What happened

On 18 August 2022, a Cessna 310R, registered VH-JQK, was being operated by Aircraft Australia on a training flight from Redcliffe, Queensland.

After completing asymmetric training sequences to the east of Brisbane, the crew flew towards the Sunshine Coast Airport to conduct instrument training. While establishing a practice instrument approach, the engines started surging alternatively. The instructor declared a MAYDAY. On descent the crew switched from the auxiliary to the main fuel tanks, which rectified the engine issues, and then completed an uneventful landing.

What the ATSB found

The crew did not completely follow the operator’s pre-flight and in-flight fuel management procedures, which required pilots to:

- cross-check fuel quantity prior to a flight with a visual confirmation or fuel log

- monitor fuel levels and tank selection every 30 minutes during a flight.

Further, the instructor was unaware of the fuel system configuration of the Cessna 310R being operated, believing the aircraft was fitted with larger auxiliary tanks than was the case. The operator had inconsistent and incomplete documentation for the aircraft, and the fuel selector plaques contained contradictory information about the size of the auxiliary tanks.

What has been done as a result

Aircraft Australia implemented a new fuel log specific for the Cessna 310R. Additionally, an internal memo outlining the changes to the data sheet for the Cessna 310R was released to ensure all pilots and students are aware of the complex fuel configuration of the aircraft. Furthermore, the operator has requested replacement of the fuel selector plaques to ensure the correct data labels are installed.

Safety message

Accidents involving fuel mismanagement are an ongoing aviation safety concern and are a reminder of the importance of monitoring fuel levels prior to, and during, flight.

This occurrence reinforces the need to:

- be fully familiar with the aircraft fuel system’s operation and capacity

- conduct a thorough pre-flight inspection including the cross checking of fuel quantity and quality

- determine the expected rate of fuel consumption prior to flight and monitoring fuel consumption during flight to confirm performance

- ensure the appropriate tank selections are made

- ensure all aircraft documentation and placarding is up to date and readily available.

Fuel management related accidents have been published by the ATSB in Avoidable Accidents No. 5 - Starved and exhausted: Fuel management aviation accidents (AR-2011-112) which outlines strategies and key messages for fuel management.

Methods for cross-checking fuel on board before flight are published by the Civil Aviation Safety Authority in Advisory Circular AC 91-15 Guidelines for aircraft fuel requirements.

The investigation

The occurrence

The trainee instructor dipped the fuel tanks and determined there was 309 litres of total fuel onboard. They were unable to recall the split of fuel between the main and auxiliary fuel tanks. Both crew recalled after the event that the fuel quantity was not cross-checked[1] between the dipsticks and fuel gauges.

The trainee instructor conducted a pre-flight briefing with the instructor outlining the asymmetric training sequences which would be conducted. The flight was expected to last 1.5–2 hours.

While taxiing, the instructor checked the fuel gauges and continued to the runway. The instructor recalled thinking at the time that both the main tanks and the auxiliary tanks were full. The flight departed Redcliffe at about 1423 and proceeded to the east over Moreton Island.

About 30 minutes into the flight, the trainee instructor switched from the main to the auxiliary fuel tanks and began the asymmetric training sequences. The trainee instructor was unable to recall why this was done. Neither pilot could later recall any fuel gauge readings during the flight.

At about 1459 the pilots decided to conduct an instrument approach to Sunshine Coast Airport to prepare the trainee instructor for an instrument rating training endorsement. The trainee instructor went under the hood[2] to simulate instrument meteorological conditions.[3]

At about 1515, the instructor made contact with the Sunshine Coast air traffic control tower controller and was cleared to fly to the west. Shortly after, the aircraft was cleared for an instrument approach and the crew began to fly the outbound leg of the approach .

At 1517 the instructor began pre-landing checks and the flaps[4] were extended to 15°. At about that time, both engines began to surge, and the instructor conducted the first 5 steps of the emergency checks including flap retraction and then unsuccessfully attempted to determine the affected engine (Figure 1). The trainee instructor noticed fuel streaking from the main tank vents, indicating fuel venting.[5] Shortly after, the engines began to operate normally for about 20 s before they started to surge alternatively with a corresponding reduction in power and yawing[6] of the aircraft.

