Executive summary

What happened

On the afternoon of 16 June 2023, a Cessna 210L, registered VH‑FTM and operated by Katherine Aviation, commenced a take‑off from runway 10 at Groote Eylandt Airport, Northern Territory with a pilot and 5 passengers on board.

Shortly after becoming airborne, at an altitude of 100 ft, the pilot reported that the engine began to surge, accompanied by fuel flow fluctuations. During the attempted turn back and landing, the aircraft passed diagonally over the runway then touched down in a clear grassed area outside the airport boundary. The aircraft continued along the ground for about 120 m and hit an embankment. The aircraft flipped and came to rest inverted on a service road.

Three passengers received serious injuries while the pilot and 2 passengers sustained minor injuries. The aircraft was substantially damaged.

What the ATSB found

The ATSB found that the engine mixture control was probably not set to full rich prior to commencing the take-off, resulting in reduced power and unanticipated engine behaviour. Likely surprised by the partial power loss, compounded by limited Cessna 210 experience, the pilot took no action to resolve the situation and did not effectively manage the attempted landing. The pilot’s take-off safety self-brief, and the aircraft operator’s documented example brief, did not include the actions to be taken in the event of a partial power loss. Additionally, the pilot had not completed weight and balance calculations for the flight and the aircraft departed 10 kg over the maximum take-off weight.

The ATSB also identified that the aircraft was likely being operated with a time-expired engine-driven fuel pump. Although the pump was unlikely to have contributed to the partial power loss, its time in service increased the likelihood of failure.

Additionally, the aircraft did not have, and was not required to have, upper torso restraints fitted to the rear passenger seats. Although any effect this had on the occupants’ injuries could not be determined, this increased the likelihood of serious injury in an accident.

What has been done as a result

On 17 June 2023, CASA issued a safety alert to Katherine Aviation that required the organisation to conduct a fleet-wide check of all time-lifed components that were either fitted or about to be fitted to the aircraft. The safety alert was issued following the identification of the time-expired engine-driven fuel pump fitted to VH-FTM. On 22 June 2023, Katherine Aviation completed the check and identified several further defects. In response, the organisation agreed to implement a maintenance incident reporting system and discontinue the cross hire of aircraft to reduce engineering workload.

Safety message

This accident highlights the challenges pilots face when dealing with unfamiliar situations during critical phases of flight. Operators can manage these challenges by documenting known operational scenarios and ensuring pilots are thoroughly trained before undertaking line operations.

Pilots can mitigate the risk by familiarising themselves with aircraft systems and the operational environment. Additionally, forward planning, such as a well-structured take-off safety brief, increases situation awareness, reduces mental workload under stress, and increases the prospect of a safe and well-managed outcome in the event of an emergency.

The ATSB research publication, Avoidable Accidents No.3: Managing partial power loss after take-off in single engine aircraft (AR-2010-055) provides further guidance.

Additionally, the ATSB SafetyWatch highlights the broad safety concerns that come out of our investigation findings and from the occurrence data reported to us by industry. One of the safety concerns is reducing the severity of injuries in accidents involving small aircraft which includes the fitment and use of seatbelts with upper torso restraints.

The investigation

| Decisions regarding the scope of an investigation are based on many factors, including the level of safety benefit likely to be obtained from an investigation and the associated resources required. For this occurrence, a limited-scope investigation was conducted in order to produce a short investigation report, and allow for greater industry awareness of findings that affect safety and potential learning opportunities |

The occurrence

On the afternoon of 16 June 2023, a Cessna 210L, registered VH-FTM and operated by Katherine Aviation, taxied for a passenger air transport flight[1] from Groote Eylandt Airport to Ngukurr Airport, Northern Territory with a pilot and 5 passengers on board.

The weather at the time was recorded as a surface wind from south–southeast at 8–12 kt, no cloud, air temperature of 27°C, and visibility greater than 10 km.

At about 1347:57, the pilot commenced the take-off from near the threshold of runway 10. The pilot recalled setting the mixture to full rich prior to commencing the take-off. The pilot recalled looking at the gauge following the application of full throttle at the commencement of the take-off and noted no anomalies at that time. The pilot recalled that at take-off power the gauge should read about 130 lb/h (82 L/h).[2]

