Executive summary

What happened

On the morning of 19 September 2022, the pilot of an Air Tractor AT-502B aircraft, registered VH‑KDR and operated by Smart Air Services, was completing aerial spray operations near Chinchilla, Queensland. After becoming concerned at not being able to contact the pilot, the spray company alerted nearby farmers to assist, and the aircraft was subsequently found in the paddock being sprayed. The pilot was fatally injured and the aircraft was destroyed.

What the ATSB found

The ATSB found that, while the pilot was conducting a spray run parallel to the paddock fence line at about 8 ft above the ground, a large bird (Australian bustard) struck the right Perspex windshield. During the impact, the right windshield was shattered, with the bird carcass found inside the aircraft.

The site examination showed that, after the birdstrike, the aircraft continued flying for a further 310 m, or about 5 seconds. However, without any flight data, it could not be exactly determined what occurred during this time. Despite this, the ATSB established that, it was likely that the birdstrike affected the pilot’s ability to control the aircraft, resulting in a collision with terrain.

Safety message

Birdstrikes are relatively common with over 1,300 occurrences reported to the ATSB in 2022. While these strikes typically result in nil-to-minor damage to an aircraft and nil-to-minor injuries to occupants, there have now been 2 confirmed fatal accidents in Australia. This accident highlights the ongoing hazards of birdstrikes to aircraft, particularly during low-level spraying operations.

Where applicable, there are published recommended practices available from the Australian Aviation Wildlife Hazard Group (2014) to manage risk of wildlife strikes for organisations that may be involved in a wildlife strike occurrence. Practices include considering the likelihood of a wildlife strike and proximity of known wildlife to aircraft manoeuvring areas and flight paths, as well as identifying wildlife characteristics such as their agility, speed, manoeuvrability, and their ability to avoid aircraft. Other considerations include the consequence of a strike, including the effects of the mass of the wildlife species, the velocity of the aircraft involved, the resultant impact force(s) and the damage that could result; and if adequate control of the aircraft can be maintained following a strike event. If a birdstrike does occur, available protections for a pilot include the wearing of flight helmets, 4‑point seatbelts, and the fitment of thicker aircraft windshields, where possible.

The investigation

| Decisions regarding the scope of an investigation are based on many factors, including the level of safety benefit likely to be obtained from an investigation and the associated resources required. For this occurrence, a limited-scope investigation was conducted in order to produce a short investigation report, and allow for greater industry awareness of findings that affect safety and potential learning opportunities. |

