What happened

On 31 August 2022, an Ayres Corporation S2R-T15, registered VH-IWI, was conducting aerial application operations. Around 100 m into a take-off roll, the pilot heard a bang as the left wing hit the ground and the aircraft performed a ground loop. No injuries were sustained.

Inspection revealed that the left main landing gear shock assembly had failed, with the left main landing gear folding outwards and contacting the bottom of the wing.

What the ATSB found

The ATSB examination identified that the lower tube of the left shock strut assembly failed at a fatigue crack, which led to the collapse of the left main landing gear and the aircraft wing to strike the ground. It is very likely that this lower tube was a part that Thrush Aircraft had instructed owner/operators to replace or modify in 1994 in accordance with a service bulletin. The reason the part was not replaced or modified was not identified.

Safety message

Manufacturers issue service bulletins to inform owners and operators about critical and useful information on aircraft safety, maintenance, or product improvement. The ATSB strongly encourages compliance with service bulletins pertaining to aircraft safety.

Additionally, on acquisition of an aircraft, it is important to review maintenance documentation to determine whether all the appropriate manufacturer issued instructions have been addressed.

The investigation

The occurrence

Three application flights were scheduled for the day, and after performing the daily aircraft inspection, the pilot commenced the first flight at around 0800 local time. Once the first flight was complete, the pilot obtained fuel and chemical, and taxied back to the airstrip to commence the second flight. The aircraft was around 100 m into the take-off roll when the left wing struck the ground, resulting in the pilot’s view being obstructed with chemical, and the aircraft started to rotate. In an attempt to stop the aircraft, the pilot applied reverse thrust. After completing a ground loop, the aircraft came to rest near the left edge of the runway. No injuries were sustained.

Initial inspection revealed that the left main landing gear shock assembly had failed, with the left main landing gear folding outwards and contacting the bottom of the wing.

Context

Operational and maintenance history

VH-IWI was manufactured by the Ayres Corporation in 1980 and first registered in Australia on the 24 December that year. The aircraft was powered by a Pratt & Whitney PT6A -15AG engine. It had accumulated 14,474.5 hours total time in service. The last maintenance took place 2 days prior to the occurrence and the right landing gear was replaced in 2012.

The Ayres Corporation[1] had issued 2 service bulletins associated with the main landing gear shock strut assembly.[2] The first, SB-AG-31,[3] was issued in 1992 in response to failures that occurred in the upper tube. This service bulletin described a modification to strengthen the upper tube, adding 4 rosette welds to the existing 2 rosette welds.[4] An entry in the aircraft maintenance logbook indicated that shock struts were welded to comply with SB-AG-31.

The second service bulletin, SB-AG-36,[5] was issued in 1994 in response to failures that occurred in the lower tube and included strengthening the lower tube. SB-AG-36 described 5 methods to comply with the bulletin:

- (1) replace shock assembly with P/N 50116-29 (new)

- (2) replace shock assembly with P/N 50116-28F1 (re-worked)

- (3) replace lower tube P/N 50116-12 with P/N 50116-12F (modified)

- (4) replace lower tube P/N 50116-12 with P/N 50116-30 (new design)

- (5) modify old lower tube P/N 50116-12

Option (5) described the removal of a plug from the top of the tube, removal of a 0.12” (3.0 mm) thick and 1 3/8” (34.9 mm) long reinforcing tube, insertion and welding (including rosette welds) of a 0.312” (7.9 mm) thick and 4.25” (108.0 mm) long reinforcing tube P/N 50116-100, and attachment of a plug by welding. No logbook record indicating compliance with SB-AG-36 was found. The current maintainer stated they were performing maintenance under the assumption that all previous maintenance had been performed according to the manufacturer’s instructions. The reason the lower tube was not replaced or modified when the service bulletin was issued was not identified.

The operator of VH-IWI acquired the aircraft in 2018. The maintainer commenced maintaining the aircraft in the 12 months leading up to the occurrence. They were not the maintainer of the aircraft when either SB-AG-31 or SB-AG-36 were issued.

ATSB technical examination

Examination of the damaged main landing gear shock strut assembly was conducted at the ATSB’s technical facilities. The overall condition of the assembly was aged, and the rubber shock biscuits were cracked (Figure 1).

Figure 1: Left main landing gear shock strut assembly

Schematic and photo showing the main landing gear shock struct assembly with components labelled. The assembly was dirty and the shock biscuit exhibited cracks.

Source: Thrush Aircraft (schematic), ATSB (photo and annotations)

The grease between the upper and lower tube was discoloured; however, there was fresh blue grease around the lubricator and within the lower tube near the point of fracture. A substantial amount of new grease appeared to have migrated out of the lower tube during the occurrence.

