The pilot landed the helicopter on the Brisbane River Helipad to disembark a passenger. As the pilot prepared to lift off, the right main wheel penetrated the pontoon deck, causing the helicopter to capsize. The circumstances were consistent with dynamic rollover. The pilot did not lower the collective pitch control (the recommended response to dynamic rollover) when the helicopter began to roll.

The helipad consisted of a plywood deck mounted on a framework that formed a floating pontoon moored to the river bank. Prior to the flight the pilot had not checked the load bearing capability of the deck, but assumed that the helipad was capable of accepting the Agusta 109 helicopter. Examination revealed that the point load imposed by the main wheels of the helicopter was close to the tested strength of the plywood pontoon decking material. The additional dynamic load effects due to helicopter movement, and wind and water action, were likely to have increased the loads on the deck surface, causing failure of the plywood.

Documentation relating to the management and maintenance of the helipad revealed that the actual load bearing capability had never been established. Potential users of the helipad had been advised of a load limit of 2,000 kg, although the origin of that figure was unknown. The pilot claimed that he was not aware of that limit.

The engineering drawings for the deck called for plywood sheets that extended the full width of the deck. However, smaller sheets were used when the deck surface was last replaced. That had the effect of introducing weaker areas where sheet ends butted together but were unsupported. The deck failure occurred at one of the sheet ends.

FACTUAL INFORMATION

History of the flight1

On 30 July 2004, at about 1120 Eastern Standard Time, an Agusta A109C helicopter, registered VH-ZZN, was being operated on a private flight from the Gold Coast to Brisbane Airport via the Brisbane River Helipad. The pilot and two passengers were on board. The intention was to disembark one of the passengers at the helipad, without shutting-down the engines, and then to continue the flight to Brisbane Airport.

The pilot reported that he established the helicopter in a low hover above the helipad and was satisfied that it was correctly positioned above the painted white landing circle. He then allowed the wheels to settle on the helipad, with the right side of the helicopter facing the river bank. The pilot said that he kept his left hand on the collective pitch control lever and his feet on the tail rotor pedals. He then gripped the cyclic control with his knees so that he could open the cockpit door with his right hand. He leaned out and checked that the helicopter was centrally positioned in the landing circle and that the right main wheel was not causing any visible stress to the helipad surface. He then applied the parking brake and closed the door before telling the passenger to disembark through the right cabin door.

The pilot recounted that when the passenger was safely clear of the helicopter, he applied a small amount of collective pitch control in preparation for lift off. He then felt the helicopter lurch and begin to roll right. The pilot immediately applied full left cyclic pitch control and maintained the collective pitch control position. However, the helicopter continued to roll rapidly right and the main rotor blades struck the walkway safety rails. The helicopter came to rest inverted between the helipad and the riverbank, with the forward fuselage against the junction between the helipad and the connecting walkway.

The helicopter was not fitted with a flight data recorder or cockpit voice recorder, nor was it required to be by relevant aviation regulations. Consequently, there was no information available regarding the events or timing of the accident sequence, including the rate of helicopter movement and any control inputs made by the pilot.

Injuries to persons

The pilot and passenger received minor injuries but were able to egress from the helicopter unassisted.

Damage to the helicopter

The helicopter was substantially damaged during the rollover sequence. Contact with the walkway destroyed the main rotor blades and damaged the forward fuselage. The fuselage was partly immersed in water. There was no fire.

Debris from the helicopter was found up to 200m from the helipad, both on and adjacent to the pedestrian/bikeway on the riverbank. There was potential for debris to have been thrown onto the adjacent road complex.

Other damage

Initial examination of the helipad revealed that the helicopter's right main wheel had broken through the deck sheeting on the edge of the white painted landing circle (Figure 1). See also page 7, 'Helipad examination'.

The helicopter's main rotor blades caused substantial damage to the walkway linking the pontoon to the riverbank.

