On 11 September 2016, at about 1000 Eastern Standard Time, a Jabiru SP500 aircraft registered 19-5503, departed Caboolture Airfield, Queensland (Qld), for a flight to Boonah Airfield, Qld. The pilot was the only person on board.

As the aircraft approached Boonah Airfield, the pilot observed large white crosses on the runway indicating the airfield was closed. The pilot elected to return to Caboolture and applied engine power to climb to cruise altitude.

At about 1055, the aircraft climbed to the north of Boonah. At a height of about 1,000 ft above ground level, the pilot noticed the engine RPM reducing and applied full throttle. At the same time, the pilot observed a low and fluctuating engine oil pressure indication. Within seconds, the engine failed and the propeller stopped rotating.

The pilot identified a paddock to the north of their position as suitable for a forced landing. They manoeuvred the aircraft to conduct a forced landing into the paddock. The pilot ensured that turns made during the forced landing were not tight and of low bank angle to avoid an aerodynamic stall. Late in the ground roll, the nose wheel dug into the soft surface, the aircraft tipped onto its nose and the right wingtip struck the ground. The aircraft then stopped and settled onto its wheels. The pilot was not injured and the aircraft sustained minor damage.

This incident is a good example of the effect an in-flight engine failure at a low altitude has on the time available to manage that failure and identify a suitable forced landing area.

What happened

On 11 September 2016, at about 1000 Eastern Standard Time (EST), a Jabiru SP500 aircraft registered 19-5503 (5503), departed Caboolture Airfield, Queensland (Qld), for a flight to Boonah Airfield, Qld. The pilot was the only person on board.

As the aircraft approached Boonah Airfield, the pilot observed large white crosses on the runway indicating the airfield was closed. The pilot elected to return to Caboolture and applied engine power to climb to cruise altitude.

At about 1055, the aircraft climbed to the north of Boonah. At a height of about 1,000 ft above ground level, the pilot noticed the engine RPM reducing and applied full throttle. At the same time, the pilot observed a low and fluctuating engine oil pressure indication. Within seconds, the engine failed and the propeller stopped rotating. The pilot broadcast a MAYDAY[1] call on the Amberley common traffic advisory frequency. Air traffic control staff at RAAF Base Amberley received the MAYDAY broadcast and initiated an emergency response.

The pilot identified a paddock to the north of their position as suitable for a forced landing. They manoeuvred the aircraft to conduct a forced landing into the paddock (Figure 1). The pilot ensured that turns made during the forced landing were not tight and of low bank angle to avoid an aerodynamic stall. Late in the ground roll, the nose wheel dug into the soft surface (Figure 2), the aircraft tipped onto its nose and the right wingtip struck the ground. The aircraft then stopped and settled onto its wheels. The pilot was not injured, and the aircraft sustained minor damage.

Figure 1: 19-5503 after the forced landing

Source: Pilot

Figure 2: 19-5503 after the forced landing

Source: Pilot

Engineering details and examination

5503 is an owner built and maintained aircraft. The engine fitted to 5503 was manufactured in 2001.

A post incident examination of the engine found the engine oil pump drive had failed.

Due to the limited scope of this investigation a post incident engineering examination was not conducted. The cause of the oil pump drive failure was not determined.

Previous occurrences

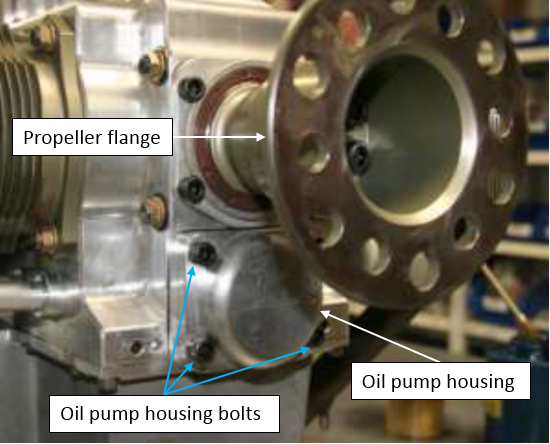

Jabiru advised that they are aware of one previous oil pump drive failure. In the previous occurrence the manufacturer found the engine maintainer had tightened the oil pump housing bolts (Figure 3) unevenly.