The occurrence

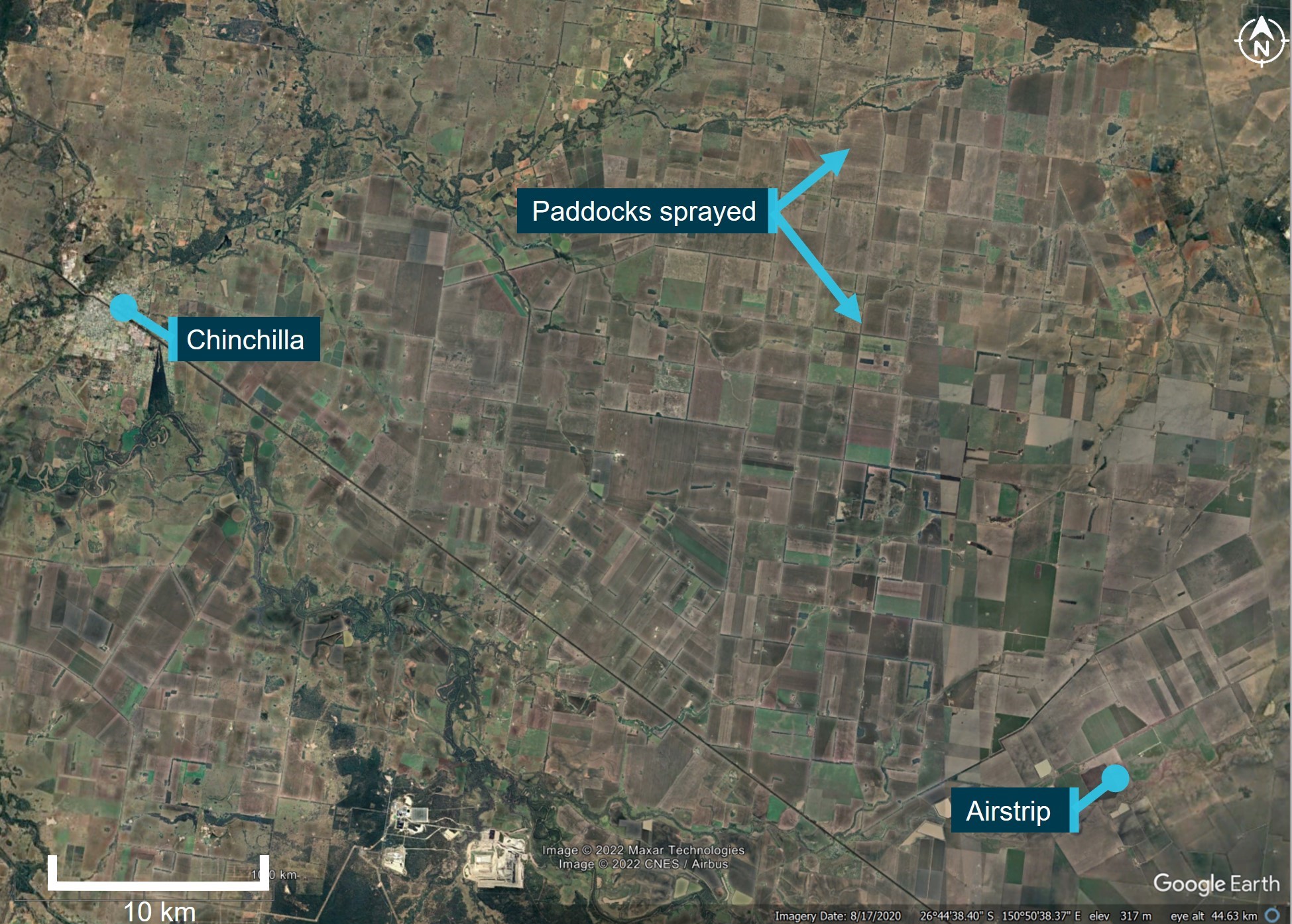

On the morning of 19 September 2022, the pilot of an Air Tractor AT-502B aircraft, registered VH‑KDR and operated by Smart Air Services, was conducting aerial spray operations on a property near Chinchilla, Queensland. The operations base for the day was at a private airstrip south-east of Chinchilla, where the aircraft was to be loaded with fungicide, pesticide, and fuel. The 2 farms to be sprayed were located several kilometres to the north of the airstrip (Figure 1).