Figure 1: The helicopter as it came to rest. The arrow points to the location of the deck surface failure

Pilot in command

The pilot, who was the chief pilot of the organisation that operated the helicopter, held a valid commercial pilot licence (helicopters). His total flying experience (all rotary wing) was 1,720 hours, of which approximately 250 hours were on the Agusta A109C type (all on VH-ZZN).

The pilot had operated onto the Brisbane River Helipad on numerous occasions since 1 July 2003 in Hughes 500 and McDonnell Douglas 600 type helicopters, and on 19 occasions in the Agusta A109C type2.

Aircraft information

The Agusta A109C was a twin turbine-engine helicopter capable of carrying up to seven passengers. Its maximum operating weight with an internal load was 2,720 kg. The helicopter was equipped with a retractable landing gear, which comprised a nose wheel and two main wheels.

The estimated weight of the helicopter at the time of the accident (including approximately 300 L aviation turbine fuel) was 2,471 kg. Under those conditions, and taking account of the centre of gravity position, the static load on each main wheel was about 930 kg.

According to documentation provided by the operator, there were no outstanding maintenance requirements for the helicopter at the time of the accident. The pilot reported that the helicopter was operating normally in the period prior to the accident.

Brisbane River Helipad

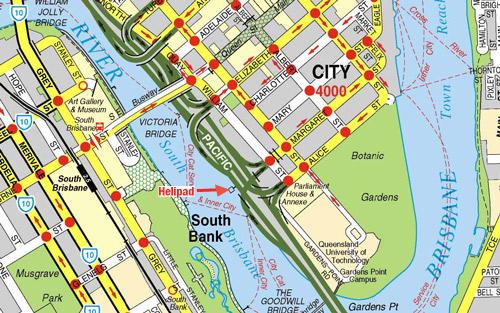

The 9.4 m square helipad was owned and administered by the Queensland State Government. It was located adjacent to the northern bank of the Brisbane River at the end of Margaret Street in Brisbane City (Figure 2). It was mounted on a tethered floating pontoon that was linked to the riverbank by an 11 m walkway. Safety rails approximately one metre high were attached to either side of the walkway. There was a pedestrian pathway and motor vehicle road infrastructure along the riverbank adjacent to the helipad.

Figure 2: The Brisbane River Helipad location

Documentation relating to the operation and maintenance of the helipad was contained in separate files that were administered by various Queensland State Government departments and branches of departments during the period 1981-2004. Through most of that time, operational control and maintenance responsibility for the helipad were held by separate departments, with maintenance aspects being handled predominantly by the department that had responsibility for maritime safety and/or harbours and marine. No record was found on the files of the original design criteria for the helipad, including the helicopter type(s), operating weights, and type of landing gear (skid or wheels) for which it was intended to be used.

Helipad examination

The helipad deck (Figure 3) consisted of 1,200 mm x 2,400 mm plywood sheeting nailed to 100 mm x 75 mm hardwood joists 600 mm apart. The joists were attached to a series of aluminium 'I' beams mounted on two pontoons. The longer (2,400 mm) sides of the plywood sheets had tongue and groove edges and butted over the approximate mid-point of every alternate joist. The shorter (1,200 mm) sides of the plywood sheets did not have tongue and groove edges and were not structurally connected. There was no supporting structure beneath those sides except at the midpoint position at the location of a joist. The central area of the helipad surface (where the helicopter landed) appeared to have been in relatively good condition.

Figure 3: After removal of the wreckage. Individual plywood decking sheets are evident. The arrow points to the location of the deck failure

Figure 4: Location of the deck failure and its relationship to the supporting framework

The location of the deck failure coincided with the corner of one of the plywood decking sheets (Figure 4). The nature of the failure was consistent with the right wheel of the helicopter bearing down on the plywood sheet midway between two adjacent joists, and near the edge of the sheet. The edge formed the shorter (1,200 mm) side of the sheet and was not structurally connected to the adjacent sheet edge.

