Safety summary

What happened

On 11 June 2017, an Airbus A330-200 aircraft, registered B-6099 and operated by China Eastern Airlines, departed Sydney Kingsford Smith Airport (Sydney Airport) Australia on a scheduled passenger service to Shanghai, People’s Republic of China (China). During take-off, one of the three structural acoustic panels of the aircraft’s left engine inlet cowling, and the inboard outer skin failed. After reducing their fuel load and responding to the incident, the aircraft returned to Sydney about 42 minutes after departing. Debris from the left engine inlet cowling was strewn along the runway and the aircraft’s flight path.

What the ATSB found

There was limited physical evidence available, as the panel and other cowling debris was ingested into the engine. Therefore, despite extensive testing conducted by the engine and cowling manufacturers, the reason for the failure could not be conclusively determined. However, it was considered that the most likely reason for the failure was a localised disbond between the acoustic panel facing sheet and the honeycomb core.

This was the fourth inlet cowling failure event internationally, where an acoustic panel manufactured by Bombardier Aerospace on behalf of Rolls-Royce, fitted to an Airbus A330 aircraft with Trent 700 engines, had failed and was ingested into the engine.

What's been done as a result

As a result of this incident, Rolls-Royce amended service bulletin RB 211-71-AG419 R2 (now R3), which related to the inspection of the inlet acoustic panels. This service bulletin included increasing the initial and follow-on inspections by reducing the interval from 24 to 12 months (thereby increasing the frequency of inspections), the introduction of revised damage limits, and referencing a newly introduced training video that demonstrated how to conduct a ‘tap test’ to identify acoustic panel damage, including delamination. In addition, the European Aviation Safety Agency (EASA) issued Airworthiness Directive (AD) 2019-0042.

The operator, China Eastern Airlines, has proactively inspected their entire fleet of Rolls-Royce Trent 700 powered Airbus A330 aircraft and also reduced their inspection intervals from 24 to 12 months, thereby increasing the frequency of inspections.

Safety message

This event demonstrated the effectiveness of the certification design requirements and flight crew training to ensure continued flight despite effectively losing the power of one of two engines during a critical phase of flight.

On 11 June 2017, an Airbus A330-200 aircraft, registered B-6099 and operated by China Eastern Airlines, was on a scheduled passenger service from Sydney Kingsford Smith Airport (Sydney Airport), Australia to Shanghai, People’s Republic of China (China).

At 2042 Eastern Standard Time,[1] with the aircraft at maximum take-off weight, the take-off from runway 34 Left (L) was commenced, with all engine parameters recorded as being normal. About eight minutes after take-off, the pilot reported to Air Traffic Control that they had an issue with the No. 1 engine (left engine) and as a result, had throttled back to idle. The pilot made a request to return to Sydney Airport.

Data recovered from the aircraft Flight Data Recorder showed that about the time of rotation, the left engine pressure ratio[2] began to decrease. At the same time, the N1[3] vibrations momentarily increased as did the N1 speed, resulting in an overspeed condition for 1 second. During this period, the left engine continued to produce thrust.

The flight crew maintained control of the aircraft and continued the climb. They reduced the left engine thrust setting to idle and declared a PAN PAN.[4] The flight crew maintained an altitude of about 5,000-6,000 ft where the aircraft was manoeuvred in the Sydney region (Figure 1), while reducing their fuel load and addressing technical issues resulting from the incident.

Figure 1: Aircraft route, departure and landing at Sydney Airport

Source; Google earth, modified by the ATSB

About 42 minutes after departing, the aircraft landed at Sydney Airport in an overweight configuration with emergency services on standby. Debris from the left engine inlet cowling was strewn on runway 34L and along the aircraft’s flight path.

The aircraft was taxied to the terminal where passengers disembarked and maintenance engineers inspected the aircraft. Damage to the left engine inlet cowling was identified, including the No. 1 and No. 3 acoustic panels, and the inboard side outer inlet cowling skin (Figure 2). In addition, substantial damage was identified to the left engine fan blades and the cold stream duct.[5] Minor airframe damage to the left wing trailing edge flaps, landing gear door, and left side of the horizontal stabiliser was also identified.

Figure 2: Left engine inlet cowling acoustic panels and inboard side outer inlet panel destroyed

Source: ATSB

Inlet cowling debris was recovered from runway 34L by the Sydney Airport Corporation. Debris was also recovered along the flight path, including fragments at a school and on public roads by the New South Wales Police Force.

__________

- Eastern Standard Time (EST): Coordinated Universal Time (UTC) + 10 hours.

- Engine pressure ratio: Is the ratio between the turbine discharge total pressure and the equivalent of the compressor inlet total pressure. The Engine Pressure Ration gauge is the primary indicator of engine thrust.

- N1: the rotational speed of the low pressure compressor in a turbine engine.

