Executive summary

What happened

On 6 November 2020, the pilot of a S.E.D.E. Morane-Saulnier MS.893A (Rallye) aircraft, registered VH‑UQI, was conducting a private flight from Moruya, New South Wales, to Archerfield, Queensland. About 22 km south-west of Archerfield Airport, the engine began running rough before eventually failing. The pilot elected to conduct a forced landing into an open but slightly undulating paddock. The approach direction resulted in a tail wind landing. The aircraft over-ran the open area before it impacted with a grove of trees, significantly disrupting the aircraft structure. A post impact fire consumed most of the fuselage.

Witnesses to the forced landing arrived at the scene and removed the unconscious pilot from the periphery of the fire zone and called emergency services. The pilot was seriously injured, and the aircraft was destroyed.

What the ATSB found

The aircraft’s engine had a catastrophic mechanical failure. The initiation of the mechanical failure was the separation of the number 2 piston connecting rod which subsequently created a hole in the upper crank case and seized the engine. The engine failure reduced the pilot’s forward visibility due to engine oil over the windscreen, as well as smoke created by escaping oil on the exhaust system.

The pilot was ferrying the aircraft on behalf of the owner and had limited aircraft type experience and knowledge of its performance capabilities. Additionally, it was found that the pre-flight planning was limited, an emergency locator transmitter or portable locator beacon was not carried on board the aircraft for the flight.

The aircraft engine had not been overhauled since 1997. The aircraft had limited usage for an extended period, possibly with no specific engine preservation done while in storage. Had the engine been overhauled at the manufacturer's recommended calendar time, the connecting rod journal bearings would have been replaced with post-modification bearings as part of the overhaul process.

Safety message

This investigation is a timely reminder for aircraft owners and maintainers to be cognisant of the manufacturer’s service information which ensures that the serviceability of engine and airframe systems are maintained to the highest standards. This includes strict monitoring of on-condition items, and that replacement of some parts may be warranted to ensure continued and safe operation. Consideration should also be given to preservation of the engine and its systems, should an aircraft be infrequently utilised.

The investigation

| Decisions regarding whether to conduct an investigation, and the scope of an investigation, are based on many factors, including the level of safety benefit likely to be obtained from an investigation. For this occurrence, a limited-scope investigation was conducted in order to produce a short investigation report and allow for greater industry awareness of findings that affect safety and potential learning opportunities. |

The occurrence

On 6 November 2020, at about 0800 Eastern Daylight-saving Time,[1] a S.E.D.E. Morane-Saulnier MS.893A Rallye (Rallye) aircraft, registered VH-UQI, departed Moruya Airport, New South Wales, for a private flight to Archerfield Airport, Queensland. The pilot, who was ferrying the aircraft on behalf of the owner and was the sole occupant, conducted the flight under the visual flight rules[2]and had planned fuel stops in Bathurst and Gunnedah, NSW. The ferry flight was a planned delivery of the aircraft to the new owner and was intended to take about 5 hours flight time.

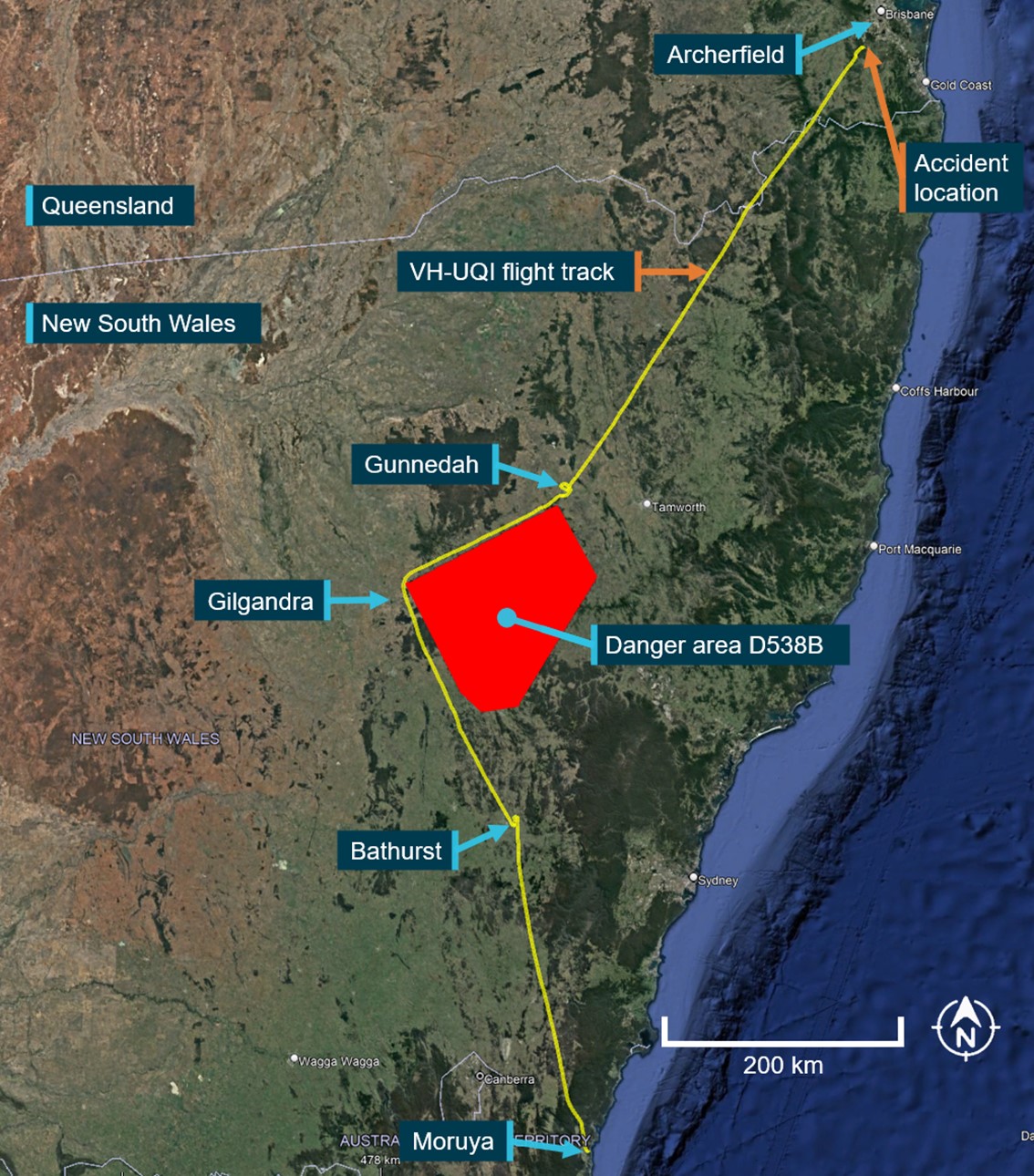

Figure 1 shows the flight track for the aircraft. The pilot flew to Bathurst without incident, where the aircraft was refuelled. Departing Bathurst, the aircraft tracked toward Gilgandra, before changing course to Gunnedah. The pilot recalled tracking around Danger area[3] 538B, a military flying area, as the reason for this indirect route.

