What happened

On 14 October 2017, a Boeing 777-300 aircraft, registered A6-ETR and operated by Etihad Airways, was on a scheduled passenger service from Abu Dhabi, United Arab Emirates (UAE) to Sydney, New South Wales. An augmented flight crew, consisting of two pilots in each crew (crew A and crew B) conducted the flight.[1]

At about 0407 Central Daylight-saving Time,[2] while in the cruise and with flight crew B flying the aircraft, the flight crew noticed a burning smell coming from an air vent. In an attempt to establish the source of the smell, they requested that cabin crewmembers check the forward galley. The cabin crew confirmed that the forward galley was clear of any burning smells or smoke. The flight crew then requested two other cabin crewmembers enter the flight deck, who confirmed the burning smell. Around this time, the aural fire bell activated, a master warning light illuminated and a warning message ‘FIRE CARGO FWD’ was displayed on the engine-indicating and crew‑alerting system.

In response, the flight crew actioned the non-normal checklist, which included arming the forward cargo fire switches located in the flight compartment overhead panel. This action resulted in numerous mechanical and electrical actions, including de-energising the recirculation fan[3] and closing the air vents in the forward cargo compartment. The flight crew then selected the cargo fire discharge switch, which discharged the two fire extinguisher bottles located in the forward cargo compartment.[4] The flight crew declared a MAYDAY[5] to air traffic control and advised of their intention to divert to Adelaide Airport, South Australia, as it was the nearest suitable airport for the aircraft type.

Flight crew A had just completed their scheduled rest period and entered the flight deck where they were briefed by flight crew B of the situation. Flight crew A assumed control of the aircraft as they were the designated crew for landing. Flight crew B remained on the flight deck to provide assistance. A rapid descent to flight level (FL)[6] 125 was conducted and the aircraft was diverted to Adelaide.

During the remainder of the flight, the cabin crew, operator and passengers were informed of the situation and the diversion. The flight crew also advised air traffic control that, if smoke or fire from the forward cargo compartment was confirmed by emergency services upon landing, they would evacuate the aircraft on the runway.

At 0455, the aircraft landed uneventfully. The emergency services advised the flight crew that they did not observe any smoke or fire emanating from the aircraft. The aircraft was taxied from the runway to taxiway ‘F6’, where the emergency services inspected the aircraft externally with a thermal imaging camera. They confirmed that there were no identified hot spots indicating an on‑going fire in the forward cargo compartment. Based on this information, as a precaution, the crew decided to conduct a rapid deplane of the passengers through passenger door 5L using mobile boarding stairs. All passengers and crew disembarked in a controlled manner and were transported to the passenger terminal. Nil injuries were reported during the disembarkation.

