What happened

On 17 September 2015, at about 1330 Eastern Standard Time (EST), the pilot of a Cirrus SR22 aircraft, registered VH-OPX (OPX), conducted a short flight from Moree Airport, New South Wales, to a private airstrip about 6 NM to the north. The pilot was the sole occupant of the aircraft.

The aircraft approached the airstrip from the south, and the pilot elected to overfly the runway at the eastern end, then turn left and join the circuit on a left downwind for runway 09. The pilot had observed the wind at Moree Airport to be from a southerly direction at about 15 kt, and therefore anticipated having a crosswind for the landing at the airstrip.

The pilot reported that the circuit and approach were normal. On final approach, the pilot extended full flap, and commenced the flare at an airspeed of about 80-90 kt. To align the aircraft with the runway, the pilot reported applying almost full left rudder and right aileron due to the crosswind.

The right main landing gear touched down first, and the aircraft bounced back into the air. The pilot immediately applied full power to initiate a go-around. However, the left wing dropped and the aircraft yawed to the left. The aircraft’s left wing and propeller then collided with a dam wall (Figure 1). The aircraft stopped abruptly and spun around. The engine separated from the aircraft and came to rest about 20 m away, the tail broke off and the nose landing gear collapsed. The pilot suffered minor injuries, and the aircraft sustained substantial damage (Figure 2).

Figure 1: Accident site

Source: Google earth – annotated by the ATSB

Figure 2: Damage to VH-OPX

Source: NSW Police Force

Pilot experience

The pilot held a private pilot licence and had about 1,400 hours of aviation experience, with 80 hours experience in the Cirrus aircraft. The pilot had not flown into that airstrip before the accident flight.

Airstrip information

Prior to conducting the flight to the private airstrip, the pilot contacted the owner and obtained information about the runway condition.

The runway was about 850 m long – unsealed for about 150 m at the western end, then sealed with bitumen for about 700 m. The runway was situated east-west, and the pilot elected to land towards the east. The aircraft initially touched down on the dirt, just prior to the start of the sealed part of the runway, which was slightly beyond where the pilot anticipated it to land.

As the aircraft overflew the runway, the pilot looked for, but did not see, a windsock by which to verify the conditions at the airstrip. The owner of the airstrip reported that there were three windsocks located at various positions near the runway.

Wind

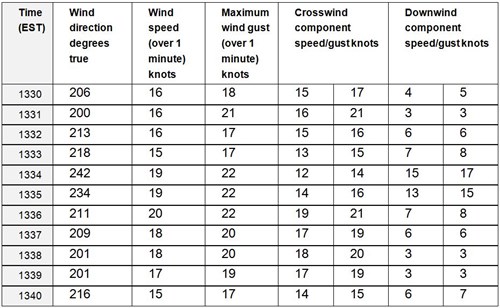

The Bureau of Meteorology provided the ATSB with the wind recorded at Moree Airport. Table 1 depicts the calculated downwind and crosswind components based on the runway direction of 090° magnetic (101° true) of the airstrip 6 NM north of Moree. As seen in the table, at 1334, a significant wind gust of 22 kt from 242°, would have equated to a downwind component of 17 kt and a crosswind of 15 kt. If the aircraft had encountered similar conditions during the landing, this may have affected the pilot’s ability to control the aircraft.

Table 1: Wind direction, speed, gusts and calculated downwind and crosswind components

Safety message

This incident highlights the importance of the identification and management of risks associated with operating into unfamiliar airfields. Pilots should carefully assess the environmental conditions, runway surface and surrounds before attempting to land at an airfield.

The Civil Aviation Safety Authority Out-N-Back video Aircraft landing areas and precautionary search and landing, stated: ‘A precautionary inspection of an unfamiliar airstrip before landing is a logical and effective way to satisfy yourself that you have chosen a suitable landing area for your aircraft, and for your skill level’. This airborne inspection includes assessing the wind velocity and direction, and whether any terrain surrounding the field may affect a go-around.

Aviation Short Investigations Bulletin - Issue 45

Purpose of safety investigationsThe objective of a safety investigation is to enhance transport safety. This is done through:

It is not a function of the ATSB to apportion blame or provide a means for determining liability. At the same time, an investigation report must include factual material of sufficient weight to support the analysis and findings. At all times the ATSB endeavours to balance the use of material that could imply adverse comment with the need to properly explain what happened, and why, in a fair and unbiased manner. The ATSB does not investigate for the purpose of taking administrative, regulatory or criminal action. TerminologyAn explanation of terminology used in ATSB investigation reports is available here. This includes terms such as occurrence, contributing factor, other factor that increased risk, and safety issue. Publishing informationReleased in accordance with section 25 of the Transport Safety Investigation Act 2003 Published by: Australian Transport Safety Bureau © Commonwealth of Australia 2015

Ownership of intellectual property rights in this publication Unless otherwise noted, copyright (and any other intellectual property rights, if any) in this report publication is owned by the Commonwealth of Australia. Creative Commons licence With the exception of the Coat of Arms, ATSB logo, and photos and graphics in which a third party holds copyright, this publication is licensed under a Creative Commons Attribution 3.0 Australia licence. Creative Commons Attribution 3.0 Australia Licence is a standard form licence agreement that allows you to copy, distribute, transmit and adapt this publication provided that you attribute the work. The ATSB’s preference is that you attribute this publication (and any material sourced from it) using the following wording: Source: Australian Transport Safety Bureau Copyright in material obtained from other agencies, private individuals or organisations, belongs to those agencies, individuals or organisations. Where you wish to use their material, you will need to contact them directly. |