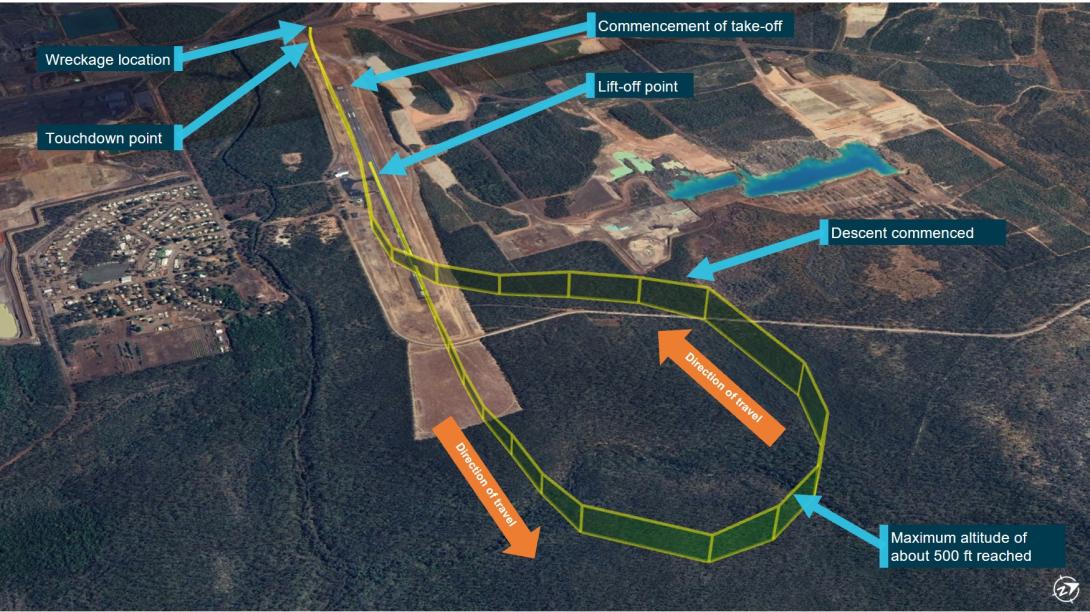

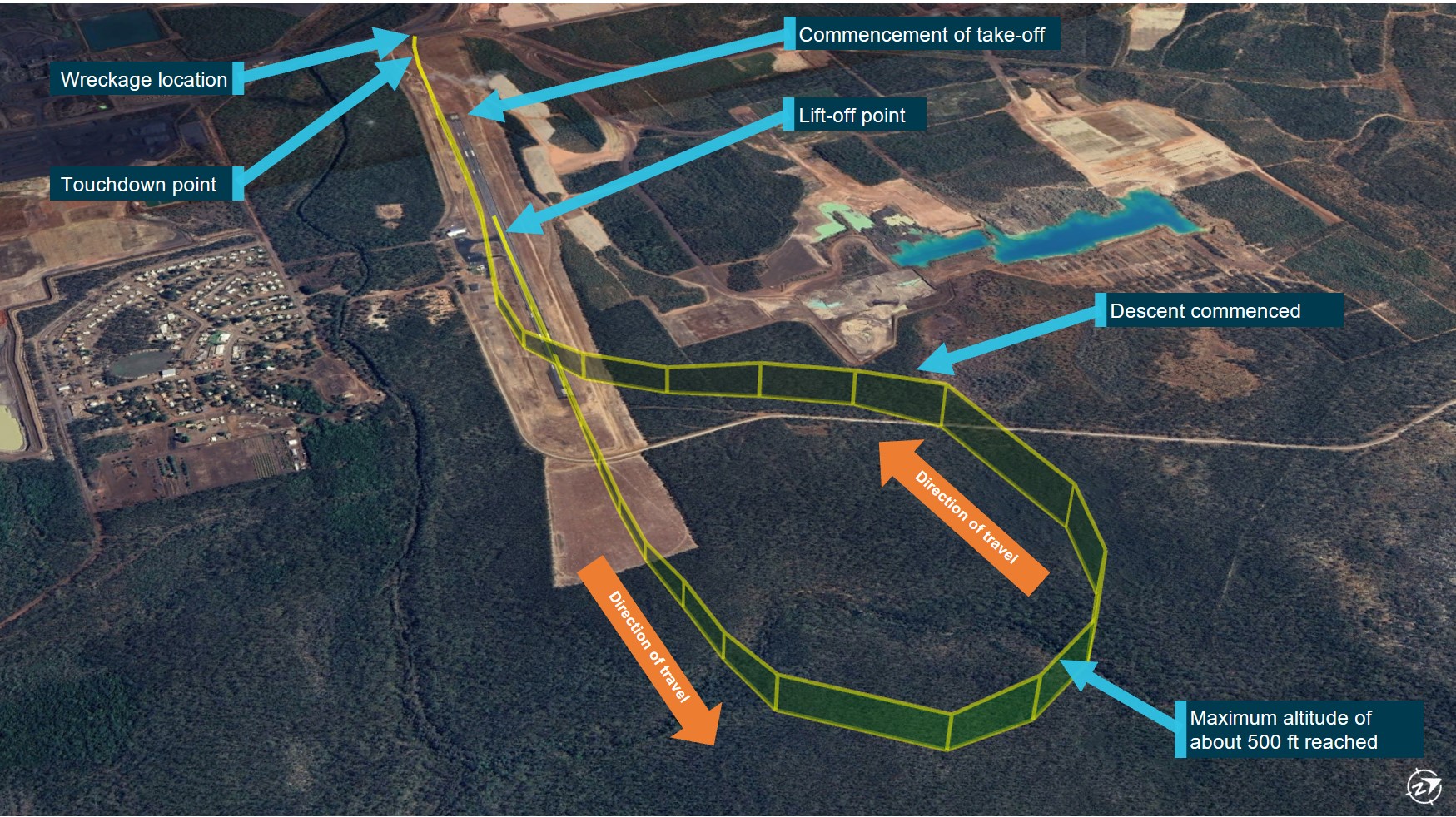

Recorded data showed that the aircraft became airborne at about the midway point of the 1,903‑metre runway (Figure 1). Shortly after becoming airborne, at an altitude of about 100 ft, the pilot noted engine surging accompanied by fuel flow fluctuations. The pilot assessed that there was insufficient runway remaining ahead of the aircraft to attempt a landing and elected to continue to climb the aircraft straight ahead with a perceived partial power loss. At this time, the recorded groundspeed was about 84 kt (accounting for wind, airspeed was about 89 kt), and the rate of climb was about 500 ft per minute.

The pilot recalled retracting the landing gear as the aircraft passed the end of the runway, and selecting flaps up once the aircraft had climbed above trees located about 800 m beyond the end of runway 10. They remembered being ‘startled’ by the situation and could not recall completing initial engine trouble checks (see Actions to address fuel flow fluctuations). The pilot assessed there were no landing options ahead of the aircraft to conduct a landing and they elected to return to the airport to land on runway 28.

At about 1349:35, 45 seconds after the aircraft became airborne, and at an altitude of about 400 ft, the pilot made a broadcast on the Groote Eylandt Airport common traffic advisory frequency (CTAF) advising that they would be returning to Groote Eylandt Airport. At the same time, the pilot commenced a left turn and the aircraft continued to climb.

At about 1349:50, the pilot levelled off the aircraft at a height of about 500 ft. At about 1349:58, the pilot had a brief discussion on the Groote Eylandt Airport CTAF with another pilot advising that the aircraft had fuel flow issues.

The pilot noted ‘decreased engine performance.’ The pilot did not recall looking at the engine and fuel system instrumentation after levelling off, or taking action to restore engine performance, as they were focusing on avoiding an aerodynamic stall. At this time the aircraft had a calculated airspeed of about 94 kt, about 29 kt faster than the calculated stall speed of the aircraft.

Figure 1: Flight path overview

Source: OzRunways and Google Earth, annotated by the ATSB

At about 1350:15, the pilot likely initiated a descent, descending to about 100 ft over the next 40 seconds (an average of 600 -fpm). The aircraft descended with a recorded average groundspeed of about 104 kt and reduced engine power. At about 1350:30 the pilot initiated a right turn.

At 1350:37 the aircraft passed diagonally over the runway near the threshold for runway 28 at a height of about 250 ft. At this location there was about 1,700 m of runway remaining to the aircraft’s right.

The pilot recalled trying to position the aircraft to land on runway 28 but remembered getting ‘further and further away’. They considered conducting a go-around, but believed the engine did not have sufficient performance to safely undertake the manoeuvre. The pilot recalled revising their intentions and aimed to touch down in a clear grassed area about 500 m beyond the threshold for runway 10, just beyond the airport boundary.

The aircraft continued the right turn and flew almost parallel to the runway. Recorded data showed that the pilot likely advanced the throttle, increasing engine power, as the aircraft descended through 200 ft, and the recorded descent rate then slowed to about 400 fpm.[3] The aircraft descended through 100 ft next to the eastern half of the runway and continued parallel to it about 50 m to the left of the runway centreline. The pilot could not recall when the landing gear was lowered.

The aircraft was recorded by a security camera as it continued to descend while tracking parallel to runway 28. At 1351:10, the aircraft flew past the end of runway 28 at a height of about 100 ft and a groundspeed of about 91 kt. At the same time, the engine power was reduced to idle.

