What happened

On 6 April 2017, the operators of a Yamaha RMAX[1] remotely piloted aircraft system (RPAS) (Figure 1) were conducting aerial spraying about 23 km west of Canberra, Australian Capital Territory. One operator was acting as the remote pilot in command of the RMAX and the other was mixing chemical, ferrying it to the aircraft and loading it into the chemical tanks, or canisters, on the aircraft.

Figure 1: Yamaha RMAX

Source: Yamaha

The aircraft had been operating normally that day for about 1 hour and 15 minutes of flight time. At about 1400 Eastern Standard Time (EST), the aircraft was about 2 to 3 m above the ground returning to land, when the pilot and loader heard a ‘clunk’. The aircraft started yawing to the left and descending. The pilot selected opposite direction yaw input (right rudder servo), but the aircraft did not respond. The aircraft collided with terrain upright but in a nose-down attitude and then rolled onto its side, resulting in substantial damage (Figure 2). The pilot did not receive any warnings on the aircraft’s ground control station prior to the accident.

Subsequent inspection revealed that the tail rotor had separated from the aircraft and landed about 30 m from the rest of the aircraft.

Figure 2: Damage to the RMAX

Source: Yamaha

Post-accident inspection

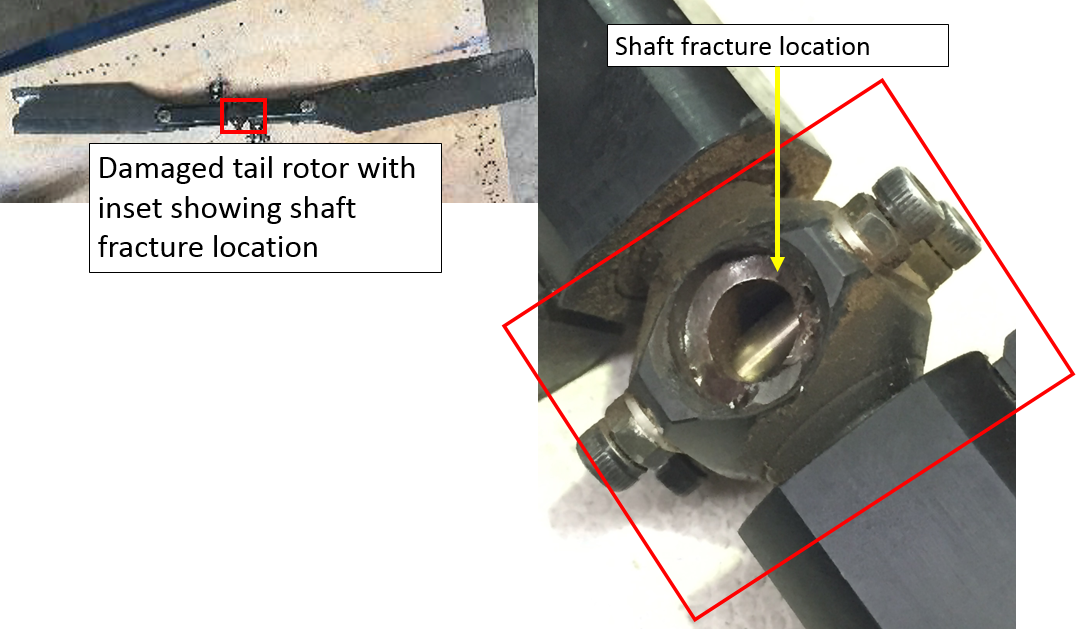

The manufacturer found that the tail rotor shaft had fractured, resulting in the tail rotor detaching from the aircraft (Figure 3).

