| Occurrence Briefs are concise reports that detail the facts surrounding a transport safety occurrence, as received in the initial notification and any follow-up enquiries. They provide an opportunity to share safety messages in the absence of an investigation. Because occurrence briefs are not investigations under the Transport Safety Investigation Act 2003, the information in them is de-identified. |

What happened

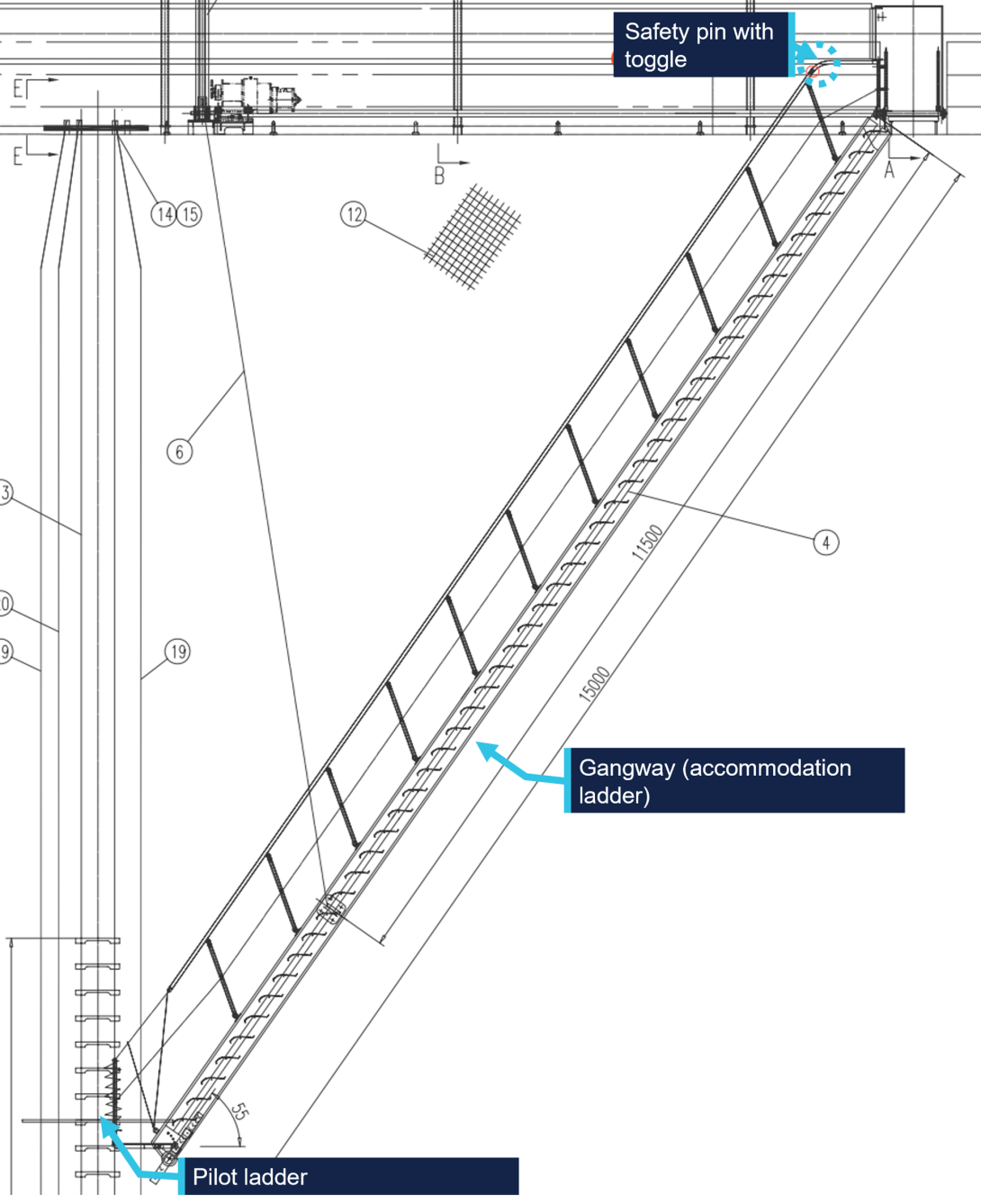

At about 1920 local time on 4 March 2025, a cargo ship arrived at the pilot boarding ground for the port of Gladstone, Queensland to board a harbour pilot. The harbour pilot had travelled to the boarding ground by boat and was planning use the pilot ladder to board the ship. The ship’s crew rigged the pilot ladder in combination with the gangway (combination ladder)[1] (Figure 1) on the starboard side following shipboard procedures.