Specialist examination concluded that the final failure occurred at the point of highest bending moment between the joists. The individual layers within the decking sheet all failed at the point of highest bending, suggesting that the plywood adhesive and the timber layers had not deteriorated due to water ingress.

Laboratory tests carried out on samples taken from the failed section of the deck revealed a bending strength of 61 megapascals (MPa). The size of the test samples was smaller than stipulated by the standard. However, that bending strength exceeded the bending strength of marine grade plywood3.

Examination of the underside of the deck revealed a significant longitudinal crack on the side of the deck opposite the failed section. The deck upper surface at that location showed no sign of damage. The crack displayed damage to the lower layers of the plywood midway between two longitudinal joists. The cracking was not adjacent to the edge of a plywood sheet and was not observed when the helipad was inspected in April 2004. Specialist assessment of the damage concluded that it was likely to have been caused by a point loading in the order of 1,200 kg.

Some areas of the deck on the river and upstream sides of the helipad were significantly degraded due to water ingress into the layers of the plywood, probably as a result of wave action. Examination of those areas indicated that both the ply adhesive and the wood itself had deteriorated significantly. Deterioration of that nature was consistent with continuous contact with, or immersion in, water for an extended period. Those areas, however, were not related to the occurrence.

Helipad load bearing capability

There were numerous references in the helipad owner's documentation regarding the pad's load bearing capability. The earliest of those appeared in drawings that were completed in 1984 for the installation of a new deck consisting of plywood sheets mounted on aluminium support beams (Drawing No. BN-5-43-1). The design strength of the replacement deck was based on a pressure of 3 kilopascals (kPa) evenly distributed over the entire deck area, although the origin of the selected value was not clear. A pressure of 3 kPa is equivalent to 306 kg evenly spread over each square metre of decking. The layout of the plywood sheets over the aluminium support beams resulted in a design panel size of 600 x 400 mm (0.24 sq.m), equivalent to 73 kg evenly distributed on each design panel. The designer's calculations showed that this loading would create a bending stress of 5.138 megapascals (MPa) in the plywood decking, which was well within the allowable working stresses for the F114 grade structural plywood selected for the repairs. There was no indication in the documentation that the design of the repairs included any consideration for point loads, such as would be experienced from wheel equipped helicopters.

In May 1982, a request to land a helicopter weighing up to 3,630 kg on the helipad was refused because 'it would be unsafe to place this weight on the helipad'. However, there was no supporting documentation for that statement.

A July 1997 document authorising a private operator to use the helipad included the statement that the applicant 'should be aware that there is a load limit for the HLS [helicopter landing site], and aircraft in excess of 1,400 kg should not access the HLS'. There was no information regarding the origin of that figure.

In late 1996, the Queensland Government commissioned a feasibility study by a town planning consultant on the future options for the helipad. The study, completed in late 1997, noted that there was:

… no evidence at hand which would indicate it's [the helipad's] safe load capabilities but it appears to be beyond the operation of the Queensland Emergency Services helicopter - a Bell 412 with a maximum take-off weight approaching 5,400 kg - but comfortably accommodates most small to medium-sized turbo driven helicopters in use in the region. The practical limit appears to be approximately 3,000 kg.

There was no supporting evidence to indicate how that conclusion was reached.

In March 1997, there was internal correspondence regarding the establishment of a deed of indemnity that was to apply to users of the helipad. A deed was developed and in early 1999 was sent to users of the helipad for signature. In June 1999, in response to a request to use the helipad, a list of 'requirements that apply to the use of the helipad' was included, for the first time, in the covering letter to the deed. Those requirements included the following:

1. The helicopter landing site is intended for the use by helicopters within the "small" utility class only i.e. helicopters up to 2,000 kg in mass, and

2. The permittee, or their nominated pilot, are responsible for ensuring that the helicopter landing site is in suitable condition before intended use.

There was no indication in the documents regarding the origin of those 'requirements'. Subsequently, there were other instances where prospective users of the helipad were provided with a copy of the requirements when they were asked to sign the deed of indemnity.