Figure 1: Location of the airstrip and area of operations

Source: Google Earth, annotated by the ATSB

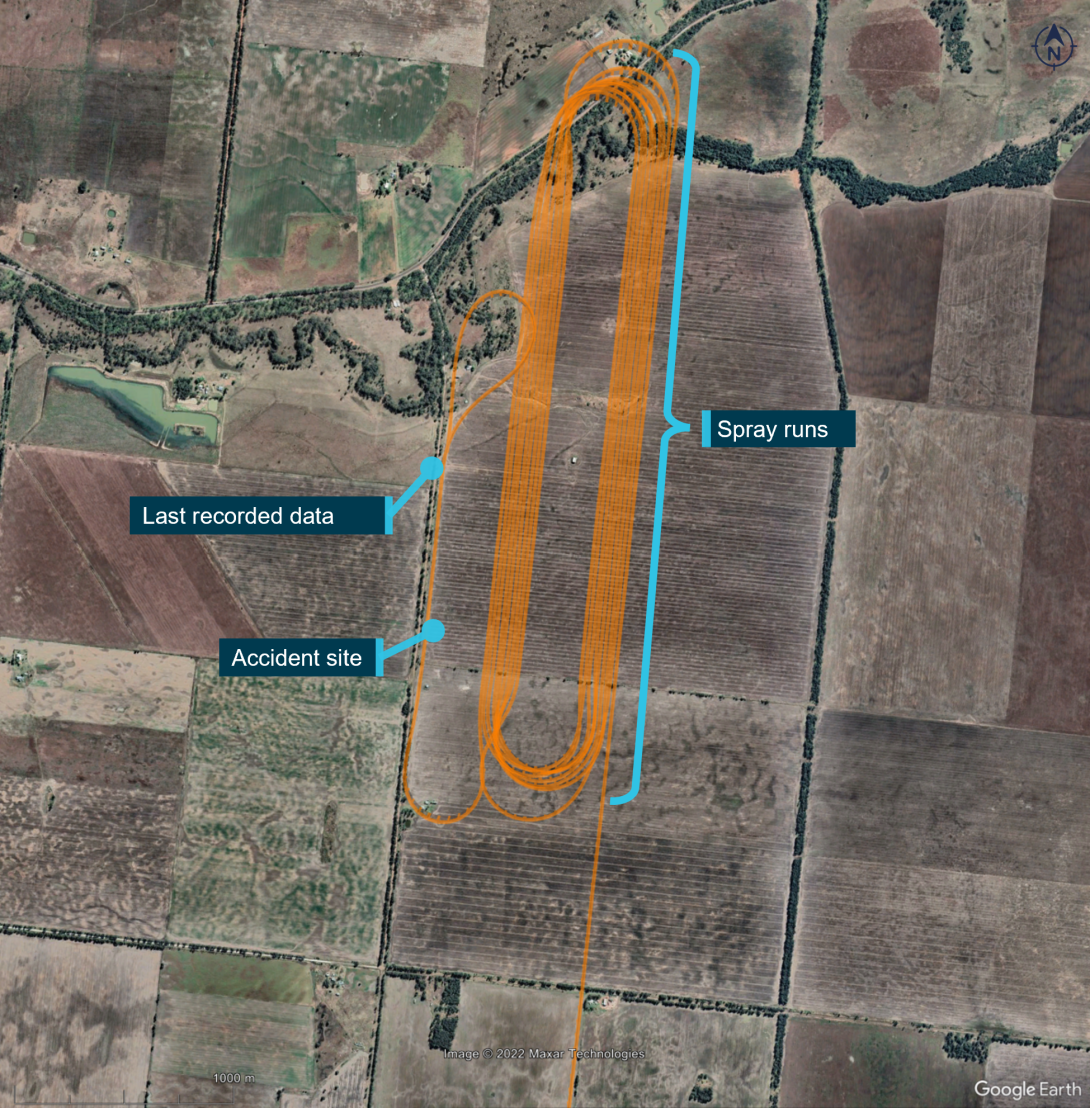

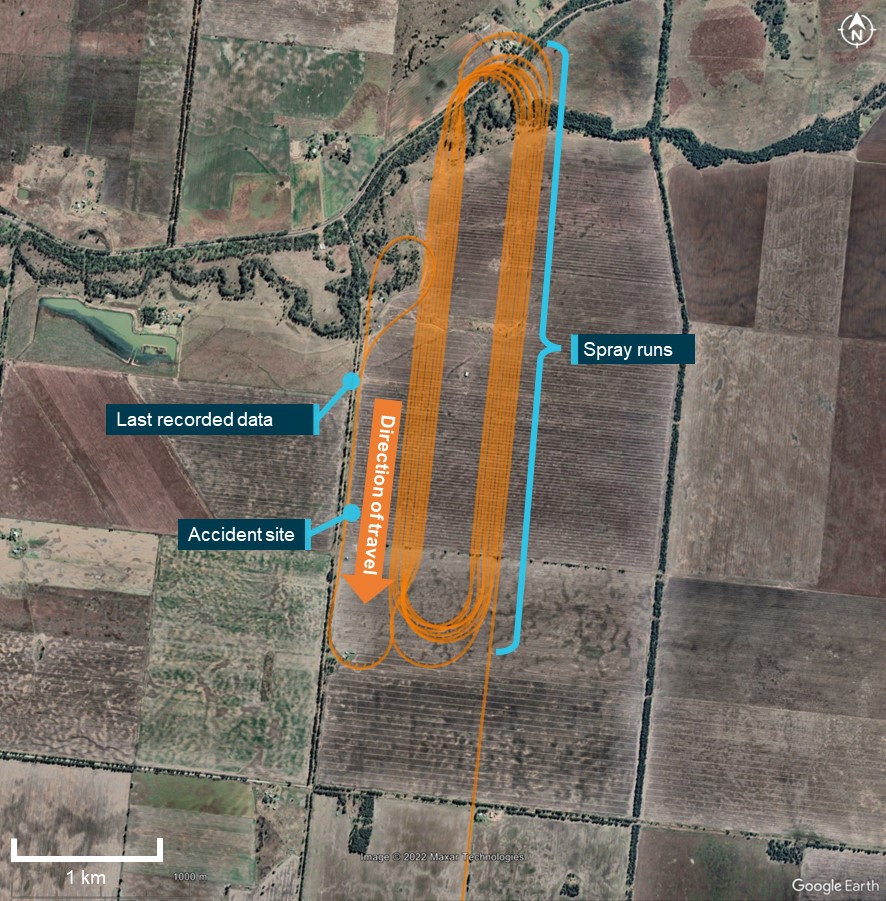

Numerous spray runs were completed on the paddocks during the morning between 0704 and 1012 local time, with the pilot returning to the airstrip on 4 occasions to reload the spray chemicals and to refuel the aircraft. Recorded GPS data from the aircraft’s Satloc[1] system identified that, at 1058, the pilot departed the airstrip to continue herbicide spraying on the northerly paddock. By 1125, the pilot had completed 17 spray runs within the paddock in a racetrack pattern (Figure 2).

At the conclusion of run 17, the aircraft was turned onto a northerly heading, flown parallel to the fence line, before being turned onto a reciprocal heading to spray this area (Figure 2). The final GPS data point recorded by the Satloc system was at 11:25:41, 3 seconds after the pilot had commenced the southerly fence line spray run.

After 1200, the loader at the airstrip attempted to phone the pilot to ask whether more fuel was required, however, no response was received. The loader was concerned at not being able to contact the pilot, and phoned the company operations manager, who then contacted nearby farmers to assist with locating the aircraft. At about 1215, a local farmer found the aircraft wreckage in the paddock where the pilot had been spraying. The pilot was fatally injured and the aircraft was destroyed.

Figure 2: Accident site and spray runs (orange)

Source: SatLoc data provided by the aircraft operator overlaid on Google Earth, annotated by the ATSB

Context

Pilot information

The pilot held a valid Class 1 Aviation Medical Certificate and a Commercial Pilot Licence (Aeroplane). The pilot also held aerial application and low-level ratings, as well as tailwheel and retractable undercarriage, manual propellor pitch control, and turbine engine endorsements.

The pilot had accumulated 3,738 hours of aeronautical experience, of which 2,681 hours was in turbine agricultural aircraft.

Aircraft information

General information

VH-KDR was an Air Tractor Incorporated 502B single-seat low-wing tailwheel aircraft manufactured in the United States in 1996. It had a total wingspan of 15.8 m and was powered by a Pratt & Whitney Canada PT6A‑34AG turboprop engine. It was first registered in Australia on 6 August 2004. It was issued with a Special Certificate of Airworthiness in therestricted category[2] on 10 August 2004. A maintenance release was issued on 9 September 2022.