The left shock strut fractured at the hole where the lower steel tube attached to the slider plate

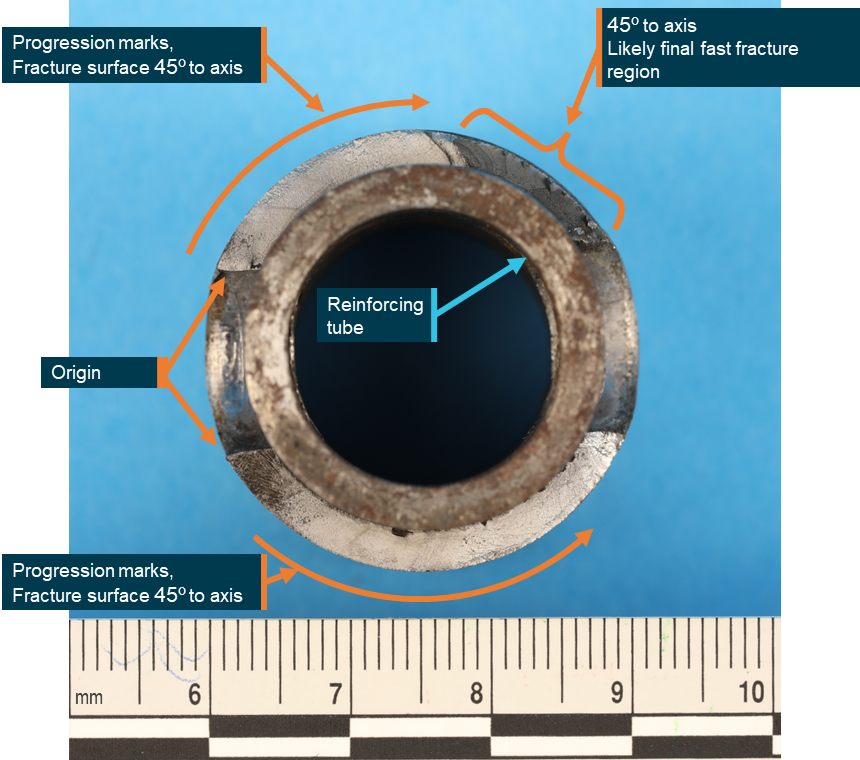

(Figure 1). This allowed the bottom portion of the lower tube to separate from the remaining shock assembly. The fracture was consistent with fatigue cracking, followed by unstable crack growth and ductile overstress (Figure 2).

Figure 2: Fractured lower tube exhibiting characteristics of fatigue fracture followed by overstress

Fracture surface exhibiting characteristic of fatigue cracking followed by overstress.

Source: ATSB

The construction of the fractured lower tube consisted of a steel tube, around 3 mm thick and 400 mm long, reinforced inside with a smaller diameter section of tube, around 3mm thick and 35 mm long, over the region of the through-hole. The reinforcing tube was welded to the lower tube at the top end. There was no end cap on the lower tube, which was present on a more recently-manufactured lower tube. There were no rosette welds connecting the lower tube and the reinforcing tube. The upper tube of the left shock strut assembly was also examined; there were 6 rosette welds present on the upper tube.

There was a handwritten marking on the side of the lower tube (Figure 3) which was identified as the characters ‘50116T012 25[?]’, with an indistinct character at the end.

Figure 3: Marker writing on the lower tube

Writing on the lower tube written in black marker. The characters are 50116T012 25[?].

Source: ATSB

Advice from Thrush Aircraft

When asked about the writing on lower tube Thrush Aircraft informed the ATSB that first 5 characters represented a drawing number,[6] the 3 numbers to the right of the ‘T’ identified the component on that drawing. The drawing number, together with the component identifier, was considered the ‘part number’ and these numbers, 50116-012, were consistent with the designation of the pre-1994 lower tube design. Thrush Aircraft suggested the final 3 digits might be an employee or serial number.

A representative from Thrush Aircraft concluded that, based on the available evidence, the failure was consistent with the failures that prompted SB-AG-36.

Safety analysis

The dimensions of the reinforcing tube[7] and the writing on the side of the part were most consistent with the original part, noting that there was no plug. This part was to be replaced or modified to comply with SB-AG-36. It was not possible to determine the exact age of the lower tube. It is very likely that this lower tube was manufactured prior to 1994 and would need to have been replaced or modified to comply with the service bulletin.

The construction of the upper tube was consistent with SB-AG-31, which was issued 2 years before SB-AG-36.

Findings

|

These findings should not be read as apportioning blame or liability to any particular organisation or individual. |

From the evidence available, the following findings are made with respect to the ground strike involving Ayres Corporation S2R-T15, registration VH-IWI at Trangie, New South Wales on 31 August 2022.

Contributing factors

- A fatigue crack initiated in the lower steel tube of the left shock assembly, located at the hole where the lower tube connected to the slider plate. The fatigue crack grew until there was a final overstress failure of the lower tube during the take-off roll.

