Safety summary

What happened

On 22 June 2019, a Robinson Helicopter Company R22, registered VH-HHQ, departed Kutchera Station, Queensland to perform mustering operations. During mustering, as the pilot was manoeuvring the helicopter, the right tail rotor (or anti-torque) pedal cracked and became stuck. The pilot was unable to dislodge the pedal and prepared for an immediate landing in accordance with the stuck pedal procedure. Just prior to landing, the helicopter struck a tree and became uncontrollable. The aircraft impacted the ground and although the pilot was uninjured, the helicopter was substantially damaged.

What the ATSB found

Following examination of the helicopter by the maintenance organisation, a significant fracture was noted at a weld located on a right angle join between two sections of tube. The right pedal was removed from the helicopter and sent to the ATSB for further examination and testing. The ATSB found that the pedal had fractured as a result of a fatigue failure, which had initiated at the welded joint, and progressed until the remaining section of the tube could no longer sustain the in‑service loads. It was considered likely that a pre-existing crack had initiated at the highest stress part of the component, and had opened up following the load applied during the manoeuvre described by pilot, rendering the pedal unserviceable.

The tail rotor pedal had been recently inspected as part of routine maintenance and while it was considered likely that the developing crack was present, it was not detected at that inspection. However, it was considered that this was due to the inherent difficulties associated with inspections at the location of the cracking.

What has been done as a result

While not required as part of the routine inspections, the maintenance organisation has added the tail rotor pedals to the list of components that undergo magnetic particle inspection at each 2,200‑hour overall.

Safety message

The location of the fatigue crack in this accident highlighted the need to be vigilant when performing inspections in difficult or hard to reach places. In the case of the tail rotor pedal, the inspection was made difficult due to the location, and required a torch and mirror to inspect a matte black surface.

Additionally, the quick thinking actions of the pilot following the failure resulted in a good outcome, with no injuries reported.

| Decisions regarding whether to conduct an investigation, and the scope of an investigation, are based on many factors, including the level of safety benefit likely to be obtained from an investigation. For this occurrence, a limited-scope investigation was conducted in order to produce a short investigation report, and allow for greater industry awareness of findings that affect safety and potential learning opportunities. |

The occurrence

On 22 June 2019, the pilot of a Robinson Helicopter Company R22 helicopter, registered VH‑HHQ, departed Kutchera Station, Queensland to perform mustering operations. While mustering, the pilot applied a small amount of right tail rotor (or anti-torque) pedal[1] to manoeuvre the helicopter to turn back in the opposite direction. During this time, and as the pilot reported repositioning in the seat, the right pedal cracked, which caused it to bend forward and become stuck. The pilot grabbed the right pedal in an attempt to free it and allow the use of the left pedal, but was unable to do so. The pilot continued the flight to the nearest safe cleared area to land and commenced the jammed pedal procedure.[2]

When about 50 ft above ground level, as the pilot was preparing to perform a running landing,[3] it was reported that a gust of wind hit the helicopter from an angle, causing it to spin. The helicopter then hit a tree and then became uncontrollable before coming to rest on the ground. The pilot shutdown the helicopter and exited. There were no reported injuries, however, the helicopter was substantially damaged.

