This preliminary report details factual information established in the investigation’s early evidence collection phase, and has been prepared to provide timely information to the industry and public. Preliminary reports contain no analysis or findings, which will be detailed in the investigation’s final report. The information contained in this preliminary report is released in accordance with section 25 of the Transport Safety Investigation Act 2003.

The occurrence

On 4 December 2024, at about 0530 local time, a Robinson R44 Raven II helicopter, registered VH-XIX, departed from Griffith Regional Airport, New South Wales to conduct a ferry flight to a property approximately 50 km east of Young. Onboard were the operator’s Griffith base manager and a loader[1] (acting as pilot for the ferry flight). They arrived at a paddock on the farm at 0744, landing next to a chemical tank. They were met by the farm manager of the property, and the pilot for the day, who had arrived shortly before by motor vehicle from Crookwell. The tasking for the day was the aerial application of herbicide across 2 properties, to be conducted under Part 138 of the Civil Aviation Safety Regulations.

The base manager, pilot, loader and farm manager discussed the day’s work and then prepared the helicopter for spraying operations, including refuelling the helicopter, attaching the spray booms and mixing herbicide. At 0912, the pilot and base manager, who had sprayed the paddocks previously, flew the helicopter on a reconnaissance mission of the intended paddocks returning 5 minutes later.

The helicopter was loaded with herbicide and, at 0921, the pilot departed for application of the first load of the day. The pilot applied 10 loads consecutively. Each load took around 10 minutes to apply, with the pilot returning for the helicopter to be replenished with herbicide, and fuel as required, before immediately departing again.

Toward the end of this activity, the farm manager from an adjacent property arrived and discussed the task for the second property with the base manager. During this time, the pilot departed for the 11th and planned final load of the job on the first farm. After 15 minutes, the base manager realised the helicopter should have returned and tried, unsuccessfully, to contact the pilot via ultra‑high frequency radio in the work vehicle. The base manager then checked a flight tracking application on their mobile phone that showed the helicopter had not moved from its last indicated location for a couple of minutes. The base manager and second farm manager departed in the farmer’s vehicle toward the intended spray area, while the loader stayed to monitor the work vehicle’s radio.

Prior to the flight, high tension powerlines that ran through the middle of the intended spray area had been identified as a hazard to the operation. The base manager and farmer headed to a location near the powerlines but could not find the helicopter. After further searching, they located the wreckage of the helicopter in a gully. They made their way down to the helicopter and found the pilot had exited the helicopter and moved approximately 1 m away but was seriously injured. Emergency services attended, however, the pilot succumbed to their injuries.

Context

Pilot information

The pilot held a commercial pilot licence (helicopter) with a single-engine helicopter class rating. The pilot had 1,035 hours total aeronautical experience, of which 637 hours were on the R44 type. Most of the pilot’s recent flying had been on the R44. The pilot also held a gas turbine design feature endorsement, and numerous piston and turbine type ratings. In addition, the pilot held aerial application, low-level, and sling operational ratings. The pilot had spent approximately 3 years flying agricultural helicopters in New Zealand where they also obtained a mountain flying operational rating.[2]

The pilot held a valid class 1 aviation medical certificate and was reported as appearing well rested and fully alert for the flight.

Helicopter information

The Robinson R44 Raven II is a 4-seat helicopter, powered by a single Textron Lycoming IO‑540‑AE1A5 piston engine driving a 2 blade semi-rigid main rotor system and 2 blade tail rotor system. The helicopter was manufactured in the United States in 2003 and first registered in Australia in May 2003. It was issued with a special certificate of airworthiness in the restricted category in January 2017. The certificate permitted VH-XIX to be used in agricultural operations and aerial surveying, among other similar operations.

A periodic inspection and minor maintenance tasks were carried out on 30 October 2024. At the time of the accident, the helicopter had accumulated about 5,820 hours. The helicopter was configured with an agricultural spray system, which consisted of 2 fibreglass chemical tanks, a flexible hose and stainless-steel tubing distribution system, a petrol‑powered water pump, valving systems, and 2 cantilevered carbon fibre spray booms, one each on either side of the fuselage.

Meteorological information

The closest Bureau of Meteorology weather station was at Young Airport, 50 km to the west of the accident site, which reported winds of 7–8 kt from the north-west and a temperature of 28°C in 30‑minute windows around the time of the accident. Cloud cover[3] was measured as few at 3,500 ft and broken at 4,800 ft. Cowra weather station, 53 km to the north, reported winds of 4–7 kt varying between northerly and westerly and a temperature around 28–30°C. Cloud cover was not recorded.

Wunderground.com is a weather network designed to provide public access to community weather stations. A weather station at Boorowa, 14 km south-south-west of the accident site, reported wind, in 5-minute windows, of 6.8 km/h (3.6 kt) gusting to 7.3 km/h (3.9 kt), from the south‑south‑west and a temperature of 19°C around the time of the accident. Another weather station at Frogmore, 8 km to the north-east, reported wind of 0.9 km/h (0.5 kt) gusting to 1.9 km/h, (1.0 kt) from the north-north-west, with a temperature of 22°C.