After refuelling, the aircraft departed Gunnedah for Archerfield. At about 55 km south-west of Archerfield, the pilot descended to below 2,000 ft above mean sea level (AMSL). The pilot’s intention was to track between two restricted areas[4] in the vicinity of Greenbank, Queensland and continue their descent to the Goodna inbound reporting point for entry into Archerfield Airport.

At about 1425 Eastern Standard Time,[5] while cruising at 2,000 ft and about 32 km south-west from Archerfield, the pilot made an inbound radio call to Archerfield air traffic control tower requesting an ‘airways clearance’, adding that their location was to the south-east of Archerfield. This call was made on the Brisbane approach frequency. Brisbane approach advised the pilot that their broadcast was on the incorrect frequency and provided the correct frequency for Archerfield Tower, however, this was not acknowledged by the pilot.

About 90 seconds later, the pilot broadcast a MAYDAY[6] call stating:

MAYDAY MAYDAY. Uniform Quebec India Uniform Quebec India. 2-0 miles south-east of Archerfield. Total engine failure.

That broadcast was again made on the Brisbane approach frequency. Brisbane approach acknowledged the MAYDAY and no further radio calls were made by the pilot of VH‑UQI.

Figure 1: Recorded flight track of VH-UQI from Moruya, NSW to accident site

Source: Google Earth and OzRunways, annotated by the ATSB

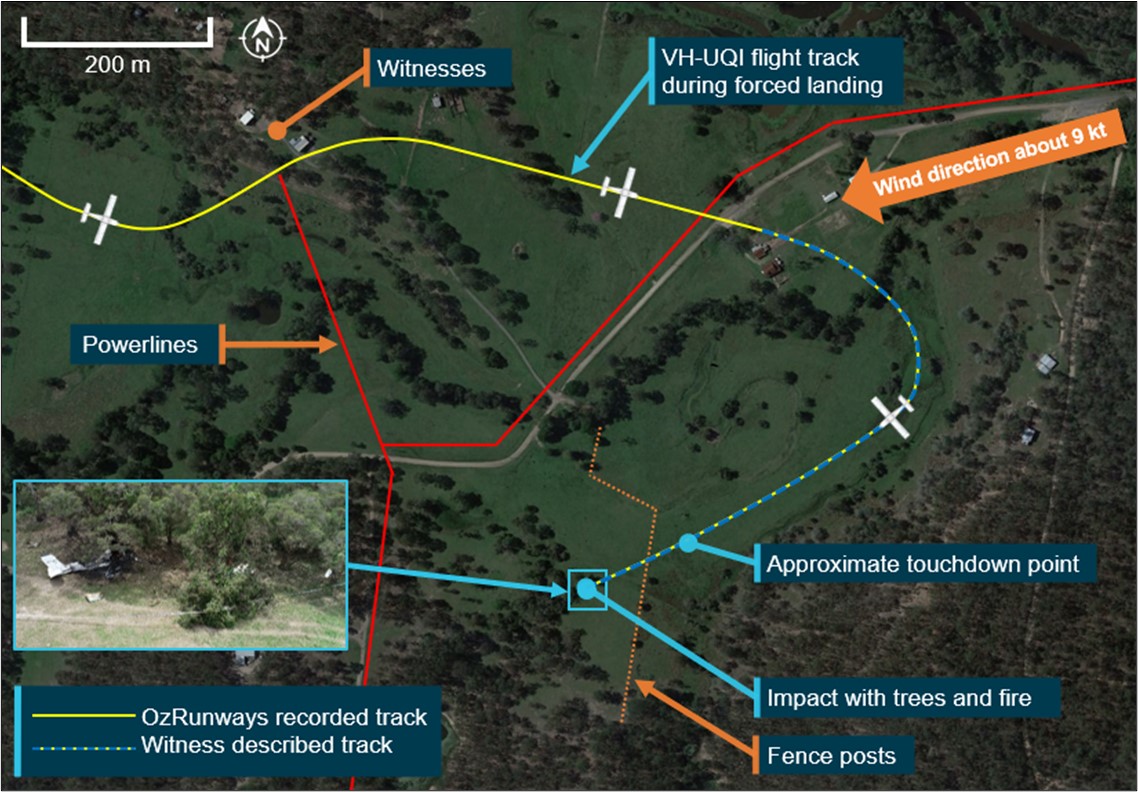

The pilot recalled that the aircraft ran rough and lost engine power, before complete engine stoppage. At the time, VH-UQI was approaching numerous built-up areas and the pilot had limited suitable forced landing area options. The pilot reported that their forward vision was obscured by black smoke and oil emanating from the engine. The recorded flight path showed that the aircraft conducted a right turn towards an open paddock (Figure 2).

The pilot had no recollection of the wind direction from the Archerfield aerodrome terminal information service[7] or from local wind indicators. The final approach was in a south-westerly direction, which was downwind. The aircraft touched down about two-thirds of the way into the paddock and then became temporarily airborne due to ground undulations before impacting trees. The impact resulted in significant disruption to the aircraft structure and initiated a post-impact fire.

Figure 2: VH-UQI flight path and forced landing area

Source: Google Earth, OzRunways and witness descriptions, annotated by the ATSB

Witnesses under the flight path observed the aircraft trailing black smoke, saw it turn towards the paddock, and subsequently observed smoke rising in the area that the aircraft had landed. They immediately attended the accident site and located the pilot at the edge of the fire, outside the cockpit. They moved the pilot a safe distance from the wreckage, alerted emergency services, and commenced first aid while waiting for emergency services to arrive. The pilot was seriously injured, and the aircraft was destroyed.

