What happened

On 12 October 2016, a Vee H Aviation Fairchild Industries Inc. SA227-DC, registered VH-VEU, conducted a regular public transport flight from Armidale, New South Wales, to Brisbane, Queensland. On board the flight were two flight crew and 13 passengers. The captain was the pilot flying (PF) and the first officer was the pilot monitoring (PM).[1]

At 0755 Eastern Daylight-saving Time (EDT), the aircraft was about 170 km south of Brisbane, cruising at FL 170,[2] when the aircraft suddenly yawed to the right.[3] The PF re-stated they had command of the aircraft and directed the PM to identify the failure. The flight crew then employed their ‘identify and confirm’ crew resource management (CRM) procedures to confirm the right engine was not delivering power and then shut down the right engine and feathered the right propeller.[4] During the diagnosis, the PM noted that all right engine indications were normal except for a low torque reading (10%) and low fuel flow (140 pounds per hour).

Air traffic control contacted the crew to confirm they were maintaining FL 170 and the PM responded with a PAN broadcast[5] that they were descending due to a right engine failure. The crew reviewed their options and decided to continue to Brisbane Airport. They completed the remaining checklist actions and briefed the passengers. The crew then requested, and were given, a direct track to Brisbane Airport from air traffic control. They completed their normal and single engine landing checklist procedures and landed at Brisbane Airport runway 19 without further incident.

Maintenance findings

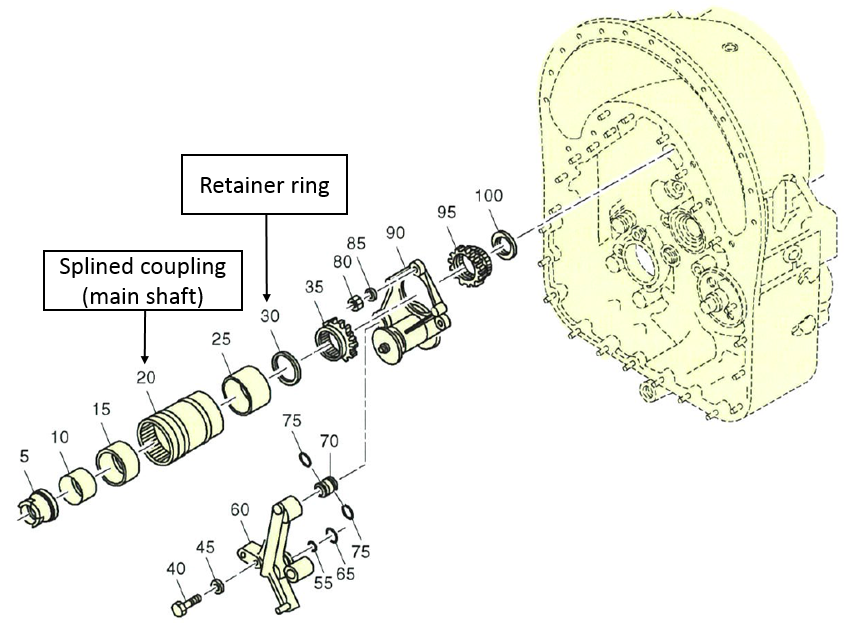

The engine installed in the aircraft was the Honeywell (previously Garrett) TPE331-12UHR-701G. The operator’s engine maintenance organisation found a retainer ring within the engine accessory gear assembly had failed, which allowed the main shaft (which drives the propeller) to de-couple from the engine driven reduction gearbox (Figure 1).

The retainer ring was shipped to the maintenance organisation from Honeywell in December 2008 as part of a batch of 10 with a certificate of conformance from the part manufacturer and Honeywell. It was fitted new to the incident engine in December 2009 at the last engine overhaul, about 2,429 hours prior to the failure. The maintenance organisation introduced this practice of replacing the retainer ring at each overhaul based upon their previous service experience of this part failing. December 2009 was the last overhaul of the accessory gear assembly prior to the failure.

In October 2015, Honeywell added temporary revision 72-241 to the maintenance manual procedure: removal and installation of accessory gear assembly, to direct the replacement of the retainer ring at each exposure. Figure 2 depicts the failed retainer ring.

Figure 1: Engine accessory gear assembly

Source: Maintenance organisation, annotated by ATSB

Figure 2: Retainer ring

Source: Operator

Continuing airworthiness maintenance interval

The operator set their maintenance interval for the incident engine in accordance with the engine manufacturer’s service bulletin for periodic inspections, (Honeywell TPE 331-72-0476). From the service bulletin, the operator set the inspection of the engine at the 7,000 hour continuing airworthiness maintenance (CAM) interval with gearbox inspection, for commercial operations. This included the requirement for the accessory gear assembly inspection in accordance with the maintenance manual procedures at the 7,000 hour interval.

The operator’s spectrometric oil-analysis programme (SOAP analysis) was set at 150 hour intervals at the time of the incident.[6] The previous SOAP analysis was conducted at about 26 hours prior to the failure and did not detect any anomalies. Further information on SOAP is available from Civil Aviation Safety Authority airworthiness bulletin (AWB 79-1): Spectrographic oil analysis program (SOAP).