Figure 1: Occurrence flight

Source: Google Maps annotated by the ATSB

At about 4,200 ft and tracking in an easterly direction, the instructor declared a MAYDAY on the tower frequency and requested direct track for runway 13.[7] The controller cleared the aircraft to descend to 1,500 ft and to track for runway 13.

After descending to 1,500 ft and when established on downwind for a visual approach to runway 13, the pilots began further troubleshooting. The instructor selected the fuel pumps on and identified that the fuel selectors were still set to the auxiliary tanks. After switching back to the main tanks, both engines regained power.

The aircraft landed and taxied to the general aviation parking area. The crew later reported that, after landing, the auxiliary tanks’ fuel gauges read zero. The auxiliary tanks were dipped and were confirmed to be empty. The main tanks were also dipped and found to be full. There were blue streaks indicating that there had been fuel venting overboard.

After discussion with maintenance staff, the pilots conducted a successful ground run of the aircraft on the main tanks and did not identify any problems. The pilots then flew back to Redcliffe without refuelling.

Context

Pilot information

Instructor

The instructor held a commercial pilot licence (aeroplane), issued in 2017 with class ratings for single and multi-engine aircraft. The instructor had a total of about 2,100 flying hours of which, about 212 hours was instructional flying. The instructor began the role of head of flying operations for the operator in May 2022 after about 15 months of non-flying. The instructor had totalled 21.1 hours on VH-JQK, the operator’s only Cessna 310, in the previous 5 months. Including previous flights in 2017–2020, the pilot had accrued an estimated about 500–600 hours on Cessna 310 variants.

Trainee instructor

The trainee instructor held a commercial pilot licence (aeroplane), issued in 2019 with class ratings for single- and multi-engine aircraft. They completed an instructor rating at the beginning of 2022 before commencing to instruct on single engine aircraft and to conduct aerial work operations. At the time of the occurrence, the trainee instructor had about 138 instructional hours and a total of about 470 flying hours of which 8 were on the Cessna 310R, all in VH-JQK.

Aircraft information

The Cessna 310R was a twin-engine, low-wing, 6-seat, unpressurised aircraft equipped with retractable landing gear. The aircraft was fitted with Continental IO-520-M piston engines. The aircraft was manufactured in 1978, and first registered in Australia on 31 October 1989. The operator became the registration holder on 9 June 2022.

Fuel tank configuration

VH-JQK’s fuel system consisted of main tanks at each wing tip and auxiliary tanks in each outboard wing section. The combined usable capacity of the main fuel tanks was about 100 US gallons (378 L), and 40 US gallons (151 L) for the auxiliary tanks. The aircraft was also fitted with a nacelle fuel tank which had been disconnected and was no longer used. The main aluminium tanks were vented to the atmosphere.

Cessna 310R aircraft could be configured with the main tanks only, or with additional auxiliary and/or wing locket tanks (see Pilot’s operating handbook). The auxiliary tanks came in two sizes, the smaller 40-gallon size and the large 60-gallon size.

The instructor had previously flown Cessna 310R aircraft with 60-gallon auxiliary tanks and assumed that VH-JQK was similarly equipped, not knowing that it had 40-gallon tanks.

Information on the aircraft fuel system for the Cessna 310R was provided by:

- the aircraft fuel selector plaques

- the fuel gauges in the aircraft

- the pilot’s operating handbook

- the company operations manual.

Fuel selector plaques

The aircraft had one fuel selector for each engine, on the floor between the pilot seats. This allowed for the selection of main fuel tanks, auxiliary fuel tanks, cross-feed and fuel shutoff through the wing selector valves located in each respective wing. The fuel selectors also had plaques defining the amount of fuel in each tank in US gallons.

