What happened

On 21 November 2016, at about 0730 Eastern Daylight-saving Time (EDT), a Bell 206B helicopter, registered VH-CHO, took off from a property about 30 km south of Bathurst, New South Wales. The pilot was conducting an aerial inspection of the property, with the farm manager on board as a passenger.

After overflying a flat area on high ground, the pilot raised the collective[1] and turned the helicopter to follow down-sloping terrain. At about 75 ft above ground level and an airspeed of about 40 kt, the pilot and passenger heard and felt a bang. The pilot looked outside to see if there was any obvious damage to the spray booms on the helicopter and in the back seat to see whether anything had fallen onto the floor, and assessed that the helicopter was too high to have collided with anything outside.

The pilot initially decided to land as soon as possible in order to check the helicopter to determine the cause of the bang, and started to slow it down. As the airspeed decreased, the helicopter started to yaw rapidly to the right and the pilot, unable to arrest the rotation with left anti-torque pedal, realised they had lost tail rotor authority. The pilot immediately rolled the throttle to the ground idle detent and as the helicopter stopped yawing, lowered the collective. The pilot saw that the rotor rpm had dropped to about 80 per cent and prepared for a hard landing. The pilot cushioned the landing by pulling back on the cyclic,[2] but the helicopter landed heavily. The belly tank (for spraying) absorbed some of the impact of the landing. The spray booms (fitted to the aircraft for spraying operations) probably helped prevent the helicopter rolling over.

The electronic locator beacon activated on impact. The pilot and passenger sustained minor injuries and the helicopter was substantially damaged (Figure 1).

Figure 1: Accident site showing damage to VH-CHO

Source: Aircraft operator

Post-accident inspection

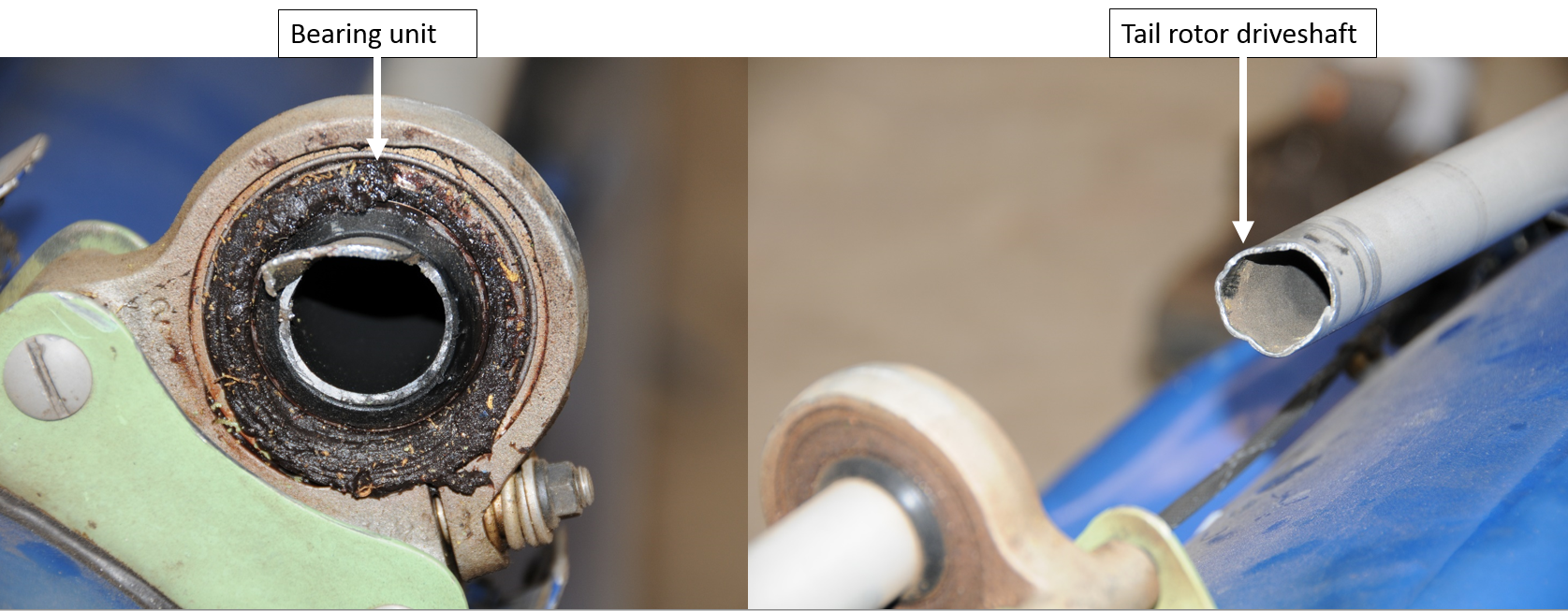

The tail rotor driveshaft had fractured at the No. 2 bearing (Figure 2).

The tail rotor blades were undamaged in the impact, which indicated that they were probably not rotating when the helicopter collided with the ground. There were scrapes inside the tail rotor driveshaft cowling, which indicates that the shaft was probably rotating when it fractured.

There was no evidence of oil leakage, overheating, or vibration of the tail rotor driveshaft system.

Figure 2: Fractured tail rotor driveshaft

Source: Aircraft engineer

Maintenance history

The helicopter had serial number 714, and was fitted with a long tail rotor driveshaft. The manufacturer required the single long driveshaft to be replaced with a segmented shaft in serial numbers 1252 and above.