Initial engineering inspection

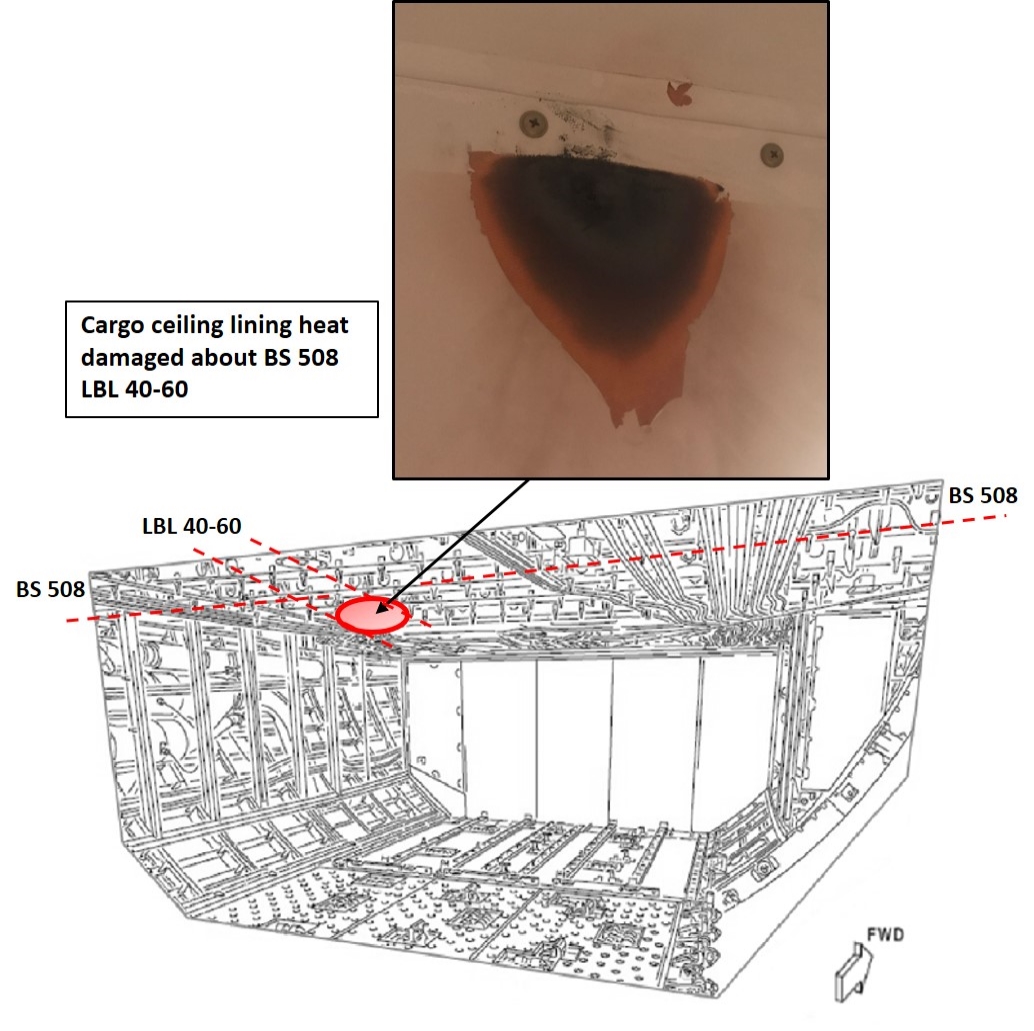

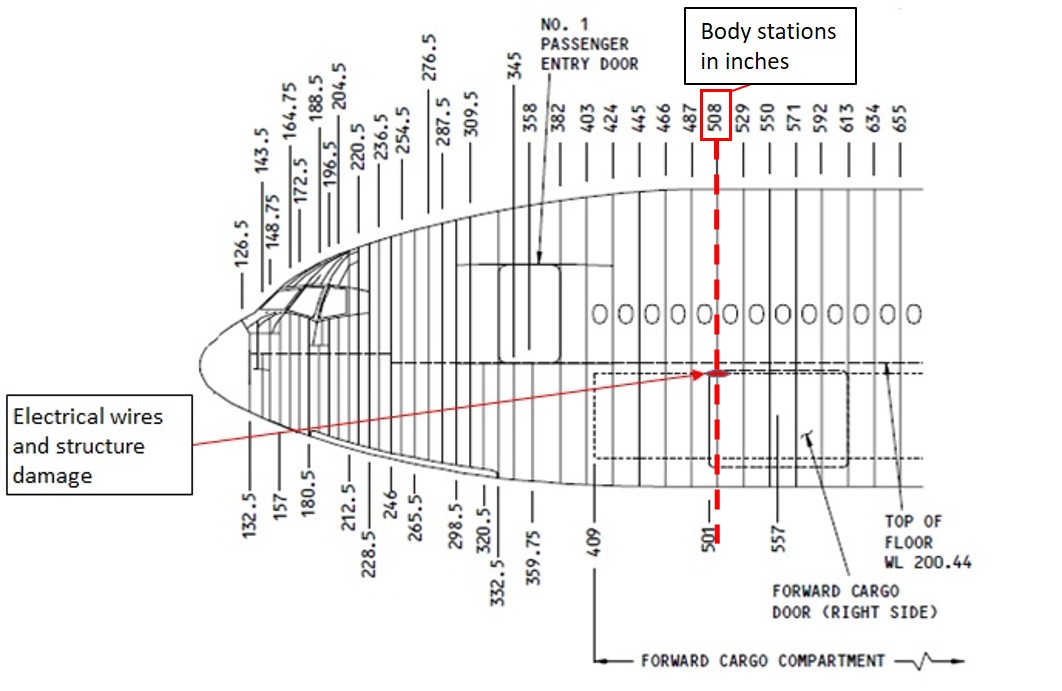

Once the forward cargo compartment was emptied of cargo, maintenance engineers inspected the cargo hold for evidence of fire. A small quantity of soot was identified in the cargo ceiling area, between the fiberglass ceiling panel and fiberglass joint sealing tape about aircraft body station (BS) 508 (Figure 1).