Windshield information

The Air Tractor 502B windshield is constructed of 3 pieces being either glass or Perspex (Figure 3). The centre windshield is manufactured from glass. The thickness of the glass on VH‑KDR was 1/4-inch, which was the standard thickness when the aircraft was manufactured. The 2 side pieces were manufactured from Perspex.

Figure 3: Air Tractor AT-502B windshield

Source: Storm Aeronautics

The ATSB contacted Air Tractor regarding the availability of thicker side windshields and they advised that there had been no consideration for using thicker material. The manufacturer stated that the windshield design on the Air Tractor is standard for the agricultural aviation industry, and in previously reported birdstrikes where the bird had entered the aircraft through either side windscreen, the bird missed the pilot and hit the back wall. Further, they described difficulties in replacing the Perspex windshield with glass due to the curvature of the design, which would increase the likelihood of glare and would add weight.

In 2009, Air Tractor issued a service letter advising that thicker centre windshields were being installed in current production aircraft. The thicker windshields were 3/8-inch thick glass compared to the original 1/4-inch. The letter also advised that the thicker windshields could be installed in existing aircraft, though not mandatory. This letter was issued after operators had reported on birdstrikes that had resulted in the bird carcass entering the cockpit through the centre windshield (refer to section titled Related occurrences).

Meteorological information

Based on information recorded from a private weather station located in the paddock being sprayed, the air temperature around the time of the accident was 26.3 °C, and the average wind speed was about 9 kt from the west-south-west. The calculated crosswind component was about 8 kt.

Wreckage and impact information

The ATSB’s on-site examination found that the aircraft had impacted the ground, adjacent to the fence line. The aircraft’s orientation was consistent with the direction of travel. The left wing had initially impacted the ground, followed by the fuselage, in a near vertical attitude. The propeller and engine were buried in the soft earth, with the spread of wreckage contained to a small area. Ground scars and damage to the left wing indicated that the wing struck the ground at about 30° to the horizontal (Figure 4). The length of the ground scar from the point of impact to the fuselage was about 12.6 m.

Figure 4: Aircraft wreckage at the accident site

Source: ATSB

Examination of the wreckage identified that:

- Inspection of the propeller and engine indicated the engine was delivering power at the time of the impact.

- Fuel and chemical product residues were also found at the accident site.

- There was no post-impact fire.

- Due to the extent of damage to the cockpit in the accident sequence, it was not possible to determine the position of the engine controls prior to the impact. However, where possible, control continuity was established.

- It was very likely the aircraft was trimmed ‘nose-up,’[3] which was reported by the operator to be the configuration[4] typically used when conducting low-level aerial spraying.

- There were no pre-existing technical failures with the aircraft that would have contributed to the accident.

A large bird carcass was found in the cockpit and severed bird wings were located about 310 m north of the wreckage, in-line with the aircraft’s track along the fence line, which indicated the approximate location of the initial birdstrike (Figure 5). Bird feathers were found along flight path in between location of wings and aircraft wreckage. Biological residue from the bird was found outside the right cockpit window and among the pieces of Perspex from that window. Further biological residue was found on the left side of the cockpit behind the pilot’s seat, indicating the bird passed through the right cockpit window in an upward trajectory towards the left side. There was no evidence of the bird striking any other part of the aircraft.

Figure 5: Site map with key locations

Source: Google Earth, annotated by the ATSB

Recorded data

The SatLoc data’s final recorded point was about 800 m north of the wreckage, and 500 m from the location of the severed bird wings (Figure 2). Based on the aircraft's previously recorded ground speed and direction of travel, there were about 5 seconds between the birdstrike occurring and the impact with the ground. The ground speed of the aircraft was about 116 kt (200 km/h), which was a similar speed to other runs, and the height was about 8 ft above ground level,[5] which was a similar height to the previous runs.