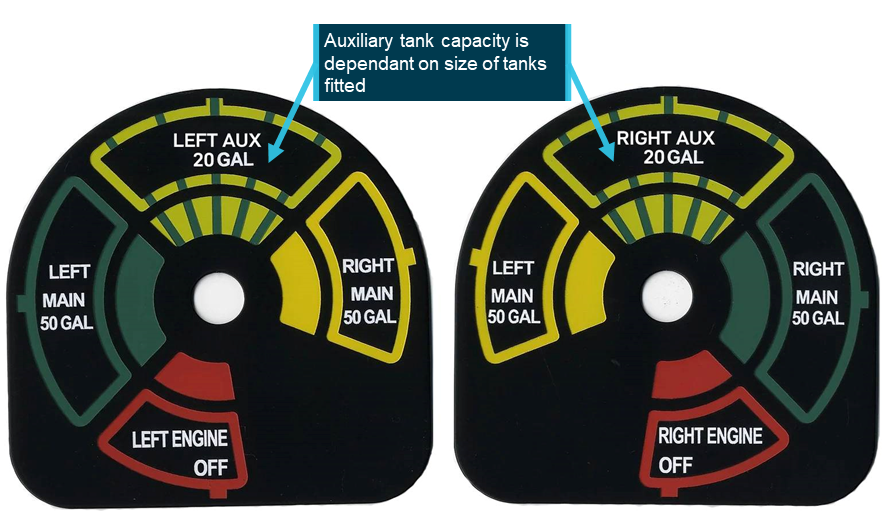

The fuel selector plaques displayed the amount of fuel available in each of the tanks. Fuel selector plaques under the Cessna 310 type certificate were required to show the fuel amount in US gallons. An exemplar is shown in Figure 2.

Figure 2: Correct aircraft fuel selector plaques

Source: Nimbus Aviation, modified by the ATSB

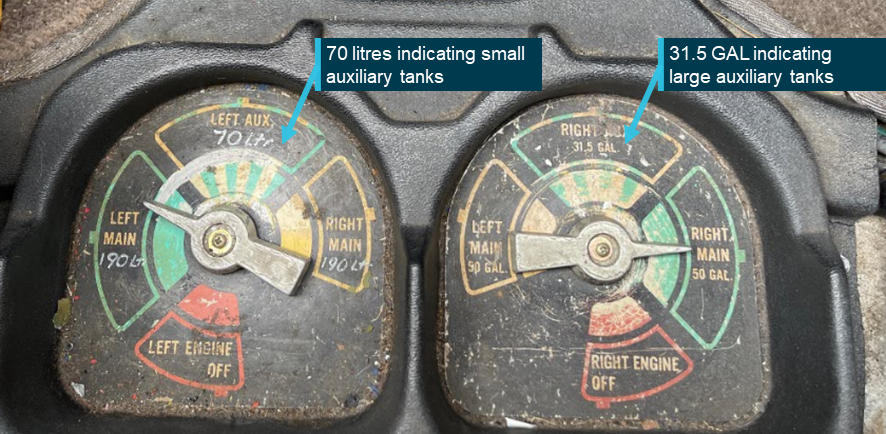

VH-JQK’s fuel selector plaques showed fuel quantities in differing units (Figure 3). On the left plaque only, an indication of fuel tank capacity was handwritten in white permanent marker with the quantities in litres. The right plaque had what appeared to be original markings from an aircraft with different auxiliary tank capacity. The left auxiliary tank was indicated as having a capacity of ‘70 Ltr’ (70 L, equivalent to 18.5 gallons), corresponding to the smaller auxiliary tank capacity (as was fitted to VH-JQK). The right plaque gave that side’s auxiliary tank capacity as ‘31.5 GAL’ (31.5 gallons, or 119.3 litres), corresponding to the larger auxiliary tank capacity.

The ATSB was not provided the aircraft logbooks or maintenance releases to confirm when the modification of the plaques, both the incorrect right-side plaque and handwritten quantities, took place.