Wreckage and impact information

The wreckage was located about 1,200 m south-south-east of the base of operations for that day, in a steep gully towards the southern end of the target spray area. The area was in hilly terrain and contained high dry grass with scattered large alive and dead eucalyptus trees.

The first items in the debris trail were the stabiliser assembly, right side carbon fibre spray boom and broken branches. These items were located next to a dead tree, with freshly broken branches on one side, near the top (Figure 1).

The helicopter was orientated on its left side and facing the direction of the travel. The main fuselage had sustained minor impact damage, with the exception of the cabin, which was significantly disrupted. Outboard sections of both main rotor blades had been liberated during the accident sequence. For the tail rotor assembly, one liberated tail rotor blade, and sections of the tailcone were scattered to the right of the ground path. Despite the disruption, all components of the helicopter were accounted for.

Two ground scars, consistent with the landing gear skids, were located between the tree and the wreckage in the gully. The ground marks were indicative of the upright helicopter sliding along the ground, prior to reaching the edge of the gully.

Figure 1: Wreckage site

Note: Ground scars from the helicopter skids are highlighted red.

Source: ATSB

While the ATSB conducted a preliminary examination of the wreckage at the site, due to access restrictions, the wreckage was relocated to a secure facility for detailed examination. This further examination identified:

- no evidence of pre-impact defects with the flight controls or structure

- approximately 55 L of low-lead aviation fuel in the fuel system, which was visibly clear of contaminants and tested negative to the presence of water

- the engine was able to be rotated, contained oil and there were no obvious defects upon external examination

- the fuel gascolator, engine oil, hydraulic fluid, and intake air filters were clear of particles

- the air intake hose had no signs of collapse, delamination or restriction

- the main and tail rotor gearboxes contained oil, with no metal contamination on the respective chip detectors.[4]

Recorded data

The helicopter had analogue instrumentation and did not record any flight or engine parameters.

A SpotTrace device was carried inside the helicopter, which broadcast the device’s position every couple of minutes when movement was detected. Anybody with access rights could see the position of the tracking device using a computer or mobile phone application. The SpotTrace device broadcast the position of the helicopter from shortly after take‑off that morning, until the helicopter stopped moving, in a position coincident with the collision with terrain.

