What happened

On 4 December 2015, the pilot of an Air Tractor AT-502B aircraft, registered VH-PTF, was conducting aerial spraying operations from Dalby Airport, Queensland.

The pilot had commenced duty for the day at about 0500 Eastern Standard Time (EST). At about 1200, the pilot took a short meal break. During the break, the pilot was provided with a map of the next area to be sprayed, which included a number of gas wells. Each gas well was on a gravel pad, with an antenna that posed a potential hazard to low-flying aircraft. The pilot was advised that there were no other known hazards, such as powerlines, in the area.

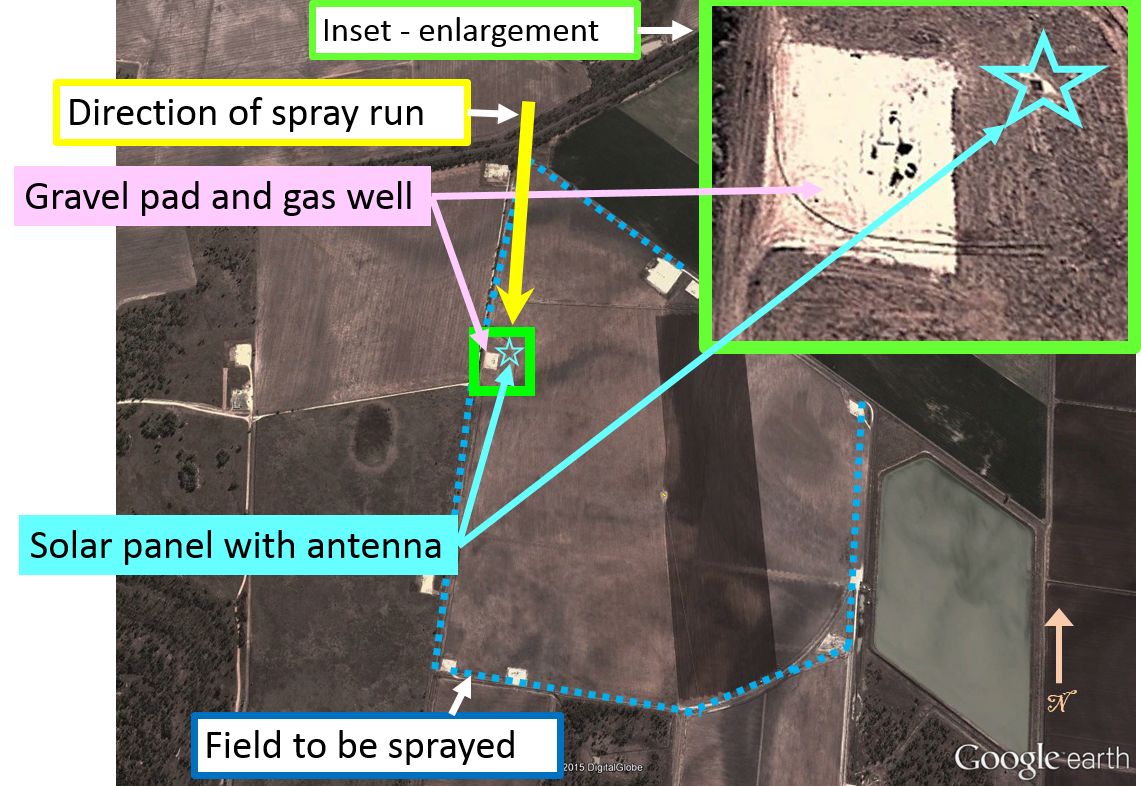

The aircraft was fuelled and 1,600 L of liquid chemical loaded into the aircraft hopper. The aircraft departed at about 1210, and tracked towards the field to be sprayed, which was about 13 NM to the south-west. The pilot then overflew the area to inspect the field, first at about 100 ft above ground level (AGL), then at about 50 ft AGL. The pilot noted the wells on the gravel pads, and verified that there were no powerlines in the treatment area. The pilot also saw a solar panel a short distance from a well, located in the crop and not on a separate pad (Figure 1). The pilot did not see an antenna at the site of the solar panel at that time.

Figure 1: Field showing well on gravel pad and solar panel

Source: Google earth – annotated by ATSB

The pilot elected to use the solar panel as a reference point and established a plan for the spraying. The aircraft then climbed and tracked a short distance away, and the pilot set up the GPS in readiness to commence the spray run.