Figure 1: Combination ladder schematic diagram

Source: Ship’s manager, annotated by the ATSB

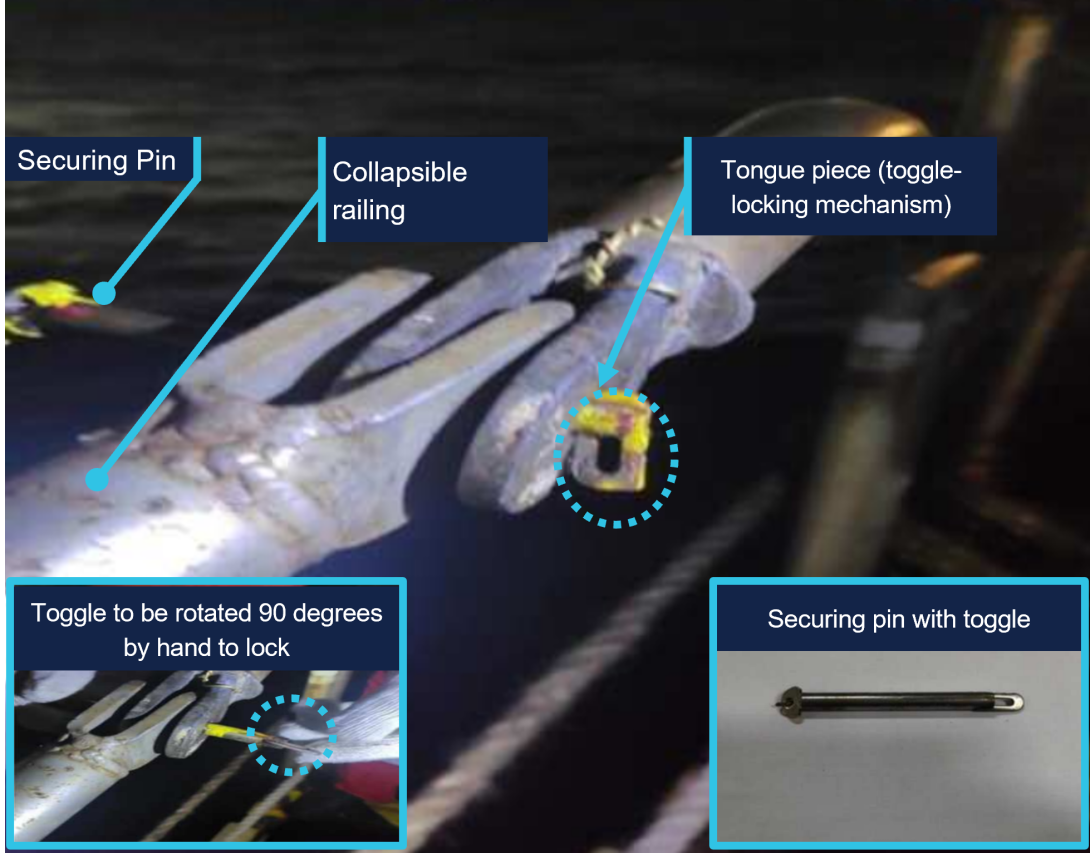

The gangway has an inboard and outboard railing. During the rigging process for pilot embarkation, the gangway is lowered, and the railing latched securely. However, on this occasion the tongue piece on the safety latch on the outboard railing was not rotated to lock the tongue at the required 90° angle (Figure 2), resulting in the securing pin not being correctly inserted. As the ship rolled and vibrated, the securing pin gradually worked its way loose. This movement eventually caused the pin to completely dislodge from its position, compromising the stability of the outboard railing.

The pilot began boarding the ship at 1925 local time. When they grasped the handrail while transitioning from the pilot ladder to the gangway, the gangway railing on outboard side partially collapsed when the locking pin dislodged. The pilot was not injured.

Figure 2: Securing pin arrangements

Source: Ship’s manager, annotated by the ATSB

Safety action

Following the occurrence, the ship’s manager advised that the following safety actions had been taken:

- Crew members have received extra training to ensure they fully understand the importance of properly engaging the securing pin's safety latch, with a focus on the correct procedure for rotating the tongue to the required angle to engage the locking mechanism. Additionally, a comprehensive review of the combination ladder securing arrangements has been started, including verification procedures for securing pins and further crew training on proper locking mechanisms.

- The ship's maintenance schedule now includes more frequent and thorough inspections of all securing mechanisms, including the securing pins of the pilot ladder and gangway. These inspections aim to identify and fix any potential issues before they lead to incidents.

- A new protocol has been implemented requiring a double-check of all securing mechanisms before use. This protocol mandated that 2 crew members independently verified that the securing pins were properly locked and secure.

- Pre-use inspection checklists have been updated to ensure securing pins are correctly engaged before pilot transfers.

-

The lessons from this incident have been shared with all ships managed by the ship manager, including training on how to correctly insert the securing pin in the locked position.

Safety message

This occurrence highlights the importance of properly securing pilot transfer arrangements, particularly ensuring that all locking mechanisms, including securing pins, are fully engaged. Ship operators, masters, and crew should perform thorough pre-use checks to verify the correct engagement of safety mechanisms before personnel transfers. Compliance with SOLAS[2] Chapter V, Regulation 23 and ISO 799-1 standards (industry best practices) assists preventing similar failures in the future.

About this report

Decisions regarding whether to conduct an investigation, and the scope of an investigation, are based on many factors, including the level of safety benefit likely to be obtained from an investigation. For this occurrence, no investigation has been conducted and the ATSB did not verify the accuracy of the information. A brief description has been written using information supplied in the notification and any follow-up information in order to produce a short summary report, and allow for greater industry awareness of potential safety issues and possible safety actions.