05 m and the total length including the bucket was 6.27 m.

Figure 4: Photo of exemplar Bambi Max bucket in the stored configuration showing the triangular spreader bar and suspension cables

Source: SEI industries, annotated by the ATSB

External load visibility

The helicopter was fitted with 2 rear vision mirrors that were located under each of the Perspex chin bubbles to provide visibility of the external hook, suspension cables and bucket. The bubble window fitted to the pilot’s left door also allowed for better visibility downwards and, to a limited extent, the rear of the helicopter (Figure 5). In response to this draft report, the pilot reported that the mirrors provided a full and clear view of the external hook and bucket.

Source: Operator, annotated by the ATSB

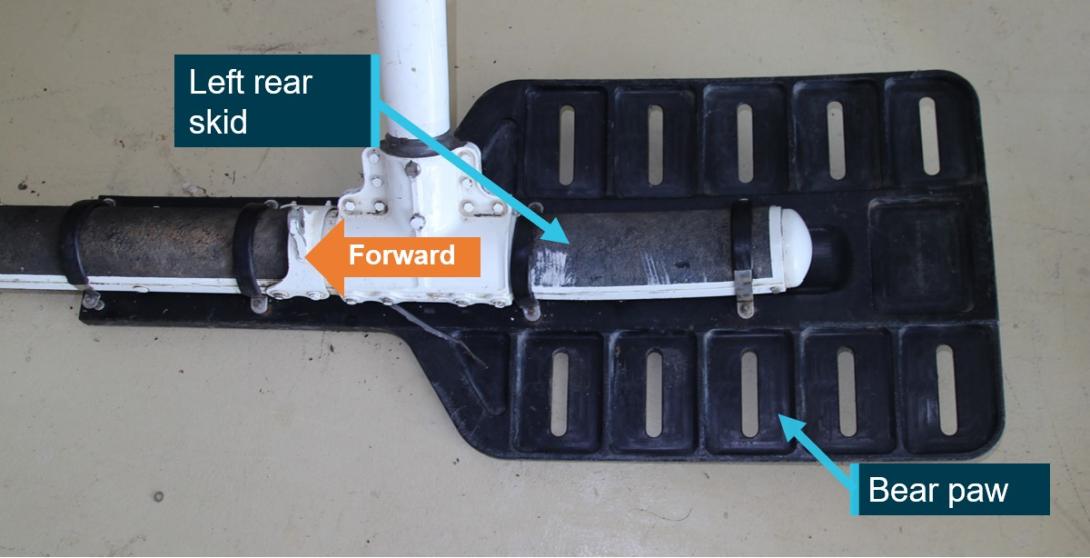

Bear paw modification

The helicopter had a pad like modification to the skids called ‘bear paws’, which are supplied as a kit of 2. The pads fit under and to the rear of each of the skids and are designed for landings off airport, on uneven or unstable terrain, helping with overall landing stability and to prevent the rear of the skids from sinking into soft surfaces. The bear paws are made from a polymer plastic and feature high impact resistance, durability and flexibility. They are secured to the skid utilising 4 metal clamps (Figure 6).

Figure 6: VH-EQW left skid with bear paw fitted

Source: ATSB

Weight and balance

The helicopter was within weight and balance limits during the transit flight to Tarome. However, when lifting the load, with the suspension cables caught over the left rear skid and a full bucket of water (weighing 1,300 kg), the load shifted significantly to the rear and to the left. In this configuration, ATSB calculations showed that the helicopter was outside its balance limitations with the addition of just a 300 kg external load and well outside the balance limitations with the addition of a full bucket of water.

Meteorological information

The weather at the time of the accident was described by the pilot as clear and calm. The Bureau of Meteorology forecast showed visibility was greater than 10 km and the wind was from the north‑west at 11 kt.

The flight was to the south-west and had a calculated tail wind component of about 3 kt. The meteorological conditions were not considered a factor in this event.

Wreckage examination

General engine and airframe examination

The helicopter was retrieved from the dam and taken to a secure facility for detailed examination. The rotor systems, drive shafts, transmissions, flight controls, exits, and engine were visually examined by the ATSB. The fuel control and overspeed governor units were removed from the engine and sent to the engine type certificate holder for functional testing. That testing did not identify any issues with the unit.

The engine drive to main rotor transmission shaft had broken out of its retaining couplings likely due to the impact. The engine manufacturer stated that the damage to the drive couplings was indicative of significant engine power driving the main rotor transmission at the time when the main rotors impacted with water, creating a sudden stoppage.

The pilot’s left front door emergency jettison system was tested and worked as designed by releasing the door from its hinges.