Figure 1: Illustration showing aircraft structure in the forward cargo hold in relation to heat damage from electrical arcing about BS 508

Source: The Boeing Company, modified by the ATSB

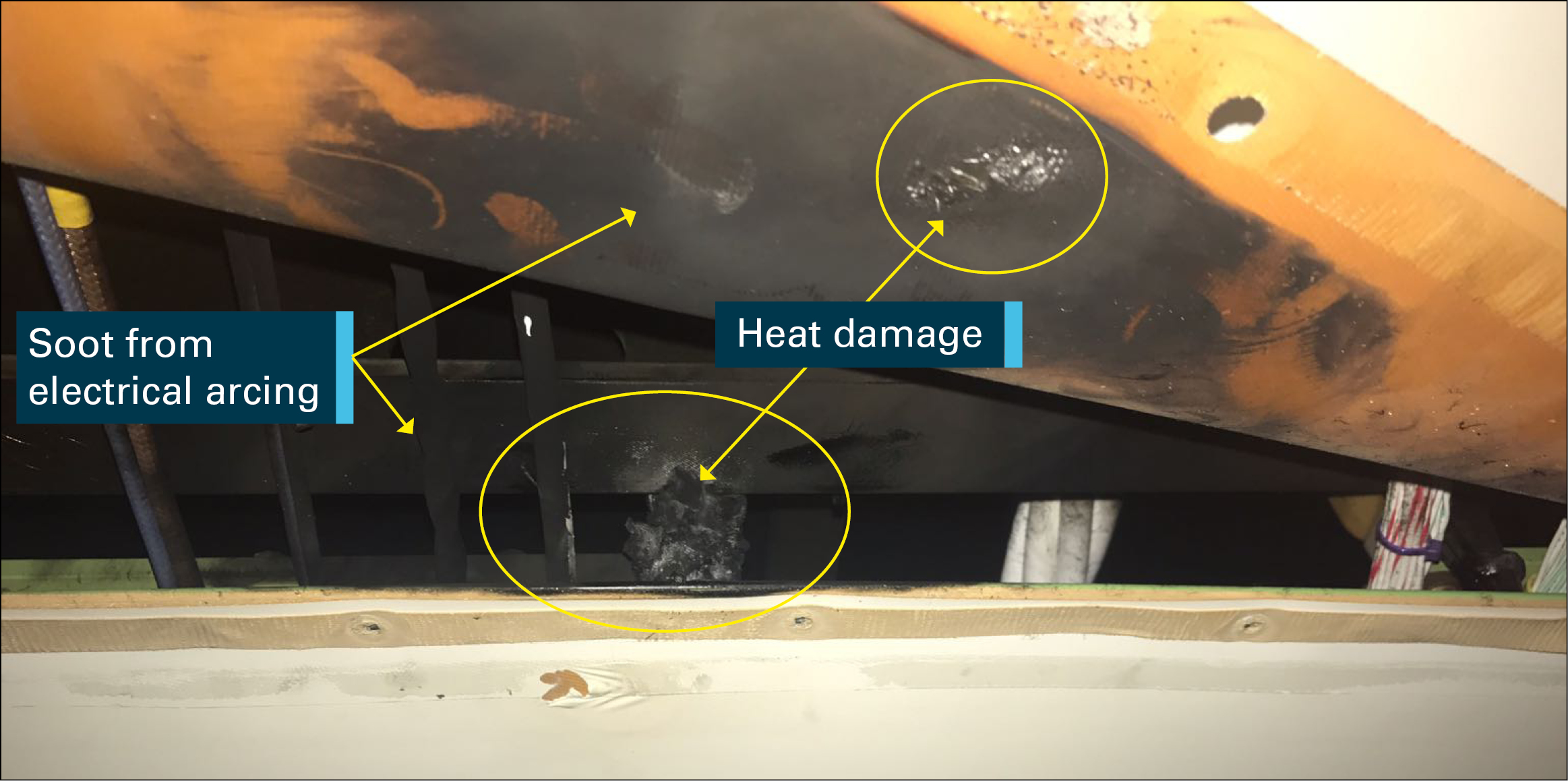

The ceiling panels were removed where soot was identified in the area between the lower side of the cabin floor and the upper side of the cargo-ceiling panel (Figure 2). Inspection of that area found heat damage and chafed 115-volt electrical wire in wiring loom P/N W5279-3002R-12 (W5279), which supplied power to the right lower recirculation fan. The chafing enabled the wire core to come in contact with a cargo ceiling panel retainer screw where the short circuited wire tracked through the polyetheretherketone resin (PEEK) stand-off brackets and carbon fibre floor beam.

Figure 2: Damaged floor beams, webs and wiring covered in soot with ceiling panel opened

Source: Etihad Airways, modified by the ATSB

In consultation with Boeing and operator’s aviation regulator, the United Arab Emirates General Aviation Authority, the operator temporarily repaired the wiring and the damage to the floor beams were evaluated. The operator conducted a non-revenue flight (nil passengers) where they flew the aircraft back to the UAE for the purpose of further inspections and permanent repairs.

Detailed engineering inspection

A detailed inspection between the forward cargo ceiling and passenger floor was conducted at the operator’s maintenance facility in the UAE. Wire bundle W5279, located at about BS 508 was found to have been incorrectly routed. Consequently, the wires had come into contact with screws and nutplates used to close out the cargo-ceiling panel to the ceiling standoff clips.

Over a prolonged period of time, the 115V recirculation fan wire located within that bundle chafed through the insulation coating, allowing the wire to short circuit. The electrical wiring and fourteen of the cargo ceiling panel standoff clips manufactured from PEEK were heat damaged. Sections of the carbon fibre beam web and beam flange at BS 508 between the left buttock[7] lines 40 to 60 were also found to be heat damaged and delaminated between 6 and 7 percent in three locations where the current tracked (Figure 3).

Figure 3: Boeing 777 aircraft showing the approximate location of the heat damaged ceiling panel, soot and heat damaged wiring loom

Source: The Boeing Company, modified by the ATSB

