Factual Information

The PIC reported that, while passing Flight Level 175 on descent, he heard a loud muffled thud and then air noise, and saw that the cabin door had opened and separated from the aircraft. There had been no door warning indication prior to the door opening.

Following the door separation, the cabin door warning light illuminated and the cabin oxygen masks deployed. The PIC completed emergency checks before diverting the aircraft to Thangool, Queensland.

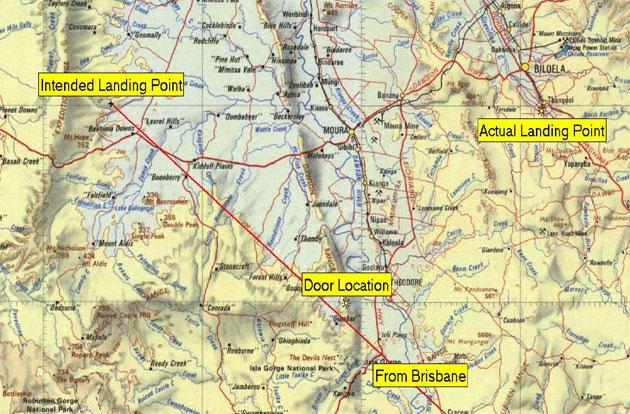

On 12 September 2004, after a search by the aircraft operator, the cabin door was found approximately 3 NM north of Glenbar, Queensland (see Figure 1). When the door was found, the external handle was not in the locked position and the latch bolts were not fully extended.

Figure 1: Location of recovered door

Aircraft cabin door

The aircraft's cabin door was an outward-opening airstair type, hinged at the bottom, with a diaphragm and mechanical over-centre locking mechanism. It was also fitted with a pressurised seal.

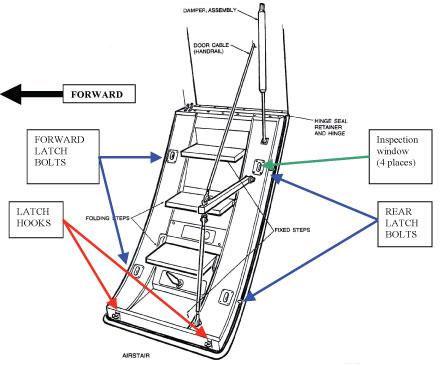

The cabin door mechanical locking system consisted of four latch bolts. Two were located on the rear side of the door and two on the forward side of the door. In addition, two latch hooks located on the top of the door engaged onto stationary locking pins located within the fuselage (see Figure 2).

Figure 2: B300 cabin door locking mechanism

Locking and unlocking of the cabin door was accomplished by means of either the external or internal door handles. Once the aircraft was pressurised, the door's pressure seal inflated. As the pressure differential between the interior and exterior of the aircraft increased, the cabin door's internal diaphragm expanded and locked the interior handle to prevent inadvertent opening in-flight. The cabin door interior trim had three positions marked for the door handle, OPEN, LATCH and LOCK (see Figure 3).

Figure 3: Cabin door interior handle in lock position

When the locking mechanism was in the LOCK position, the door handle could not be moved to the LATCH or OPEN position until a release button on the internal diaphragm was depressed.

Each forward and rear latch bolt was marked with green line indicators, which aligned with stationary arrow heads that indicated that the cabin door was locked. The green line indicators were viewed through inspection windows at four locations on the inside of the door.

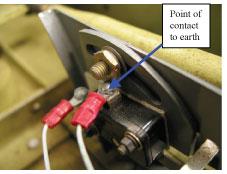

The recovered door was sent to the Australian Transport Safety Bureau for further examination. The investigation found that the mechanical latching mechanism was intact, however the door's rear latch hook sense switch terminal screw and the sense switch adjustment nut were located in very close proximity and intermittently contacted (see Figure 4).

Figure 4: Rear latch hook sense switch

The rear latch hook sense switch mounting plate showed no significant distortion and there was no evidence of in-service movement of the rear latch hook sense switch adjustment mechanism.

A circuit test of the three sense switches located within the door (two switches for the two latch hooks and one for the door handle position), determined that it was possible for the rear latch hook sense switch terminal to contact the switch mounting plate retaining nut, providing a short circuit to earth. This had the effect of rendering the door handle centre lock sense switch inoperative. In this condition, the door handle centre lock sense switch would not provide an indication to the crew of an unlocked door.

The examination also found that the door handle reached a position of maximum resistance between the LATCH and LOCK position just prior to the mechanism reaching the over-centre and locked position. It was possible to move the locking handle to this high resistance position, where the green line indicators on the latch bolts appeared to align with the stationary arrow heads in the inspection windows, but the latching hook had not yet activated the centre locking mechanism handle sense switch.