What happened

On the afternoon of 29 January 2025 an Avions de Transport Regional GIE ATR-72 was being prepared for an air transport flight from Kalgoorlie-Boulder Airport to Perth Airport, Western Australia (WA). The weather was clear with a temperature of around 38°C. The aircraft had been parked since its arrival that morning at about 0900 local time and the flight crew had fitted the engine air intake covers in anticipation of an extended stop.

The flight crew returned to the aircraft at about 1500 and started preparing for the upcoming flight. The operator had recently emphasised the risk of high cabin temperatures to the passengers, so the flight crew was focused on cooling down the heat-soaked aircraft. As the ATR-72 is not equipped with an auxiliary power unit,[1] the use of the air-conditioning packs required starting the number 2 engine in hotel mode.[2]

After the pilots boarded the aircraft, the first officer started to prepare the flight deck for engine start. The captain disembarked and walked toward the rear of the aircraft to check the airport windsock which was not visible from the cockpit to ensure the correct orientation.[3] The captain then reboarded and joined the first officer for the engine start.

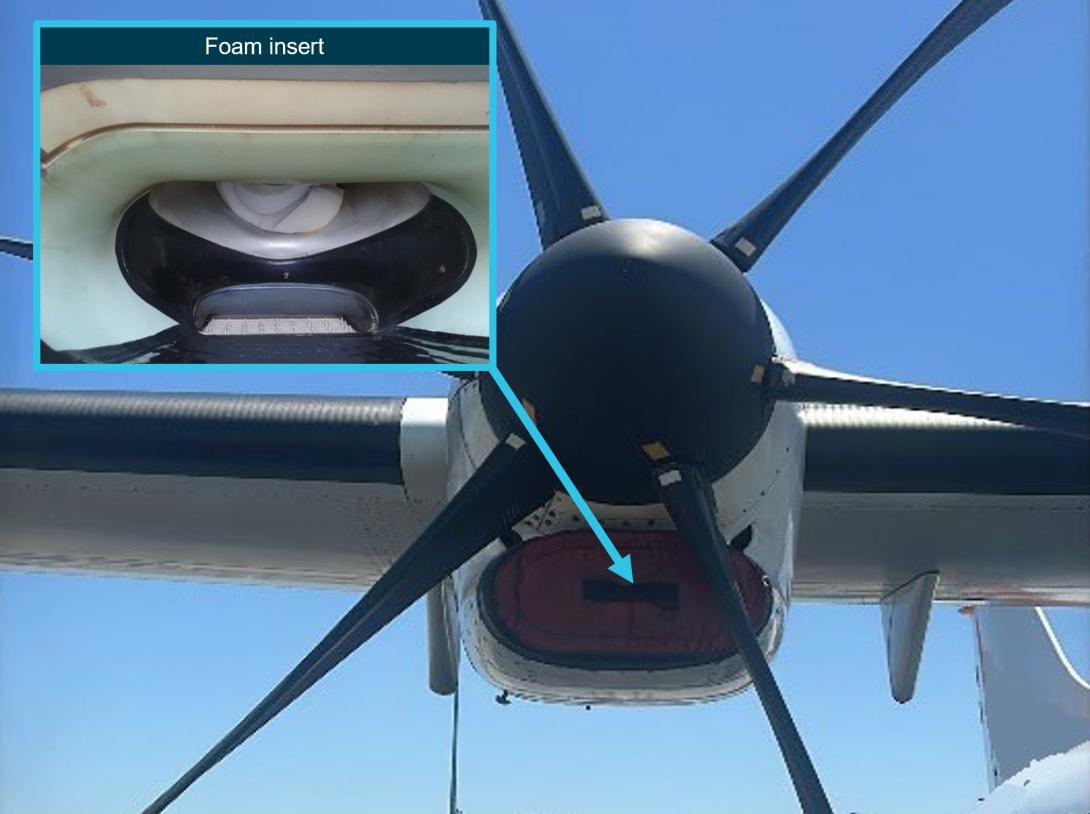

A ground handler was in attendance to make sure the exclusion area around the engine was cleared. After they gave the ‘start-engine’ hand signal, the flight crew started the number 2 engine with the air bleed valve selected ‘off’.[4] The engine start proceeded normally, but when the engine bleed was set to ‘on’ the crew noticed an immediate rise of the inter-turbine temperature. Closing the bleed valve resulted in the temperature dropping back to normal, but another attempt to open the bleed valve saw the temperature rise again. At this point, the first officer realised that the intake covers had not been removed (Figure 1) and they immediately shut down the engine.

The flight crew then disembarked and found that the engine air intake covers had not been removed from either engine. Additionally, the foam insert from the right-side intake cover had separated and was lodged in the intake (Figure 1 inset). They informed the company operations department and after consultation with the approved maintenance organisation, it was decided that the aircraft should not be flown until an engineer could inspect and test run the engine.

Engineers of the operator’s part 145 maintenance organisation attended the aircraft and conducted an inspection of the number 2 engine, followed by a test run at idle and 90% torque. They did not identify any abnormalities, and the aircraft was subsequently released to service.

Figure 1: Installed intake cover

Source: Operator provided photos, annotated by the ATSB

Further inspection of the covers found that neither had a ‘remove before flight’ streamer attached and that the stitching on both the number 2 and number 1 cover was in poor condition (Figure 2) and partly loose, which allowed the foam insert to separate from the cover.

Figure 2: Engine inlet cover with damaged stitching

Source: Operator provided photo

Safety action

The operator’s internal investigation report recommended fitting warning flags to the intake covers of the incident aircraft and that all intake covers across its fleet be checked to further avoid intake cover internal foam ingestion into engines.

The internal report also recommended that involved pilots are reminded of operator’s external inspection procedures and receive training in human factors.

Safety message

This incident highlights the importance of preparing the aircraft for flight in accordance with the company and manufacturer’s procedures, even when competing priorities exist. Conducting pre‑flight activities out of sequence increases the risk of missing critical steps and should be avoided.

Intake and pitot covers may be hard to see due to their location, lighting and weather conditions. To reduce the risk of them being missed during a pre-flight inspection, they should have a contrasting colour and ‘remove before flight’ flags. Operators should make sure they are periodically inspected as part of their maintenance system, so they remain fit for purpose.

About this report

Decisions regarding whether to conduct an investigation, and the scope of an investigation, are based on many factors, including the level of safety benefit likely to be obtained from an investigation. For this occurrence, no investigation has been conducted and the ATSB did not verify the accuracy of the information. A brief description has been written using information supplied in the notification and any follow-up information in order to produce a short summary report, and allow for greater industry awareness of potential safety issues and possible safety actions.

[1] The auxiliary power unit (APU) is a small gas turbine engine mounted in the tail cone of some larger aircraft to provide autonomous electrical and mechanical power without the use of the engines.

[2] Hotel mode engages the hydraulic propeller brake and allows the turbine to be run to provide auxiliary power and compressed air to the aircraft without the propeller spinning. Compressed air is used to drive the air-conditioning packs which provide cooling to the cabin and cockpit.

[3] The manufacturer’s documentation warns against starting the engine in hotel mode with a significant tailwind, as exhaust gasses being blown back into the engine casing may trigger a (false) fire alarm.

[4] Pressurised air diverted from the engine’s compressor stage is delivered through the bleed valves for air conditioning and pressurisation as well as de-icing.