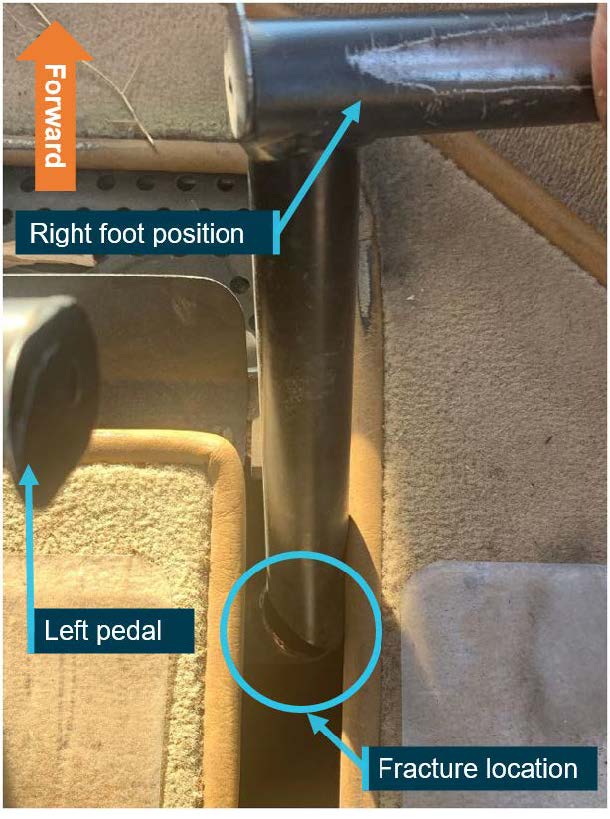

Following examination of the helicopter by the maintenance organisation, a significant fracture was noted on the right tail rotor pedal assembly at a weld located on a right angle join between two sections of thin walled tube (Figure 1). This join was between the vertical section of tube where the pilot places their foot, and the horizontal tube connecting to the tail rotor controls, and sits slightly below the cabin floor. The pedal was removed from the helicopter and sent to the ATSB’s technical facilities in Canberra for further examination and testing.

Figure 1: Fractured right tail rotor pedal as installed on VH-HHQ

Source: Operator, annotated by the ATSB

Context

Tail rotor pedal examination

The ATSB’s initial examination of the right tail rotor pedal (part number A330-1), which had a matte black surface, found that:

