On Monday, 22 March 2004, the pilot in command of the Fairchild Industries SA-227 aircraft, registered VH-HPE, operating a scheduled Regular Public Transport flight, reported that excessive forward control column force had been required 'to trim the aircraft nose down' during departure from Sydney Airport. The pitch trim selector was switched to the copilot position, control was passed to the copilot, who was then able to trim the aircraft, and the flight continued to Taree, NSW. After landing, an examination by the crew revealed that the pilot in command's (left side) control yoke pitch trim switch was operating in the reverse sense from normal operation.

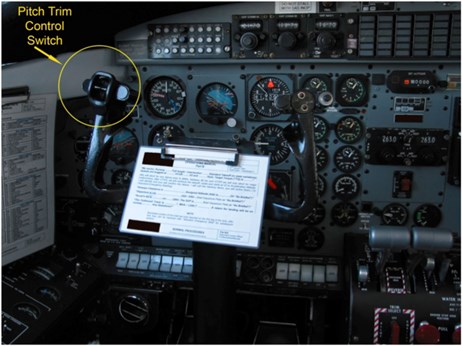

Discussions were held between the flight crew and the operator's chief pilot and chief engineer and a decision was made to continue with the following two scheduled flights before the aircraft returned to a suitable maintenance facility for rectification. A subsequent engineering examination revealed that the pilot in command's pitch trim switch had been installed upside-down and had to be removed and re-installed in the correct orientation (refer figure 1). The pitch trim system was checked for correct operation and the aircraft was returned to service.

Figure 1: Left side pitch trim control switch

In the days preceding the occurrence, the aircraft underwent scheduled maintenance at a contractor maintenance facility. During maintenance, there was a requirement to replace the left side control column pivot bearings. To access the bearings, it was necessary to remove the control yoke and the control yoke pitch trim switch by de-soldering the switch wiring and removing the switch from the yoke housing. After the control column bearings were replaced, the control yoke was re-installed and the trim switch wiring was re-soldered to the respective terminals. The trim switch was then re-installed into the control yoke and the engineers reported that they conducted a full installation and duplicate functional check of the pitch trim system and completed the documentation in the aircraft maintenance worksheets.

During the investigation, the aircraft maintenance engineers responsible for the switch installation and functional check indicated that they had completed the work and that the duplicate functional check was conducted with no apparent discrepancies. The aircraft was then handed over to other maintenance engineers for the completion of further maintenance tasks. The following day, the scheduled departure of the aircraft was delayed due to on-going maintenance rectifications. None of these further maintenance tasks involved the aircraft pitch trim system. Following the delay, the aircraft departed on the occurrence flight after the crew had conducted pre-flight checks, including a check of the pitch trim system cockpit indication for correct operation. The aircraft maintenance engineers had been assigned the maintenance tasks away from their normal location on a weekend and the aircraft was required for scheduled operations on the Monday morning.

The maintenance contractor and the aircraft operator conducted separate investigations into the trim switch misalignment and concluded that the only plausible scenario leading to the misalignment was that the engineers responsible for the pitch trim switch installation had installed the switch incorrectly. The discrepancy had not been detected during the installation and duplicate functional checks or the flight crew's pre-flight checks.

The type certificate data sheet holder for the aircraft type reported that the aircraft Minimum Equipment List (MEL) provides no relief for flight with one pitch trim system inoperative and so the decision to continue the scheduled flights in this condition was contrary to the requirements of the operator's flight operations manual.