The gearbox is fitted with a single magnetic drain plug (chip detector).[7] If a metallic particle is detected by the chip detector inflight, it will activate a caution light to advise the flight crew. The inspection interval for the chip detector is set at 300 hours. The last inspection was about 144 hours prior to the incident and no anomalies were found. There were no activations of the chip detector between the last scheduled inspection and the incident flight, and the chip detector did not activate during the incident flight.

The operator also conducts propeller dynamic balance checks at 600 hour intervals. There have been no out-of-limit vibration indications since engine installation. The last check was performed 17 September 2016.

Safety analysis

The operator had several preventive maintenance inspections in place, which included an overhaul of the gearbox, SOAP analysis, magnetic drain plug inspection and propeller dynamic balance. The previous overhaul was about 2,429 hours prior to the failure at which time the retainer ring was fitted new to the gearbox. During the time interval to failure of the retainer ring, the SOAP analysis, magnetic drain plug inspections and propeller dynamic balance checks did not detect any anomalies. Therefore, the failure of the retainer ring was within the required gearbox inspection intervals and without prior warning of an impending failure.

Findings

These findings should not be read as apportioning blame or liability to any particular organisation or individual.

- The retainer ring failed within the prescribed maintenance interval.

- There was no prior warning of an impending failure of the retainer ring.

Safety action

Whether or not the ATSB identifies safety issues in the course of an investigation, relevant organisations may proactively initiate safety action in order to reduce their safety risk. The ATSB has been advised of the following proactive safety action in response to this occurrence.

Operator

As a result of this occurrence and subsequent to an update by the engine manufacturer to the engine manufacturer’s service bulletin, the aircraft operator has advised the ATSB that they are taking the following safety actions:

SOAP analysis

The operator reduced their SOAP analysis interval from 150 hours to 100 hours.

Damaged parts

The damaged parts from the gearbox were sent to the engine manufacturer for analysis.

Safety message

Following the aircraft yaw, the flight crew actively employed their crew resource management procedures to identify and confirm the engine fault and then shut down the right engine. The use of these procedures reduced the risk of an incorrect diagnosis of the fault or activation of the incorrect engine controls during shut down.

__________

- Pilot Flying (PF) and Pilot Monitoring (PM): procedurally assigned roles with specifically assigned duties at specific stages of a flight. The PF does most of the flying, except in defined circumstances; such as planning for descent, approach and landing. The PM carries out support duties and monitors the PF’s actions and the aircraft’s flight path.

- Flight level: at altitudes above 10,000 ft in Australia, an aircraft’s height above mean sea level is referred to as a flight level (FL). FL 170 equates to 17,000 ft.

- Yawing: the motion of an aircraft about its vertical or normal axis.

- Feathering: the rotation of propeller blades to an edge-on angle to the airflow to minimise aircraft drag following an in-flight engine failure or shutdown.

- PAN PAN: an internationally recognised radio call announcing an urgency condition which concerns the safety of an aircraft or its occupants but where the flight crew does not require immediate assistance.

- SOAP is a method to test the health of engines by performing laboratory testing of the engine oil. A sample of oil showing an increase in parts per million of iron material could be a warning of impending failure. The chemical composition of any metal particles in the oil sample is compared to various engine parts to detect the location of abnormal wear.

- A chip detector is a device, often a permanent magnet, for gathering metal chips from the engine oil to provide early warning of an impending failure. A magnetic drain plug is a removable chip detector.

Aviation Short Investigations Bulletin - Issue 57

Purpose of safety investigationsThe objective of a safety investigation is to enhance transport safety. This is done through:

It is not a function of the ATSB to apportion blame or provide a means for determining liability. At the same time, an investigation report must include factual material of sufficient weight to support the analysis and findings. At all times the ATSB endeavours to balance the use of material that could imply adverse comment with the need to properly explain what happened, and why, in a fair and unbiased manner. The ATSB does not investigate for the purpose of taking administrative, regulatory or criminal action. TerminologyAn explanation of terminology used in ATSB investigation reports is available here. This includes terms such as occurrence, contributing factor, other factor that increased risk, and safety issue. Publishing informationReleased in accordance with section 25 of the Transport Safety Investigation Act 2003 Published by: Australian Transport Safety Bureau © Commonwealth of Australia 2017

Ownership of intellectual property rights in this publication Unless otherwise noted, copyright (and any other intellectual property rights, if any) in this report publication is owned by the Commonwealth of Australia. Creative Commons licence With the exception of the Coat of Arms, ATSB logo, and photos and graphics in which a third party holds copyright, this publication is licensed under a Creative Commons Attribution 3.0 Australia licence. Creative Commons Attribution 3.0 Australia Licence is a standard form licence agreement that allows you to copy, distribute, transmit and adapt this publication provided that you attribute the work. The ATSB’s preference is that you attribute this publication (and any material sourced from it) using the following wording: Source: Australian Transport Safety Bureau Copyright in material obtained from other agencies, private individuals or organisations, belongs to those agencies, individuals or organisations. Where you wish to use their material, you will need to contact them directly. |