Context

Pilot information

The pilot held a valid private pilot (aeroplane) licence, issued in August 2020 (3 months before the accident) with a single engine aeroplane class rating and endorsements for manual pitch propeller control and retractable undercarriage. The pilot held a valid Class 2 aviation medical certificate that was issued on 30 July 2019 with no listed restrictions. The pilot had about 99 hours total flying time prior to the accident flight.

Aircraft type training and familiarity

The pilot had previous flying experience in Cessna 152, 172, and Piper PA28 aircraft. They had planned to carry out a familiarisation flight on VH-UQI with an instructor 2 days prior to the flight, however due to other work commitments, they had arrived at the aerodrome late in the afternoon after the instructor had left for the day. The pilot then conducted a short (18 minute) familiarisation flight by themself. Prior to that, the pilot had had no familiarisation on the aircraft type to allow them to experience the slow speed and short landing performance characteristics of VH-UQI (see Aircraft information). Further, the pilot reported at interview that they were not aware of the aircraft’s performance characteristics.

Prescribed aircraft type training was not required under Civil Aviation Safety Regulation 1998 (CASR) Part 61 in relation to the Rallye. Furthermore, there was not a large aircraft performance disparity between the Rallye and the Piper Cherokee PA-28 that the pilot was previously operating.

Flight planning

After discussing the flight with an instructor, the pilot opted to conduct the flight inland (rather than along the coast) to avoid controlled airspace, which also enabled them to fly at a higher altitude and to have more favourable weather for the flight. The pilot stated they were utilising a tablet with the OzRunways RWY[8] application for navigation.

Danger area D538B (Figure 1), located between Bathurst and Gunnedah was visible on the OzRunways application when active on RWY, however there was no evidence that the pilot had previously considered avoiding D538B during pre-flight planning. A direct route to Gunnedah was possible at the planned altitude on the day of the flight.

Archerfield Airport was a busy metropolitan aerodrome operating as Class D controlled airspace. The pilot was unfamiliar with the Archerfield area and Class D operations and stated that they had an increased level of ‘nervousness’, due to inexperience when operating in controlled airspace.

The pilot recalled that their fuel plan was to fill the aircraft to maximum at Bathurst and Gunnedah. This would have allowed sufficient fuel for the conduct of the flight. The total usable fuel quantity for the Rallye is 178 L. The aircraft was fuelled to full 2 days prior to departure. The pilot refuelled at Bathurst on the day of the accident with about 75 L and then again at Gunnedah, with about 90 L.

Meteorological Information

Forecast conditions for the delivery flight from Moruya to Archerfield provided by the Bureau of Meteorology (BoM) indicated good flying conditions, visibility more than 10 km, and little cloud along the intended track.

BoM also provided the ATSB with an Aviation Safety Investigation Meteorological Report regarding the weather conditions at the occurrence location. The following was noted:

- Visibility greater than 10 km

- Nil significant weather or cloud

- Mod turbulence below 6,000 ft

- Wind forecast from the south-south-west at 6-9 kt from 1,000-5,000 ft

One-minute automatic weather station observations were provided by the BoM for the nearest station to the accident site, Greenbank military base, which indicated that the wind close to ground level was fluctuating below 10 kt from east to north-east.

Aircraft information

The S.E.D.E. Morane-Saulnier MS.893A[9] Rallye is a single engine, low wing, 4 seat aircraft of all metal construction and fitted with fixed tricycle, trailing link undercarriage. It is powered by a Lycoming O-360 4-cylinder piston engine driving a Hartzell 2-blade constant speed propeller. It has interconnected full-span leading-edge slats,[10] wide-chord slotted ailerons,[11] and wide-span Fowler-type flaps.[12] The combination of full-span slats and large Fowler flaps provide the aircraft with its capability for slow-speed flight performance required for short field take-off and landing.

Information from the aircraft flight manual indicated that the landing distance required for the aircraft in nil wind conditions at 26° C, were about 160 m at 1,000 kg gross weight and about 125 m at 750 kg. Both distances were with flaps in full down position, extended to 30°. The approach speeds were 65 kt and 54 kt respectively.

VH-UQI was manufactured in France in 1969 and was imported into Australia in the same year. The aircraft total time in service was 2,321.92 hours and the previous annual inspection was at 2,312.73 hours on 20 May 2020. The aircraft had a current certificate of registration, airworthiness, and maintenance release with no noted defects. The previous owner had owned VH-UQI for about 20 years and had stored the aircraft for about 7 years at Moruya, a coastal airport. The aircraft had seen little use in that time and was sold because of this.

Engine information

The engine fitted to VH-UQI was last overhauled in 1997 and had accrued about 324 hours since overhaul. The time between overhaul schedule as listed in Lycoming Service Instruction SI 1009BE was 12 years or 2,000 hours, whichever came first.

Although the engine had exceeded the calendar schedule of the manufacturer’s time between overhaul, this was permissible when the engine was maintained in accordance with the Civil Aviation Safety Authority (CASA) on-condition[13] requirements. At the last annual inspection in May 2020, the maintenance organisation had completed a piston engine condition report, verifying the engine serviceability, which then permitted the engine to continue in service.

Connecting rod journal bearings

Copper-lead alloy connecting rod journal bearings were initially supplied by Lycoming prior to 1995. These were replaced by aluminium-tin alloy bearings, which were available between 1995 to 2001 (corresponding with the time of the last engine overhaul in 1997.) These were then superseded in September 2004 by Lycoming Service Instruction No. 1512. The aluminium-tin bearings were required to be replaced with the upgraded bearings (copper-lead alloy) whenever new bearings were to be installed (such as at engine overhaul).