No pre-impact defects in the engine, flight controls or emergency exits were identified.

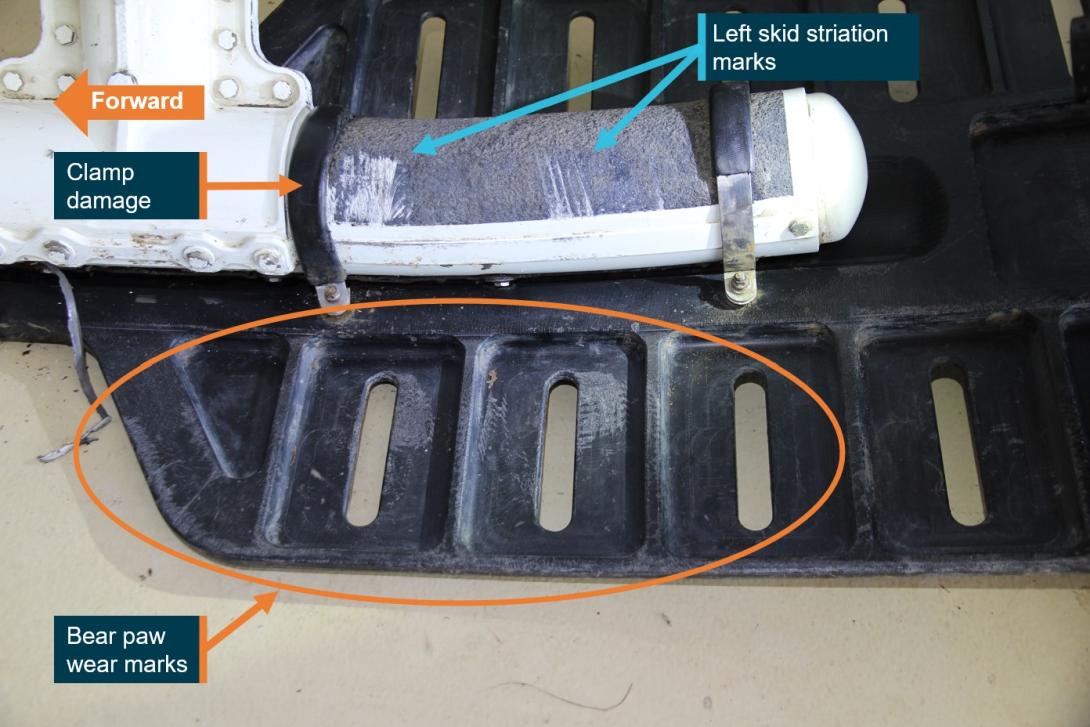

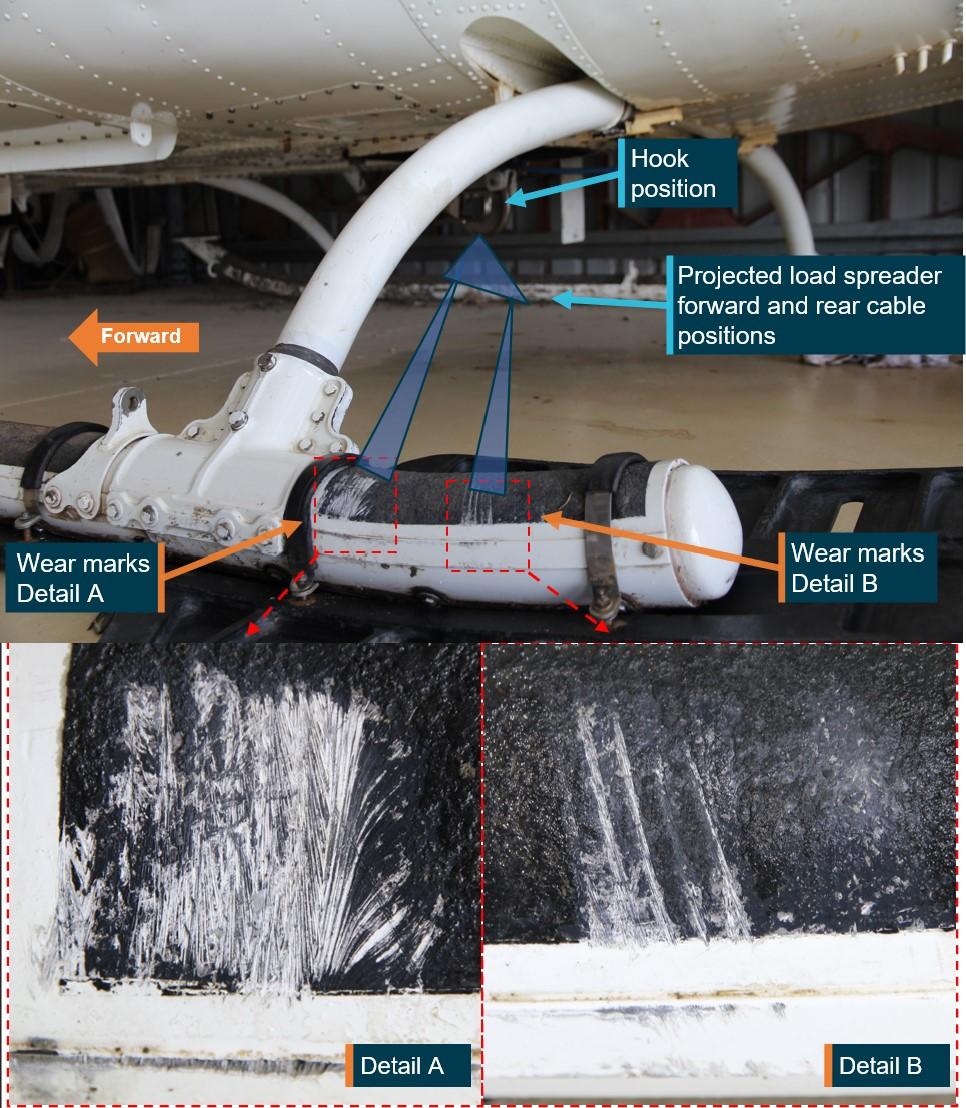

Skid examination

The left and right skid had their bear paw pads removed to facilitate the transport of the wreckage to the storage facility. The right skid did not have any notable damage. The left skid had several striation type wear marks at the rear of the skid (Figure 7).

Figure 7: Rear of left and right skid sections with the left skid showing wear marks

Source: ATSB

The left bear paw was refitted to the left skid to facilitate inspection as an assembly. It was noted that the bear paw had permanent deformation damage that indicated that it had rotated counterclockwise (viewed from the rear) until it had come into contact with the rear skid support. There was also damage to one of the attachment clamps, which had been forced forward at its upmost point. That clamp was directly in front of the forward set of wear marks on the rear of the skid. There was further abrasion damage that indicated the left bear paw had flexed downward under significant load on its outboard side (Figure 9).

Figure 8: Left rear skid showing corresponding skid and bear paw damage

Source: ATSB

The ATSB conducted testing with string lines and a spreader bar configured in a similar manner to the water bucket suspension cables. It was identified that, if both sets of cables were caught over the left skid, the position of the forward and rear cable positions was consistent with the locations of the striation type wear damage found on the left skid[3].

Figure 9 shows the left rear skid, viewed from an outboard direction, showing projected alignment with the hook, cable spreader and multiple bucket suspension cables. Detail A and B show close‑up wear patterns consistent with numerous stainless-steel cable wear striations that aligned with the direction of the external cargo hook attachment point.