In April 2004, a helicopter operator not associated with VH-ZZN contacted the helipad owner requesting confirmation that an Agusta A109C helicopter could land on the helipad. The operator noted that the weight of the Agusta A109C was between 2,000 and 3,000 kg and that, because the helicopter was equipped with wheel instead of skid type landing gear, a 'wheel footprint' of about '1,200 kg per mainwheel' would exist. A reply was sent to the operator advising that the helicopter weight exceeded the 2,000 kg limit that formed part of the standard terms of use for the helipad. The operator replied, noting that skid equipped helicopters weighing greater than 2,000 kg, such as the AS350 Squirrel5, had landed on the helipad.

In May 2004, the Civil Aviation Safety Authority (CASA) contacted the helipad owner regarding the helipad. CASA requested the weight restrictions and the conditions of use of the helipad, and asked whether the weight limit was clearly marked on the helipad. That request, along with the earlier questions and information regarding the suitability of the helipad for the Agusta 109 helicopter, generated activity by the helipad owner including the proposal that a safety audit of the helipad be conducted as a matter of priority.

The justification for the proposed audit was that there may be safety issues associated with the helipad that were not being adequately addressed, such as appropriate usage and signage, and the proximity of the helipad to pedestrian and motor vehicle traffic adjacent to the helipad. At the time of the accident, those issues had not been progressed.

Helipad maintenance history

The helipad owner conducted major maintenance on the helipad in 1984, 1997, 2000 and 2004. In the intervening periods, minor maintenance was conducted. The maintenance activities generally involved work on the flotation pontoons, mooring chains, and the walkway linking the pontoon to the riverbank, and the helipad deck. For the purposes of this report, however, discussion of maintenance activities will focus on the helipad deck.

The drawings for the helipad prepared in 1984 (Drawing No. BN-5-43-1) indicated nominal deck dimensions of 9,400 mm x 9,400 mm and specified a series of hardwood plywood 'rot proofed' decking sheets 9,400 mm x 1,200 mm, with minimum stress grade F11.

At the commencement of the work phase of the repairs conducted in 1984, the contractor proposed standard size plywood sheeting 2,400 mm x 1,200 mm for the decking but that was deemed not acceptable by the helipad owner because the sheet size was not in accordance with the drawing specifications. Subsequently, a special order of 9,400 mm x 1,200 mm plywood sheeting was obtained. The repairs to the helipad, including the installation of the new 9,400 mm long plywood decking sheets on aluminium support beams, were completed in March 1985.

The major maintenance undertaken on the helipad in 1997 included the replacement of two plywood decking sheets and painting of the deck. The documentation indicated that the replacement plywood sheets were 9,400 mm long.

Inspection of the helipad in May 2000 revealed that, in addition to other items requiring rectification, most of the plywood decking was badly deteriorated and beyond repair. On 4 May 2000, the company that subsequently won the contract to conduct the repairs was asked to provide a price:

… to replace any damaged structural plywood sheeting of the deck of the helipad (both a price to replace each sheet and a price to replace all the sheeting). The plywood shall [be] in accordance with Drawing No. BN-5-43-1 and classified as Marine Grade Structural Plywood.

The contractor provided a price to remove and replace all sheets/deck and to coat all surfaces with a product that he stated would waterproof all surfaces and provide total protection to the pontoon/helipad for many years. The contractor was awarded the contract on 16 May 2000. Aside from the reference contained in drawing No. BN-5-43-1, the documents did not refer to the plywood decking sheet size. Documents dated early September 2000 indicated that the rectification works had been inspected as being completed. There was no confirmation in those documents regarding the grade of plywood or sheet size used on the deck.

Another inspection of the helipad was conducted in December 2003. Among the defects identified were four areas of deck sheeting that had loosened, and that the deck needed repainting. The pontoon was removed from the river in March 2004 and the repairs undertaken. There was no reference to any plywood deck panels or supporting beams being replaced during that work. The helipad was returned to service on 21 April 2004.