The helicopter was fitted with a data augmentation monitoring system, which did not show any abnormalities.

The tail rotor bearings were ‘on condition’ items, that is, were required to be replaced if worn on inspection. The driveshaft was inspected every 1,200 hours and was in good condition apart from the fracture after the accident.

On 18 August 2016, the No. 1 and No. 3 tail rotor driveshaft bearings and tail rotor gearbox were replaced. On 29 September 2016, the No. 1 tail rotor bearing and bearing hanger were replaced. Post-accident inspection did not reveal any abnormalities.

Manufacturer comments

The helicopter manufacturer (Bell Helicopter) reported that the single long tail rotor driveshaft (P/N 206-040-330-001) was replaced with the segmented shafts in Bell 206B helicopters about 45 years ago. At serial number 1252, all Bell 206B helicopters and follow-on Bell 206B3 helicopters were equipped with segmented shafts. The change was made for ease of maintenance in replacing hanger bearings. In addition, if a segmented shaft was damaged, only it would have to be replaced and not the entire long shaft. The long shaft is still procurable through Bell Helicopter. The manufacturer reported that the long tail rotor driveshaft has not been a safety concern with no recent failures recalled.

Manufacturer investigation

The helicopter manufacturer inspected the tail rotor driveshaft and found that it fractured as a result of fatigue cracking. The origin of the fatigue was associated with an area of corrosion pitting, intergranular corrosion and associated cracking on the outside surface of the driveshaft tube, around both sides of the second hanger bearing inner ring location. The driveshaft was otherwise found to comply with the manufacturer’s requirements.

Pilot comments

The pilot provided the following comments:

- When the pilot heard the bang, the helicopter was at a very high-power setting with the blades highly pitched. Although the pilot rolled the throttle off, it took a couple of seconds before the yawing stopped, then they put the collective down and by that time the rotor rpm had dropped.

- There were about 30 gallons (114 litres) of fuel on board and the helicopter was loaded well within weight and balance limitations.

- The temperature was 18.5 °C, the wind light and variable, and the elevation about 3,200 ft above mean sea level. The conditions were well within the performance limitations of the helicopter.

- If the pilot had been able to get into a position where they could do a run-on landing, there may not have been any damage.

- The pilot did not know the tail rotor authority was lost until it was too late to do anything other than land immediately.

Safety analysis

The pilot and passenger heard a bang, which was probably the tail rotor driveshaft failing in flight, as indicated by the scraping inside the tail rotor driveshaft cowling. This resulted in a loss of authority of the tail rotor, and the lack of tail rotor blade damage suggests the blades were (near) stationary at the time of ground impact. The manufacturer’s examination found that the driveshaft tube fractured as a result of fatigue cracking that was associated with an area of corrosion pitting on the outside surface of tube, adjacent to the location of the second hanger bearing. The pilot slowed the helicopter to make an approach to land and check out the cause of the bang, which caused the helicopter to start yawing to the right. The pilot then realised they had lost tail rotor authority, rolled off the throttle to stop the yaw, and as the rotor rpm had dropped they were then committed to an immediate landing.

Findings

These findings should not be read as apportioning blame or liability to any particular organisation or individual.

- The tail rotor driveshaft tube fractured as a result of fatigue cracking that likely originated from corrosion pitting on its outside surface. This resulted in a loss of tail rotor authority.

- The helicopter was low and slow when tail rotor authority was lost, limiting the time available for the pilot to assess the circumstances and manage the forced landing.

Safety message

This incident highlights the importance of robust and current training in emergency procedures. Being able to identify a problem and react quickly can reduce the severity of damage and injuries.

Purpose of safety investigationsThe objective of a safety investigation is to enhance transport safety. This is done through:

It is not a function of the ATSB to apportion blame or provide a means for determining liability. At the same time, an investigation report must include factual material of sufficient weight to support the analysis and findings. At all times the ATSB endeavours to balance the use of material that could imply adverse comment with the need to properly explain what happened, and why, in a fair and unbiased manner. The ATSB does not investigate for the purpose of taking administrative, regulatory or criminal action. TerminologyAn explanation of terminology used in ATSB investigation reports is available here. This includes terms such as occurrence, contributing factor, other factor that increased risk, and safety issue. Publishing informationReleased in accordance with section 25 of the Transport Safety Investigation Act 2003 Published by: Australian Transport Safety Bureau © Commonwealth of Australia 2017

Ownership of intellectual property rights in this publication Unless otherwise noted, copyright (and any other intellectual property rights, if any) in this report publication is owned by the Commonwealth of Australia. Creative Commons licence With the exception of the Coat of Arms, ATSB logo, and photos and graphics in which a third party holds copyright, this publication is licensed under a Creative Commons Attribution 3.0 Australia licence. Creative Commons Attribution 3.0 Australia Licence is a standard form licence agreement that allows you to copy, distribute, transmit and adapt this publication provided that you attribute the work. The ATSB’s preference is that you attribute this publication (and any material sourced from it) using the following wording: Source: Australian Transport Safety Bureau Copyright in material obtained from other agencies, private individuals or organisations, belongs to those agencies, individuals or organisations. Where you wish to use their material, you will need to contact them directly. |

__________

- Collective: a primary helicopter flight control that simultaneously affects the pitch of all blades of a lifting rotor. Collective input is the main control for vertical velocity.

- Cyclic: a primary helicopter flight control that is similar to an aircraft control column. Cyclic input tilts the main rotor disc, varying the attitude of the helicopter and hence the lateral direction.