Medical and pathological information

The post-mortem report indicated that the pilot did not have any pre-existing medical conditions nor consumed any substances likely to have contributed to the accident. The report indicated that the pilot sustained significant head injuries in the accident. It was also noted that feathers were found on the pilot’s neck and chest, but it could not be determined whether they were the direct result of the birdstrike or from the accident sequence. Therefore, it was unknown whether these injuries sustained were due to the birdstrike or collision with terrain, or both.

Bird identification

Recovered biological specimens of the bird, including wing feathers and residue from the carcass, were analysed by the Australian Centre for Wildlife Genomics at the Australian Museum. The specimens were identified as a Ardeotis australis, commonly known as an Australian bustard (or bush/wild/plains turkey) (Australian Museum 2020).

The Australian bustard is a large bird, 80 to 120 cm in length and a wingspan of up to 230 cm (Ziembicki 2010). An average adult bird weighs 4.5 kg, however, males can weigh up to 8 kg (Bird Fact 2022). Australian bustards are capable of flying but are mostly ground dwelling. They are Australia’s heaviest flying bird. The bird carcass recovered had a wingspan of at least 120 cm and a length of 100 cm; the gender was unknown.

Survival aspects

First responders to the accident site identified that the pilot had been fastened into the seat by the aircraft’s 4‑point restraint harness. A flight helmet was found within the wreckage, which the pilot had been wearing, but it had become dislodged and sustained damage to the right-side shell and left‑side earpiece during the accident sequence. The left-side helmet strap had separated from the earpiece. Yellow paint transfer from the rear of the cockpit was found on the back of the helmet. Bird biological residue was found on the inner surface of the helmet visor.

Severe compression of the forward fuselage and cockpit region had occurred as a result ground impact forces. The accident was not considered survivable.

Related occurrences

Birdstrikes are a recognised hazard in aviation and there are mitigators in place around airports, however, there are challenges when operating outside of these areas. A review of Australian and international data and investigation reports found the following occurrences involving birdstrikes during aerial spraying operations.

Australian data

A review of the ATSB occurrence database from 2000 to 2022 found that 30 birdstrike occurrences were reported during aerial spraying operations. Of those, one resulted in minor injury, 20 resulted in minor damage, and one resulted in substantial damage. For example:

- On 4 February 2000, the pilot of an Air Tractor 502B was conducting aerial spraying operations 15 km west of Moree, New South Wales. As the aircraft approached the start of a spray run at approximately 50 ft above ground level, a large bird struck the front windshield. The pilot sustained minor injuries and the aircraft sustained minor damage.

- On 9 November 2011, an Air Tractor 802A struck an Australian bustard while conducting aerial spraying operations, 37 km south-east of Emerald Airport, Queensland. The impact damaged the wing, resulting in a loss of control and the aircraft sustained substantial damage. The pilot was uninjured.

In 2022, there were 2 fatal accidents involving birdstrikes, including this accident. The other accident was a private helicopter flight, investigated as AO-2022-034. This was the only fatal birdstrike confirmed in Australia.

United States data

A review of the United States Federal Aviation Administration wildlife strike database identified 2 birdstrikes resulting in damage to the windshield while conducting aerial spraying operations:

- On 15 April 2000, the pilot of an Air Tractor 502B reported that a red-tailed hawk struck and damaged the windshield during a spray run near Prescott, Washington, resulting in minor injuries.

- On 9 June 2017, the pilot of an Air Tractor 502B reported a birdstrike occurring while conducting spraying operations about 10 miles west of Salt Lake City Airport, Utah. The birdstrike damaged the right front window, which resulted in the door opening. The pilot was uninjured and conducted a precautionary landing. The bird species was unknown.