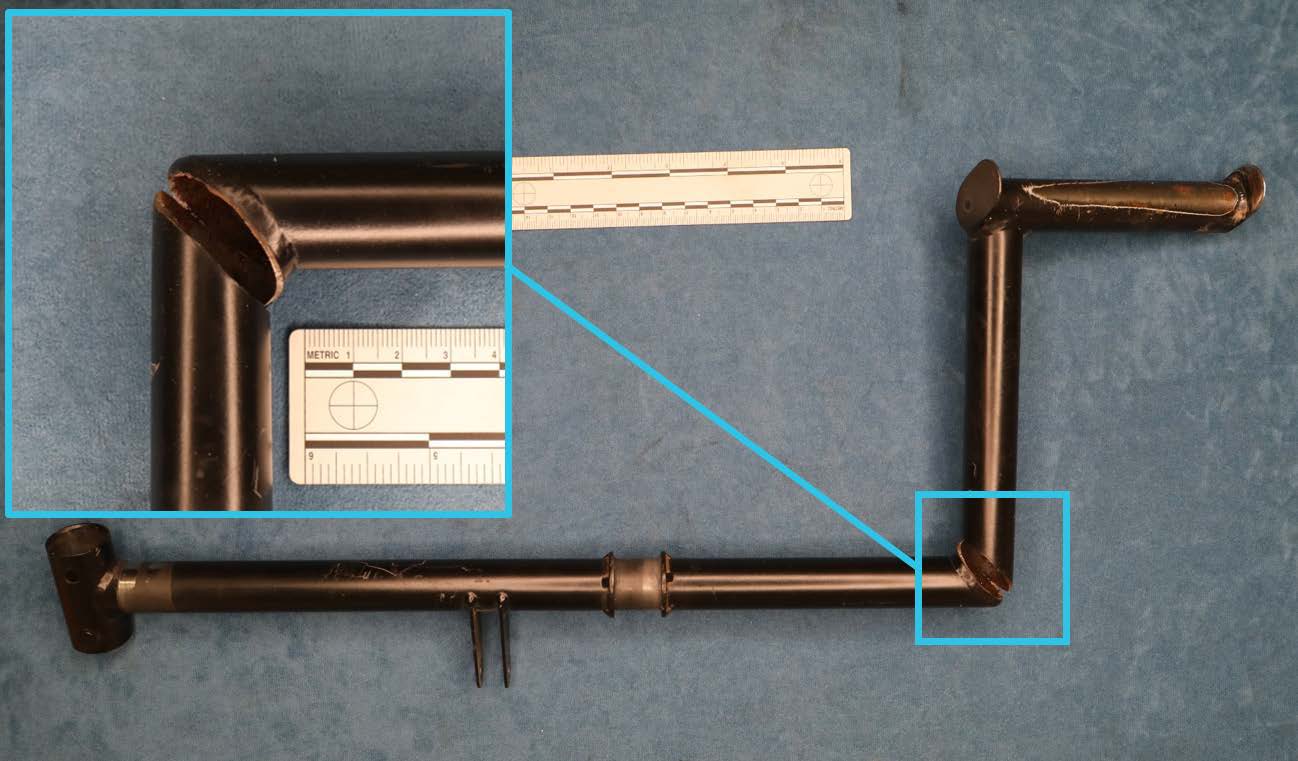

- The weld had fractured on the side of the pedal closest to the pilot seat (Figure 2).

- While the fracture was not through the entire section of the tube, the pedal assembly was no longer capable of maintaining loads and transferring pilot inputs.

- The pedal did not show any evidence of dints, scratches or other signs of mechanical damage.

- Wear, in the form of missing paint and a shiny smooth surface, was observed on the pedal surface in contact with the pilot’s foot.

Some evidence of corrosion product was observed within the tubes. Robinson advised that this was the first known occurrence of internal corrosion. As part of the manufacturing process, to ensure the removal of any residual moisture, a small breather hole was left open, and the entire assembly heated to remove any internal moisture, before the breather hole was welded shut. Robinson also advised that the amount of corrosion observed appeared to be more than residual moisture from manufacture. They stated that, as the tubes were completely sealed, there was no inspection to detect internal corrosion.

Figure 2: Right tail rotor pedal as received by the ATSB, showing the location of the fracture

Source: ATSB

Following the initial examination, the pedal was fractured in the ATSB laboratory to separate and expose the two fracture surfaces. The majority of the fracture surface was discoloured and exhibited evidence of pre-existing cracking consistent with a fatigue failure (Figure 3). While the surface features were difficult to distinguish, the discolouration was indicative that the crack had been present for some period of time prior to the failure. While it appeared that the crack had initiated along the edge of the weld, no exact origin could be identified. However, the location of cracking was coincident with the location where the pilot input on the vertical tube was transferred to the horizontal tube, which is connected to the tail rotor push-pull tube assembly. As such, this area was subject to the largest torsional bending stress.

Figure 3: Right tail rotor pedal fracture surface following fracture by the ATSB

Source: ATSB

Following the examination of the fracture surface, it was then sectioned in the region adjacent to the likely origin for further inspection. The general fracture surface profile was consistent with a fatigue fracture. While the internal surface of the tube exhibited some evidence of pitting and general corrosion, there was no evidence that the crack initiated at one of these locations. Additionally, as the tubes were completely sealed, it was more likely that the corrosion product was the result of moisture ingress following the initiation of the fatigue crack.

The microstructure of the weld and tube was consistent with a low alloy steel in the heat-treated condition. A microhardness traverse test was conducted from the fracture surface through the weld heat affected zone into the parent metal and was consistent with the material type in the heat-treated condition. These observations complied with the information provided by the manufacturer.

Maintenance history

The helicopter (serial number 4071) had accumulated 5,828.4 hours total time-in-service at the time of the accident. Inspection of the tail rotor pedals was performed at both the 100-hourly inspection and 2,200-hour overhaul. The most recent 100-hourly inspection was performed 37.2 hours prior to the failure, while the 2,200-hour overhaul was completed in February 2017. At the 100-hourly inspection, the maintenance manual task for the pedals stated:

Inspect condition. Verify no cracks. Verify security and operating clearance.