Figure 3: VH-JQK fuel selector plaques

Source: Operator, annotated by the ATSB

Fuel gauges

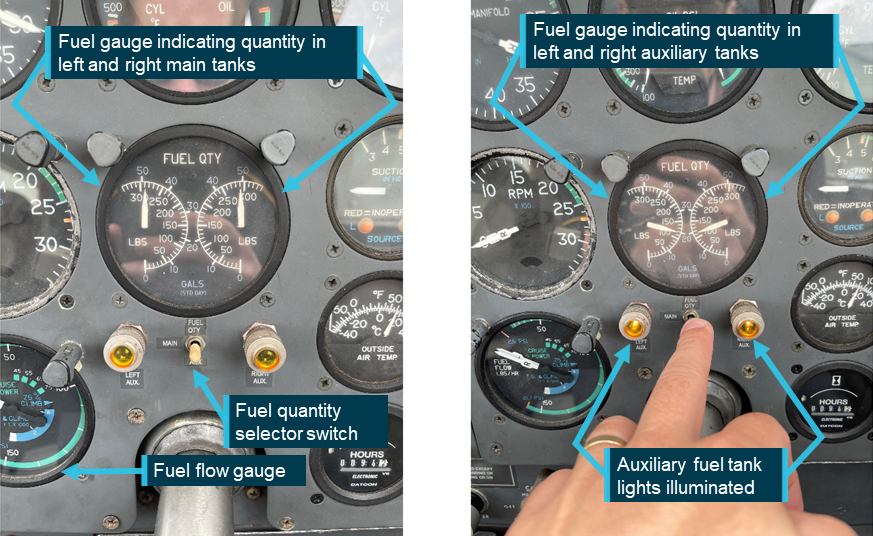

The fuel quantity gauge (Figure 4) was located above the right side control column and normally indicated the fuel quantity (in both gallons and pounds) in the selected tanks. The fuel quantity in the non-selected tanks could be displayed instead through the use of a momentary toggle switch below the gauge. Two yellow lights (one for each side) illuminated when the auxiliary tank on that side was selected.

Figure 4: Fuel gauges in VH-JQK

Source: Operator, annotated by the ATSB

Pilot’s operating handbook

The operator used 2 versions of the pilot’s operating handbook (POH):

- a generic softcopy version

- a hardcopy which was carried in the aircraft.

The softcopy POH included multiple aircraft serial numbers and inconsistent registration details throughout the document, none of which matched VH-JQK. This version of the POH did not indicate the fuel tank configuration of VH-JQK.

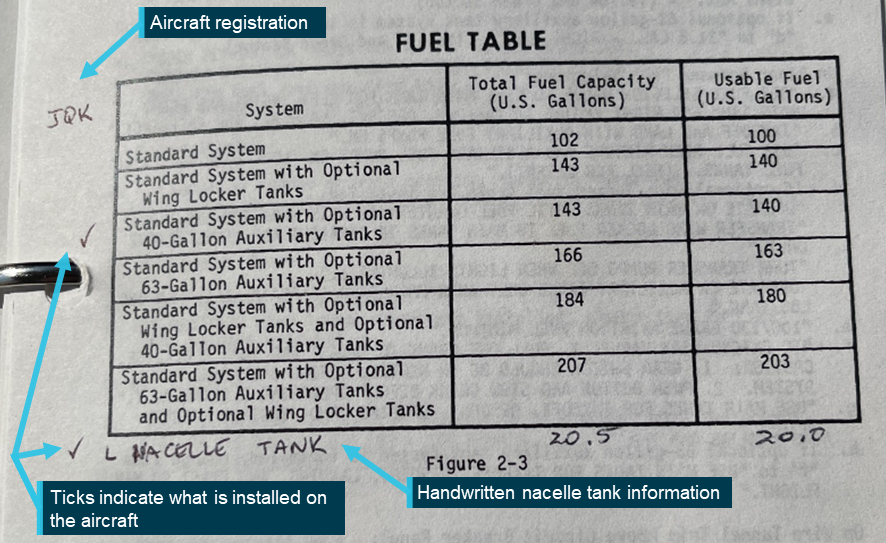

The POH carried in the aircraft included an aircraft flight manual approval from the Civil Aviation Safety Authority, but the approval did not specify the serial number of the approved aircraft. The POH was not specific to VH-JQK’s particular configuration (showing the 6 possible fuel tank configurations available for Cessna 310R aircraft) but had handwritten markings indicating VH-JQK’s fuel system configuration (Figure 5).