Site & Wreckage information

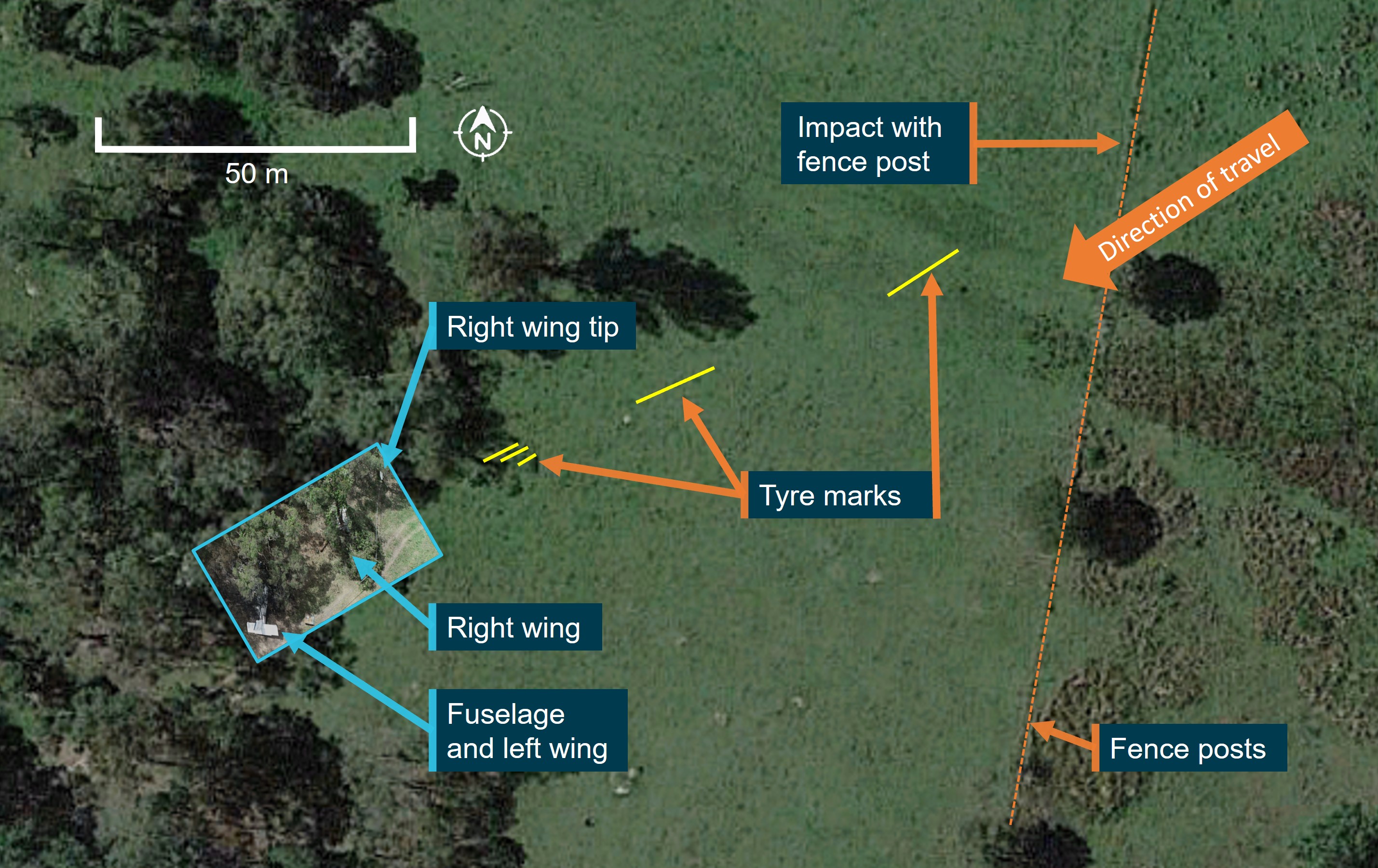

The accident site was located about 22 km south-west of Archerfield Airport. The main wreckage was situated in trees at the south-west end of a sparsely vegetated paddock, which was oriented in a north-east / south-west direction and was about 400 m in length with a relatively clear approach from obstacles due to sparse vegetation. The first impact point was with a fence post, followed by intermittent wheel marks in the grass, indicating that the aircraft had bounced multiple times during the landing. The distance from initial impact with the fence to the main wreckage was about 170 m (Figure 3).

Figure 3: Aircraft ground contact and accident site

Source: Google Earth, annotated by the ATSB

The right-wing tip struck trees about 2 m above the ground and separated from the wing. The right wing then impacted another tree, between the wing root and midway along the wing, then separated from the fuselage. This impact pivoted the aircraft 90° to the right. The fuselage and left wing travelled a further 10 m before coming to rest. The forward left side of the aircraft impacted a large tree, resulting in the engine, firewall and nose gear separating from the fuselage.

The engine, fuselage and left wing were exposed to a post-impact fire, and the empennage section remained largely unburnt (Figure 4). Examination of the aircraft structure and flight controls did not identify any pre-impact defects. The flaps were determined to be in the full down position at impact.