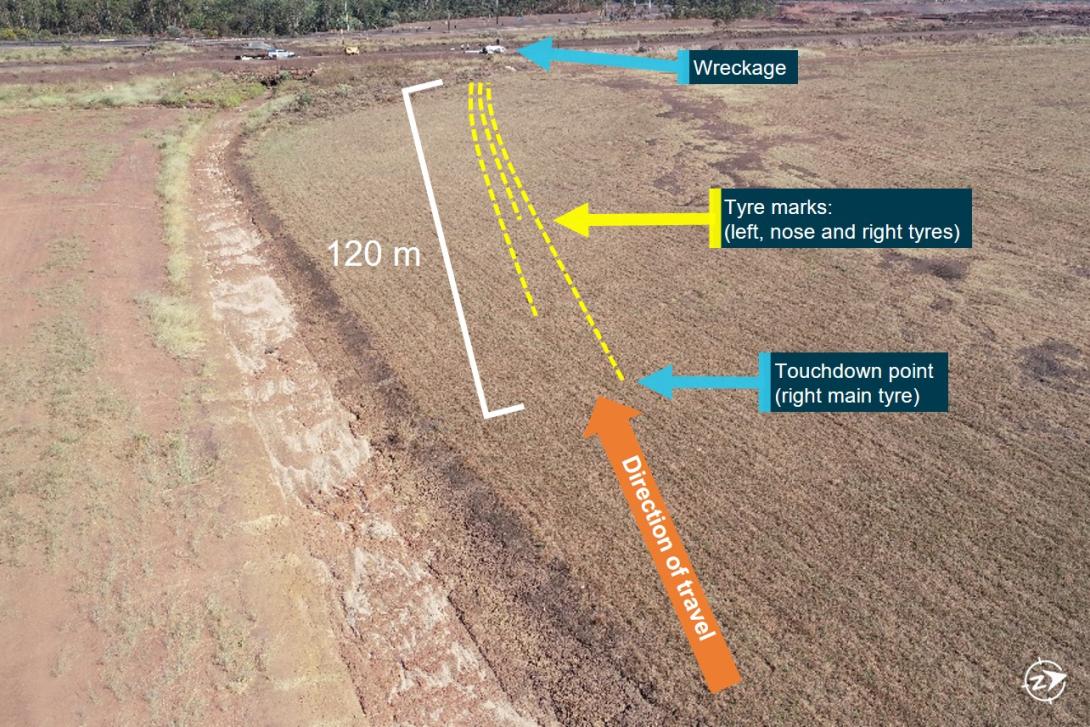

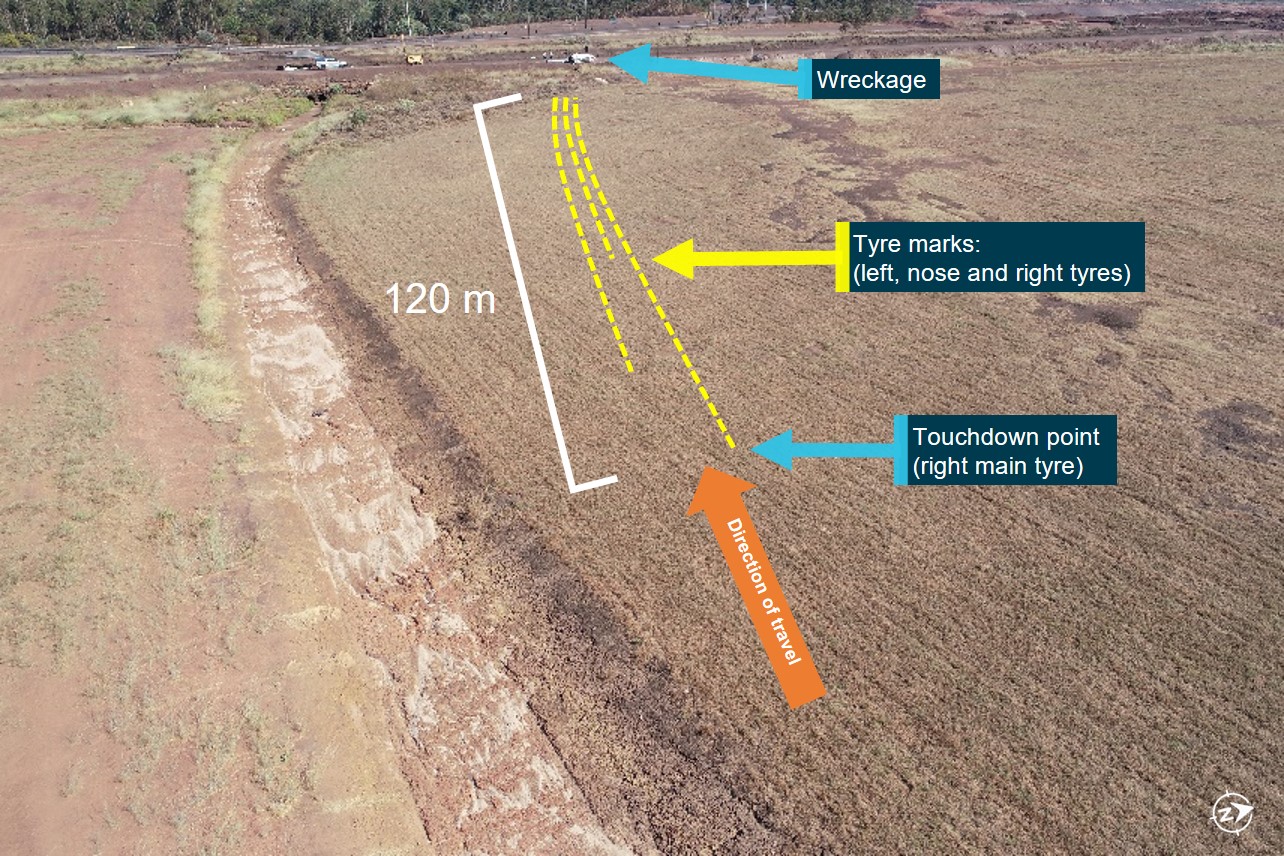

The aircraft was recorded by a second security camera as it touched down in the clear grassed area. The aircraft continued along the ground for about 120 m and collided with an embankment on the eastern side of a culvert, outside of the aerodrome boundary, at about 62 kt (Figure 2). The aircraft traversed the culvert and then struck a larger embankment on the western side, flipped, and came to rest inverted on a service road (Figure 3).

Figure 2: Touchdown point overview

Source: ATSB

Figure 3: Site overview

Source: ATSB

The pilot and passengers exited the aircraft prior to the arrival of first responders. Three passengers received serious injuries while the pilot and 2 passengers sustained minor injuries (see Occupant restraints and injuries). The aircraft was substantially damaged, and there was no fire.

Context

Pilot information

The pilot held a valid class 1 aviation medical certificate and a commercial pilot licence (aeroplane), and last completed a flight review on 8 March 2023. At the time of the accident, the pilot had about 320 hours total aeronautical experience, including about 47 hours flying the Cessna 210.

The pilot commenced employment with Katherine Aviation in May 2023 with no prior commercial aviation experience. The pilot underwent 18.7 hours flying the Cessna 210 in May 2023 as pilot in command under supervision prior to passing a standard proficiency check on 29 May 2023. The check flight included 2 exercises for engine failure after take-off that were recorded as having been conducted to ‘high standard’. A review of the pilot’s training records identified no ongoing competency issues.

The pilot reported not feeling fatigued at the time of the accident.

Operator information

Katherine Aviation was a Civil Aviation Safety Regulation (CASR) Part 135 and 138 approved operator with 8 operational bases located throughout the Northern Territory, including Groote Eylandt. Katherine Aviation ceased operations in December 2023 and CASA cancelled both its CASR Part 135 and 138 approvals at the request of the organisation.

Airport information

Groote Eylandt Airport is located about 1 km north of the town of Angurugu on Groote Eylandt, Northern Territory. The airport has an elevation of 53 ft above mean sea level and a single sealed 1.9 km long runway, orientated in a 095°–275° magnetic direction (Figure 4). Groote Eylandt Airport was located within non-controlled Class G airspace and had a designated common traffic advisory frequency on which pilots were required to make positional broadcasts when operating within the vicinity of the airport.

Figure 4: Groote Eylandt Airport and surrounding area

Source: ATSB

Aircraft information

General aircraft information

The Cessna 210L is a high-wing, all-metal, unpressurised aircraft with a retractable landing gear. The accident aircraft, serial number 21061159, was manufactured in 1976 and was first registered in Australia in May 1976. It had a single Continental IO-520 fuel injected reciprocating piston engine driving a McCauley Propellers 3 blade constant-speed propeller.

The operator’s system of maintenance required a periodic inspection to be carried out every 200 flying hours or 12 months and the last periodic inspection was completed on 15 February 2023. It had flown 124.8 hours since the inspection and accrued 17,001.4 hours total time in service. The aircraft carried a current maintenance release with no defects recorded.

Previous power loss occurrence

In March 2023, a pilot of VH-FTM reported a drop in fuel flow and a partial power loss while taking off from Bickerton Island Airport, Northern Territory. The pilot rejected the take-off and grounded the aircraft. A licensed aircraft maintenance engineer (LAME) drained a small quantity of water from the fuel tanks, carried out an engine ground run, and could not reproduce the defect. It was reported that no endorsements were made on the maintenance release due to the limited work carried out.