- PAN PAN: an internationally recognised call announcing an urgency condition that concerns the safety of an aircraft or its occupants but where the flight crew does not require immediate assistance.

- Cold stream duct is the composite core between the engine core and fan cowling that directs smooth airflow around the engine core and directs thrust from the fan blades.

Engine information

The aircraft is powered by two Rolls-Royce Trent 772B-60 engines (Trent 700). Each engine is a three-spool high bypass turbo fan, rated at 72,000 pounds of thrust.

Left engine damage examination

The left engine was removed and sent to Hong Kong Aero Engine Services, a joint owned Rolls-Royce maintenance and repair facility. The engine was inspected for foreign object debris damage and N1 overspeed under the supervision of the Air Accident Investigation Authority (Hong Kong) on behalf of the ATSB.

All fan blades were damaged and determined to be unrepairable. White paint and acoustic panel weave pattern witness marks were identified on the fan blades. The paint and weave pattern was consistent with the outer skin painted surface of the inlet cowling[6] and the acoustic panel carbon fibre weave (brochier) impacting the blades during the failure sequence. Composite engine core panels within the cold stream duct aft of the fan blades also had significant foreign object debris damage, where sections of the acoustic lining were loose, missing or damaged.

Several of the fan blades had smeared traces of foreign material. Energy dispersive X-ray analysis was conducted and the material was found to be consistent with debris liberated from the collapsed inlet cowling during the event.

In addition, an ultraviolet light inspection was conducted on the engine inlet cowling, fan blades and spinner. Fluorescence was identified on one fan blade, towards the blade root. Rolls‑Royce concluded that this was consistent with organic material, likely from a small bird. Nil engine damage was identified from that material.

No other significant engine damage was found.

Engine inlet cowling information

Inlet cowling description

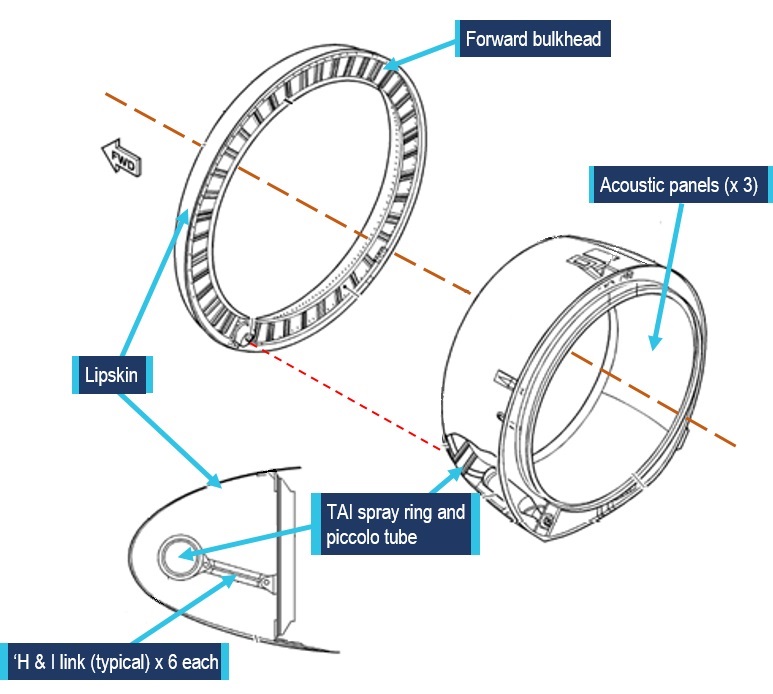

The engine inlet cowling is manufactured by Bombardier Aerospace on behalf of Rolls-Royce. The engine inlet cowling (Figure 3) is designed to supply smooth flow of air to the engine and across the nacelle outer surfaces. The inlet cowling includes:

- three all-composite material structural intake barrel panels (acoustic panels) designed to resist the dynamic pressures during flight and engine thrust

- two outer skin panels, a rear bulkhead and an intake cowl leading edge (lipskin) assembly, which contains the forward bulkhead.

Figure 3: Left engine inlet cowling components, highlighting the inboard side outer skin in yellow and No. 1 acoustic panel that failed in red