The Jabiru engine overhaul manual part 7.8.17 contains the following guidance on this part of the engine assembly:

Fit the outer pump housing over the gears and insert & hand tighten the retaining cap screws. Use Loctite 243 on the threads and ensure the Jabiru bird is oriented correctly.

While the housing is still loosely held to the engine, rotate the crankshaft through at least 2 full revolutions. This turns the cam and allows the oil pump to find its preferred position. The housing can now be tightened to the value given in Table 9.[2] Failure to turn the engine can result in the oil pump being offset from the cam axis – this applies side loads to the cam and can eventually crack it or break the tip off altogether.

Figure 3: Oil Pump Housing (not incident engine)

Source: Jabiru

ATSB comment

In December 2014, the Civil Aviation Safety Authority (CASA) introduced instrument 294/14 imposing operation limitations on aircraft fitted with Jabiru engines. In July 2015, this instrument expired and was replaced by instrument 102/15.

In July 2016, instrument 102/15 expired. CASA then introduced instrument 65/16 – Conditions and direction concerning certain aircraft fitted with engine manufactured by Jabiru Aircraft Pty Ltd. removing restrictions on Jabiru engines which met criteria detailed within the instrument.

The engine fitted to the aircraft was a Generation 1[3] engine. The pilot reported that the engine was maintained in accordance with Jabiru directions and complied with all Service Bulletins and Service Letters.

The ATSB determined that the operational restrictions imposed by instrument 65/16 did not apply to this aircraft.

Findings

These findings should not be read as apportioning blame or liability to any particular organisation or individual.

- The oil pump drive failed leading to engine failure and forced landing.

- The soft surface of the paddock used for the forced landing resulted in damage to the landing gear.

Safety message

This incident is a good example of the effect an in-flight engine failure at a low altitude has on the time available to manage that failure and identify a suitable forced landing area.

The ATSB booklet Avoidable Accidents No. 3 - Managing partial power loss after take-off in single-engine aircraft contains information that is also relevant to a complete engine power loss in flight.

The booklet shows that you can prevent or significantly minimise the risk of damage following a partial or complete engine power loss by using the strategies below:

- Pre-flight decision making and planning for emergencies and abnormal situations for the particular aerodrome

- conducting a thorough pre-flight and engine ground run to reduce the risk of a partial power loss occurring

- taking positive action and maintaining aircraft control either when turning back to the aerodrome or conducting a forced landing until on the ground, while being aware of flare energy and aircraft stall speeds.

Purpose of safety investigationsThe objective of a safety investigation is to enhance transport safety. This is done through:

It is not a function of the ATSB to apportion blame or provide a means for determining liability. At the same time, an investigation report must include factual material of sufficient weight to support the analysis and findings. At all times the ATSB endeavours to balance the use of material that could imply adverse comment with the need to properly explain what happened, and why, in a fair and unbiased manner. The ATSB does not investigate for the purpose of taking administrative, regulatory or criminal action. TerminologyAn explanation of terminology used in ATSB investigation reports is available here. This includes terms such as occurrence, contributing factor, other factor that increased risk, and safety issue. Publishing informationReleased in accordance with section 25 of the Transport Safety Investigation Act 2003 Published by: Australian Transport Safety Bureau © Commonwealth of Australia 2016

Ownership of intellectual property rights in this publication Unless otherwise noted, copyright (and any other intellectual property rights, if any) in this report publication is owned by the Commonwealth of Australia. Creative Commons licence With the exception of the Coat of Arms, ATSB logo, and photos and graphics in which a third party holds copyright, this publication is licensed under a Creative Commons Attribution 3.0 Australia licence. Creative Commons Attribution 3.0 Australia Licence is a standard form licence agreement that allows you to copy, distribute, transmit and adapt this publication provided that you attribute the work. The ATSB’s preference is that you attribute this publication (and any material sourced from it) using the following wording: Source: Australian Transport Safety Bureau Copyright in material obtained from other agencies, private individuals or organisations, belongs to those agencies, individuals or organisations. Where you wish to use their material, you will need to contact them directly. |

__________

- MAYDAY: an internationally recognised radio call announcing a distress condition where an aircraft or its occupants are being threatened by serious and/or imminent danger and the flight crew require immediate assistance.

- Table 9 of the Jabiru engine overhaul manual.

- A Jabiru 3300 engine in the manufacturer serial number range 33A0001 – 33A0960.