Engine run-up checks

On the day of the accident, the pilot conducted 4 flights in VH-FTM during the morning and recalled no issues with the aircraft’s performance. The pilot recalled undertaking engine run‑up checks on the first flight of the day and did not identify any abnormalities. They did not undertake engine run‑up checks for the accident flight, and there was no requirement to do so in the operator’s procedures.

Fuel system

The aircraft was fitted with 2 internal fuel tanks, one in each wing, with a combined capacity of 340 L total (336 L useable). The aircraft was refuelled prior to the accident flight, with records indicating the aircraft departed Groote Eylandt Airport with 240 L of fuel (120 L in each of the tanks). The pilot recalled checking the fuel for water following refuelling and identified no contamination.

Engine mixture settings

The IO-520 engine mixture is set by the pilot to control the ratio of air to fuel delivered to the engine’s cylinders. This affects engine power and fuel usage, among other things. The following description is summarised from several sources including Schwaner (1991), Robson (2014) and Federal Aviation Administration (2023).

If a take-off was commenced with the mixture control in the ‘ground lean’ position (at lower airport elevations), it would result in a disproportionately low fuel component of the air-fuel ratio.[4] Indications of this, compared to a take-off with the mixture control set to full rich, include reduced fuel flow as less fuel is delivered to the engine cylinders. Additionally, as the fuel component of the air-fuel ratio reduces, there is less unburnt (cooling) fuel within the exhaust gas, so exhaust gas temperatures[5] (EGTs) increase, peaking at the stoichiometric (chemically maximised)[6] ratio.

If the fuel component of the air-fuel ratio is reduced beyond the stoichiometric ratio, EGTs begin to reduce again as there is less fuel available for combustion. Peak power generally occurs at a richer setting than at peak EGT.

Rough running can also be a symptom of an excessively lean air-fuel ratio.

Engine mixture settings for ground operations and take-off

The aircraft operator required ground operations to be undertaken with the engine leaned[7] to a ‘ground lean’ setting. The operator’s instructions stated:

Once the engine is started and RPM is stable lean the engine using the mixture control until a rise in RPM is observed. Lean further to achieve a slight RPM drop. Approximately a 10‑20 RPM drop is appropriate (“GROUND LEAN”).

The pilot was then required to advance the mixture control to full rich[8] prior to commencing the take-off in accordance with the operator and aircraft manufacturer instructions.

Fuel vaporisation

In high-temperature and/or high-altitude conditions, liquid fuel in a fuel system can boil, creating vapour. This can cause rough running or reduce available power, and when very severe, prevent fuel from reaching the engine (a condition called vapour lock).

The use of an auxiliary fuel pump, upstream of the vapour, can alleviate these effects. The Cessna 210L pilot’s operating handbook required the auxiliary fuel pump to be switched to ‘LO’ (low) for engine start and then off again. It advised that if the engine does not start, the pilot can switch the auxiliary fuel pump to ‘HI’ (high) momentarily to ‘clear [fuel] vapor from lines’.

According to experts in discussions with the ATSB, vaporisation that does not reach vapour lock can produce significant drops in fuel flow rates, but these tend to be erratic and intermittent and there is not a drop to a consistently low flow rate. It would often manifest on engine start as either trouble starting or immediate rough running. In an aircraft like the Cessna 210, the vapour will ultimately clear, including some returned to the fuel tanks from fuel pump oversupply.

Actions to address fuel flow fluctuations

Cessna service information letter (SIL) SE 79-25 (April 1979) Fuel flow stabilization provided information to aid pilots in the recognition and management of fuel vapor accumulation that could occur within the aircraft’s fuel system.[9] It stated that:

…indications of fuel vapor accumulation are fuel flow gauge fluctuations greater than 1 gal/h [equivalent to 3.8 L/h or 6 lb/h]. This condition with leaner mixtures or with larger fluctuations may result in power surges.

It went on to state that ‘fuel vapor indications are most likely to appear during climb and the first hour of cruise on each tank especially when operating at higher altitudes or in unusually warm temperatures.’

A supplement to SIL SE 79-25, released in June 1979, provided aircraft owners with a recommended procedures placard and a ‘special procedure card’ to be placed in the aircraft. The placard procedures to follow in the event of fuel flow fluctuations/power surges were:

- AUX FUEL PUMP — ON, ADJUST MIXTURE

- SELECT OPPOSITE TANK

- WHEN FUEL FLOW STEADY, RESUME NORMAL OPERATIONS

The placard was located on the right side of the instrument panel in VH-FTM but the procedure card was not found after the accident. Checking and setting the mixture control is a common step in diagnosing and resolving fuel flow fluctuations/power surges in light piston-engine aircraft.

The pilot did not recall receiving training on the actions to take in the event of fuel flow fluctuations and was not aware of the placard on board VH-FTM.

Weight and balance

The pilot weighed[10] each passenger and their baggage prior to the flight and entered these weights onto the aircraft manifest. However, the pilot did not complete the weight and balance calculations for the flight as they perceived there to be ‘time pressure’ to depart.

The ATSB calculated that, at the time of take-off, the aircraft had a gross weight of 1,734 kg, 10 kg above the maximum take-off weight. The baggage compartment had been loaded with 62 kg of baggage and equipment,[11] which was 8 kg above the 54 kg maximum compartment weight limitation. The aircraft was calculated to be within take-off balance limits.

Normal landing distance

At a gross weight of about 1,734 kg, flaps 30°, and the prevailing weather and environmental conditions at the time, the aircraft required a ground roll landing distance of about 268 m.

Take-off safety (self) brief

The pilot’s take-off safety brief[12] included actions to be taken in the event of a problem (not specifically defined) that might be encountered on the runway, airborne with runway remaining, or airborne without runway remaining. However, having commenced operations from the airport only 11 days prior to the accident, the pilot reported not being very familiar with the potential landing areas when departing using runway 10. Neither the pilot’s take-off safety brief, nor the aircraft operator’s documented example brief, contained the actions to be taken in the event of a partial power loss.

Site and wreckage

Accident site

The ATSB conducted an on-site examination of the aircraft wreckage. The aircraft initially struck an embankment on the eastern side of the culvert before impacting a larger embankment on the western side in an upright attitude. The culvert was located about 700 m to the west of the threshold for runway 10. The impact resulted in the detachment of the nose wheel and the right lateral displacement of the engine assembly. The aircraft then rotated vertically, pivoting at the nose, before coming to rest inverted (Figure 5).

Figure 5: Wreckage of VH-FTM

Source: ATSB

Wreckage examination

All major sections of the aircraft’s structure were accounted for at the accident site. Flight control continuity was established where possible and the wing flaps[13] were retracted. The landing gear was extended and propeller damage was indicative of the engine running at low power at the time of impact. Fuel system components were examined and found to be free from contamination or obstruction. The ATSB took fuel samples at various points throughout the aircraft’s fuel system that showed no evidence of contamination with water.

Engine examination

Under observation by the ATSB, the engine was disassembled and examined at a Civil Aviation Safety Authority (CASA)-approved engine overhaul facility. The engine condition was consistent with its recorded time in service since overhaul, and no internal or external defects were identified that may have contributed to the fuel flow fluctuations and engine surging reported by the pilot.

Engine-driven fuel pump

The engine-driven fuel pump produces metered fuel pressure to the engine. In April 2022, the aircraft was under maintenance following a period of inactivity. It was reported that the engine could not be started and that a time-expired fuel pump was fitted for troubleshooting purposes. The engine could then be started, and the aircraft was released to service without replacing the pump with one that was not time‑expired. The operator reported that they suspect the time‑expired fuel pump was still fitted at the time of the accident.