There was no requirement to remove the bearing block cover plates, an access cover on the floor of the cabin, covering the horizontal portion of the rail rotor pedal. While the location of cracking in this occurrence was slightly under the cabin floor, Robinson advised that the affected weld would normally be visible using a torch and a mirror during the inspection. They also advised that the pedal needed to be moved forward and backward to see both sides. In addition to the 100-hourly inspections, at each 2,200-hour overhaul the pedals were removed for closer inspection.

The manufacturer further advised that, where maintenance was undertaken at a field service centre, as was the case for VH-HHQ, the pedals were subject to visual inspection only. However, if the overhaul was performed at the Robinson factory (not available in Australia), the pedals would be examined using a magnetic particle inspection (MPI).[4] This technique would be more likely to identify surface defects, as the paint would be removed prior to the testing, and the contrasting nature of the test medium would mean that cracks would be highly visible.

Similar failures

Robinson advised that they were aware of previous in-service fractures near the weld, however, the cause was either attributed to a modification to the assembly which involved some type of pedal extension (one case) or impact/mechanical damage. A search of the Civil Aviation Safety Authority’s defect report service and ATSB occurrence databases for the previous 10 years did not identify any other similar failures.

Safety analysis

While manoeuvring during mustering operations, the right tail rotor pedal failed and became stuck. The pilot elected to land immediately, but during this, the helicopter struck a tree. The helicopter became uncontrollable and impacted the ground, resulting in substantial damage.

The tail rotor pedal failed as a result of a fatigue failure at a right angle welded joint between two sections of thin walled tube. While the ATSB’s examination identified that the fatigue failure had initiated adjacent to the weld line, the exact origin could not be determined. This location of the cracking was also coincident with the point of maximum torsional bending stress in normal operation. The microstructure and hardness of the tube and weld were consistent with the requirements as specified by the manufacturer.

The pedal had undergone a visual examination at the most recent 100-hourly inspection. While it was likely the crack was present at this inspection, the nature and location of the crack would have made it inherently difficult to detect. The developing fatigue crack would have initially presented as a hairline feature, and it was located on a matte black surface, at a change in section slightly below the level of the cabin floor.

Findings

|

ATSB investigation report findings focus on safety factors (that is, events and conditions that increase risk). Safety factors include ‘contributing factors’ and ‘other factors that increased risk’ (that is, factors that did not meet the definition of a contributing factor for this occurrence but were still considered important to include in the report for the purpose of increasing awareness and enhancing safety). In addition, ‘other findings’ may be included to provide important information about topics other than safety factors. These findings should not be read as apportioning blame or liability to any particular organisation or individual. |

From the evidence available, the following findings are made with respect to the tail rotor pedal failure and collision with terrain involving Robinson R22 helicopter, VH HHQ near Kutchera Station, Queensland, on 22 June 2019.

Contributing factors

- While conducting mustering operations, the right tail rotor pedal failed due to fatigue cracking. During the subsequent emergency landing, the helicopter struck a tree and became uncontrollable, before coming to rest on the ground.

- Due to undetermined reasons, a fatigue crack had initiated adjacent to a weld at a high stress location on the pedal. It was likely that the crack had been present at the most recent maintenance inspection, but the location of the weld may have made it difficult to detect in-situ.

Safety actions

| Whether or not the ATSB identifies safety issues in the course of an investigation, relevant organisations may proactively initiate safety action in order to reduce their safety risk. All of the directly involved parties are invited to provide submissions to this draft report. As part of that process, each organisation is asked to communicate what safety actions, if any, they have carried out to reduce the risk associated with this type of occurrences in the future. The ATSB has so far been advised of the following proactive safety action in response to this occurrence. |

Increased maintenance inspections

As a result of this accident, the maintenance provider has advised that, although not required by the maintenance manual, the tail rotor pedal assembly will now be included with other components that are sent for magnetic particle inspection at every 2,200-hourly overhaul.