In addition, Air Tractor reported another 3 instances involving birdstrikes resulting in minor windshield damage and nil injuries:

- On 30 October 2015, an Air Tractor AT-402B struck a bird during mosquito control activity.

- On 24 August 2020, while returning from a drop during firebombing operations, the windshield of an Air Tractor AT-802A broke due to a birdstrike.

- On 24 October 2021, an ibis entered the cockpit through the windshield of an Air Tractor AT‑802.

South African data

On 11 September 2008, the pilot of an Air Tractor 502B was conducting aerial spraying operations on a farm in the Caledon region of South Africa. During a spray run, a witness on the ground, who was approximately 700 m from the aircraft heard an aircraft noise and immediately after, an explosion. The aircraft wreckage was located in a field in an inverted position. The pilot was fatally injured.

Bird remains and feathers were identified inside the aircraft cockpit. A piece of glass windshield was also found within the cockpit that was covered in bird remains. The carcass of a blue crane was found near the wreckage. The investigation was unable to determine if the pilot was incapacitated or fatally injured as a result of the collision with the bird before the impact with the ground.

As a result of the investigation, the South African Civil Aviation Authority (investigation CA 18/2/3/8548) made the following recommendation:

Request the Air Tractor manufacturer to investigate the possibility of replacing the existing windshield with a thicker, stronger windshield to be used by clients operating these aircraft in areas of high bird activity.

The following year, Air Tractor published a service letter with details of a new, thicker windshield available to be fitted (refer to section titled Windshield information).

Safety analysis

Birdstrike and resulting collision with terrain

The location and impact point of the aircraft wreckage was consistent with the previously recorded flight path. Further, the presence of the Australian bustard carcass inside the aircraft wreckage, and the identification of the bird’s wings around 310 m north of the wreckage, indicated that the aircraft had experienced a birdstrike while flying the southbound spraying track at about 8 ft above ground level.

Considering the recorded ground speed of the aircraft on the 17 previous spray runs and up to the last recorded data point, it was likely that the aircraft struck the bird while flying at about 116 kt (200 km/h). This resulted in a collision with sufficient energy to break the right Perspex windshield as evidenced by the biological residue found on the aircraft and broken windshield pieces.

Given the expected track and speed of the aircraft, and the location of the bird wings to the wreckage, the aircraft sustained flight for about 5 seconds following the birdstrike. As the aircraft was operating around 8 ft above ground level, and the wingspan (total of 15.8 m) was longer than this height, it was likely the aircraft entered a short climb to result in a near vertical attitude at impact, indicative of a loss of control. There was also significant damage to the pilot’s helmet as well as a small amount of bird biological residue found in the visor. However, in that time, the ATSB could not determine exactly what occurred as a result of the bird entering the aircraft as no flight data was recorded nor was the extent of the pilot’s injuries from the birdstrike known. That is, whether the pilot sustained a level of incapacitation due to a direct strike from the bird, or whether they experienced a level of startle or distraction following the event.

Therefore, with no other reasonable explanation and having excluded a pre-existing medical condition, it was likely that the birdstrike affected the pilot’s ability to control the aircraft when operating at low-level, resulting in a loss of control and collision with terrain.

Findings

|

ATSB investigation report findings focus on safety factors (that is, events and conditions that increase risk). Safety factors include ‘contributing factors’ and ‘other factors that increased risk’ (that is, factors that did not meet the definition of a contributing factor for this occurrence but were still considered important to include in the report for the purpose of increasing awareness and enhancing safety). In addition ‘other findings’ may be included to provide important information about topics other than safety factors. These findings should not be read as apportioning blame or liability to any particular organisation or individual. |

From the evidence available, the following findings are made with respect to the birdstrike and collision with terrain involving Air Tractor 502B, VH-KDR, on 19 September 2022.

Contributing factor

- During aerial spraying operations at low-level, a large bird (Australian bustard) struck the right windshield of the aircraft and entered the cockpit. This likely affected the pilot’s ability to control the aircraft, resulting in a collision with terrain.