After the accident, the fuel pump was bench tested, disassembled, and examined at a CASA-approved component overhaul facility under the supervision of the ATSB. The fuel pump functioned normally, however, testing of the low-pressure flow (applicable to the pressure at idle RPM) was limited by accident damage. When disassembled and examined, the pump had wear consistent with its age but was otherwise in good condition.

Recorded data

The pilot was using an electronic flight bag (EFB) application on a tablet throughout the flight. Data recovered from this application captured flight parameters every 5 seconds. Additionally, the aircraft was fitted with a J.P. Instruments EDM-900 engine data management system. Data recovered from this unit captured engine parameters every 6 seconds throughout the accident flight and 2 previous flights on the same day.

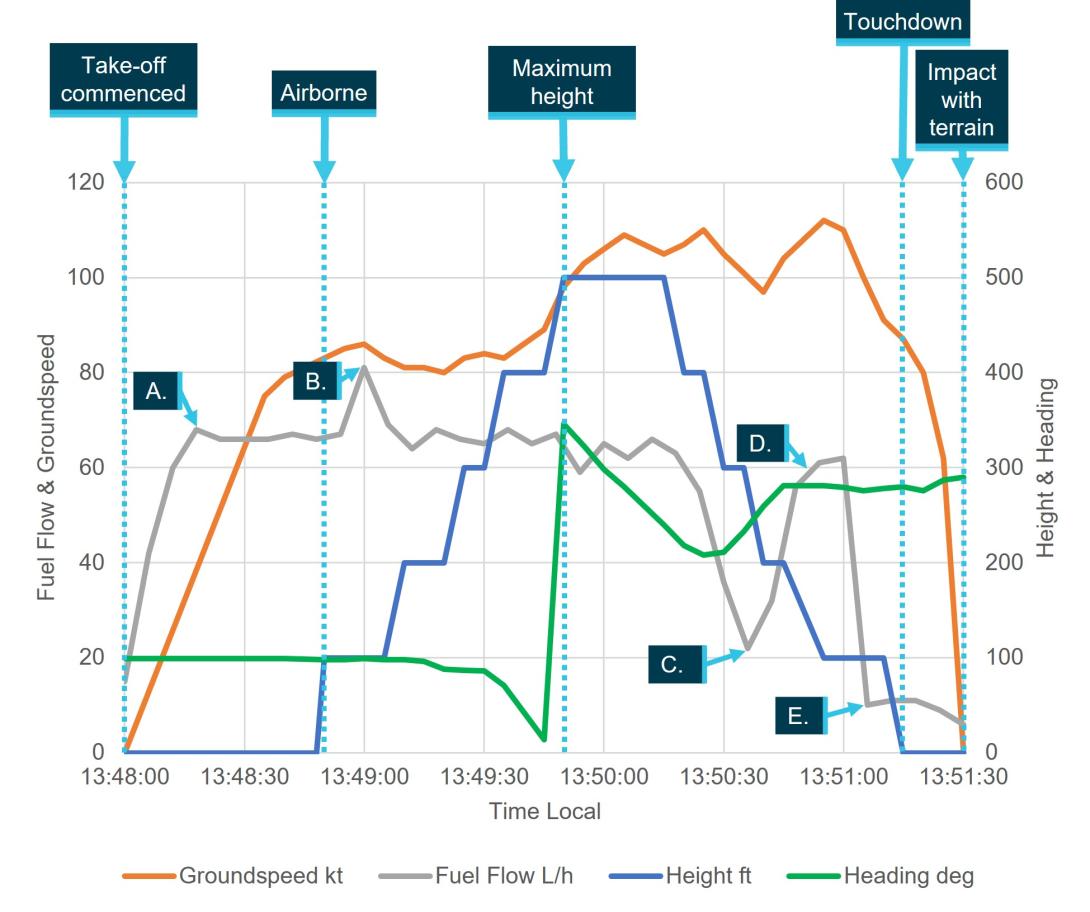

The groundspeed, fuel flow, and altitude information from the EFB and EDM-900 is depicted in Figure 6. The data indicates that:

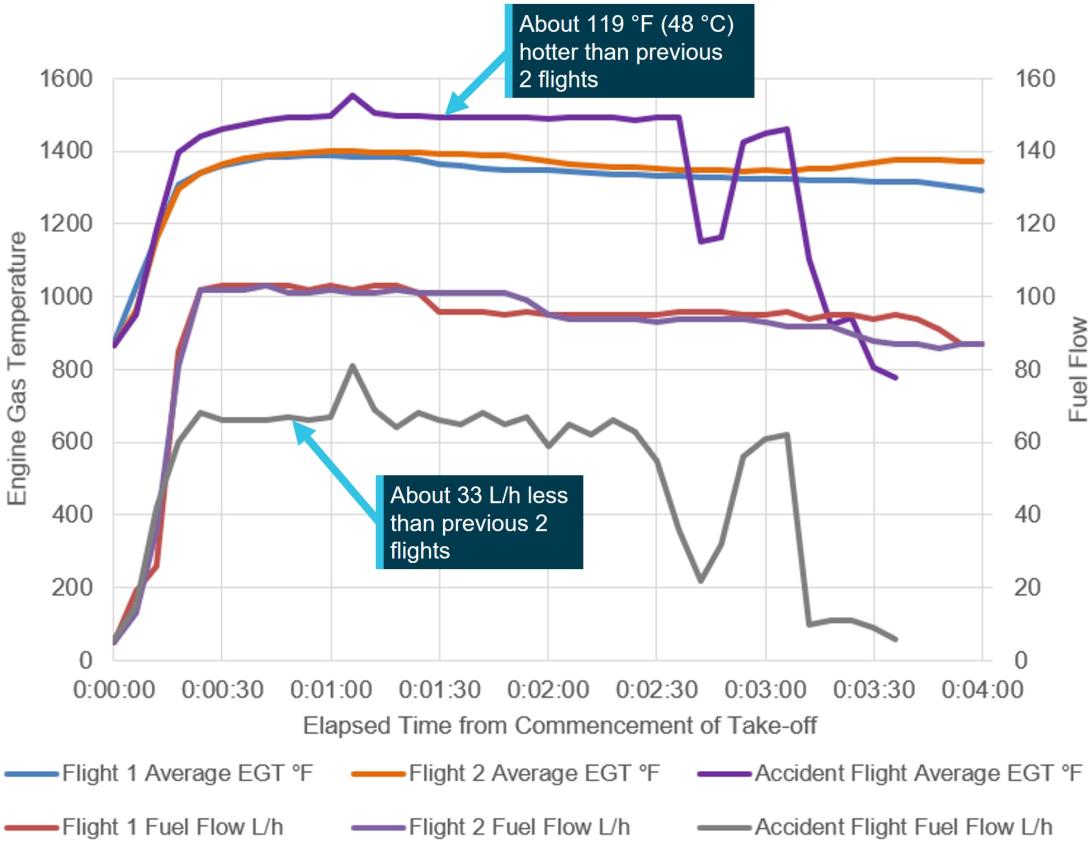

- On application of full throttle by the pilot (A), the fuel flow reached a mean of about 66 L/h (104lb/h), about 33 L/h less than recorded at take-off power on previous flights that day (Figure 7).

- After the aircraft became airborne, the fuel flow increased to about 81 L/h for 1 data point (B) then fluctuated in the range 59-69 L/h, with an average of 66 L/h, before reducing significantly during the first part of the descent (C).