Sources and submissions

Sources of information

The sources of information during the investigation included the:

- the pilot

- Robinson Helicopter Company

- the helicopter owner and maintainer.

References

United States Federal Aviation Administration (2019), Helicopter Flying Handbook, FAA-H-8083-21B.

Submissions

Under section 26 of the Transport Safety Investigation Act 2003, the ATSB may provide a draft report, on a confidential basis, to any person whom the ATSB considers appropriate. That section allows a person receiving a draft report to make submissions to the ATSB about the draft report.

A draft of this report was provided to the following directly involved parties:

- the pilot

- the helicopter owner

- the helicopter maintainer

- Robinson Helicopter Company

- National Transportation Safety Board

- Civil Aviation Safety Authority.

Any submissions from those parties were reviewed and, where considered appropriate, the text of the draft report was amended accordingly.

Purpose of safety investigationsThe objective of a safety investigation is to enhance transport safety. This is done through:

It is not a function of the ATSB to apportion blame or provide a means for determining liability. At the same time, an investigation report must include factual material of sufficient weight to support the analysis and findings. At all times the ATSB endeavours to balance the use of material that could imply adverse comment with the need to properly explain what happened, and why, in a fair and unbiased manner. The ATSB does not investigate for the purpose of taking administrative, regulatory or criminal action. TerminologyAn explanation of terminology used in ATSB investigation reports is available here. This includes terms such as occurrence, contributing factor, other factor that increased risk, and safety issue. Publishing informationReleased in accordance with section 25 of the Transport Safety Investigation Act 2003 Published by: Australian Transport Safety Bureau © Commonwealth of Australia 2020

Ownership of intellectual property rights in this publication Unless otherwise noted, copyright (and any other intellectual property rights, if any) in this report publication is owned by the Commonwealth of Australia. Creative Commons licence With the exception of the Coat of Arms, ATSB logo, and photos and graphics in which a third party holds copyright, this publication is licensed under a Creative Commons Attribution 3.0 Australia licence. Creative Commons Attribution 3.0 Australia Licence is a standard form licence agreement that allows you to copy, distribute, transmit and adapt this publication provided that you attribute the work. The ATSB’s preference is that you attribute this publication (and any material sourced from it) using the following wording: Source: Australian Transport Safety Bureau Copyright in material obtained from other agencies, private individuals or organisations, belongs to those agencies, individuals or organisations. Where you wish to use their material, you will need to contact them directly. |

__________

- The tail rotor pedal is used to change the pitch of the tail rotor, in order to control the torque of the main rotor and to provide movement about the yaw axis of the helicopter.

- This procedure is required where a mechanical failure leads to the inability of the pilot to change or control tail rotor thrust even though the tail rotor is still capable of producing anti-torque thrust. The Robinson Helicopter Company R22 Pilot’s Operating Handbook did not include any guidance related to jammed (or stuck) pedals. The United States Federal Aviation Administration Helicopter Flying Handbook included a generalised description of procedures when more specific procedures were not available:

The landing profile for a stuck neutral or a stuck right pedal is a low-power approach terminating with a running or roll-on landing. The approach profile can best be described as a shallow to normal approach angle to arrive approximately 2–3 feet landing gear height above the intended landing area with a minimum airspeed for directional control. The minimum airspeed is one that keeps the nose from continuing to yaw to the right. - A running landing is used to transition from forward flight to landing on the surface when there may not be sufficient power available to sustain a hover. This manoeuvre may also be conducted in some emergency situations such as certain tail rotor failures or stuck pedals.

- Magnetic particle inspection is a non-destructive testing process widely used to inspect ferromagnetic materials, such as iron, nickel, cobalt and some of their alloys, for surface and shallow sub-surface discontinuities.