Figure 4: VH-UQI accident site

Source: ATSB

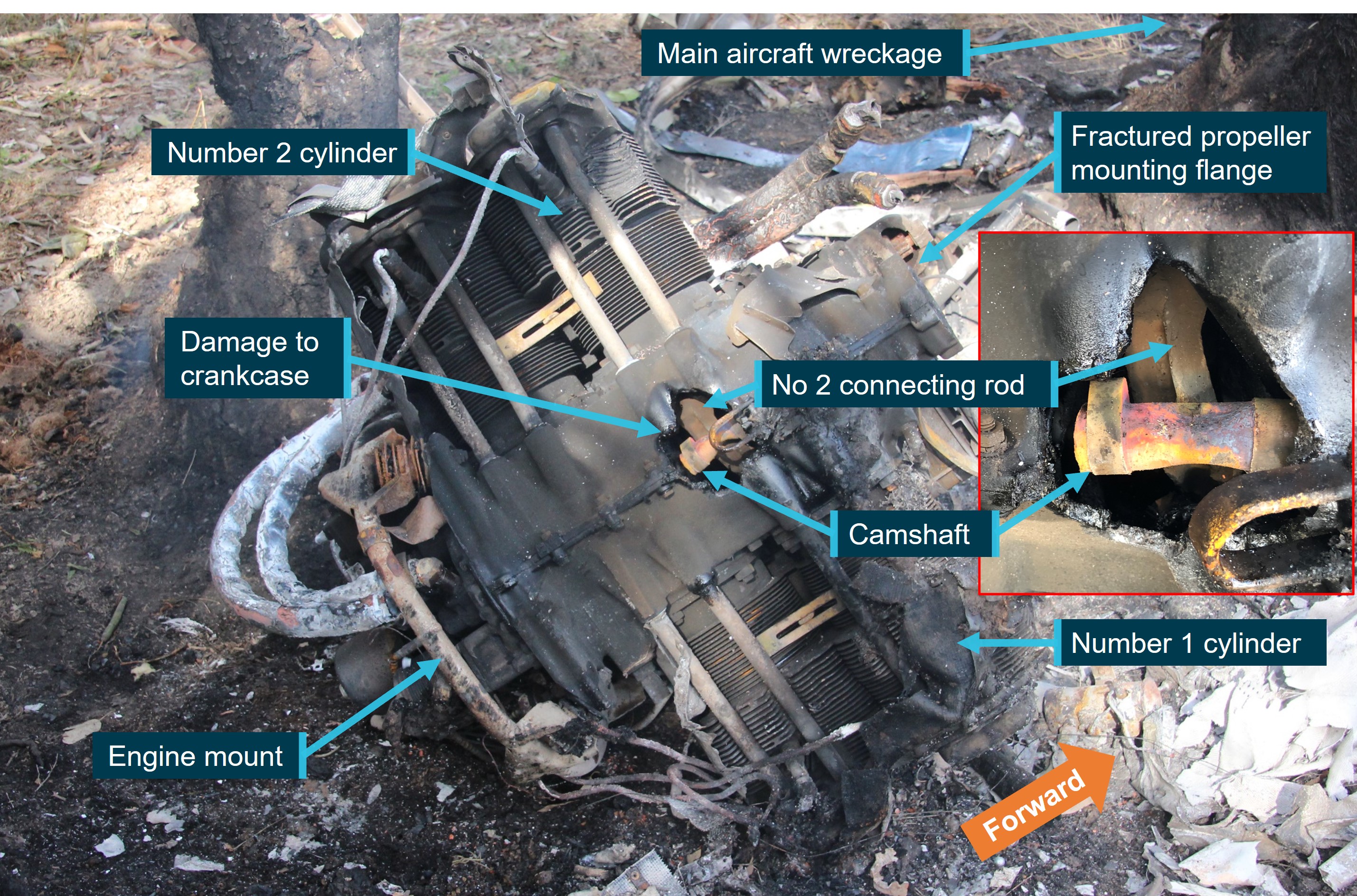

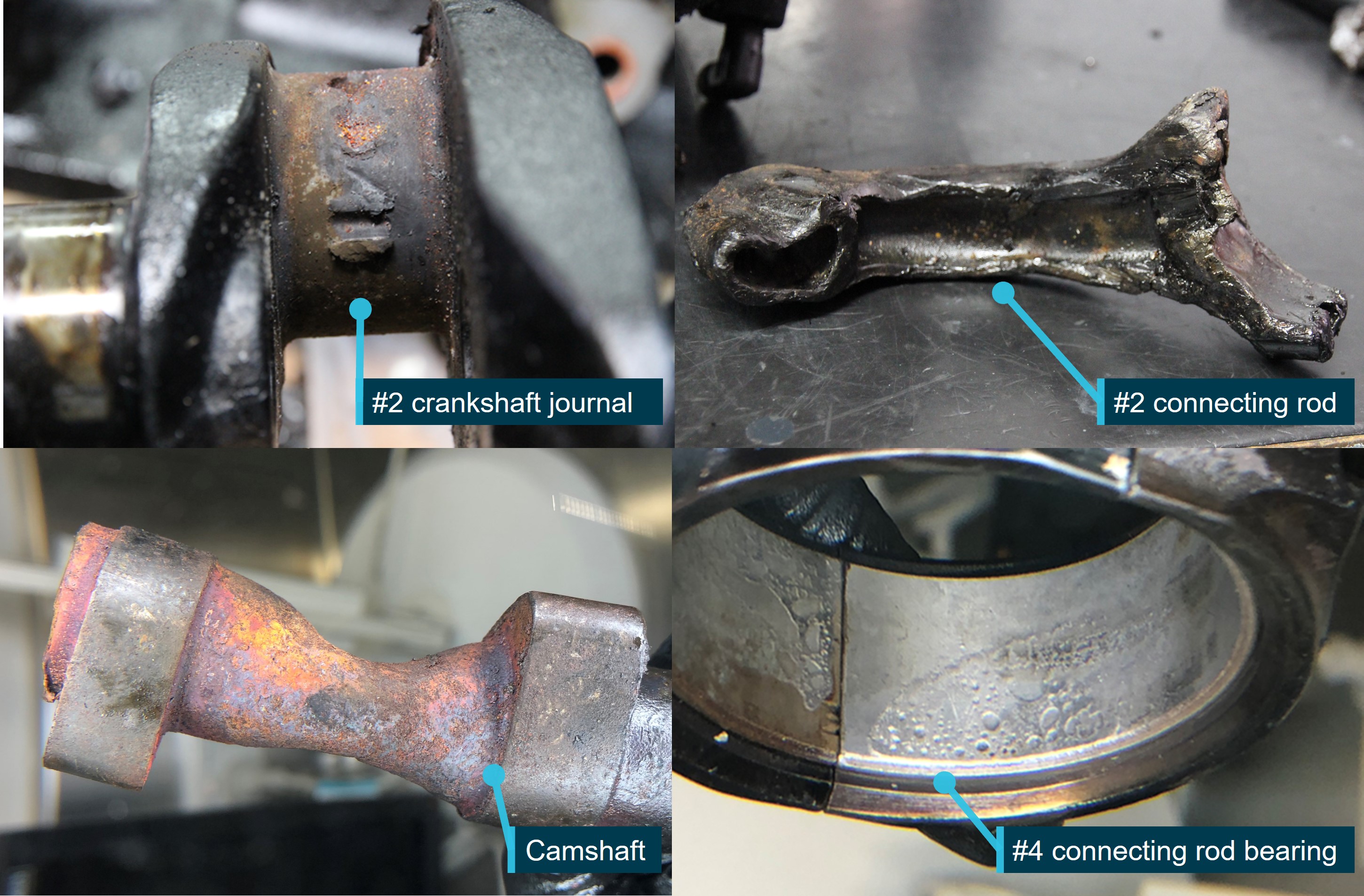

On-site engine examination

On-site examination of the engine identified a large hole in the top of the crankcase, between the number 1 and 2 cylinders. Visible through the hole was the fractured camshaft and number 2 piston connecting rod (Figure 5).

Figure 5: Engine assembly showing a hole in the crank case and internal damage

Source: ATSB

A smaller hole was noted on the underside of the crankcase, adjacent the number 1 cylinder and forward of the number 2 cylinder. The propeller and it’s mounting flange on the crankshaft had fractured in overload level with the front of the crankcase and was not affected by fire.