Source: Rolls-Royce, modified by the ATSB

Acoustic panels

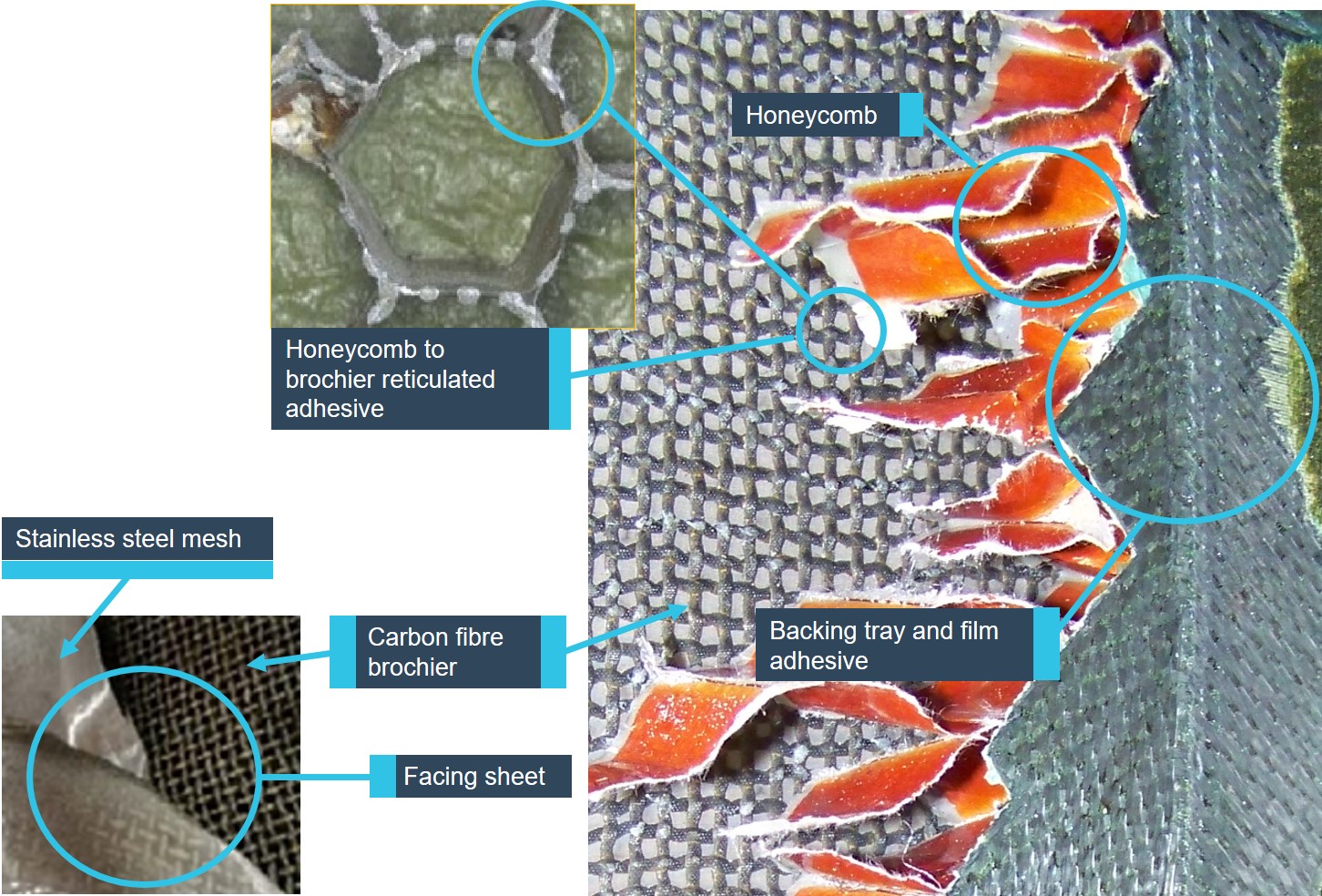

The upper inlet cowling acoustic panels, No. 1 and No. 3 fitted to B-6099 were manufactured from 3/4 inch honeycomb cell with a 1.5 lbs/ft3 density core. The panel consisted of a backing tray, manufactured from three layers of carbon fibre weave (Figure 4). This was then adhered to the 3/4 inch honeycomb with film adhesive. A facing sheet, consisting of a carbon fibre brochier and stainless steel mesh, was then adhered to the other side of the honeycomb with reticulated adhesive.

During flight and engine operations, the fan applies a pressure load on the inlet cowling acoustic panels. The facing sheet, honeycomb core and backing tray in each panel is designed in combination to absorb this load and maintain its rigidity. However, either of the following may lead to unequal load distribution that could adversely affect and compromise structural rigidity:

- if the facing sheet or backing tray is damaged

- a disbond between the honeycomb core and facing sheet or backing tray

- a blockage of the facing sheet weave that resulted in pressure variation across the facing sheet (leading to pressure across the honeycomb cell being unable to equalise).

Figure 4: Diagram showing the construction of the 3/4 inch 1.5 lbs/ft3 density honeycomb core acoustic panel

Source: Bombardier Aerospace, modified by the ATSB

B-6099 inlet cowling history

The damaged inlet cowling (serial number 1530) fitted to the left engine of B‑6099 was manufactured during January 2008. At the time of the incident, it had operated for a total of 41,023 hours and 8,051 cycles. The inlet cowling had been inspected for delamination ‘on‑wing’ four times since the introduction of Rolls-Royce service bulletin (SB) RB 211‑71‑AG419. The most recent inspection was performed in March 2017, in a United States Federal Aviation Administration (FAA) approved facility in China. During that inspection, nil delamination was identified on the incident panels.