Figure 3: Tail rotor showing fracture location

Source: Yamaha

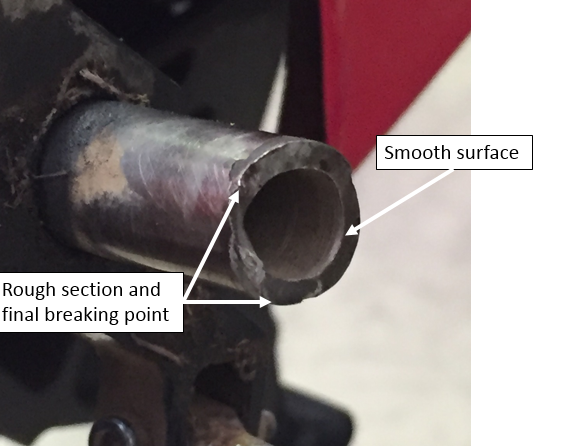

The manufacturer assessed that the fracture had probably existed for some time, as one section of the fracture site was smooth, indicating a pre-existing fracture. Another section of the fracture was rough indicating the failure occurred during the accident flight (Figure 4). The tail rotor blade (Figure 3) probably struck the tail cover after the shaft failed, as this allowed excessive movement in the tail rotor head.

Figure 4: Fractured tail rotor shaft

Source: Yamaha

Manufacturer investigation report

The manufacturer had conducted routine maintenance on the aircraft in October 2016. At that time, they found chips in the tail rotors and a broken antenna (fitted to the tail of the aircraft). The manufacturer replaced the antenna and tail rotor blades but was unable to determine how long the aircraft had been operating with the damage to the blades. Damage to the tail rotor blades may have caused an imbalance and extra load on the tail rotor shaft.

The manufacturer found the following factors may have contributed to the failure of the shaft:

- Impact with a small branch at the time the blades sustained chip damage.

- Possibly flying with rotor blades out of balance after the first impact, for an unknown period.

- Other damage to the aircraft indicative of mishandling during transport, which may have resulted in stress fractures to the rotor shaft.

Findings

These findings should not be read as apportioning blame or liability to any particular organisation or individual.

- The tail rotor drive shaft probably failed due to an existing fracture, resulting in the aircraft colliding with terrain.

Safety action

Whether or not the ATSB identifies safety issues in the course of an investigation, relevant organisations may proactively initiate safety action in order to reduce their safety risk. The ATSB has been advised of the following safety action in response to this occurrence.

Aircraft manufacturer

As a result of this occurrence, the aircraft manufacturer has advised the ATSB that they are taking the following safety actions:

Communication and reporting hub

Yamaha Motor Australia (YMA) is implementing an online form so that operators can send information and notification of incidents directly to Yamaha operations and maintenance departments.

YMA will modify operator’s manuals to better reflect handling standards.

Safety message

This accident highlights the importance of reporting all incidents and accidents, particularly to ensure adequate inspection and maintenance is conducted before returning the aircraft to operations.

Aviation Short Investigations Bulletin Issue 61

Purpose of safety investigationsThe objective of a safety investigation is to enhance transport safety. This is done through:

It is not a function of the ATSB to apportion blame or provide a means for determining liability. At the same time, an investigation report must include factual material of sufficient weight to support the analysis and findings. At all times the ATSB endeavours to balance the use of material that could imply adverse comment with the need to properly explain what happened, and why, in a fair and unbiased manner. The ATSB does not investigate for the purpose of taking administrative, regulatory or criminal action. TerminologyAn explanation of terminology used in ATSB investigation reports is available here. This includes terms such as occurrence, contributing factor, other factor that increased risk, and safety issue. Publishing informationReleased in accordance with section 25 of the Transport Safety Investigation Act 2003 Published by: Australian Transport Safety Bureau © Commonwealth of Australia 2017

Ownership of intellectual property rights in this publication Unless otherwise noted, copyright (and any other intellectual property rights, if any) in this report publication is owned by the Commonwealth of Australia. Creative Commons licence With the exception of the Coat of Arms, ATSB logo, and photos and graphics in which a third party holds copyright, this publication is licensed under a Creative Commons Attribution 3.0 Australia licence. Creative Commons Attribution 3.0 Australia Licence is a standard form licence agreement that allows you to copy, distribute, transmit and adapt this publication provided that you attribute the work. The ATSB’s preference is that you attribute this publication (and any material sourced from it) using the following wording: Source: Australian Transport Safety Bureau Copyright in material obtained from other agencies, private individuals or organisations, belongs to those agencies, individuals or organisations. Where you wish to use their material, you will need to contact them directly. |

__________

- Yamaha RMAX is a remotely piloted helicopter, body length 2.75 m (3.63 m including rotor), with a load capacity of 28 kg.