What happened

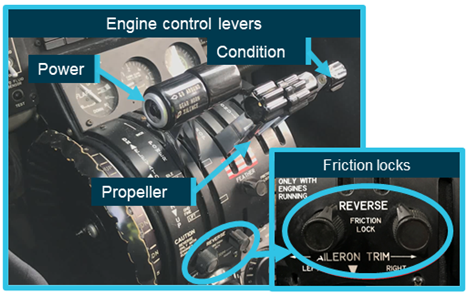

On the night of 19 August 2021, the pilot and medical crew of a Hawker Beechcraft King Air B200C aircraft, registered VH‑VAH, departed Essendon Fields Airport, Victoria on a patient retrieval flight. During the take-off, there was a loss of left engine power and an uncommanded left yaw. The pilot initially managed the situation as an engine power loss situation. However, shortly after, they identified that the left engine power lever had migrated rearwards to the idle position. The pilot moved the power lever back to take-off power and adjusted the friction lock to prevent further movement. The flight continued without further incident.

(Source: Operator, modified by the ATSB)

Why did it happen

The left engine power lever had migrated rearwards as the friction lock had not been sufficiently adjusted during pre-flight checks.

The cockpit to engine nacelle power lever control cables in King Air series aircraft were spring loaded towards idle. This was to protect the engines in the event of any power lever cable issues, and to reduce the effect of hysteresis (or backlash) in the system. The effect of the springs migrating the power levers was managed by adjusting the friction locks. The left engine was more susceptible to power lever migration as its cable connecting it to the engine was shorter when compared with the right engine.

When correctly set, the friction locks provided adequate resistance for the power levers to remain in position. However, if not adequately set, power lever migration could occur. This was typically experienced when the pilot removed their hand from the levers during take-off and could lead to the aircraft yawing towards the engine experiencing the power lever migration, a significant reduction in power, and the auto‑feather system disarming.

A characteristic of the King Air friction locks was that they required careful adjustment as some aircraft had a narrow range between no friction and too much friction. In addition, the desired resistance could be inconsistent between power levers in the same aircraft and other aircraft, and this could change over time due to wear. This characteristic has been experienced among different King Air operators and pilots and has also been considered as a potential factor in several fatal accidents.

Safety advisory notice

The Australian Transport Safety Bureau advises pilots and operators of the King Air series aircraft (c90, 200, and 300) that the power lever friction locks require careful adjustment to prevent power lever migration towards the idle position, particularly during take-off. Inadvertent migration of one power lever towards idle can result in power reduction and yaw that, when occurring at low height, can result in catastrophic outcomes. Operators should ensure pre-flight checks provide opportunities to confirm friction lock settings before the take-off run, and ensure pilots have adequate knowledge of friction lock sensitivity to help prevent and recover from inadvertent power lever migration.

Read more about this ATSB investigation: AO-2021-034