The outer area surrounding the upper crankcase hole was heavily coated with engine oil, as were sections of windshield and the unburnt empennage. A coating of engine oil was evident on the inner surfaces of the engine cowls and over the outside of the exhaust muffler, which was the likely source of the black smoke. The engine cowls, right magneto and exhaust muffler had separated from the engine and were unburnt. The engine was removed from the accident site and taken to an approved overhaul facility for a further detailed examination by the ATSB.

Engine examination

The engine was disassembled and inspected under the supervision of the ATSB. The examination revealed that all components were heat affected from the post-impact fire. The crankcase had large holes either side of the number 2 cylinder and a series of adjacent impact marks on the internal surface. The number 2 connecting rod was fractured and separated from the crankshaft journal and piston. The connecting rod fracture surfaces were significantly damaged, which precluded any meaningful materials failure analysis.

The piston pin boss had fractured due to overstress; however, the piston pin showed no damage. The crankshaft showed significant impact damage and wear of the number 2 journal. The other journals were also discoloured but were otherwise undamaged. The number 2 journal bearing was destroyed, such that only small fragments remained. The number 1, 3 and 4 journal bearings did not exhibit any cracking, damage, or severe wear. Discrete areas of the bearing surface had a ‘cratered’ appearance, which was likely the result of localised melting of the thin bearing layer adjacent to the crankshaft journal. The absence of any significant operational wear associated with these areas, indicated that the melting was most likely due to the post-impact fire.

It was also found that the crankshaft oil supply galleries to the internal components were unobstructed. The damage to the number 2 conrod and bearing journals were consistent with the engine failure initiating due to breakdown of the number 2 bearing (Figure 6).

Figure 6: Damaged engine components removed from VH-UQI

Source: ATSB

The connecting rod journal bearings fitted to the engine for VH-UQI were part number LW-13521 and marked with a manufacture date of 12-95. These were premodification bearings composed of an aluminium-tin alloy on a steel backing, which had been superseded in September 2004 by Lycoming Service Instruction No. 1512. The LW-13521 bearings were required to be replaced with the upgraded bearings whenever new bearings were to be installed (such as at engine overhaul).

The upgraded bearings have a bearing surface composed of a copper-lead alloy, which provides increased durability and is more resilient to wear during operation. The properties of lead within the alloy acts as a lubricant, while the copper provides high strength and fatigue resistance. The aluminium-tin alloy bearings became standard use in Lycoming engines during the 1990’s. Prior to their introduction, the bearings used were made of a copper-lead alloy.

ATSB research on piston engine structural failure

In 2007, the ATSB published a research and analysis report (B20070191) into aircraft reciprocating (piston) engine failures. The report examines 20 high-power[14] piston engine structural failure occurrences in Australia, between 2000 and 2005. The report focused on failures of the combustion chamber, connecting rods and crankshaft assemblies. The failures of engine crankshafts could be linked to failure of the bearings, both crankshaft main bearings and the connecting rod (big end) bearings.

The report found an increasing trend (for the period 1993 – 2003) that bearings composed with an aluminium-tin alloy would separate from the steel backing material. The same separation was not observed on bearings with a copper-lead alloy.

The ATSB research report noted that the CASA Airworthiness Bulletin AWB 85-001 Issue 4 (April 2006), Textron Lycoming engine bearings, also stated that the aluminium-tin bearings had a high failure rate and were therefore being replaced with the original copper-tin bearings.

Aircraft storage practices

In March 2017, CASA released Airworthiness Bulletin AWB 85-021, Piston engine low utilisation maintenance practices. This AWB related to protection of piston engines, through preservation techniques dependent on aircraft inactivity.

The geographical location of the aircraft influences the extent of the preservation that should be considered by the operator and maintenance personnel. Aircraft engines exposed to coastal areas and environments where there is high relative humidity can experience corrosion at a greater rate than an engine located in an area with more favourable environmental conditions.

The recommendations were to have a preservation regime for engine protection to prevent internal engine wear due to corrosion, to carry out oil changes based on calendar time limits, and that engine ground running is not a substitute for regular flying and can aggravate the corrosion condition.

The preservation and utilisation for VH-UQI could not be determined due to the logbooks being carried onboard the aircraft for the ferry flight. These were to be delivered with the aircraft to the new owner, however they were consumed by fire at the accident site and could not be referenced. The previous owner stated that they could not remember any specific storage practices used to preserve the aircraft or the engine during periods on non-usage.

Survivability

The cabin structure surrounding the cockpit was severely disrupted during the accident sequence. Further, the pilot’s seat belt attachment failed at the inboard mounting point. That led to the pilot being ejected from the cockpit, fortuitously to an area outside the fire zone.

VH-UQI was not fitted with an emergency locator transmitter (ELT) and the pilot did not carry a portable locator beacon (PLB). The carriage of an ELT and/or PLB was a requirement under Civil Aviation Regulation (CAR) 252A unless, among other requirements, the aircraft would be operating within a 50 NM radius from the original point of departure.

The pilot had not lodged a flight plan or arranged a SARTIME[15] to be held by a responsible person. The new owner of VH-UQI was awaiting the arrival the aircraft at Archerfield Airport but was not in receipt of a flight plan.

Other information

Several flight planning resources exist to assist pilots with the entry to Class D airports such as Archerfield. The Civil Aviation Safety Authority Stay OnTrack series is a good example of this, providing detailed and easy to read instructions, illustrations, pictures and further references to increase understanding prior to arrival. In particular to Archerfield, there was a procedures overview for pilots that included providing air traffic control with the phrase ‘unfamiliar with Archerfield’ to assist pilots. There was also radio call proformas and detailed instructions for arrivals.

Safety analysis

Introduction

While enroute from Gunnedah to Archerfield, VH-UQI had a catastrophic engine failure about 22 km to the south-west of its destination. With reduced visibility due to smoke and oil on the windscreen, the pilot conducted a forced landing in an open, slightly undulating field with a 9 kt tail wind. The aircraft touched down towards the end of a clear area, impacted trees at the paddock boundary. The pilot was seriously injured, and the aircraft was destroyed.

This analysis will explore the engine history and failure, flight planning and decision making of the pilot in command, and post impact survivability factors.

Engine information

Engine failure mode

The ATSB determined that the initiating factor of the engine failure was likely the breakdown of the number 2 connecting rod journal bearings. This would have resulted in excessive clearance between the connecting rod and crankshaft journal. Therefore, this allowed increased flexure of the big end bearing housing under continued loading cycles, and ultimately fatigue failure of the connecting rod and damage to the surrounding components.