Sources and submissions

Sources of information

Sources of information during the investigation were gathered from:

- Smart Air Services Pty Ltd

- the aircraft loader

- Air Tractor Incorporated

- Pratt & Whitney Canada

- Civil Aviation Safety Authority

- maintenance organisation for VH-KDR

- Queensland Police Service.

References

Australian Museum (2020) Australian Bustard. Retrieved from https://australian.museum/learn/animals/birds/australian-bustard/

Bird Fact (2022) Australian Bustard - Ardeotis australis. Retrieved from https://birdfact.com/birds/australian-bustard

Ziembicki, M (2010) Australian Bustard. CSIRO Publishing: Collingwood.

Submissions

Under section 26 of the Transport Safety Investigation Act 2003, the ATSB may provide a draft report, on a confidential basis, to any person whom the ATSB considers appropriate. That section allows a person receiving a draft report to make submissions to the ATSB about the draft report.

A draft of this report was provided to the following directly involved parties:

- Smart Air Services Pty Ltd

- the aircraft loader

- Air Tractor Incorporated

- Pratt & Whitney Canada

- Civil Aviation Safety Authority

- Transportation Safety Board of Canada

- United States National Transportation Safety Board.

Submissions were received from Air Tractor Incorporated. The submission was reviewed and, where considered appropriate, the text of the report was amended accordingly.

Purpose of safety investigationsThe objective of a safety investigation is to enhance transport safety. This is done through:

It is not a function of the ATSB to apportion blame or provide a means for determining liability. At the same time, an investigation report must include factual material of sufficient weight to support the analysis and findings. At all times the ATSB endeavours to balance the use of material that could imply adverse comment with the need to properly explain what happened, and why, in a fair and unbiased manner. The ATSB does not investigate for the purpose of taking administrative, regulatory or criminal action. TerminologyAn explanation of terminology used in ATSB investigation reports is available here. This includes terms such as occurrence, contributing factor, other factor that increased risk, and safety issue. Publishing informationReleased in accordance with section 25 of the Transport Safety Investigation Act 2003 Published by: Australian Transport Safety Bureau © Commonwealth of Australia 2023

Ownership of intellectual property rights in this publication Unless otherwise noted, copyright (and any other intellectual property rights, if any) in this report publication is owned by the Commonwealth of Australia. Creative Commons licence With the exception of the Coat of Arms, ATSB logo, and photos and graphics in which a third party holds copyright, this publication is licensed under a Creative Commons Attribution 3.0 Australia licence. Creative Commons Attribution 3.0 Australia Licence is a standard form licence agreement that allows you to copy, distribute, transmit and adapt this publication provided that you attribute the work. The ATSB’s preference is that you attribute this publication (and any material sourced from it) using the following wording: Source: Australian Transport Safety Bureau Copyright in material obtained from other agencies, private individuals or organisations, belongs to those agencies, individuals or organisations. Where you wish to use their material, you will need to contact them directly. |

[1] Satloc: an aerial guidance system that provides the pilot with guidance commands to fly accurate spray patterns.

[2] Restricted category aircraft are limited to operate and carry personnel only for specified purpose/s.

[3] The elevator trim control lever was found to be in the ‘nose-up’ position. However, the left elevator trim tab was found to be in the ‘up’ position, which would be consistent with the control lever in the ‘nose-down’ position. This discrepancy likely resulted from compression of the fuselage due to the impact with terrain. This was based on the rod connecting the controls to the trim tab likely sliding towards the rear of the aircraft while the fuselage compressed, moving the trim tab ‘up’ or in the ‘nose-down’. Therefore, it was likely that the aircraft was trimmed nose-up prior to the accident.

[4] If forward pressure was removed from the yoke, the aircraft would climb for safety reasons.

[5] The data was adjusted based on the location of the SatLoc antenna and the spray broom as there was approximately 8 ft between these points.