- For reasons not identified, it was highly likely that the lower tube of the left landing gear shock assembly was not replaced or modified to comply with SB-AG-36, which was issued to prevent similar failures.

Sources and submissions

Sources of information

The sources of information during the investigation included the:

- pilot of the occurrence flight

- Civil Aviation Safety Authority

- Thrush Aircraft

- maintenance organisation for VH-IWI

References

Main Landing Gear Shock Strut Inspection and Repair, Service Bulletin: SB-AG-31, Ayres Corporation, 3 November 1992. [Online]. Available: https://thrushaircraft.com/support/technical-publications/Service%20Bulletins/sb-ag-31%20MAIN%20LANDING%20GEAR%20SHOCK%20STRUT%20INSPECTION%20AND%20REPAIR.pdf [Accessed: 18 November 2022].

Main Landing Gear Shock Strut Modification, Service Bulletin: SB-AG-36, Ayres Corporation, 25 March 1994. [Online]. Available: https://thrushaircraft.com/support/technical-publications/Service%20Bulletins/sb-ag-36%20MAIN%20LANDING%20GEAR%20SHOCK%20STRUT%20MODIFICATION.pdf. [Accessed: 18 November 2022].

Maintenance Manual Model S2R-T15 Model S2R-T34, Serial Numbers T15-020 & Subsequent Numbers T34-091 & Subsequent Numbers, Thrush Aircraft Inc., 25 October 1990. Revised: 24 July 1991.

Submissions

Under section 26 of the Transport Safety Investigation Act 2003, the ATSB may provide a draft report, on a confidential basis, to any person whom the ATSB considers appropriate. That section allows a person receiving a draft report to make submissions to the ATSB about the draft report.

A draft of this report was provided to the following directly involved parties:

- pilot of the occurrence flight

- maintenance organisation for VH-IWI

- Civil Aviation Safety Authority

- Thrush Aircraft

Purpose of safety investigationsThe objective of a safety investigation is to enhance transport safety. This is done through:

It is not a function of the ATSB to apportion blame or provide a means for determining liability. At the same time, an investigation report must include factual material of sufficient weight to support the analysis and findings. At all times the ATSB endeavours to balance the use of material that could imply adverse comment with the need to properly explain what happened, and why, in a fair and unbiased manner. The ATSB does not investigate for the purpose of taking administrative, regulatory or criminal action. TerminologyAn explanation of terminology used in ATSB investigation reports is available here. This includes terms such as occurrence, contributing factor, other factor that increased risk, and safety issue. Publishing informationReleased in accordance with section 25 of the Transport Safety Investigation Act 2003 Published by: Australian Transport Safety Bureau © Commonwealth of Australia 2023

Ownership of intellectual property rights in this publication Unless otherwise noted, copyright (and any other intellectual property rights, if any) in this report publication is owned by the Commonwealth of Australia. Creative Commons licence With the exception of the Coat of Arms, ATSB logo, and photos and graphics in which a third party holds copyright, this publication is licensed under a Creative Commons Attribution 3.0 Australia licence. Creative Commons Attribution 3.0 Australia Licence is a standard form licence agreement that allows you to copy, distribute, transmit and adapt this publication provided that you attribute the work. The ATSB’s preference is that you attribute this publication (and any material sourced from it) using the following wording: Source: Australian Transport Safety Bureau Copyright in material obtained from other agencies, private individuals or organisations, belongs to those agencies, individuals or organisations. Where you wish to use their material, you will need to contact them directly. |

[1] In 2003, Ayres Corporation’s assets were purchased by Thrush Aircraft, the current producer of the aircraft.

[2] The main landing gear shock strut reduces the landing loads transmitted from the landing gear to the fuselage.

[3] Main Landing Gear Shock Strut Inspection and Repair, Service Bulletin: SB-AG-31, Ayres Corporation, 3 November 1992. [Online]. Available: https://thrushaircraft.com/support/technical-publications/Service%20Bulletins/sb-ag-31%20MAIN%20LANDING%20GEAR%20SHOCK%20STRUT%20INSPECTION%20AND%20REPAIR.pdf. [Accessed: 18 November 2022].

[4] A rosette weld, also known as a plug weld, is a process that fuses two metals together by making a weld inside small circular holes.

[5] Main Landing Gear Shock Strut Modification, Service Bulletin: SB-AG-36, Ayres Corporation, 25 March 1994. [Online]. Available: https://thrushaircraft.com/support/technical-publications/Service%20Bulletins/sb-ag-36%20MAIN%20LANDING%20GEAR%20SHOCK%20STRUT%20MODIFICATION.pdf. [Accessed: 18 November 2022].

[6] The drawing number together with the component identifier was considered the ‘part number’.

[7] The reinforcing tube was around 3mm thick and 35 mm long, while the pre-1994 reinforming was described as 0.12” (3.0 mm) thick and 1 3/8” (34.9 mm) long.