The ATSB research and analysis report B20070191 was based on information compiled from incidents involving high-power horizontally opposed piston engines. Although not high-power engine, the engine fitted to VH-UQI contained bearings that were composed of the same material which had failed in the high-powered engines. The ATSB report stated that the bearings with an aluminium-tin composition were found to have sections of the bearing material separate from the backing, leading to bearing failure. The upgraded bearings have a copper-lead alloy composition, which does not exhibit the material separation failure mode seen in the aluminium-tin type.

Analysis of the remaining connecting rod bearings removed from VH-UQIs engine showed limited damage to the bearing surface that might have indicated a developing, material-related failure mode. As such, from the available evidence, the ATSB was unable to conclusively determine the reason for the number 2 connecting rod journal bearing failure. However, the original bearings fitted to the engine and low aircraft utilisation without preservation have shown to contribute to previous bearing failures under similar circumstances.

Modification history

The connecting rod journal bearings fitted to VH-UQI were a pre-modification type that had been superseded in September 2004 by Lycoming Service Instruction No. 1512. The engine had been maintained in accordance with the CASA regulatory requirements for an on-condition engine and had not been overhauled since 1997 (23 years prior to the accident). Had the engine been overhauled utilising the engine manufacturer’s recommended calendar time of every 12 years, it is likely that the journal bearings would have been replaced with upgraded bearings which had improved endurance, corrosion, and wear qualities.

Low utilisation maintenance practices

Since the last engine overhaul in 1997, VH-UQI had flown about 324 hours, which was an average of about 14 hours per year. As the aircraft logbooks were destroyed in the post-accident fire, it is unknown if the aircraft had been under-utilised for extended periods of time prior to the flight and what preservation, if any, had been performed on the engine. No preservation activities were remembered by the previous owner, so it is possible none were done. It was unable to be determined if the limited usage may have led to the failure of the connecting rod bearing.

Emergency landing

After the engine failure, the pilot attempted to conduct an emergency landing into a paddock immediately to their right. They reported reduced visibility through the windscreen due to smoke and oil emanating from the engine during the conduct of the emergency landing. The length of the paddock chosen was about 400 m with a relatively clear approach. There was sufficient area to bring the aircraft to a stop safely with knowledge of the aircraft capabilities. The pilot was unaware of the local wind indicators and conducted a descending right turn from the original direction of travel. This led to the aircraft positioning to land with a tailwind, substantially increasing the landing distance required.

The tailwind significantly increased the aircraft groundspeed while landing, contributing to the aircraft touching down about two thirds of the way into the paddock, before passing between a fence post and a tree. Still travelling at significant speed, VH-UQI became temporarily airborne over ground undulations and then impacted trees. The lack of pilot familiarisation of the aircraft and its slow speed performance capabilities may have exacerbated the consequences of the off‑field landing.

Pre-flight planning and preparation

The pilot had conducted limited aircraft familiarisation prior to the accident flight. While specific aircraft type training was not required, the pilot was unaware of the aircraft’s slow speed performance capability. A full understanding of this capability may have been beneficial when responding to the engine failure and forced landing.

The pilot did not use a flight log or formal flight plan and diverted around Danger Area 538B adding an extra 150 km of non-essential distance to the flight track.

Many sources of information were available to educate and reduce the pilot’s anxiety over the entry to Class D airspace and in particular Archerfield. This information along with appropriate pre-flight preparation including awareness of local area procedures and correct radio frequencies for communication, would have prepared the pilot for the final stages of the flight and provided greater navigational awareness.

The lack of aircraft familiarisation before the ferry flight, minimal pre-flight preparation for the flight, the non-carriage of emergency locator beacon and absence of a flight note with a responsible person, substantially increased the safety risk of the flight.

Had the pilot utilised flight planning resources and gained an awareness of local operating information and publication for Archerfield, then they would have been less reliant on electronic navigation during the flight and more situationally aware.

Emergency locator transmitter

Emergency locator transmitters (ELT) and/or portable personal locator beacons (PLB) are carried on aircraft so that in the event of an accident in a remote location, the aircraft wreckage and its occupants can be located quickly and efficiently by SAR operations.

Finding the aircraft wreckage quickly not only increases the chance of survival of the occupants, but also reduces the risk to crew of SAR aircraft who commonly need to operate in less-than-optimal conditions. In this instance, not carrying an ELT and/or PLB, did increase the risk of delayed search and rescue action, however, in this case was fortuitously witnessed by nearby landowners. Additionally, the pilot did not leave a flight note with a responsible person in case the flight did not reach its intended destination, diverted to other locations, or if a timely activation of a search and rescue (SAR) response was required.

Findings

|

ATSB investigation report findings focus on safety factors (that is, events and conditions that increase risk). Safety factors include ‘contributing factors’ and ‘other factors that increased risk’ (that is, factors that did not meet the definition of a contributing factor for this occurrence but were still considered important to include in the report for the purpose of increasing awareness and enhancing safety). In addition ‘other findings’ may be included to provide important information about topics other than safety factors. These findings should not be read as apportioning blame or liability to any particular organisation or individual. |

From the evidence available, the following findings are made with respect to the engine failure and collision with terrain involving a S.E.D.E. Morane-Saulnier MS-893A, 22 km south-west of Archerfield Airport, Queensland, on 6 November 2020.

Contributing factors

- The engine sustained a mechanical failure, most likely as a result of material degradation and impulse loading of the number 2 connecting rod journal bearing.

- After experiencing an inflight engine failure, the pilot conducted a downwind forced landing into a paddock while experiencing reduced visibility from smoke and oil over the windscreen. The landing roll could not be arrested before over-running the paddock and impacting trees.

Other factors that increased risk

- The pilot's pre-flight planning, preparation, and aircraft familiarisation was limited for the flight, leading to a reduced situational awareness and reduced ability to effectively manage the emergency.

- The aircraft was not fitted with a fixed or portable emergency locator transmitter. Further, the pilot did not leave a flight note with a responsible person for the ferry flight. This increased the risk of post-impact survival factors, such as delayed search and rescue arrival medical attention.

Other findings

- The aircraft had limited usage for an extended period, possibly with no specific engine preservation done while in storage.

- Had the engine been overhauled at the manufacturer's recommended calendar time, the connecting rod journal bearings would have been replaced with post-modification bearings as part of the overhaul process.