Operator's information regarding the helipad

The helicopter operating company's operations manual included a register of helicopter landing sites that were used by the company, and pertinent details regarding those sites. The Brisbane River helipad was included in that register. The register details included a caution note regarding river craft during approach and departure, and local pedestrian traffic during approach termination. The register contained no information regarding the load capability of the helipad.

An email dated 1 December 2003 was sent by the helipad owner to the company operating the helicopter regarding access by that operator to the Brisbane River Helicopter Landing Site. The email stated that the deed of indemnity applying to the operator was attached to the email along with:

a copy of the cover sheet that accompanies the Deed of Indemnity as this cover sheet provides details of access restrictions etc.

However, the investigation was unable to establish conclusively that details of the access restrictions had been attached to the email. The deed of indemnity, signed by the helicopter pilot under the company seal, was returned to the helipad owner by facsimile on 1 December 2003 under the signature of the company operations manager.

The pilot reported that he had not sought any information from the helipad owner regarding the load capability of the helipad and claimed that he was not aware that the helipad had a load rating. He stated that he had never seen any document regarding a load rating for the helipad and that the helipad owner had never advised him of a weight limit for operating on the helipad. His rationale for not seeking information regarding the load capability of the helipad was that both the helipad owner and CASA were aware that he was operating the helicopter onto the helipad and neither organisation had advised him against such operations. He had therefore presumed that it was safe to land on the helipad.

The pilot believed that a Bell 412 helicopter operated by the helipad owner had landed on the helipad, and that 'countless other helicopters of larger sizes' than the Agusta 109 had operated onto the helipad. (Personnel involved in the operation of the helipad owner's Bell 412 helicopters reported that they had never operated the Bell 412 helicopter type onto the Brisbane River helipad. No record was found to indicate that any helicopter larger than the Agusta 109, or any other wheel equipped helicopter, had landed on the helipad.)

Operator's procedures

The operator advised that its standard procedures for operating onto a marine helipad included the following after-landing checks:

• visually determine if the helicopter is actually centred on the heli-pad;

• visually observe the deck of the pad to make sure [sic] it is holding the aircraft well; and

• Apply the handbrake and allow passenger(s) disembarkation.

The pilot reported that he followed those procedures for all landings on helipads with both wheel and skid equipped helicopters, and did so on this occasion. In the case of the Agusta A109C, it was necessary to open the door to view below, and fore and aft of, the helicopter. When he checked after landing whether the right main wheel was causing any stress to the helipad surface, it was as part of his standard practice and not because he was unsure as to whether the deck would support the helicopter.

Regulatory aspects

The Civil Aviation Safety Authority issued the Civil Aviation Advisory Publication (CAAP) 92-2(1), in January 1996 titled Guidelines for the establishment and use of helicopter landing sites (HLS). The CAAP included the following introductory statement:

The information contained in this publication is advisory only. There is no legal requirement to observe the details as set out. The Civil Aviation Regulations detail the legal requirements that must be complied with in relation to use of areas for takeoff and landings by a helicopter. While there may be a number of methods of ensuring that the requirements of the Civil Aviation Regulations are met, this CAAP sets out criteria which ensures compliance with the regulations. The CAAP must be read in conjunction with the Civil Aviation Regulations.

The following text appeared under the heading 'Purpose of this CAAP':

Civil Aviation Regulation 92 (1) states that: "an aircraft shall not land at, or take-off from, any place unless: … (d) the place …. is suitable for use as an aerodrome for the purposes of the landing and taking off of aircraft; and, having regard to all the circumstances of the proposed landing or take-off (including the prevailing weather conditions), the aircraft can land at, or take-off from, the place in safety."

Regulation 92 (1) does not specify the method of determining which "circumstances", other than the prevailing weather conditions, should be considered in any particular case. These matters are the responsibility of the pilot in command and, in some circumstances, are shared with the aircraft operator.