Figure 5: Pilot’s operating handbook carried in VH-JQK

Source: Operator, annotated by the ATSB

The Federal Aviation Administration (FAA) Pilot’s Handbook of Aeronautical Knowledge (2022)[8] stated that while the POH may appear similar for different aircraft of the same make and model, each manual should be unique and contain specific information about a particular aircraft, such as the equipment installed and the weight and balance information. If a manual does not indicate a specific registration and serial number, it should be limited to general study purposes only. The online POH did not accurately indicate the installed fuel tanks in VH-JQK and due to multiple serial numbers through the manual, the document was unable to support pilot understanding of specific differences with VH-JQK.

The POH recommended to use fuel from the main tanks during both take-off and landing (for aircraft fitted with 40-gallon auxiliary tanks).

The POH stated that when all fuel tanks were full, the main tank fuel should be used after take-off for about 60 minutes or until 180 lb (102 L) or less is remaining. Auxiliary tanks should then be selected. This was necessary to provide space in the main fuel tanks for vapour and unused fuel to be returned from the engine driven fuel pumps when operating on auxiliary fuel.

If sufficient space was not available in the main tanks for this diverted unused fuel, the main tanks could overfill, and fuel could be lost out of overboard fuel vents. It was recommended that auxiliary fuel was used until either exhausted or the flight phase had reached the top of descent.

At the time of the occurrence the trainee instructor reported that they did not fully know that excess fuel was returned to the main fuel tanks when the auxiliary tanks were selected. The trainee instructor reported they had relied on the instructor to know the differences in the fuel system.

Operator’s operations manual

The operator’s operations manual outlined the entire fleet of aircraft operated by the company. The only Cessna 310 data sheet available in the operations manual was for a Cessna 310H, which had significantly different performance and fuel system characteristics. The operations manual did not contain information on fuel tank availability and capacity for VH-JQK, the Cessna 310R or the 310H.

In the flight planning section of the operations manual, a generic fuel flow rate was provided fora generic Cessna 310 and did not identify a specific model. The flight planning fuel flow rate was of 100 L/hour.

The data sheet section of the operations manual identified the Cessna 310H has a fuel flow rate of 90 L/hour, while the operator’s cross hire list, also found in the operations manual, detailed the Cessna 310R as having a fuel flow of 120 L/hour. The typical cruise fuel flow rate of the Cessna 301R is about 117 L/hour.

Operator fuel management procedures

Pre-flight

The operator’s operation manual required the pilot in command (in this case, the instructor) ensure that a determination of the quantity of usable fuel on board was conducted before flight. Fuel quantity gauge readings were to also be cross-checked, to ensure accurate fuel calculation against one of the following:

- visual confirmation – full, tabs or dipstick reading

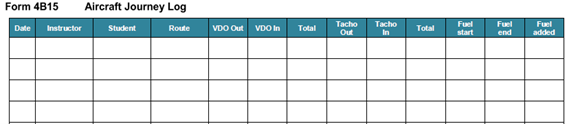

- calculated – a comparison of the fuel on board from the previous flight with fuel added with reference to the operator’s aircraft journey log form (Figure 6).

Figure 6: Operator aircraft journey log

Source: Operator

Should a pilot identify any significant discrepancy between the actual and calculated quantities, this was required to be reported to maintenance engineer staff for further investigation.

This fuel log was generic for the operator’s fleet and did not distinguish between the contents of the main fuel tanks and the auxiliary fuel tanks for the Cessna 310R. The log did not indicate which units should be used.