During the inspection following the incident, it was identified that the adjacent acoustic panel (No. 2), that did not fail, had three local acoustic lining repairs. This indicated that the method used to inspect the panels ‘on-wing’ resulted in past repairs. Therefore, it is reasonable to conclude that the inspection method to identify delamination was likely an effective technique.

Left engine inlet cowling damage examination

The damaged inlet cowling (serial number 1530) was removed from the aircraft and sent to the Bombardier Aerospace manufacturing facility in Northern Ireland, United Kingdom for a detailed investigation.

Accredited representatives from the United Kingdom’s Air Accidents Investigation Branch (AAIB) and their advisers Rolls‑Royce, Bombardier, and the European Aviation Safety Agency (EASA) and the French Bureau of Enquiry and Analysis for Civil Aviation Safety (BEA) and their adviser Airbus assisted the ATSB with the investigation.

The investigation found that the No. 1 acoustic panel (inboard upper) had collapsed (Figures 2 and 4) where a large portion of the centre section was missing. The inboard outer skin panel was almost completely missing, with only small sections remaining attached around the rear bulkhead and the leading edge lipskin assembly. The No. 2 acoustic panel (lower panel) remained intact.

The No. 3 acoustic panel (outboard upper) displayed superficial damage in the form of tears, gouges and impact marks to the stainless steel mesh and carbon fibre brochier facing sheet. The damage observed on this panel was consistent with secondary impacts following the break-up and release of material from the No. 1 acoustic panel and inboard outer skin separation.

Fragments recovered from the runway and along the aircraft’s flight path were also examined. An attempt to re-assemble and reconstruct the panel was made but was unsuccessful and inconclusive.

Key observations from the examination and testing of the limited sample from the inlet cowling included:

- The inlet cowling structure (Figure 5) was compared to the design drawings, and was determined to be comparable.

- A detailed visual inspection did not identify any specific region of damage that may have been significant or inconsistent with the design.

- Examination with an ultraviolet light did not identify any significant organic matter that may have contributed to the incident.

- Ultrasonic and ‘tap test’ inspections of the remaining intact acoustic panels (No. 2 and No. 3) and cowling structure did not identify any evidence of delamination.

- In addition to the above observations, borescope inspections of the inlet cowling assembly forward structure found the thermal anti-ice (TAI) spray ring and piccolo tube intact. However, several TAI ‘H’ and ‘I’ links that secure the TAI spray ring to the forward bulkhead were found fractured and damaged at several locations. The forward bulkhead was also cracked around the radius for about one‑third of the circumference. The investigation determined that the H and I link fractures, bulkhead cracking and other minor cracking was pre-existing and not a result of the acoustic panel failure. The existing European Aviation Safety Agency airworthiness directive 2016-0086R1 indicated this type of damage would typically result from acoustic excitation and vibrations. No evidence was found to suggest that these defects contributed to the failure of the No. 1 acoustic panel in this event.

- Impact damage (a depression) in the lower radius of the engine cowling was also found, but this was inconsistent with the acoustic panel failure. The circumstances of this damage could not be determined, nor if this contributed to the failure of the inlet cowling acoustic panel.

Figure 5: Location of the ‘H & I links’ that retain the thermal anti-Ice spray ring within the inlet cowling

Image source: Rolls-Royce, modified by the ATSB

Acoustic panel testing

No. 1 acoustic panel testing

The majority of the failed No. 1 inlet cowling acoustic panel was ingested into the engine and was not recovered. Examination was therefore limited to the remaining material available (Figure 6), including the adjacent panels that did not fail.

The fracture surfaces of the remaining structure showed a range of failure mechanisms including tearing, shearing and peeling of the honeycomb core from the inner facing sheet and carbon fibre backing tray. As the section of the No. 1 inlet cowling acoustic panel that likely initiated the failure sequence was not recovered, the findings were inconclusive.

Examination of build records determined that the No. 1 and No. 3 acoustic panels were manufactured and fitted to the engine cowling about the same time. Therefore, it was likely that both would be a similar product in terms of materials and workmanship standards. Further, both panels would have likely been exposed to the same operating loads and environmental conditions during the inlet cowlings service life. On that basis, the intact No. 3 acoustic panel was utilised for destructive testing as a representative of the failed No. 1 acoustic panel.

Figure 6: Damaged acoustic panel showing construction and honeycomb to brochier bond elements

Source: ATSB

No. 3 Acoustic panel testing

Acoustic panel No. 3 was removed from the support structure for examination and testing, with the following observations made:

- Detailed visual inspection- nil visual defects other than FOD damage.