Figure 9: Outboard of left rear skid showing hook position and likely position of spreader with forward and rear cables aligned with wear damage

Source: ATSB

Pre-flight checks with an external load

Wagtendonk (1996), in Principles of Helicopter Flight, stated that:

When a cable or strap has been attached to the helicopter hook it is most important to ensure that the cable does not pass over the skid or undercarriage leg. As the aircraft rises and the strain is taken on the load, this could cause a serious rolling sequence. Use the mirror or look directly at the cable. Sadly, non-compliance with this simple rule continues to cause problems.

Common best practice is for the bucket to be positioned at the front of the helicopter and for the suspension cables to be routed from the hook between the skids to the front. This gives the pilot the best view of the bucket during take-off and reduces the chances of the suspension cables fowling. If the cables are routed and connected from the back of the helicopter, there is potential that the cables can be caught by the skid and not seen during take-off.

The pilot reported that, during their pre-flight check, the bucket was placed at the front of the helicopter and was functionally tested.

Helicopter underwater escape training

Helicopter underwater escape training (HUET) has been in use around the world since the 1940s and is considered best practice in the overwater helicopter operating industry. HUET is designed to improve survivability after a helicopter ditches or impacts into water. Research of such accidents has shown that occupants who survive the initial impact will likely have to make an in‑water or underwater escape, as helicopters usually rapidly roll inverted post-impact due to the position and mass of the engine/s, transmission and main rotor system. The research has also shown that drowning is the primary cause of death following a helicopter accident into water.