Boeing determined that the wiring loom W5279 was likely to have been incorrectly positioned during the aircraft build in 2013. Boeing reported that this was the fifth reported incident involving wire chafing and arcing in the cargo area of a Boeing 777 aircraft. However, this was the first event that triggered the cargo fire warning system and that had been detected in flight. In all of these cases, the wiring loom had been installed incorrectly during manufacture, allowing screws to chafe wires and short circuit.

Recirculation fan wiring protection system

The 115V recirculation fan wiring system is protected by an electrical load control unit (ELCU) that is located in the aircraft’s main equipment centre. The ELCU is designed to protect the electrical circuit from over-current or differential loads by automatically opening (‘tripping’) to remove power. In this incident, despite the damage sustained to recirculation fan wiring it was reported that the ELCU did not open.

The circuit was tested during the repair of the wiring loom where it was identified that the ELCU functioned as designed. Boeing surmised that in this case, it was possible that the chafed wire may have been intermittently shorting to earth through the PEEK stand-off brackets. It is likely that the insulation properties of the PEEK prevented sufficient current draw to trip the ELCU.

Boeing also surmised that it was likely that the crew’s action of arming the forward cargo fire switches de-energised the chafed wire within loom W5279, thereby preventing further current flow and short circuit.

Cargo compartment fire protection

Materials used in the construction of passenger compartment interiors and in the space between the cabin floor and cargo ceiling are required by the United States Federal Aviation Administration to be self-extinguishing (i.e. stop burning after the heat source has been removed) or better. For example, electrical wire and cable insulation must be self-extinguishing. Cargo liners form part of the passive fire protection feature. In addition, the primary purpose of a cargo liner is to prevent a fire, originating in a cargo compartment, from spreading to other parts of the aircraft and to seal the compartment to help contain the suppression agent in that area.

In Class C cargo compartments, which include the lower cargo compartments of all passenger aircraft, the sidewall and ceiling liner panel installations are fire tested to determine flame penetration resistance. All other materials must be self-extinguishing.