- The fuel flow increased again to the previous level at around 200 ft (D), before being reduced to idle (E) when the aircraft was beside the runway, about 250–500 m from the eastern end.

Figure 6: VH-FTM groundspeed, fuel flow, height and heading data

Source: ATSB

Engine RPM fluctuated consistently with the EGTs and other parameters. The EGTs on the accident flight were found to be around 119 °F (48 °C) hotter than recorded at take-off power on previous flights that day (Figure 7).

Figure 7: VH-FTM take-off fuel flow and average EGT for flights on 16 June 2023

Source: ATSB

Occupant restraints and injuries

VH-FTM had three rows of seats, with two seats per row. The pilot, who was seated in the front left seat, received minor lacerations to their lower body. The front right seat passenger received serious injuries, including to the head, limbs, and abdomen, and spinal fractures. Two of the passengers seated in the rear of the aircraft received serious injuries including to the limbs and head. The remaining 2 passengers in the rear received minor injuries.

The front 2 seats were each fitted with a lap belt and one upper torso restraint (UTR). The rear seats were fitted with lap belts only with no UTRs. This was consistent with part 90.105 of the Civil Aviation Safety Regulations 1998 (CASR) which only required the front row seats to be fitted with an approved safety harness comprising a lap belt and at least one shoulder strap (restraint). Currently, small aeroplanes manufactured after 12 December 1986 and helicopters manufactured after 17 September 1992 are required to have UTRs fitted for all seats.

In 2019, the ATSB released the following safety advisory notice to operators of small aeroplanes and helicopters, and safety recommendation to the Civil Aviation Safety Authority (CASA):

AO-2017-005-SAN-028: The Australian Transport Safety Bureau strongly encourages operators and owners of small aeroplanes manufactured before December 1986 and helicopters manufactured before September 1992 to fit upper torso restraints to all seats in their aircraft (if they are not already fitted).

AO-2017-005-SR-027: The Australian Transport Safety Bureau recommends that the Civil Aviation Safety Authority consider mandating the fitment of upper torso restraints (UTRs) for all seats in small aeroplanes and helicopters, particularly for those aircraft (a) being used for air transport operations and/or (b) for those aircraft where the aircraft manufacturer has issued a mandatory service bulletin to fit UTRs for all seats (or such restraints are readily available and relatively easy to install).

In response to the safety recommendation, CASA acknowledged that fitting UTRs had merit, and that it encouraged operators to do so, but it did not support the mandatory fitment of UTRs for all seats in small aeroplanes and helicopters.

Partial power loss after take-off in single-engine aircraft

Partial engine power loss is more complex and more frequent than a complete engine power loss. The ATSB report Managing partial power loss after take-off in single-engine aircraft (AR‑2010‑055) identified 242 reported occurrences between 2000 and 2010 involving single-engine aircraft sustaining a partial engine power loss after take-off. The report stated that after take-off, a partial power loss is 3 times more likely in a light single-engine aircraft than a complete engine failure. In two-thirds of these occurrences, the pilot turned back toward the aerodrome.

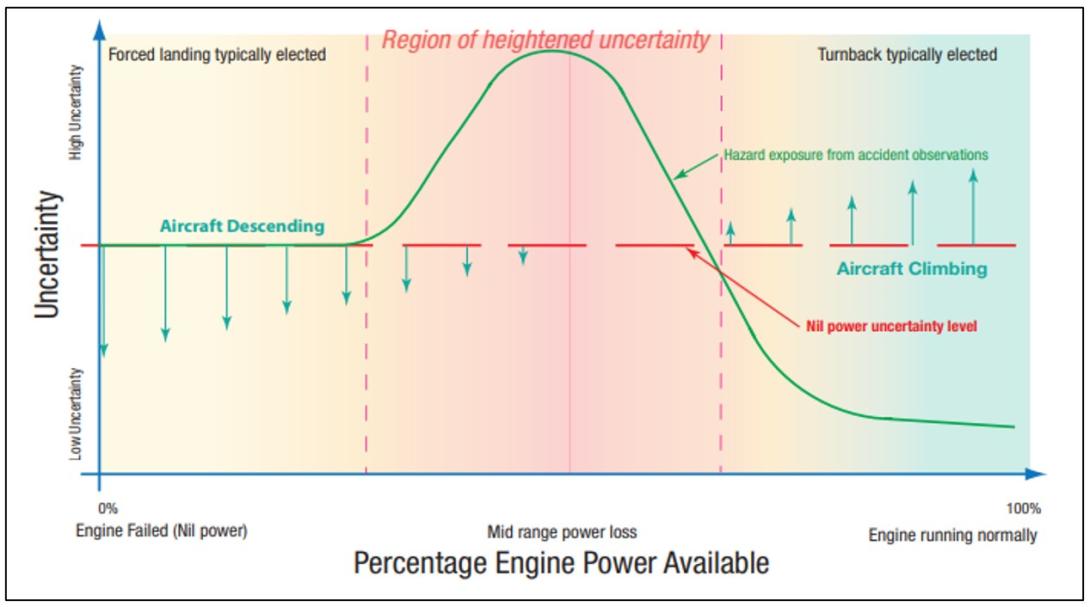

When the amount of power lost is close to that experienced with a complete loss, the pilot is likely to identify the severity of the situation readily and take action similar to that expected for a total power loss. At the other end of the spectrum, where the remaining engine power allows the aircraft to climb, more options are available to the pilot, such as climbing slowly into the circuit or carefully turning back to the aerodrome (Figure 8).

Figure 8: Conceptual uncertainty by amount of power loss

Source: ATSB

A turn back requires accurate flying during a period of likely high stress. According to the ATSB report AR-2010-055, a take-off safety brief gives pilots a much better chance of maintaining control of the aircraft, and helps the pilot respond immediately. Considerations include planning for rejecting a take-off, landing immediately within the airport, landing beyond the airport, and conducting a turnback towards the airport.

The ATSB’s research suggested that the following initial actions should be performed when responding to a partial loss in power:

- Maximise height and distance — climb at the manufacture’s recommended ‘best rate’ or ‘best angle’ speeds depending on the aircraft and location.

- Time permitting, conduct basic initial engine trouble checks in accordance with the aircraft manufacturer’s advice.

- Fly the aircraft to make a landing. If a turn is conducted, be mindful that an increase in elevator input to maintain a desired descent path will reduce the margin to the stall. Having a planned minimum turning height is also recommended, with CASA suggesting a minimum height of 200 ft above ground level.

- Below the minimum turning height, if continued climb to a safer altitude is possible, it should be done with level wings. With insufficient remaining power to climb, landing ahead is the only option.

- Re-assess landing options throughout any manoeuvres.

- Land the aircraft.

Safety analysis

Introduction

Shortly after becoming airborne, at an altitude of about 100 ft, the engine fuel flow increased to 81 L/h for 1 data point, then fluctuated around an average of 66 L/h with a range of about 10 L/h. This is consistent with the pilot’s recollection of fuel flow fluctuations (as would have been indicated on the gauge at the time). Exhaust gas temperatures (EGTs) were also around 48 °C hotter than recorded at take-off power on previous flights that day.

Although there are a range of potential reasons for surging (RPM fluctuations), the much lower average fuel flow and hotter EGTs than on previous flights are strongly indicative of an issue with the fuel supply.

An inspection of the aircraft wreckage did not identify any engine, fuel system, or other mechanical factors that may have led to the partial power loss. The pilot noted no engine performance issues during earlier flights that day, there was sufficient fuel on board the aircraft, and no fuel contamination was apparent.

The engine driven fuel pump fitted to the aircraft had likely exceeded its overhaul life. However, when tested it functioned normally and was likely doing so at the time of the accident.