- Ultrasonic examination-nil delamination or water identified.

- Tap test-nil delamination identified.

- A C-scan ultra-sonic inspection was performed and compared to the initial build C-scans conducted at the time of manufacture in 2008. It was determined to have nil degradation.

- The acoustic panel was sectioned into sample specimens and a series of tests were conducted, which included climbing drum peel [7] and flatwise tensile [8] tests. These tests showed the bond was within the design specifications. Nil adverse findings in materials, process or workmanship were identified.

Rolls-Royce findings

Following the visual examination of the left engine inlet cowling and the visual and destructive testing of the No. 1 and No. 3 acoustic panels, Rolls-Royce concluded in respect to the No. 1 acoustic panel failure that:

… disbond between facing sheet and honeycomb was the most likely cause but this is impossible to confirm with most of the panel destroyed. Possibility of a disbond between backing tray and honeycomb could not be ruled out and has been considered, but we think this is less likely for a number of reasons:

- No reported experience of disbonds at the back tray interface through in-service inspections. A significant amount of experience of facing sheet disbonds had been identified.

- Facing sheet is much more vulnerable to in-service damage than backing tray.

- Recovered sections of panel from the collapse events have shown a good bond between backing tray and honeycomb.

- Use of a film adhesive at the backing tray interface achieves virtually 100% contact between the adhesive and the ends of the honeycomb cells.

- The facing sheet interface bond, between the reticulated honeycomb and the carbon fibre weave on the brochier, will only occur between the ‘high spots’ or contact areas which results in more variation.

Cowling acoustic panel conformance during manufacturing

As part of Bombardier Aerospace (the manufacturer) quality assurance and quality control processes, each component is inspected and certified at the time of manufacture to ensure that the design drawing specifications are met. Manufactured parts that did not conform to the specifications were subjected to a ‘concession’ process. The purpose of the concession process was to determine if the non-conforming part was acceptable for use, or what work was required to either make it conform or to bring it to a state where the non-conformance was acceptable. That work could be in the form of rework, rectification or repair/salvage.

In the case of the No. 1 acoustic panel, during the manufacturing process two concessions were raised where non-conformances were identified. Under the manufacturer’s approved process, that component was evaluated and certified as ‘fit for service’ with concessions applied.

The ATSB considered conducting an in-depth review of the Bombardier Aerospace concession process in light of this incident, but concluded that it was unlikely to identify systemic issues. This was in consideration that the manufacturer had in place a system designed to identify non-conforming components (in this case proved effective) and the system was approved by the regulator (the European Aviation Safety Agency). This was also supported by the premise that the component was in-service over a prolonged period and operating under a variety of conditions where defects were not identified during scheduled maintenance inspections. Furthermore, Rolls-Royce and Bombardier Aerospace conducted a detailed study of the manufacturing and build process of the inlet cowling after this incident. The study determined that the panels were manufactured within the accepted levels of the design specifications and within the manufacturer’s quality assurance and quality control requirements.

Similar occurrences

This was the first acoustic panel failure event experienced by China Eastern Airlines. However, it was the fourth event worldwide on a Rolls-Royce Trent 700 powered Airbus A330 aircraft. In all these events, the acoustic panels that failed were of the same design and modification status; that is, they contained the pre-modification 3/4 inch, 1.5 lbs/ft3 density honeycomb core panel:

- October 2006: The first unit to fail was at 20,300 flight hours and 5,186 flight cycles. That acoustic panel was the No. 1 panel fitted to the right engine. At the time of the event, the aircraft was in a take-off/go-around configuration.

- August 2009: The second unit to fail was at 32,950 flight hours and 16,849 flight cycles. That acoustic panel was the No. 3 panel fitted to the left engine. At the time of the event, the aircraft was in a ‘low speed/abort take-off configuration’.

- May 2017: The third unit to fail was at 38,553 flight hours and 12,410 flight cycles. That acoustic panel was the No. 3 panel fitted to the left engine. At the time of the event, the aircraft was in a low speed/abort take-off configuration. At the time of writing, the investigation into this event was ongoing. However, similar to the China Eastern incident, the evidence required to determine the failure of the panel was ingested into the engine and likely destroyed.

- June 2017: The fourth unit to fail was the China Eastern Airlines 41,023 flight hours and 8,051 flight cycles. The No. 1 panel fitted to the left engine had been on-wing since new. At the time of the incident, the aircraft was in a ‘take-off/climb configuration’.

Following the 2006 and 2009 intake cowling failure events, Rolls-Royce and Bombardier Aerospace conducted a detailed investigation and root cause analysis.

That analysis established the pressure and disbond area required to initiate the collapse of an acoustic panel of pre-modified status 3/4 inch, 1.5 lbs/ft3 honeycomb core. It was determined that 6 PSI was the maximum uniform pressure exhibited during certification aerodynamic load cases of the inlet cowling. Furthermore, it was established the during the maximum certification aerodynamic load, an area of 22 x 22 inch of disbond in the centre of the No. 1 panel acoustic panel, would be required to initiate the collapse.