Safety analysis

The flight crew identified a burning smell in the flight deck and completed the appropriate actions to manage the situation. By arming the forward cargo fire suppression system, electrical power was removed from the recirculation fans, which prevented further arcing and damage to the structural carbon fibre beam, support brackets and wiring. Even though there was a significant amount of soot and electrical arcing, de-energising the electrical circuit manually before sufficient current went to ground negated the electrical load control unit from tripping. It was likely that, once the electrical current was deactivated by arming the forward cargo fire switches, the smoke had also stopped. Discharging the fire bottles in the forward cargo space, even though procedurally correct, had nil effect on this occasion as the source of the electrical arcing was in the sealed zone between the cargo ceiling panel and the passenger floor compartment, not in in the cargo compartment.

A post-incident inspection of the aircraft found an electrical wiring harness (W5279) was in an incorrect location. Consequently, one of the forward cargo ceiling liner retainer screws chafed on the wires, which resulted in the electrical current from the chafed wire dispersing through the passenger floor carbon fibre beam about body station 508. That electrical current generated significant heat where 14 of the cargo ceiling polyetheretherketone resin standoff brackets were heat damaged and several areas of the structural carbon fibre beam were chafed and delaminated. The smoke generated from the arcing was of a magnitude that it migrated through the forward cargo ceiling liner into the forward cargo compartment and activated the forward cargo fire detection system.

This incident was the fifth reported case where damage to the wire bundles in the forward (and aft) cargo compartment of a Boeing 777 aircraft has occurred from chafing on a ceiling liner screw and/or nutplate. This was the first event that triggered the cargo fire warning and the only event to have been detected in air. A subsequent investigation conducted by Boeing found that the wire bundle W5279 had been incorrectly routed, likely during aircraft manufacture, and had not been installed as per the design drawings. Slight variations of the wire bundle position allowed it to run directly above the screw and nutplate, which chafed the wire bundle over time.

Findings

These findings should not be read as apportioning blame or liability to any particular organisation or individual.

- During cruise, a burning smell was detected in the flight deck and the forward cargo compartment fire warning activated. The flight crew armed and set the forward cargo fire suppression system and diverted the aircraft to the nearest airport for a safe landing.

- A wiring loom situated above the forward cargo compartment about body station 508 was incorrectly routed, likely during manufacture of the aircraft. Over several years, wires in that loom chafed against the support structure and short circuited. Electrical arcing created smoke that activated the forward cargo smoke detector.

Safety actions

Whether or not the ATSB identifies safety issues in the course of an investigation, relevant organisations may proactively initiate safety action in order to reduce their safety risk. The ATSB was advised of the following proactive safety action in response to this occurrence.

Aircraft manufacturer

As a result of this occurrence, Boeing advised the ATSB that they have taken the following safety actions:

Fleet communication

Boeing issued a ‘Fleet Communication’, 777-FTD-24-18001 to all Boeing 777 aircraft operators informing them of this issue:

Boeing has received reports of five separate in-service events where a ceiling liner screw in the forward cargo compartment was found in contact with a wire bundle, resulting in a short to ground that damaged cargo ceiling standoffs, the wire bundle, and the floor beam in some cases.

Wire installation inspections

Boeing recommend interim action:

Operators can choose to inspect the wire bundle runs in the forward cargo compartment and locate instances where the ceiling liner screws and nutplates are in contact or do not have 0.13 Inch clearance with the wire bundle. Wire harnesses should have a minimum separation distance of 0.13 inch to sharp edges of structure and equipment per SWPM (D6-54446), Sec 20-10-11 Page 39, table 21 ‘Minimum Clearance’. If a riding condition is found, Boeing can provide technical assistance if required to provide corrective action. The wire routing installation drawings can be reviewed to determine the correct routing of wire bundles in the cargo compartment.

In addition, Boeing has issued Service Bulletin 777-24-0157, which would require operators to inspect for and correct similar conditions that led to this occurrence. Service Bulletin 777-24-0157 relate to all Boeing 777-200,777-200LR, 777-300ER aircraft line numbers 1-1527 inclusive.