The pilot commenced the first spray run, tracking towards the solar panel. As the aircraft came within about 20-30 m of the panel, the pilot noticed a pole behind the panel, protruding about 3 m above the crop, with an antenna on it. The pilot immediately conducted a climb to avoid the pole and antenna, but the aircraft struck the pole (Figure 2).

The pilot’s primary concern was to check that the aircraft was still controllable. The pilot conducted a climb to a safe height and checked the flight controls and all controls responded normally. The pilot could not see any damage to the aircraft or any fuel venting from the tanks. The pilot then checked the engine instruments and all indications were normal. There was a slight vibration, which the pilot assessed as possible damage to a panel on the airframe, or a blade of the spray pump used to disperse the load. The pilot therefore switched the pump off, but the vibration continued.[1]

Figure 2: Bore with solar panels and pole (after collision)

Source: Aircraft operator

At that stage, the pilot decided that it was not necessary to dump the chemical load. The pilot decided to land as soon as practicable and assess the damage to the aircraft. They elected to return to Dalby, where there were emergency services available. The pilot broadcast on the UHF radio advising the company that the aircraft had struck a pole, was still flying normally, and would be returning to the airport. However, as the aircraft was relatively heavy, the pilot elected to spray about 500-600 L of the chemical, at a higher flow rate than normal, to reduce the load prior to returning to land.

During the return flight, the aircraft still had a minor vibration. The pilot overflew the runway at Dalby to check the wind direction and speed before joining the circuit. The pilot conducted the approach about 5 kt faster than normal, due to the weight of the aircraft and the unknown effect of the damage caused by the collision with the pole. The aircraft landed safely at about 1240, and the pilot was uninjured. The aircraft sustained damage to the left wing and the propeller (Figure 3).

Pilot comments

The pilot provided the following comments:

- Most of the gas wells had an antenna on a pole, similar to the one the aircraft struck, however they were of a considerable height and on a gravel pad. The pilot had assumed that the gas company equipment was located on gravel pads.

- The galvanisation on the pole had no shine and it blended into the background of the crop. A line of trees beyond the crop also made the pole difficult to see. It would have stood out more clearly against a blue background of sky.

- The solar panels were located on a ground water quality bore, with the (pole and) antenna for satellite transmission.

- Pilots from the same company had previously conducted spraying operations in that field, but the pole had not been in place then.

Figure 3: Damage to propeller (left) and wing damage (right)

Source: Aircraft operator

Safety message

This incident highlights the importance of communication in identifying risks for low-level flying operations. Additionally, unknown hazards can be very difficult to see. The use of clearly visible markings may help pilots identify hazards during a field inspection. Pilots can then make a plan to avoid them during spraying operations.

The ATSB report Wirestrikes involving known wires: A manageable aerial agriculture hazard, cautioned pilots to conduct an aerial reconnaissance to confirm the location of wires and other hazards. Having a plan and a procedure to minimise the risk of collision with hazards is a valuable mitigation strategy. Further risk management strategies for agricultural operations are detailed in the Aerial Application Pilots Manual.

Aviation Short Investigations Bulletin - Issue 47

Purpose of safety investigationsThe objective of a safety investigation is to enhance transport safety. This is done through:

It is not a function of the ATSB to apportion blame or provide a means for determining liability. At the same time, an investigation report must include factual material of sufficient weight to support the analysis and findings. At all times the ATSB endeavours to balance the use of material that could imply adverse comment with the need to properly explain what happened, and why, in a fair and unbiased manner. The ATSB does not investigate for the purpose of taking administrative, regulatory or criminal action. TerminologyAn explanation of terminology used in ATSB investigation reports is available here. This includes terms such as occurrence, contributing factor, other factor that increased risk, and safety issue. Publishing informationReleased in accordance with section 25 of the Transport Safety Investigation Act 2003 Published by: Australian Transport Safety Bureau © Commonwealth of Australia 2016

Ownership of intellectual property rights in this publication Unless otherwise noted, copyright (and any other intellectual property rights, if any) in this report publication is owned by the Commonwealth of Australia. Creative Commons licence With the exception of the Coat of Arms, ATSB logo, and photos and graphics in which a third party holds copyright, this publication is licensed under a Creative Commons Attribution 3.0 Australia licence. Creative Commons Attribution 3.0 Australia Licence is a standard form licence agreement that allows you to copy, distribute, transmit and adapt this publication provided that you attribute the work. The ATSB’s preference is that you attribute this publication (and any material sourced from it) using the following wording: Source: Australian Transport Safety Bureau Copyright in material obtained from other agencies, private individuals or organisations, belongs to those agencies, individuals or organisations. Where you wish to use their material, you will need to contact them directly. |

__________