Based on the available evidence, those investigations concluded that the failures were most likely the result of local disbonding of the acoustic skin between the facing sheet brochier and honeycomb.

Factors identified that could affect panel structural integrity

Previous investigations during the 2006 and 2009 events identified potential factors that could adversely affect the structural integrity of the acoustic panels. In particular, one consideration was the honeycomb to facing sheet bond made during the manufacturing process of the acoustic panel assembly. During the China Eastern Airlines investigation, this was again examined. Rolls‑Royce and Bombardier Aerospace determined the most likely contributors were:

- Bond line variation associated with the panel lay-up process: The panel lay-up process is a method of draping layers of composite matting over a mould and curing to produce facing and backing skins. These are then bonded to the honeycomb core to produce the sandwich panel. The facing sheet can only be adhered to the honeycomb at the ‘high spots’ or contact areas of the carbon fibre open weave (brochier) material. The brochier used in this process has the potential to introduce variation in the facing sheet to honeycomb bond line.

- Bond line variation associated with the stabilisation process: The stabilisation process was identified as another stage of the manufacturing process that could introduce bond line variation at the honeycomb to facing sheet interface. During bonding of the facing sheet to the honeycomb there is a stabilisation process, which includes an additional heat cycle that allows excess adhesive to run down the cell walls, away from the ultimate bonded junction. This is to control cosmetically unacceptable bleed-through on the stainless steel mesh surface (referred to as ‘leopard spotting’).

- Unaccounted in-service deterioration: The possibility that a disbond between the honeycomb and facing sheet initiated from in-service damage could not be ruled out. The most likely causes of this type of damage were considered to be engine fan blade handling, maintenance inspections, birdstrikes or other foreign object debris damage.

Inspection of the pre-modified acoustic panels

After the second inlet cowling acoustic panel failure in 2009, the manufacturer introduced service management action that included a tap test inspection[9] to determine the condition of the acoustic panels, and provided associated repair limits and acceptable damage limit criteria for varying sizes of disbond. That service action was contained in:

- Rolls-Royce SB RB 211-71-AG419: Air intake cowling-inspection of intake acoustic panels, issued in March 2011 (revision 1).

- Bombardier SB RB 211-NAC-71-018: Nacelle-powerplant-air intake-Inspection of intake cowl –inspection of acoustic panels, issued March 2011 (revision 1, 10 May 2011; revision 2, June 2014).

- Airbus SB A330-71-3024: Powerplant-air intake cowl-inspection on T700 of the air intake cowling, issued in May 2011.

EASA issued Airworthiness Directive (AD) 2011‑ 0173[10] in September 2011 and the FAA issued AD 2012-22‑18 in December 2012. These directives mandated operators to conduct inspections in accordance with the manufacturer’s service bulletin to establish continued airworthiness of the aircraft.

Acoustic panel product improvement

Based on the outcome from the 2006 and 2009 investigations, Rolls-Royce decided to ‘redesign the acoustic panels to improve their robustness’. Consequently, in July 2014 they introduced modification SB RB 211-71-H205 (Introduction of an air intake nose cowling assembly with revised acoustic panels featuring increased density and reduced cell size honeycomb cores). In response, Airbus also issued SB A330-71-3030 (Air intake cowling-improve acoustic panel on RR-Trent 700 engines), July 2014.

That modification effectively halved the honeycomb cell size, and doubled its density and brochier adhesive contact area by introducing 3/8 inch, 3.0 lbs/ft3 density core for all three inlet cowling acoustic panels. The changes effectively resulted in higher honeycomb core strength due to the density increase and higher bond. The modification also introduced additional strengthening plies around the P2T2[11] probe in the upper portion of the inlet cowling. In addition, the adhesive stabilisation process was deleted. While that process was originally introduced to reduce ‘leopard spotting’, Rolls‑Royce stated that, ‘although this was a fully qualified process, it was not considered best practice so it was agreed to remove this step for post-modified panels’. Although this could result in more ‘leopard spotting’, this was considered a secondary concern to eliminating any factors that could potentially introduce variation in bond strength.

The SB RB 211-71-H205 modification was introduced into the production line in 2014. By August 2019, it was estimated that there was about 900 pre-modified engine inlet cowlings with the 3/4 inch, 1.5 lbs/ft3 honeycomb core acoustic panels still in-service ‘on-wing’. This included approximately 177 pre-modified units retrofitted to the latest production line/standard since this event. Rolls-Royce reviewed the failure rate of these panels and considered the consequences. Based on the known number of unit’s ‘on-wing’ and the world fleet flight hours of 43 million (2017), they concluded that four units failing (including this incident) with the current consequences was an acceptable failure rate.