Boeing Engineering performed an investigation of all cargo ceiling wire bundle installation engineering drawings. Boeing will add additional spacing as a precaution when wire bundles are in close proximity to ceiling liner screws.

…inspect and made changes to wire bundles near ceiling liner nutplate locations, in the forward and aft cargo compartments. If this service bulletin is not done, wire chafing can result in a short circuit and a system failure.

There have been five reports of wire chafing on ceiling liner screws or nutplates. Several ceiling liner support standoffs were damaged by heat which was caused by the grounding path. The floor beam was also damaged. Wire bundles near heat damaged ceiling liner support standoffs have also been damaged. The wire bundles that do not have the correct clearance from the ceiling liner screws, can result in chafing causing exposed conductors and shorting.

Boeing has also taken action in their production line by inspecting aircraft from line number 1529 for correct installation. Boeing are also considering installation and design changes to new production aircraft to alter the position of the effected wiring loom to prevent recurrence.

Safety message

Despite complex systems of design and manufacturing, training, and quality control, errors do occur during manufacturing that may not be apparent for some time. In this case, the aircraft was manufactured 4 years prior to the incident.

While this was a serious incident, the severity of the damage sustained was minimised through regulatory design requirements, material composition, system protections and crew actions. In response to this, and four other incidents, the aircraft manufacturer utilised their system of communication to alert all operators of the issue and took actions in an effort to prevent reoccurrence. Regardless of this, operators and maintenance providers are another line of defence for detecting errors. Due diligence during scheduled aircraft maintenance and defect rectification will assist with ensuring that aircraft systems meet the design intent and function accordingly.

Purpose of safety investigationsThe objective of a safety investigation is to enhance transport safety. This is done through:

It is not a function of the ATSB to apportion blame or provide a means for determining liability. At the same time, an investigation report must include factual material of sufficient weight to support the analysis and findings. At all times the ATSB endeavours to balance the use of material that could imply adverse comment with the need to properly explain what happened, and why, in a fair and unbiased manner. The ATSB does not investigate for the purpose of taking administrative, regulatory or criminal action. TerminologyAn explanation of terminology used in ATSB investigation reports is available here. This includes terms such as occurrence, contributing factor, other factor that increased risk, and safety issue. Publishing informationReleased in accordance with section 25 of the Transport Safety Investigation Act 2003 Published by: Australian Transport Safety Bureau © Commonwealth of Australia 2018

Ownership of intellectual property rights in this publication Unless otherwise noted, copyright (and any other intellectual property rights, if any) in this report publication is owned by the Commonwealth of Australia. Creative Commons licence With the exception of the Coat of Arms, ATSB logo, and photos and graphics in which a third party holds copyright, this publication is licensed under a Creative Commons Attribution 3.0 Australia licence. Creative Commons Attribution 3.0 Australia Licence is a standard form licence agreement that allows you to copy, distribute, transmit and adapt this publication provided that you attribute the work. The ATSB’s preference is that you attribute this publication (and any material sourced from it) using the following wording: Source: Australian Transport Safety Bureau Copyright in material obtained from other agencies, private individuals or organisations, belongs to those agencies, individuals or organisations. Where you wish to use their material, you will need to contact them directly. |

__________

- A crew that comprises more than the minimum number required to operate the aircraft and in which each crew member can leave their assigned position and be replaced by another appropriately qualified crew member for the purpose of inflight rest.

- Central Daylight-saving Time (CDT): Coordinated Universal Time (UTC) + 10.5 hours.

- Recirculation fans move air throughout the cabin.

- After a time delay, the remaining three extinguisher bottles discharge at a reduced flow rate into the selected compartment. If the aircraft lands before all the bottles discharge, one of the remaining bottles discharges into the selected compartment at a reduced rate on touchdown.

- MAYDAY: an internationally recognised radio call announcing a distress condition where an aircraft or its occupants are being threatened by serious and/or imminent danger and the flight crew require immediate assistance.

- Flight level: at altitudes above 10,000 ft in Australia, an aircraft’s height above mean sea level is referred to as a flight level (FL). FL 125 equates to 12,500 ft.

- Buttock (butt) line is an axis of measurement. Buttock line zero is the theoretical longitudinal line down the centre of a fuselage. In this instance, left buttock line 40 is 40 inches to the left of the centre-line.