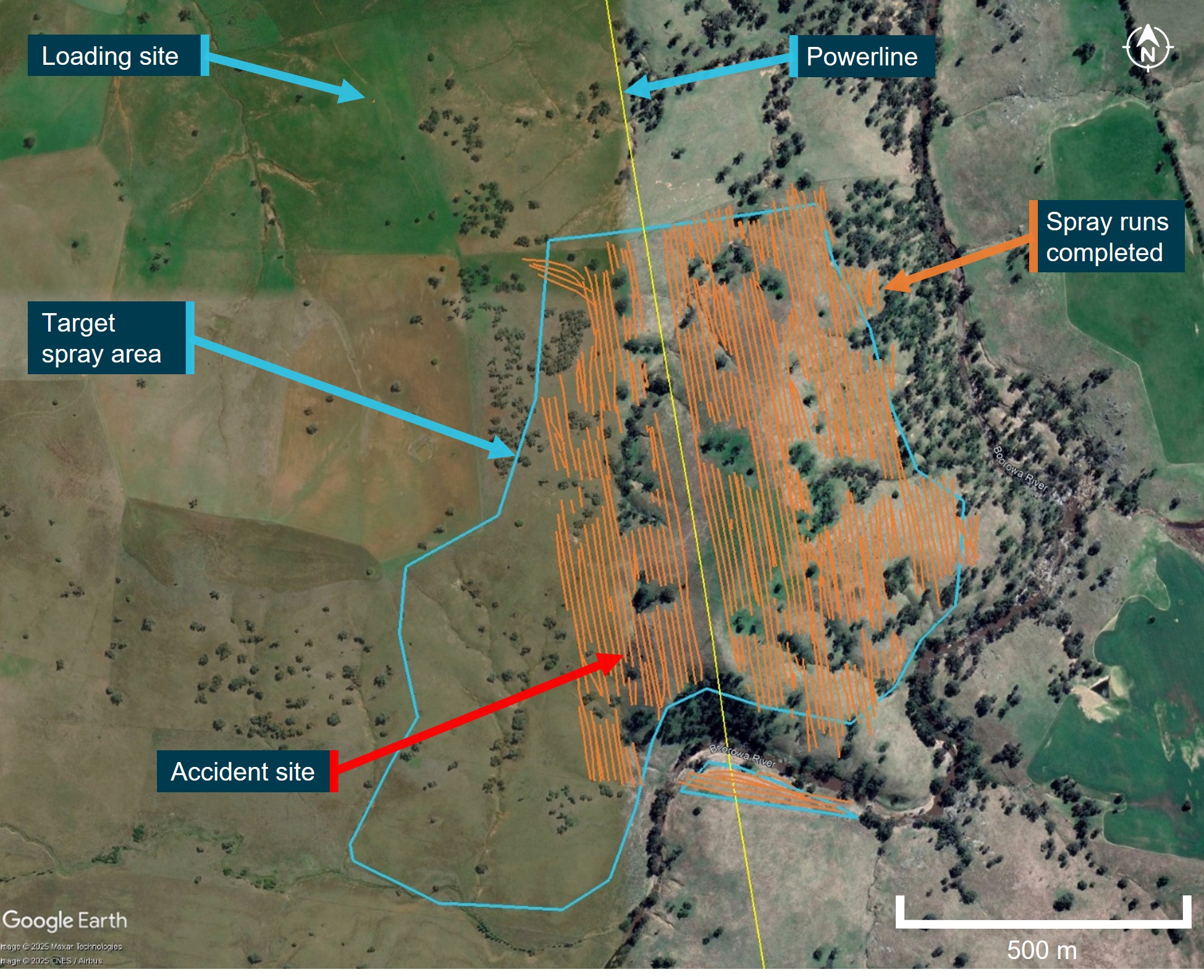

To assist with aerial application tasks, the helicopter was also fitted with a Tracmap GPS guidance device with recording capability. The flight tracks from the day of the accident were recorded and downloaded, including information about when the spray valve was open (Figure 2 in orange), up until a couple of minutes before the accident. Due to the sudden removal of power, some data collected towards the end of the flight was not able to be downloaded. A chip level recovery[5] was conducted from the device but it contained no further information.

Figure 2: Tracmap spray runs completed

Note: The last few minutes of the flight and spray runs were not recorded.

Source: Google Earth Pro, annotated by the ATSB using operator and onboard data sources

Further investigation

To date, the ATSB has conducted witness interviews, collected documentation and recorded data, and examined the site and wreckage.

The investigation is continuing and will include review and examination of:

- witness accounts

- recorded data

- the wreckage

- helicopter documentation

- operational records

- pilot medical records, qualifications and experience.

A final report will be released at the conclusion of the investigation. Should a critical safety issue be identified during the course of the investigation, the ATSB will immediately notify relevant parties so appropriate and timely safety action can be taken.

Acknowledgements

The ATSB would like to acknowledge the assistance of the Young branch of the NSW Police Force during the onsite stages of the investigation.

Purpose of safety investigationsThe objective of a safety investigation is to enhance transport safety. This is done through:

It is not a function of the ATSB to apportion blame or provide a means for determining liability. At the same time, an investigation report must include factual material of sufficient weight to support the analysis and findings. At all times the ATSB endeavours to balance the use of material that could imply adverse comment with the need to properly explain what happened, and why, in a fair and unbiased manner. The ATSB does not investigate for the purpose of taking administrative, regulatory or criminal action. TerminologyAn explanation of terminology used in ATSB investigation reports is available here. This includes terms such as occurrence, contributing factor, other factor that increased risk, and safety issue. Publishing informationReleased in accordance with section 25 of the Transport Safety Investigation Act 2003 Published by: Australian Transport Safety Bureau © Commonwealth of Australia 2025

Ownership of intellectual property rights in this publication Unless otherwise noted, copyright (and any other intellectual property rights, if any) in this report publication is owned by the Commonwealth of Australia. Creative Commons licence With the exception of the Commonwealth Coat of Arms, ATSB logo, and photos and graphics in which a third party holds copyright, this report is licensed under a Creative Commons Attribution 4.0 International licence. The CC BY 4.0 licence enables you to distribute, remix, adapt, and build upon our material in any medium or format, so long as attribution is given to the Australian Transport Safety Bureau. Copyright in material obtained from other agencies, private individuals or organisations, belongs to those agencies, individuals or organisations. Where you wish to use their material, you will need to contact them directly. |

[1] Loader: the term used to denote ground support personnel whose functions include assisting with mixing chemicals, loading and dispatching the aircraft.

[2] A mountain flying rating is not a rating classification available under the Civil Aviation Safety Regulations Part 61 licencing system but is a valid rating in some countries.

[3] Cloud cover: in aviation, cloud cover is reported using words that denote the extent of the cover – ‘few’ indicates that up to a quarter of the sky is covered, ‘scattered’ indicates that cloud is covering between a quarter and a half of the sky, ‘broken’ indicates that more than half to almost all the sky is covered, and ‘overcast’ indicates that all the sky is covered.

[4] Chip detector: a magnetic device used to gather chips of metal from engine or transmission oil to provide early warning to maintenance personnel of impending engine failure. Depending on the installation, it can be linked to an in-cockpit indicating light to provide immediate advice to aircrew.

[5] Chip level recovery: involves removing (desoldering) the memory integrated circuit (IC) package from the circuit board of the device and, using dedicated hardware and software tools, reading an image of the IC contents directly from the IC.