These guidelines set out factors that may be used to determine suitability of place for the landing and taking off of helicopters. Experience has shown that, in most cases, application of these guidelines will enable a take-off or landing to be completed safely, provided that the pilot in command:

• has sound piloting skills; and

• displays sound airmanship.

Under the heading 'Factors that should be considered prior to using an HLS', the CAAP stated, in part, that:

The pilot of the helicopter operating to, from or at an HLS should ensure that:

• the HLS is clear of all:

- persons, other than persons essential to the helicopter operation; and

- objects and animals likely to be a hazard to manoeuvring the helicopter, other than objects essential to the helicopter operation; and

• no person outside the helicopter, other than a person essential to the operation is within 30 m of the helicopter; and

• appropriate permission from the owners and authorities has been given.

The CAAP also listed recommended criteria for two types of HLS - Basic and Standard.

The CAAP defined a basic HLS as 'a place that may be used as an aerodrome for infrequent, opportunity and short-term basis for all types of operation, other than RPT, by day under helicopter VMC6'. The criteria for a basic HLS included that it should be large enough to accommodate the helicopter safely and should have a surface capable of withstanding the static and dynamic load imposed by the helicopter.

The CAAP defined a standard HLS as a place that may be used as an aerodrome for helicopter operations by day or night. The recommended criteria for a standard HLS were more comprehensive than those for a basic HLS.

Documents from the helipad owner revealed that in 1992 the question arose as to whether the helipad complied with the then Civil Aviation Authority (CAA) regulations. In 1994, that issue was raised again and there was concern that if the helipad was moved a further 11 metres away from the riverbank to comply with CAA regulations, such action could conflict with the requirements of the Harbours Act.

The consultant undertaking the feasibility study commissioned in late 1996 advised the helipad owner at that time that the CAA requirement impacting on the distance of the helipad from the riverbank had been removed, and that it was now up to the pilot to determine the suitability of a particular location for landing.

The consultant's report, completed in October 1997, expanded on the advice given in late 1996 and discussed some aspects of CAAP 92-2(1). The study noted that 'the type of HLS to be authorised for use at this site under the Civil Aviation Regulations is a little obscure but would appear to fit the 'Marine HLS' model'. The study concluded that the 'existing facility' did not conform to the Marine HLS criteria due to the proximity of the adjacent infrastructure. The study did not address the basic or standard HLS load bearing criteria contained in the CAAP. There was no evidence on the files examined that there had been any follow-up by the helipad owner regarding the criteria of the helipad against those of the CAAP.

Dynamic rollover

A phenomenon known as dynamic rollover can occur during helicopter operations. It arises when the helicopter is placed in a situation where it is pivoting or rolling around a wheel or skid that is in contact with a fixed object.

Dynamic rollover can occur during or prior to the hover when any part of the helicopter acts as a pivot and the helicopter exceeds a critical angle of roll. This angle is dependant upon control limits and, in most helicopters, is in the order of 15 degrees.

Rough ground or obstructions that pin a wheel or skid to the ground can contribute to dynamic rollover. Several rollover accidents have been caused by hitting an obstruction with the landing gear or by attempting a take-off with an obstruction next to the gear.

Regardless of rotor design, actions needed to correct a roll rate are the same and should be instinctive: simultaneously reduce collective and adjust cyclic to maintain lateral trim.7

Once started, dynamic rollover cannot be stopped by application of opposite cyclic control alone. For example, if the right skid or wheel of a helicopter contacted an object and became the pivot point while the helicopter started to roll to the right. Even with full left cyclic applied, the main rotor thrust vector and its moment would follow the aircraft as it continued rolling to the right. Quickly applying down collective is the most effective way to stop the development of dynamic rollover. The phenomenon can occur in both skid and wheel equipped helicopters, and all types of rotor systems.8

Dynamic rollover has been identified in Australia9 and overseas as a contributing factor in helicopter accidents.