Engine performance

Power loss, fuel flow fluctuations and surging

The partial power loss was likely due to the engine mixture control being incorrectly set at the commencement of take-off. This resulted in an air-fuel ratio that was too lean and manifested as reduced power and unanticipated engine behaviour.

The EDM-900 engine data management system data is consistent with this scenario and indicated that on application of full throttle, the average fuel flow attained during take-off was about 66 L/h. This was about 33 L/h less than other take-offs that day. The fuel flow indications were consistent with a reduced fuel component of the air-fuel ratio, where less fuel is being delivered to the cylinders, and would have resulted in reduced engine power. The exhaust gas temperatures (EGTs) were also found to be around 48°C hotter than recorded at take-off power on previous flights that day. The hotter EGTs were also consistent with a reduced fuel component of the air-fuel ratio where there is less unburnt (cooling) fuel within the exhaust gas, resulting in increased EGTs.

The operator required ground operations to be undertaken with the mixture control set to a ‘ground lean’ setting. For take-off, both the operator and aircraft manufacturer procedures then required the mixture control to be set to ‘full rich’. Combined with the recorded data, it is therefore probable that the mixture control, which is used to adjust the air-fuel ratio, was left in the ‘ground lean’ position for take-off.

There were no indications of mechanical failure with the engine or fuel system, and no contaminants were present within the fuel tested. Consequently, these factors were considered unlikely to have contributed to the power loss. Fuel vaporisation was also considered unlikely to have been present during the flight. While fuel vaporisation can produce significant variation in fuel flow rates, and consequently the fuel component of the air-fuel ratio, the effect on fuel flow would likely be erratic and intermittent and not a consistent reduction as captured by the EDM-900 data.

Reasons for probable incorrect mixture control settings

The pilot reported perceiving time pressure to depart and this, coupled with their relative inexperience flying the Cessna 210, may have contributed to the pilot overlooking the mixture control setting prior to take-off. Although the pilot recalled setting the mixture control to full rich, the accuracy of a person’s memory about a sequence of events involving a serious incident or accident can be affected by a range of factors including workload, the complexity of the events, the pace at which the events occur, and interference from other sequences of events that may occur before and after the sequence of interest (Davis 2001).

Pilot actions

Initial response

The pilot recalled looking at the aircraft’s fuel flow gauge on the application of full throttle and noted no anomalies. However, the gauge would likely have been indicating the significantly reduced fuel flow. Had the pilot identified this indication at this early stage, or during the take-off, the take-off could have been aborted while the aircraft was still on the runway.

Once airborne and having determined that they could not land on the remaining runway or cleared area beyond the runway, the pilot’s initial actions to fly the aircraft at a safe speed and continue to gain altitude were appropriate and consistent with the ATSB’s previous guidance on the management of a partial power loss.

The aircraft was 10 kg over the aircraft’s maximum take-off weight and this likely reduced the aircraft’s climb performance. Nevertheless, recorded data indicates the aircraft was able to achieve a rate of climb of about 500 ft per minute at about 89 kt.

Having levelled off, the aircraft spent about 25 seconds at 500 ft which would have provided sufficient time to conduct initial engine troubleshooting actions such as those placarded on the instrument panel (which would prompt a mixture adjustment and likely resolved the problem). The recorded fuel flow fluctuations exceeded the amount for which the actions were required. However, the pilot reported being ‘startled’ by the situation and was focused ‘on not stalling the aircraft’, although there was a significant margin above the stall speed.

An unexpected event, such as a partial power loss during take-off, can result in the cognitive-emotional response commonly defined as ‘surprise’. Surprise can be described as a combination of physiological, cognitive, and behavioural responses which can include an inability to comprehend and analyse, a failure to recall appropriate operating practices, freezing, and a loss of situation awareness (Rivera et al. 2014). It is likely that the pilot was impacted by the effects of surprise following the partial power loss and this, compounded by their relative inexperience flying the Cessna 210, resulted in the omission of the engine trouble checks.

Return to the airport

The pilot recalled being unfamiliar with emergency landing options beyond the airport and elected to conduct a left turn to return to the airport to land on runway 28. The aircraft passed diagonally over the runway near the threshold for runway 28, at an altitude of about 250 ft, while descending. At that time, there was about 1,700 m of runway to the aircraft’s right.

Considering the ideal response from this point, it was likely possible to decrease power, extend flap, lower landing gear and establish a controlled descent, for example, with a rate of descent of no greater than 1,000 fpm. This would allow a descent from 250 ft to near ground level in about 15 seconds. In this time, without reducing speed, the aircraft would cover about 800 m distance, with sufficient runway left to flare, land, and stop. Reducing speed (while maintaining a safe buffer above the stall) would provide more time and distance to descend and align the aircraft with a suitable landing surface.

The pilot recalled diverging from the runway, and made a limited attempt to correct the lateral deviation, instead revising their landing plan for a cleared area beyond the airport boundary. From this point, a successful forced landing would be more likely with reduced speed. However, once it was apparent that a landing could be completed, the aircraft was not fully configured for a forced landing by lowering flap, resulting in the aircraft landing further along the selected landing location and at a higher touchdown speed. The lack of aircraft control inputs to realign with the runway and the misconfiguration of the aircraft for landing were likely a result of the continued effects of surprise.

Take-off safety brief

The pilot’s take-off safety brief did not include the landing options beyond the airport or the actions to take in the event of a partial power loss. The aircraft operator’s example brief also did not include these elements. Had the brief included these aspects, the pilot would have been better prepared to manage the situation and likely less affected by surprise.

Time-expired engine-driven fuel pump

A time expired fuel pump had been fitted to the aircraft in April 2022 for troubleshooting purposes and was likely still fitted to the aircraft at the time of the accident. While the pump functioned normally during post-accident testing, its internal components had wear consistent with the pumps time in service. Operation of components in excess of the stated overhaul periods increases their likelihood of failure, and therefore safe operation of the aircraft.

Occupant injuries

While the front seats were fitted with lap belts and shoulder straps, the rear seats were fitted with lap belts with no upper body restraints. The rear seats were not required by regulation in this instance.

The occupants in the front and rear seats received several upper body injuries between them. The liveable space in the aircraft was compromised by significant damage to the cockpit and cabin areas. This made it more likely that the aircraft occupants, particularly their upper bodies, would come into contact with the aircraft structure during the accident sequence even had upper torso restraints been fitted and used. However, upper torso restraints can significantly reduce the risk of injury, compared to lap belts only, by minimising the flailing of the upper body and the potential of impacts involving the head and upper body.

Weight and balance

Although the pilot weighed each passenger and their baggage prior to the flight and entered these weights onto the aircraft manifest, the pilot did not complete the weight and balance calculations for the flight as they perceived there to be time pressure to depart. The ATSB later calculated that the aircraft was 10 kg over the maximum take-off weight. While this would have had a slight effect on the aircraft’s performance, if weight and balance is not confirmed by finalising the calculations there is a risk of a more significant effect.

Findings

|

ATSB investigation report findings focus on safety factors (that is, events and conditions that increase risk). Safety factors include ‘contributing factors’ and ‘other factors that increased risk’ (that is, factors that did not meet the definition of a contributing factor for this occurrence but were still considered important to include in the report for the purpose of increasing awareness and enhancing safety). In addition ‘other findings’ may be included to provide important information about topics other than safety factors. These findings should not be read as apportioning blame or liability to any particular organisation or individual. |

From the evidence available, the following findings are made with respect to the partial engine power loss and collision with terrain involving Cessna 210L VH-FTM, near Groote Eylandt Airport, Northern Territory on 16 June 2023:

Contributing factors

- The pilot probably did not set the engine mixture control to full rich prior to commencing the take-off as required by the operator and manufacturer procedures. This resulted in an incorrect air-fuel ratio (too lean) which manifested as a partial power loss with unanticipated engine behaviour.