Since the introduction of SB RB 211-711-H205, there have been no recorded failures of the post‑modified 3/8 inch, 3.0 lbs/ft3 honeycomb core acoustic panels.

China Eastern Airlines reported in July 2017 they had 62 pre-modified inlet cowlings in-service and 59 post‑modified inlet cowlings fitted to their fleet of Airbus A330 aircraft powered by Trent 700 engines.

In-flight communications

Following comments from stakeholders, the ATSB reviewed the flight crew and cabin crew communications, utilising the cockpit voice recorder.

The review found that the flight crew were communicating in Mandarin in the flight deck and using English throughout the emergency to communicate with air traffic control and the cabin crew. The flight crew worked with air traffic control, where the salient issues were relayed and navigation instructions were given, acknowledged, and actioned.

During the occurrence, the flight and cabin crew communicated with the passengers stating the situation and intended actions. About 8 minutes prior to landing, the flight crew made a general passenger announcement in English. Shortly after, the cabin crew gave a pre-landing briefing to the passengers in several languages, including English.

All announcements captured on the cockpit voice recorder were considered clear, concise and appropriate for the situation.

__________

- Inlet cowling, in this case is the device forward of the engine fan blades that directs smooth airflow into the engine and across the nacelle outer surfaces and is designed to mitigate noise through the use of acoustic panels.

- A test performed that peels the flexible material from rigid backing material that establishes an accurate measurement of peel resistance to determine the peel strength

- Flatwise tensile strength of sandwich panels is a measure of the strength between the substrate and core material, or the bond between core and facings of an assembled sandwich panel.

- Inspection process consisting of taping composite materials with a coin or designated tool to search for delamination or other flaws detected by change in sound.

- The EASA Airworthiness Directive was superseded by 2019-042, issued on 27 February 2019.

- Probe that measures the air pressure in that section of the engine inlet cowling.

Acoustic panel failure during take-off

During the take-off from runway 34 Left at Sydney Airport, New South Wales, the left engine pressure ratio decreased and momentarily over-sped. The aircraft was subsequently returned to Sydney Airport for an uneventful landing. Debris was found on the runway and along the aircraft’s flight path. A post-flight inspection found that one of three acoustic panels and the inboard outer skin on the left engine failed. The panel and other cowling debris was ingested into the engine, resulting in damage to the engine fan blades and cold stream duct.

Reasons for the acoustic panel failure

The acoustic panels on the Trent 700 engines were manufactured by Bombardier Aerospace on behalf of Rolls-Royce. The panels fitted to B-6099 were constructed from a 3/4 inch honeycomb cell, 1.5 lbs/ft3 density honeycomb core.

Extensive testing was conducted. Rolls-Royce and Bombardier Aerospace considered that the failure was most likely due to a localised disbond between the facing sheet and honeycomb core. However, as the majority of the panel was ingested into the engine, there was limited evidence available and this could not be conclusively determined. In addition, it could not be established if environmental or ground support activities contributed to the event. Likewise, the reason for the three earlier similar incidences of 3/4 inch acoustic panels failing on Trent 700 engines on other aircraft could not be established with certainty. For all four events, the panels failed at largely different flight hours and cycles, therefore, nil conclusions could be drawn with regard to operational characteristics.

In comparison, tests conducted on the adjacent acoustic panel manufactured and fitted about the same time as the failed panel, did not identify any deficiencies in design, build or significant in‑service deterioration. Therefore, it was reasonable to conclude that the manufacturing or design process likely did not contribute to the failure.

In response to the earlier incidents, Rolls-Royce initiated a number of actions including the introduction of a tap test inspection to identify potential delamination of the brochier from the honeycomb. The ATSB had considered if these inspections were ineffective, incorrectly performed or did not address the root cause of the acoustic panel failure. The tap test had been conducted on the failed panel about 3 months prior and nil delamination was detected. However, as damage was identified and repaired on the adjacent intact panel, the inspection technique was considered likely effective.

Rolls-Royce also introduced a product improvement, which strengthened the panels from being constructed from a 3/4 inch to a 3/8 inch honeycomb cell (3.0 lbs/ft3 density honeycomb core), effectively doubling the bond joint between the honeycomb and brochier. To date, there have been nil reports of 3/8 inch panels failing.

Based on the available evidence, Rolls-Royce postulated that the most likely cause of the acoustic panel failure was a localised disbond between the honeycomb core and facing sheet. It was likely that the disbond grew to a critical size, greater than 22x22 inch area resulting in the panel collapsing at high engine power during take-off.

However, the reason for the local disbonding could not be established. Nevertheless, contributing factors such as maintenance activities, ground handling and foreign object debris damage could not be discounted as possible initiation source of the likely disbond.