Fear, anxiety, panic, and inaction are the common behavioural responses experienced by occupants during a helicopter accident. In addition to the initial impact, in-rushing water, disorientation, entanglement with debris, unfamiliarity with seatbelt release mechanisms and an inability to reach or open exits have all been cited as problems experienced when attempting to escape from a helicopter following an in-water accident (Rice & Greear, 1973).

HUET involves a module (replicate of a helicopter cabin and fuselage) being lowered into a swimming pool to simulate the sinking of a helicopter. The module can rotate upside down and focuses students on bracing for impact, identifying primary and secondary exit points, egressing the wreckage and surfacing. HUET is normally part of a program of graduated training that builds in complexity, with occupants utilising different seating locations, exits and visibility (via the use of ‘blackout’ goggles). This training is conducted in a controlled environment with safety divers in the water.

HUET is considered to provide individuals with familiarity with the crash environment and confidence in their ability to cope with the emergency situation (Ryack et al., 1986). Interviews with survivors from helicopter accidents requiring underwater escape frequently mention they considered that HUET was very important in their survival. Training provided reflex conditioning, a behaviour pattern to follow, reduced confusion, and reduced panic (Hytten, 1989).

The pilot conducted HUET training in March 2021, with a renewal due in 2024. The pilot reported that familiarity with the helicopter, the open area in the cabin (all seats removed) and HUET assisted with their ability to successfully escape from the sinking helicopter.

Helicopter water bucket operation accidents

The helicopter manufacturer stated that, between 1974 and 2017, there were 6 accidents involving Bell Helicopters conducting external lift operations where the suspension cable became entangled with the skids and the helicopter lost control during water uplift. Two of those accidents involved the Bell 204/205 helicopter and 4 were Bell 206s.

The Flight Safety Foundation conducted a study titled External loads, powerplant problems and obstacles challenge pilots during aerial fire-fighting operations. The study utilised data from helicopter accident reports in the United States between 1974 and 1998.

The study showed that, it was over twice as likely for a firefighting helicopter to be involved in an accident when compared to private helicopter flights. Of the 97 accidents studied, 4 instances were due to water bucket cables being caught on the skids leading to a loss of control during uplift. Further, there were 2 instances where the unloaded water bucket or external load cable came into contact with the tail/tail rotor due to excessive speed, turbulence and manoeuvring.

Two recent accidents, one in 2017 (New Zealand Transport Accident Investigation Commission report AO-2017-001) and one in 2019 (French Bureau d'Enquêtes et d'Analyses report 2019‑0023) also involved helicopter buckets coming into contact with the tail rotor. Those accidents were partly attributed to operating at airspeeds above the manufacturers’ velocity never exceed speeds.

Safety analysis

Suspension cable caught on left rear skid

Video evidence showed the Bambi Bucket suspension cables were caught over the left rear skid when the helicopter was on approach to the dam and remained attached to the skid during the water uplift. This evidence was consistent with:

- The ATSB’s wreckage examination, which identified that the left rear skid and bear paw showed multiple areas of damage including striation marks indicative of contact with the bucket suspension cables.

- Testing of the striation marks alignment with the fore and aft cable positions when attached to the external cargo hook with the triangular load spreader.

The video ruled out the capture of the cables over the skid during the water collection phase. However, the ATSB was unable to identify if the cables had become captured due to pre-flight bucket and cable positioning, take-off manoeuvring or during the transit flight to the dam.

Just before the video ceased, it showed the initiation of the full water bucket uplift followed by the helicopter pitching up and rolling left slightly. The ATSB weight and balance calculations concluded that any bucket weight above 300 kg (full is 1,300 kg) acting over the left rear skid, would be sufficient to move the centre of gravity outside of the helicopter’s balance limit. Therefore, it was almost certain that as the load of water was lifted, the helicopter’s centre of gravity moved aft and left as a result of the suspension cables being caught over the skid. The tethered weight created an asymmetric lifting point, which resulted in a rapid loss of control and subsequent collision with water.

Helicopter underwater escape training

The pilot conducted HUET about 2.5 years prior to the accident. This likely assisted their ability to egress the helicopter through a rear door while inverted and underwater. HUET has been shown to significantly increase the chances of survival in the event of collision with water.

No pre-impact defects

The ATSB wreckage examination did not identify any pre-impact mechanical issues with the helicopter. Further, the engine manufacturer concluded that the engine was supplying significant power to the transmission at the time of the impact with water.

Findings

| ATSB investigation report findings focus on safety factors (that is, events and conditions that increase risk). Safety factors include ‘contributing factors’ and ‘other factors that increased risk’ (that is, factors that did not meet the definition of a contributing factor for this occurrence but were still considered important to include in the report for the purpose of increasing awareness and enhancing safety). In addition ‘other findings’ may be included to provide important information about topics other than safety factors. These findings should not be read as apportioning blame or liability to any particular organisation or individual. |

From the evidence available, the following findings are made with respect to the loss of control and collision with water involving Bell Helicopter Company 204B helicopter, near Tarome, Queensland, on 20 September 2023.