The helicopter manufacturer advised that the critical dynamic rollover angle for the A109C had not been determined. The static lateral rollover limit for the helicopter was 27.8 degrees at minimum flight weight (the most critical condition). The maximum slope from which the helicopter was able to takeoff and land with adequate safety margins was 10 degrees.

1. Only those investigation areas identified by the headings and subheadings were considered to be relevant to the circumstances of the occurrence.

2. The Hughes 500 and McDonnell Douglas 600 were small utility type helicopters whose normal maximum operating weights were less than 2000 kg. Both were equipped with skid type landing gear.

3. Table B1 of AS/NZS 2272 1996 Plywood Marine stated that 'The stress grade of plywood manufactured to this standard is a minimum of F14. The sectional properties, if required, shall be calculated by the method specified in AS/NZS 2269'. Table 4.1 of AN/NZS 2269 Plywood-Structural stated that the characteristic bending strength of F14 plywood was 40 MPa.

4. 'Stress grade' refers to the classification of a piece of timber to indicate, for purposes of structural design, a set of basic working stresses and stiffness appropriate to that piece. The grade is designated by a number preceded by the letter F eg. F8. The letter stands for "force" and the number is the amount of stress, in megapascals, that the timber will withstand without bendin beyond acceptable limits in a test situation.

5. It was reported that a single-engine Eurocopter Squirrel helicopter, which had a maximum all-up weight of 2,100 kg and a twin-engine Eurocopter Squirrel helicopter, which had a maximum all up weight of 2,540 kg had operated onto the Brisbane River Helipad. However, the operating weights of the helicopters on those occasions were not established.

6. Visual Meteorological Conditions (VMC) define the in-flight conditions (visibility and distance from cloud) under which aircraft should operate to conduct flight under the visual flight rules (VFR).

7. Rotorcraft Dynamic Rollover. A new look at the problem. Flight Safety Australia, April 1999.

8.Rotorcraft Flying Handbook (FAA-H-8083-21) 2000, Federal Aviation Administration, Flight Standards Service.

9.ATSB report 200300982.

ANALYSIS

The circumstances of the accident are consistent with dynamic rollover occurring after the right wheel penetrated the helipad surface and acted as a pivot point about which the helicopter rolled. As the helicopter rolled, the main rotor blades contacted the walkway. Because the timing and order of the events that occurred during the rollover were not available, a detailed analysis of the accident sequence was not possible. However, the pilot's response of applying opposite cyclic control, but not lowering the collective pitch control when the helicopter began to roll was not the most effective method of preventing the development of the rollover. Whether the rollover may have been prevented and/or the consequences limited had the pilot lowered the collective pitch control was not able to be determined.

The pilot did not establish before the landing that the load capability of the helipad was appropriate to the requirements. He appeared to have two bases to support his decision to operate the Agusta A109C onto the helipad. One was that neither the helipad owner, nor CASA, had told him that he could not. Such reasoning was inadequate and demonstrated a low level of risk awareness. The second was that other helicopters of operating weight similar to the Agusta A109C had used the helipad. That reasoning was also inadequate because it did not take into account that those helicopters were skid-equipped, and would not subject the helipad deck to the point loads that would exist with the Agusta A109C. It demonstrated an inadequate level of knowledge.

The location of the deck failure was where the plywood would be subject to the greatest bending for a given load, and consequently, where a failure was most likely to occur. The potential for a similar failure would have been present since changes were made to the plywood sheeting size and grade. However, variability between factors such as helicopter wheel positions, dynamic movement of the helipad, and the pilot's flight control inputs would have changed the effect on the deck of each landing. It is likely that the crack in the underside of the plywood in the area of the deck opposite the failure location was an example of the effect of those factors during a previous landing by the helicopter.

