Safety Advisory Notice

To R44 helicopter operators

Fatigue cracking in an R44 helicopter clutch shaft resulted in the total loss of drive to the main rotor system while airborne.

What happened

On the morning of 22 December 2020, the pilot of a Robinson R44 helicopter was conducting aerial agricultural spray operations on a property 13 km south‑east of Clare Valley Aerodrome, South Australia. After completing numerous spray runs throughout the morning, the pilot was preparing to land the helicopter adjacent to a loading vehicle for replenishment of chemical product by a ground crewman when a loud bang emanated from the rear of the helicopter.

The pilot reported that, following the noise, the helicopter descended rapidly and there was significant resistance from the flight controls. The helicopter collided heavily with the loading vehicle, coming to rest on its side. The pilot and crewman were uninjured. The operator’s preliminary on-site assessment of the substantially damaged helicopter identified that a mechanical disruption had occurred to the drive system.

Fractured clutch shaft yoke

Source ATSB

Why did it happen

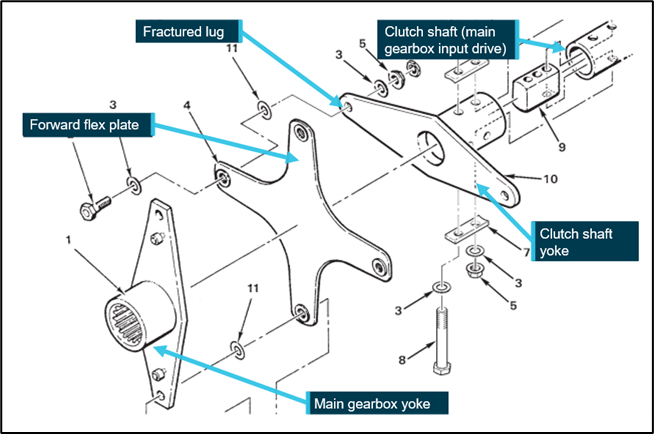

The ATSB’s preliminary metallurgical examination of the drive train components identified that the clutch shaft forward yoke had fractured. The fracture occurred at a bolt hole on the yoke lug that connected with the forward flex plate (Figure 1) and was due to the development of fatigue cracking that progressed almost entirely through the yoke cross‑section.

Figure 1: Main gearbox forward flex plate and yoke assemblies

Source: Robinson Helicopter Company illustrated parts catalogue, annotated by the ATSB

The fracture resulted in the loss of engine drive to the main rotor system. Corrosion product and fretting damage were identified in the vicinity of the bolt hole adjacent to the fatigue fracture surfaces.

The airworthiness of the yoke is not limited to a total time in service (no life-limit) and it is required to be inspected at every 100-hour, or annual, inspection. The opportunity to conduct a detailed examination of the yoke contact surfaces for defects is generally limited to those occasions when the bolts are removed and the yoke is separated from the forward flex plate. That is only scheduled to occur during 12 year/2,200 hour overhaul inspections.

A general visual inspection of the assembled clutch shaft yoke during the 100‑hour (or annual) inspection may not easily identify defects such as corrosion, fretting and/or cracking.

While the specific circumstances that led to the fatigue crack on the accident helicopter are still under investigation, the ATSB has issued the following safety advisory notice to advise R44 operators of a potential safety concern.

Safety advisory notice

AO-2020-064-SAN-014: The ATSB advises operators of R44 helicopters to note the preliminary finding of this accident and to look for the presence of corrosion, fretting or cracking, which may not be visually obvious, during all inspections of the clutch shaft yoke. Any identified defects should be notified to both the ATSB and the Civil Aviation Safety Authority.

Read more about this ATSB investigation: Loss of control and collision with terrain involving Robinson R44 II, VH-HOB, near Clare, South Australia, on 22 December 2020