From the evidence available, the following findings are made with respect to the failure of the left engine inlet cowling fitted to China Eastern Airlines Airbus A330-200 aircraft, registered B-6099 that occurred on 11 June 2017 during take-off from Sydney Airport, New South Wales. These findings should not be read as apportioning blame or liability to any particular organisation or individual.

Contributing factors

- During take-off, one of the three acoustic panels and the inboard outer skin of the left engine inlet cowling separated and were ingested into the engine. The engine sustained damage and the aircraft returned to the departure airport.

Other Key findings

- The ATSB and the engine manufacturer, Rolls-Royce, were unable to determine conclusively the reason for the acoustic panel failure.

Whether or not the ATSB identifies safety issues in the course of an investigation, relevant organisations may proactively initiate safety action in order to reduce their safety risk. The ATSB has been advised of the following proactive safety action in response to this occurrence.

China Eastern Airlines

Following this incident, the operator immediately instigated visual and tap test inspections on both the pre-modified and post-modified cowlings to confirm serviceability in accordance with the Rolls-Royce Service Bulletins. In addition, they increased the frequency of the tap test inspection from every 24 months to 12 months for all pre-modified inlet cowlings.

Rolls-Royce

Rolls-Royce has introduced a tap test inspection video to provide operators and maintainers with additional guidance on how to conduct this inspection. In December 2018, Rolls-Royce also issued an amendment to Rolls-Royce SB RB 211-71-AG419 R2 (now R3). That amendment included the introduction of revised damage limits and the inspection interval reduced from 24 months to 12 months.

European Aviation Safety Agency (EASA)

Amendments to Rolls-Royce SB RB 211-71-AG419 (R3) and Airbus Service Bulletin A330‑713024 R4 have been incorporated into the European Aviation Safety Agency airworthiness directive AD 2019-042 (superseded AD 2011-0173R1).

Sources of information

The sources of information during the investigation included the:

- Air Accident Investigation Authority (Hong Kong)

- Air Accidents Investigation Branch (United Kingdom)

- Airbus Industries

- Bombardier Aerospace

- Bureau of Enquiry and Analysis for Civil Aviation Safety (France)

- Cathay Pacific Airways Ltd.

- China Eastern Airlines

- European Aviation Safety Agency

- Rolls-Royce plc.

Submissions

Under Part 4, Division 2 (Investigation Reports), Section 26 of the Transport Safety Investigation Act 2003 (the Act), the Australian Transport Safety Bureau (ATSB) may provide a draft report, on a confidential basis, to any person whom the ATSB considers appropriate. Section 26 (1) (a) of the Act allows a person receiving a draft report to make submissions to the ATSB about the draft report.

A draft of this report was provided to Civil Aviation Safety Authority, Rolls-Royce plc, the Air Accidents Investigation Branch United Kingdom, the French Bureau of Enquiry and Analysis for Civil Aviation Safety, Bombardier Aerospace Inc., Airbus, European Aviation Safety Agency, China Eastern Airlines, the Hong Kong Air Accident Investigation Authority, and Cathay Pacific Airways Ltd.

Submissions were received from Rolls-Royce Plc and the Air Accidents Investigation Branch (United Kingdom). The submissions were reviewed and, where considered appropriate, the text of the report was amended accordingly.

Purpose of safety investigationsThe objective of a safety investigation is to enhance transport safety. This is done through:

It is not a function of the ATSB to apportion blame or provide a means for determining liability. At the same time, an investigation report must include factual material of sufficient weight to support the analysis and findings. At all times the ATSB endeavours to balance the use of material that could imply adverse comment with the need to properly explain what happened, and why, in a fair and unbiased manner. The ATSB does not investigate for the purpose of taking administrative, regulatory or criminal action. TerminologyAn explanation of terminology used in ATSB investigation reports is available here. This includes terms such as occurrence, contributing factor, other factor that increased risk, and safety issue. Publishing informationReleased in accordance with section 25 of the Transport Safety Investigation Act 2003 Published by: Australian Transport Safety Bureau © Commonwealth of Australia 2019

Ownership of intellectual property rights in this publication Unless otherwise noted, copyright (and any other intellectual property rights, if any) in this report publication is owned by the Commonwealth of Australia. Creative Commons licence With the exception of the Coat of Arms, ATSB logo, and photos and graphics in which a third party holds copyright, this publication is licensed under a Creative Commons Attribution 3.0 Australia licence. Creative Commons Attribution 3.0 Australia Licence is a standard form licence agreement that allows you to copy, distribute, transmit and adapt this publication provided that you attribute the work. The ATSB’s preference is that you attribute this publication (and any material sourced from it) using the following wording: Source: Australian Transport Safety Bureau Copyright in material obtained from other agencies, private individuals or organisations, belongs to those agencies, individuals or organisations. Where you wish to use their material, you will need to contact them directly. |