What happened

On 5 July 2024, the pilot of a Eurocopter AS350 B3 was conducting an underslung load operation from Broken Hill Airport, New South Wales. After completing pre-flight inspections[1] of the aircraft, underslung load and cargo hook, the operator proceeded with a system test flight for an upcoming electromagnetic survey. Shortly after take-off, about 0935 local time, the underslung load released from the cargo hook and dropped about 6 m impacting the ground. There were no injuries to ground crew, no damage to aircraft or property and minimal damage to the underslung load.

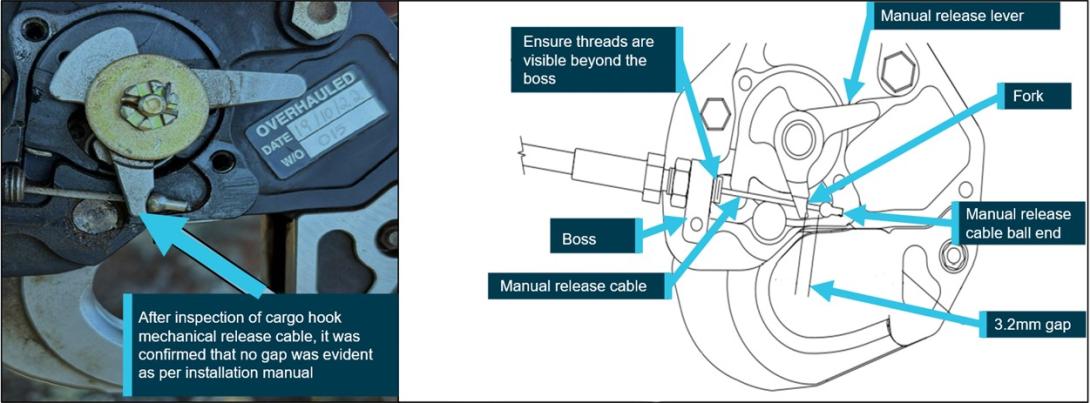

Post-incident inspection of the cargo hook identified that the manual release cable had insufficient clearance between the manual release cable ball end and the manual release lever fork (Figure 1).

When the pilot was increasing lift on the aircraft the manual release cable triggered and inadvertently initiated the manual release lever on the cargo hook, releasing the underslung load.

Figure 1: Cargo hook release mechanism

Safety action

The operator immediately rendered the cargo hook as unserviceable and suspended underslung operations. After an engineering inspection, the operator proactively replaced the cargo hook.

Safety message

This incident highlights the importance of detail and accuracy during the installation process of the cargo hook. Underslung loads are a regular part of some helicopter operations, including survey flying, firebombing and aerial construction. The consequences of an uncommanded/inadvertent release of the underslung load has the potential for fatal consequences, damage to property or the load itself.

The required clearance of the manual release mechanism on the cargo hook is not visible during a pilot’s preflight inspection. Engineering organisations are encouraged to develop processes that ensure critical component installations are checked in duplicate by appropriate persons.

Pilots are also encouraged to conduct a thorough inspection and testing of the cargo hook manual release system prior to conducting underslung load operations as part of their pre-flight inspection.

About this report

Decisions regarding whether to conduct an investigation, and the scope of an investigation, are based on many factors, including the level of safety benefit likely to be obtained from an investigation. For this occurrence, no investigation has been conducted and the ATSB did not verify the accuracy of the information. A brief description has been written using information supplied in the notification and any follow-up information in order to produce a short summary report, and allow for greater industry awareness of potential safety issues and possible safety actions.

[1] Inspection of the cargo hook included weak link and underslung load rigging equipment.