Contributing factors

- The Bambi Bucket suspension cables were caught over the left rear skid. Consequently, as the load of water was lifted, it was almost certain that the helicopter’s centre of gravity moved aft and left, the tethered weight over the skid created an asymmetric lifting point. This resulted in a loss of control and the helicopter collided with water.

Other findings

- The pilot conducted helicopter underwater escape training 2.5 years prior to the accident. This training increased the pilot's chances of survival when the helicopter became submerged in the dam.

- There were no pre-impact defects identified with the helicopter.

Sources and submissions

Sources of information

The sources of information during the investigation included:

- pilot

- operator and chief pilot

- Civil Aviation Safety Authority

- Queensland Police Service

- aircraft manufacturer

- aircraft maintenance organisation

- Airservices Australia

- witnesses

- video footage of the accident flight and other photographs and videos taken on the day of the accident.

References

Rice, E, V., & Greear, J. F. (1973). Underwater escape from helicopters. In Proceedings of the Eleventh Annual Symposium, Phoenix, AZ: Survival and Flight Equipment Association, 59-60. Cited in Brooks C., (1989). The Human Factors relating to escape and survival from helicopters ditching in water. AGRAD.

Ryack, B. L., Luria, S. M., & Smith, P. F. (1986). Surviving helicopter crashes at sea: A review of studies of underwater egress from helicopters. Aviation, Space, and Environmental Medicine, 57(6), 603-609.

United States Federal Aviation Administration, (2019). Helicopter Flying Handbook. https://www.faa.gov/sites/faa.gov/files/regulations_policies/handbooks_manuals/aviation/helicopter_flying_handbook/hfh_front.pdf

Wagtendonk, W.J. (1996). Principles of Helicopter Flight, Aviation Supplies & Academics, Inc. Washington, USA.

Veillette, P. R. (1999). External loads, powerplant problems and obstacles challenge pilots during aerial fire-fighting operations (Flight Safety Foundation). https://flightsafety.org

Submissions

Under section 26 of the Transport Safety Investigation Act 2003, the ATSB may provide a draft report, on a confidential basis, to any person whom the ATSB considers appropriate. That section allows a person receiving a draft report to make submissions to the ATSB about the draft report.

A draft of this report was provided to the following directly involved parties:

- pilot

- chief pilot

- aircraft maintenance organisation

- National Transportation Safety Board

- aircraft and engine manufacturers

- Civil Aviation Safety Authority.

Submissions were received from the pilot and chief pilot. The submissions were reviewed and, where considered appropriate, the text of the report was amended accordingly.

Purpose of safety investigationsThe objective of a safety investigation is to enhance transport safety. This is done through:

It is not a function of the ATSB to apportion blame or provide a means for determining liability. At the same time, an investigation report must include factual material of sufficient weight to support the analysis and findings. At all times the ATSB endeavours to balance the use of material that could imply adverse comment with the need to properly explain what happened, and why, in a fair and unbiased manner. The ATSB does not investigate for the purpose of taking administrative, regulatory or criminal action. TerminologyAn explanation of terminology used in ATSB investigation reports is available here. This includes terms such as occurrence, contributing factor, other factor that increased risk, and safety issue. Publishing informationReleased in accordance with section 25 of the Transport Safety Investigation Act 2003 Published by: Australian Transport Safety Bureau © Commonwealth of Australia 2024

Ownership of intellectual property rights in this publication Unless otherwise noted, copyright (and any other intellectual property rights, if any) in this report publication is owned by the Commonwealth of Australia. Creative Commons licence With the exception of the Commonwealth Coat of Arms, ATSB logo, and photos and graphics in which a third party holds copyright, this report is licensed under a Creative Commons Attribution 4.0 International licence. The CC BY 4.0 licence enables you to distribute, remix, adapt, and build upon our material in any medium or format, so long as attribution is given to the Australian Transport Safety Bureau. |

[1] The wind information, density altitude and recorded ground speed was used to calculate the indicated airspeed.

[2] Collective: a primary helicopter flight control that simultaneously affects the pitch of all blades of a lifting rotor. Collective input is the main control for vertical velocity.

[3] On 27 October 2024 after directly involved party submissions were completed the pilot advised that they were going to carry out their own testing and reenactments on a Bell 204 helicopter with a Bambi Bucket fitted to ascertain what had occurred.