Sources and submissions

Sources of information

The sources of information during the investigation included:

- the Bureau of Meteorology

- the Civil Aviation Safety Authority

- Airservices Australia

- the pilot

- witnesses

- the maintenance organisation

- OzRunways recorded data.

References

Australian Government 2021, Aircraft Reciprocating-Engine Failure: An Analysis of Failure in a Complex Engineered System, Australian Transport Safety Bureau, Canberra, ACT, viewed 7 December 2021, <https://www.atsb.gov.au/publications/2007/b20070191>Australian Government 2021, AWB 85-001 Issue 4 – Textron Lycoming Engine Bearings, Civil Aviation Safety Authority, Canberra, ACT, viewed 7 December 2021, <https://www.casa.gov.au/content-search/airworthiness-bulletins/textron-lycoming-engine-bearings>

Australian Government 2021, AWB 85-021 Issue 1 – Piston Engine Low Utilisation Maintenance Practices, Civil Aviation Safety Authority, Canberra, ACT, viewed 7 December 2021, <https://www.casa.gov.au/content-search/airworthiness-bulletins/piston-engine-low-utilisation-maintenance-practices>.

Australian Government 2021, Visual Flight Rules Guide, Civil Aviation Safety Authority, Canberra, ACT, viewed 7 December 2021, <https://www.casa.gov.au/resources-and-education/publications-and-resources/industry-guides-and-publications/pilot-guides/visual-flight-rules-guide>

Lycoming Engines 2021. Service Instruction No 1512 Main and connecting rod bearing upgrade, viewed 7 December 2021, Lycoming Engines <https://www.lycoming.com/content/service-instruction-no-1512 >.

Lycoming Engines 2021. Service Instruction No 1009BE Time Between Overhaul (TBO) Schedules, viewed 7 December 2021, Lycoming Engines <https://www.lycoming.com/service-instruction-1009-be>.

Wikipedia 2021, SOCATA Rallye family, viewed 7 December 2021, Wikipedia, <https://en.wikipedia.org/wiki/SOCATA_Rallye_family>.

Submissions

Under section 26 of the Transport Safety Investigation Act 2003, the ATSB may provide a draft report, on a confidential basis, to any person whom the ATSB considers appropriate. That section allows a person receiving a draft report to make submissions to the ATSB about the draft report.

A draft of this report was provided to the following directly involved parties:

- the pilot of VH-UQI

- the owner of VH-UQI

- the Civil Aviation Safety Authority

- the maintenance provider.

A submission was received from the Civil Aviation Safety Authority. The submission was reviewed and, where considered appropriate, the text of the draft report was amended accordingly.

Purpose of safety investigationsThe objective of a safety investigation is to enhance transport safety. This is done through:

It is not a function of the ATSB to apportion blame or provide a means for determining liability. At the same time, an investigation report must include factual material of sufficient weight to support the analysis and findings. At all times the ATSB endeavours to balance the use of material that could imply adverse comment with the need to properly explain what happened, and why, in a fair and unbiased manner. The ATSB does not investigate for the purpose of taking administrative, regulatory or criminal action. TerminologyAn explanation of terminology used in ATSB investigation reports is available here. This includes terms such as occurrence, contributing factor, other factor that increased risk, and safety issue. Publishing informationReleased in accordance with section 25 of the Transport Safety Investigation Act 2003 Published by: Australian Transport Safety Bureau © Commonwealth of Australia 2023

Ownership of intellectual property rights in this publication Unless otherwise noted, copyright (and any other intellectual property rights, if any) in this report publication is owned by the Commonwealth of Australia. Creative Commons licence With the exception of the Coat of Arms, ATSB logo, and photos and graphics in which a third party holds copyright, this publication is licensed under a Creative Commons Attribution 3.0 Australia licence. Creative Commons Attribution 3.0 Australia Licence is a standard form licence agreement that allows you to copy, distribute, transmit and adapt this publication provided that you attribute the work. The ATSB’s preference is that you attribute this publication (and any material sourced from it) using the following wording: Source: Australian Transport Safety Bureau Copyright in material obtained from other agencies, private individuals or organisations, belongs to those agencies, individuals or organisations. Where you wish to use their material, you will need to contact them directly. |

[1] Eastern Daylight-saving Time: Coordinated Universal Time (UTC) +11 hours.

[2] Visual flight rules (VFR): a set of regulations that permit a pilot to operate an aircraft only in weather conditions generally clear enough to allow the pilot to see where the aircraft is going.

[3] Danger area: Airspace of defined dimensions in which activities dangerous to flight may exist at specific times.

[4] Restricted area: Airspace within which the flight of aircraft is restricted in accordance with specified conditions.

[5] Eastern Standard Time: Coordinated Universal Time (UTC) +10 hours.

[6] MAYDAY: an internationally recognised radio call announcing a distress condition where an aircraft or its occupants are being threatened by serious and/or imminent danger and the flight crew require immediate assistance.

[7] Aerodrome terminal information service (ATIS): a continuous and repetitive broadcast that provides current, routine information to arriving and departing aircraft. That information normally includes current meteorological conditions at the airfield, as well as expected approach requirements.

[8] OzRunways utilises approved data for electronic maps to be used for navigation. RWY is the application utilised on Android devices.

[9] During 1966, the Morane-Saulnier company changed its name to Societe de Construction d'Avions de Tourisme et d'Affaires (S.O.C.A.T.A.). The aircraft is also known as a SOCATA MS.893A.

[10] Slat: Moveable portion of leading edge of aerofoil, which in cruising flight is recessed against main structure and forms part of the profile; at high angle of attack either lifts away under its own aerodynamic load or is driven under power to move forward and down and leave an intervening slot.

[11] Aileron: Control Surface, traditionally hinged to outer wing and forming part of the trailing edge, providing control in roll about the longitudinal axis.

[12] Fowler flap: Special form of split flap that moves at first rearwards and then downwards along a track, thus producing an initial large increase in lift and at full deflection giving high lift and drag for landing.

[13] On-condition: Performed only when the condition of an item demands, instead of at scheduled intervals.

[14] The high-power engines analysed as part of the study were Lycoming TIO-540 and IO-540, and Continental TSIO-520 and GTSIO-520 engines.

[15] SARTIME: An abbreviation for ‘time search action required’. A SARTIME is the time nominated by a pilot for the initiation of Search and Rescue (SAR) action.