FACTUAL INFORMATION

At about 1921 CST, on 13 July 2004, the left engine of a Fairchild Industries Inc. SA227 DC aircraft, registered VH-KEX, failed during the climb phase after take-off. The aircraft was being operated on a scheduled passenger service from Ceduna to Adelaide, South Australia with 2 crew and 17 passengers.

The crew continued the climb and levelled off at 2,500 ft. The crew broadcast a PAN1 and returned the aircraft to Ceduna aerodrome where the engine was replaced and the aircraft returned to service.

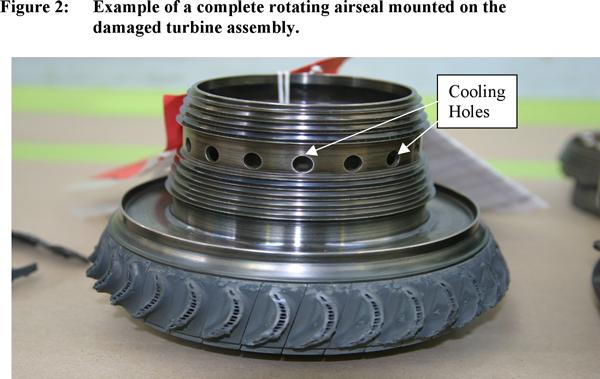

A subsequent examination of the engine, a Garrett TPE331-12UHR, by the operator, in the presence of Australian Transport Safety Bureau (ATSB) investigators, found that the turbine rotating airseal had failed transversely through the cooling holes around the centre of the cylindrical section. That resulted in the liberation of the seal flange and substantial damage to the downstream turbine module (refer Figures 1 and 2).

Since 1995, the engine manufacturer had received four reported failures of the rotating airseal for the TPE331-12 engine. These failures were attributed to progressive thermal cracking. As a result, the manufacturer introduced several service bulletins related to modifications to improve core engine airflow and the introduction of a Fluorescent Penetrant Inspection (FPI) to the rotating airseal. The requirements of these service bulletins had been complied with on this engine during manufacture and FPI was performed at scheduled intervals as required by the manufacturer.

A review of the engine's maintenance history revealed that the aircraft operator's maintenance schedule was in compliance with the manufacturer's requirement and utilised Engine Condition Trend Monitoring (ECTM), a maintenance procedure to monitor the health of an engine. ECTM data did not reveal any degradation of engine performance. At the time of the failure, the rotating airseal had completed 12,326 cycles since new (CSN). The airseal had a manufacturer's recommended life of 20,000 CSN.

The last recorded inspection of the rotating airseal was a FPI at 6,997 hours since new (TSN) and 9,060 CSN by the operator.

At 8,234 TSN and 10,607 CSN, the engine had been subjected to a sudden stoppage as a result of a kangaroo strike. Following that event, an uncommanded stoppage inspection was carried out by the operator. That inspection did not require an examination of the rotating airseal. A further 815 hours (1,129 cycles) later, the engine's propeller governor failed. The operator performed a precautionary overheat inspection of the engine with no defects found.

At the time of the release of this report, the manufacturer had not advised the ATSB of any actions taken as a result of this incident.

The failure of the rotating airseal was consistent with progressive thermal cracking.

- PAN - urgent message follows (international signal)