The aircraft journey log was requested by the ATSB for the investigation; however, the operator was unable to locate and produce the document.

In-flight

The operator’s operations manual stated:

During all flights, at a 30-minute interval, our pilots conduct a fuel quantity check whereby the usable fuel remaining is evaluated to compare planned fuel consumption with actual fuel consumption. This is accomplished by cross-referencing the fuel remaining on gauges with an appropriately calculated fuel log covering aircraft endurance – litres and minutes of fuel remaining. Our pilots determine the expected usable fuel remaining on arrival at the destination aerodrome and whether the usable fuel remaining is sufficient to complete the planned flight.

Post flight

Upon return from a flight, pilots were required to complete the fuel documentation including the journey log with the amount of fuel at shutdown.

Related occurrences

Fuel management and fuel starvation incidents and accidents continue to occur in twin engine aircraft. Examples of ATSB investigations of these include:

- Fuel starvation and forced landing involving Piper PA-28, VH-BDB, 15 km WSW of Bankstown Airport, NSW, on 19 September 2017 (AO-2017-094AO-2017-094)

- Fuel starvation involving Cessna 206, 3.5 NM NE of Aldinga, SA, on 3 February 2019

(AB-2019-004) - Cessna C310R, VH-HCP, 3km E Newman Aerodrome on 26 January 2001 (200100348)

The ATSB found that pilot understanding of, and management of aircraft fuel systems played a crucial role in these occurrences.

The 2013 ATSB publication, Avoidable Accidents No. 5: Starved and exhausted: Fuel management aviation accidents (AR-2011-112) focused on accidents involving fuel starvation due to fuel management, stating:

Keeping fuel supplied to the engines during flight relies on the pilot’s knowledge of the aircraft’s fuel supply system and being familiar and proficient in its use. Adhering to procedures, maintaining a record of the fuel selections during flight, and ensuring the appropriate tank selections are made before descending towards your destination will lessen the likelihood of fuel starvation at what may be a critical stage of the flight.

Safety analysis

Overview

Surging can be a result of a piston engine being starved of fuel. In this case, the crew observations of surging and fuel streaking from the main tanks during and after the flight were consistent with the main tanks being full and the auxiliary tanks being empty. Once the fuel selectors were switched to the main tanks, the engines recovered. The surging was therefore almost certainly caused by the auxiliary fuel tanks emptying while selected during the flight.

After departure, the crew operated for about 30 minutes with the main fuel tanks selected before changing to the auxiliary tanks. At a fuel flow rate of 120 L/hour, the engines would have used about 120 L at the time the surging began. This alone would not have been enough to empty the auxiliary tanks, which held about 140 L; however, in this aircraft, unused fuel from the fuel pumps would also be transferred from the auxiliary tanks to the main tanks.

This would have reduced the quantity of fuel in the auxiliary tanks at a faster rate than just engine consumption in the period between switching to auxiliary tanks and the engine surging. This would explain why the auxiliary tanks were exhausted of fuel. In addition, the main tanks became full during this period and excess fuel was lost overboard through venting.

The auxiliary tanks continued to be used until they became exhausted, resulting in fuel starvation and engine surging. This analysis will examine the reasons for this fuel starvation, the crew’s management of fuel throughout the flight, and the information provided by the operator for pilots to manage fuel.

Fuel management

The operator was unable to locate the aircraft journey log and the fuel on board prior to the occurrence could not be determined. Operator requirements detailed that the fuel on board at the start of the flight were to be recorded in the aircraft journey log. However, this was not done. This journey log was intended to indicate the amount of total fuel left on board the aircraft from the previous flight and be used as a basis for planned versus actual fuel usage for the flight. The journey log would not have given the pilots an exact indication as to how much fuel was left in each tank.

The aircraft journey log, the fuel gauges and the dipstick readings were available to cross-check the fuel quantities to allow highest level of certainty of the amount of usable fuel onboard.