Documentation regarding maintenance of the helipad indicated that the installation of the smaller size sheeting most likely occurred during repairs that were completed in September 2000. At that time, other than by way of the design drawings prepared in 1984, full-width plywood sheeting was not specifically addressed either by the oversighting government department or the contractor conducting the repairs.

The strength of the helipad deck compared with the load imposed by the helicopter can be demonstrated from the following information:

| Decking design load | 73 kg (evenly distributed on each 600 mm x 400 mm panel) |

|---|---|

| Calculated static load on each helicopter main wheel | 928 kg (spread over the tyre footprint, which approximates a point load of 66 MPa) |

| Decking design stress | 5.138 MPa |

| Measured strength of plywood from failed deck | 61 MPa |

| Strength of marine grade plywood | 40 MPa |

It is apparent that the strength of the plywood used in the decking (61 MPa) was approximately 12 times greater than required by the design (5.138 MPa). By comparison, the load applied by each main wheel (928 kg) was approximately 13 times greater than the design load (73 kg per panel).

It is unlikely that the helipad owner calculated the load bearing capability of the helipad with respect to specific helicopters that used the helipad, or their type of landing gear. In particular, the reason for the 2,000 kg load limit, as advised to users of the helipad, appears to be unsubstantiated. The potential for the plywood to be subjected to point loads by helicopter wheels, was not taken into account during the design of the replacement deck. Together with the dynamic movement of the deck by wind and wave action, that effect would have significantly increased the effective ratio of wheel loading to deck design load.

The load limit issues, the installation of plywood deck sheeting of size inappropriate given the existing supporting structure, and the poor condition of some areas of the deck indicated shortcomings in the maintenance and management oversight of the helipad.

Prior to April 2004 there was apparently no awareness within the helipad owner's organisation of the significance of helicopter landing gear configuration to the load bearing capability of the helipad. Nor were there indications that the owner was aware of CAAP 92-2(1), or the guidance it contained. It is likely that those issues were unrecognised due to a lack of aviation technical expertise within the helipad owner's organisation.

CONCLUSIONS

Factors

- Management and maintenance of the helipad did not encompass all the aspects necessary to ensure that the actual load bearing capability of the helipad, including for skid and wheel type landing gear equipped helicopters, was known.

- The actual load bearing capability of the helipad was less than that required for safe use by the Agusta A109C helicopter.

- The pilot did not check before the flight, whether the helipad was capable of safely accepting the loads imposed by the Agusta A109C helicopter.

SAFETY ACTION

On 11 November 2005, CASA advised that is was considering a review of Civil Aviation Advisory Publication (CAAP) 92-2(1) - Guidelines for the establishment and use of helicopter landing sites, which would take into account issues including helipad load bearing capability, including how such information is relevant to owners and users of helipads, the differences in deck-imposed loads for wheel compared to skid equipped helicopters, and whether the load bearing capability of a helipad should be painted on the landing surface.

CASA also advised that it represented Australia on the International Civil Aviation Organization Aerodromes Panel which has established a Heliport Design Working Group to review the design standards for helicopter landing sites. Recommendations from the working group, which are expected in mid 2006, may assist in a review of the CAAP.

On 18 October 2005, the Queensland Government advised that it had undertaken significant action to review and enhance its management and operation of its helicopter landing sites in Queensland since the accident. Those measures included:

- closure and removal of the helipad from the Brisbane River;

- the conduct of an audit of Queensland Government owned helicopter landing sites;

- establishment of a project within the Department of Public Works assisted by a whole of government reference group to develop comprehensive guidelines for administration of Queensland Government helicopter landing sites, in consultation with the Civil Aviation Safety Authority; and

- engagement of a consultant to prepare the guidelines, due for completion in December 2005.

On 9 January 2006, the Queensland Government advised that:

… the consultant appointed to develop guidelines for the management of government helicopter landing sites has been given an extension until 25 January 2006 to complete the guidelines. Following review by the Committee and government consideration, it is anticipated that the guidelines will be finalised and adopted during the first quarter of 2006.