- Likely surprised by the partial power loss, the pilot did not attempt to troubleshoot the issue by checking the mixture control setting and did not effectively manage the aircraft’s flightpath during the attempted landing on runway 28.

Other factors that increased risk

- The pilot’s take-off safety brief (self-brief), and the aircraft operator’s documented example brief, did not contain the actions to be taken in the event of a partial power loss.

- The aircraft was likely being operated with a time-expired engine-driven fuel pump, increasing the likelihood of its failure.

- The aircraft did not have, and was not required to have, upper torso restraints fitted to the rear passenger seats, increasing the likelihood of serious injury in an accident.

- The pilot did not complete the weight and balance calculations for the flight as they perceived there to be time pressure to depart, and the aircraft was 10 kg over the maximum take-off weight.

Safety actions

| Whether or not the ATSB identifies safety issues in the course of an investigation, relevant organisations may proactively initiate safety action in order to reduce their safety risk. All of the directly involved parties are invited to provide submissions to this draft report. As part of that process, each organisation is asked to communicate what safety actions, if any, they have carried out to reduce the risk associated with this type of occurrences in the future. ATSB has so far been advised of the following proactive safety action in response to this occurrence. |

Safety action addressing time-lifed components

On 17 June 2023, CASA issued a safety alert to Katherine Aviation that required the organisation to conduct a fleet wide check of all time-lifed components that were either fitted or about to be fitted to the aircraft. The safety alert was issued following the identification of the time-expired engine-driven fuel pump fitted to VH-FTM. On 22 June 2023, Katherine Aviation completed the check and identified several further defects. In response, the organisation agreed to implement a maintenance incident reporting system and discontinue the cross hire of aircraft to reduce engineering workload.

Sources and submissions

Sources of information

The sources of information during the investigation included:

- pilot of the accident flight

- Katherine Aviation

- Civil Aviation Safety Authority

- United States National Transportation Safety Board

- Northern Territory Police Force

- Bureau of Meteorology

- maintenance organisation for VH-FTM

- Groote Eylandt Airport

- first responders

- McLarens Aviation, acting for the insurer

- security camera footage of the accident flight

- recorded data from aircraft’s EDM-900 unit.

References

Australian Transport Safety Bureau. (2013). Avoidable accidents no. 3: Managing partial power loss after take-off in single-engine aircraft (AR-2010-055). Canberra, Australia.

Davis, D., & Follette, W. C. (2000). Foibles of witness memory for traumatic/high profile events. J. Air L. & Com., 66, 1421.

Federal Aviation Administration. (2023). Pilot’s Handbook of Aeronautical Knowledge. U.S.

Rivera, J., Talone, A. B., Boesser, C. T., Jentsch, F., & Yeh, M. (2014). Startle and surprise on the flight deck: Similarities, differences, and prevalence. In Proceedings of the human factors and ergonomics society annual meeting (Vol. 58, No. 1, pp. 1047-1051). Sage CA: Los Angeles, CA: SAGE Publications.

Robson, D. (2014). Basic Aeronautical Knowledge including Human Factors (3rd ed). Brisbane, Qld, Australia: Aviation Theory Centre.

Schwaner, J. (2017). Sky Ranch engineering manual: Operation, failure, repair, piston aircraft engines (2nd ed). Aircraft Technical Book Company LLC.

Submissions

Under section 26 of the Transport Safety Investigation Act 2003, the ATSB may provide a draft report, on a confidential basis, to any person whom the ATSB considers appropriate. That section allows a person receiving a draft report to make submissions to the ATSB about the draft report.

A draft of this report was provided to the following directly involved parties, and parties with an involvement:

- pilot of the accident flight

- Katherine Aviation

- Civil Aviation Safety Authority

- United States National Transportation Safety Board

- McLarens Aviation, acting for the insurer

Submissions were received from McLarens Aviation.

The submissions were reviewed and, where considered appropriate, the text of the report was amended accordingly.

Purpose of safety investigationsThe objective of a safety investigation is to enhance transport safety. This is done through:

It is not a function of the ATSB to apportion blame or provide a means for determining liability. At the same time, an investigation report must include factual material of sufficient weight to support the analysis and findings. At all times the ATSB endeavours to balance the use of material that could imply adverse comment with the need to properly explain what happened, and why, in a fair and unbiased manner. The ATSB does not investigate for the purpose of taking administrative, regulatory or criminal action. TerminologyAn explanation of terminology used in ATSB investigation reports is available here. This includes terms such as occurrence, contributing factor, other factor that increased risk, and safety issue. Publishing informationReleased in accordance with section 25 of the Transport Safety Investigation Act 2003 Published by: Australian Transport Safety Bureau © Commonwealth of Australia 2024

Ownership of intellectual property rights in this publication Unless otherwise noted, copyright (and any other intellectual property rights, if any) in this report publication is owned by the Commonwealth of Australia. Creative Commons licence With the exception of the Coat of Arms, ATSB logo, and photos and graphics in which a third party holds copyright, this publication is licensed under a Creative Commons Attribution 3.0 Australia licence. Creative Commons Attribution 3.0 Australia Licence is a standard form licence agreement that allows you to copy, distribute, transmit and adapt this publication provided that you attribute the work. The ATSB’s preference is that you attribute this publication (and any material sourced from it) using the following wording: Source: Australian Transport Safety Bureau Copyright in material obtained from other agencies, private individuals or organisations, belongs to those agencies, individuals or organisations. Where you wish to use their material, you will need to contact them directly. |

[1] The flight was operated under Civil Aviation Safety Regulations Part 135 (Air transport operations - smaller aeroplanes).

[2] The fuel flow gauge was located on the lower centre of VH-FTM’s instrument panel and depicted fuel flow in lb/h.

[3] The recorded data was rounded to the nearest 100 ft, and showed no change in altitude for 15 seconds.

[4] The air-fuel ratio refers to the ratio of the weight of air to that of the fuel when the mixture is delivered to the engine cylinders. This ratio is crucial for determining the efficiency of combustion and, consequently, the power output of the engine.

[5] The temperature of the exhaust gases at the exhaust manifold.

[6] The stoichiometric ratio, or chemically correct mixture (CCM), is the chemically perfect air-fuel ratio that would theoretically result in the consumption of all oxygen and fuel during combustion.

[7] The manipulation of the cockpit mixture control resulting in the reduction of the fuel component of the air-fuel ratio provided to the combustion cylinders.

[8] Full rich only applies at lower-elevation aerodromes (below 3,000 ft), which includes Groote Eylandt Airport.

[9] Fuel vapour accumulation can result in vapour lock, which prevents the supply of fuel due to bubble(s) of vapour in the fuel lines.

[10] VH-FTM carried passenger and cargo weighing scales that had been recently calibrated.

[11] Baggage and equipment were weighed by the ATSB at the accident site.

[12] A self-brief undertaken by the pilot of a single-pilot operation prior commencing take‑off.

[13] A movable surface on the trailing edge of a wing that, when extended, increases both lift and drag and reduces the stall speed. Flaps are extended to improve take-off and landing performance. The Civil Aviation Safety Authority publication Flight Instructor Manual (Aeroplane) states that when landing without flaps ‘the descent path may be flatter, making judgment more difficult…Due to the absence of drag there may be a longer float period’.

Source: ATSB

Source: ATSB Source: ATSB

Source: ATSB