The interval between in-flight fuel quantity checks of 30 minutes was set out by the operator to prompt pilots to remain aware of the aircraft fuel state. The trainee instructor was uncertain as to why the tanks were changed from main to auxiliary after 30 minutes, earlier than the normal 60 minutes outlined in the POH, and both crew were unable to recall the fuel gauge quantity throughout the flight. This indicates that it was likely the crew were not checking the fuel gauges every 30 minutes.

Post flight inspection indicated that although the auxiliary tanks were empty, the main tanks were completely full. The aircraft was able to be flown back to Redcliffe without issue, this indicated that the total amount of usable fuel on board was sufficient for the planned flight.

The pilots did not completely follow operator’s pre-flight and in-flight fuel management procedures including keeping a fuel log, cross-checking the amount of fuel on board, and tracking fuel quantity throughout the flight. This resulted in the pilots continuing to select fuel from the auxiliary tanks beyond the point when they were empty and subsequently the starvation of both aircraft engines.

Familiarity with the aircraft fuel system

The instructor was not familiar with the fuel capacity of VH-JQK. The auxiliary fuel tank capacity was significantly lower than other previous Cessna 310R aircraft the instructor had operated. They had assumed that the auxiliary tanks held about 100 L more than VH-JQK could.

The trainee instructor relied on the instructor’s experience on the Cessna 310 aircraft and had limited experience of the aircraft and fuel system. Familiarisation with the aircraft’s fuel system should have been completed prior operating the aircraft and not relied solely on the instructor’s previous experiences.

Aircraft fuel system documentation

The data sheets which were provided in the operator’s operations manual did not provide the correct information about the current Cessna 310 variant being flown by the operator and instead provide a generic fuel flow rate for the C310.

There was no clear information set around the Cessna 310R fuel flow rates or fuel tank configuration within the operations manual. Effective fuel planning and fuel management rely on the accuracy of the predicted fuel consumption rate. With 3 different fuel flow rates outlined in the operations manual, the inconsistent data impedes the accuracy of the of the fuel consumption data used for planning and decision-making.

These fuel flow rates were recorded in L/hour yet the fuel quantity for the Cessna 310R was variously measured in gallons, litres and pounds. Accurately calculating and managing fuel is a critical aspect of safe aircraft operation. Using different units of measurement for fuel calculation and management can introduce unnecessary complexity and lead to errors.

For example, converting units can make it more difficult to cross-check the fuel levels and detect fuel discrepancies or leaks. It was not possible to determine whether this was a factor in the occurrence, however, it can lead to difficulties in remembering and calculating fuel quantities.

The hardcopy POH incorrectly indicated that there was a nacelle tank installed. Clear information about the capacity and usability of the nacelle tanks was not provided to pilots and students.

Fuel selector plaques

The fuel selector plaques were incorrectly labelled. The left plaque provided the incorrect unit of measure, and the right plaque provided the incorrect size of auxiliary tanks available.

The ATSB determined that the fuel selector plaques did not contribute to the occurrence as both the instructor and student instructor did not recognise the inconsistent markings on the selector. However, inconsistent and incorrect markings have the potential to cause pilots to inadvertently make incorrect fuel calculations.

Findings

|

ATSB investigation report findings focus on safety factors (that is, events and conditions that increase risk). Safety factors include ‘contributing factors’ and ‘other factors that increased risk’ (that is, factors that did not meet the definition of a contributing factor for this occurrence but were still considered important to include in the report for the purpose of increasing awareness and enhancing safety). In addition, ‘other findings’ may be included to provide important information about topics other than safety factors. These findings should not be read as apportioning blame or liability to any particular organisation or individual. |

From the evidence available, the following findings are made with respect to the fuel starvation event involving Cessna 310, VH-JQK, near Sunshine Coast Airport, Queensland, on 18 August 2022.

Contributing factors

- The pilots did not establish the amount of fuel on board prior to the flight or manage the fuel state throughout the flight.

- The instructor was not aware that the aircraft had a 140L usable fuel auxiliary tank capacity and assumed that it had the same 238L capacity as other Cessna 310 aircraft they had flown.

Other factors that increased risk

- The operator had inconsistent and incomplete technical documentation for the aircraft.

- The aircraft’s fuel selector plaques contained contradictory and incorrect information about the capacity of the auxiliary tanks, and in different units.

Safety actions

Safety action by Aircraft Australia

After an internal investigation, Aircraft Australia implemented a new fuel log specific for the Cessna 310R. They have released an internal memo for the company operations manual outlining the changes to the data sheet for the Cessna 310R to ensure all pilots and student are aware of the fuel configuration of the aircraft. The operator has also requested fuel selector plaques replacement to ensure the correct data labels are installed.

Sources and submissions

Sources of information

The sources of information during the investigation included:

- the instructor and trainee instructor of the occurrence flight

- Aircraft Australia

- Flightradar 24.

Submissions

Under section 26 of the Transport Safety Investigation Act 2003, the ATSB may provide a draft report, on a confidential basis, to any person whom the ATSB considers appropriate. That section allows a person receiving a draft report to make submissions to the ATSB about the draft report.

A draft of this report was provided to the following directly involved parties:

- Civil Aviation Safety Authority

- instructor and trainee instructor of VH-JQK

- Aircraft Australia.

Submissions were received from:

- Civil Aviation Safety Authority.

The submissions were reviewed and, where considered appropriate, the text of the report was amended accordingly.

Purpose of safety investigationsThe objective of a safety investigation is to enhance transport safety. This is done through:

It is not a function of the ATSB to apportion blame or provide a means for determining liability. At the same time, an investigation report must include factual material of sufficient weight to support the analysis and findings. At all times the ATSB endeavours to balance the use of material that could imply adverse comment with the need to properly explain what happened, and why, in a fair and unbiased manner. The ATSB does not investigate for the purpose of taking administrative, regulatory or criminal action. TerminologyAn explanation of terminology used in ATSB investigation reports is available here. This includes terms such as occurrence, contributing factor, other factor that increased risk, and safety issue. Publishing informationReleased in accordance with section 25 of the Transport Safety Investigation Act 2003 Published by: Australian Transport Safety Bureau © Commonwealth of Australia 2023

Ownership of intellectual property rights in this publication Unless otherwise noted, copyright (and any other intellectual property rights, if any) in this report publication is owned by the Commonwealth of Australia. Creative Commons licence With the exception of the Coat of Arms, ATSB logo, and photos and graphics in which a third party holds copyright, this publication is licensed under a Creative Commons Attribution 3.0 Australia licence. Creative Commons Attribution 3.0 Australia Licence is a standard form licence agreement that allows you to copy, distribute, transmit and adapt this publication provided that you attribute the work. The ATSB’s preference is that you attribute this publication (and any material sourced from it) using the following wording: Source: Australian Transport Safety Bureau Copyright in material obtained from other agencies, private individuals or organisations, belongs to those agencies, individuals or organisations. Where you wish to use their material, you will need to contact them directly. |

[1] Cross-checked: The use at least two different verification methods to determine the amount of fuel on board.

[2] Under the hood: Indicates that the pilot is using a hood to restrict visibility outside the cockpit while simulating instrument flight. An appropriately rated pilot is required in the other control seat while this operation is being conducted.

[3] Instrument meteorological conditions (IMC): weather conditions that require pilots to fly primarily by reference to instruments, and therefore under instrument flight rules (IFR), rather than by outside visual reference. Typically, this means flying in cloud or limited visibility.

[4] Flaps: movable surfaces on the trailing edge of the wing that help the aircraft gain lift.

[5] Fuel venting: the process of releasing excess fuel vapours from the fuel tanks of an aircraft.

[6] Yawing: the motion of an aircraft about its vertical or normal axis.

[7] Runway number: the number represents the magnetic heading of the runway in the nearest tens of degrees. The runway identification may include L, R or C as required for left, right or centre.