Boeing Commercial Aircraft Group, 747-436, G-BNLK

1. FACTUAL INFORMATION

1.1. Examination brief

The disassembled components of an electric air-cooling fan

(figure 1) were received by the ATSB Technical Analysis unit for

examination and analysis of the damaged fan impeller. The fan unit

had been fitted to a Boeing 747 aircraft (registration G-BNLK) to

provide forced air circulation for a forward galley chiller unit.

During the early stages of a flight on 10 August 2002, a small fire

developed in the forward cargo compartment adjacent to this unit

(figure 2). Physical and recorded evidence suggested the fire had

initiated from electrical arcing that was a result of a wiring

short-circuit near the fan terminal housing.

|

|

| FIGURE 1: Cooling fan assembly. Inlet is at top. | FIGURE 2: Cooling fan location (arrowed) behind cargo hold wall. |

1.2. Samples received

Data plates affixed to the fan housing (figures 3 & 4)

identified the unit as a three-phase unit (part number 73259E,

serial number 3676), manufactured by Sunstrand (San Diego,

California) in 1994. The fan was an axial flow design, with a

single bell-shaped impeller manufactured from a moulded resin

material. The motor and fan outlet guide vane assembly shared an

integral housing which also carried the (damaged) electrical

terminal housing. The motor was a brushless (induction) design,

with the armature supported on sealed rolling element bearings.

Surrounding the impeller was an aluminium shroud, which formed the

fan intake and also provided for the mounting and support of the

unit and its associated ducting.

|

|

| FIGURE 3 & 4: Data and wiring information plates affixed to the fan housing. |

|

1.3. Visual examination

1.3.1. Impeller

The impeller unit had been effectively 'cobbed', with all eleven

blades fractured at or immediately adjacent to the impeller hub

(figure 5). The uneven, irregular nature of the fractures suggested

the failure occurred as a cascading fragmentation event, with

multiple sections of blade breaking away and striking others,

causing further break-up. A study of all fracture surfaces failed

to identify any evidence of pre-existing defects or cracking that

may have precipitated the initial blade failure, nor was any

indication found of unusual hard-object impact damage that may have

suggested foreign object ingestion. There was some evidence however

that suggested early damage to the impeller blade forward corners -

many blades showed breakage of a curved lip of material from the

corners in a manner that suggested possible contact with the fan

shroud (figure 6).

The inside surfaces of the impeller body carried a heavy coating

of a powdery brown dust (figure 7), which was also evident inside

the armature core and around the end of the motor housing. This

material was loose and easily wiped away by hand and a sample was

taken for later qualitative chemical analysis.

|

|

| FIGURE 5: 'Cobbing' of all the blades from the impeller body. |

FIGURE 6: Scalloped fracture form at the forward edge of several impeller blades. |

|

|

| FIGURE 7: Dusty brown deposit on inside of impeller body. |

|

1.3.2. Fan shroud

Produced as a machined die-casting from an aluminium alloy, the

fan shroud encased the full impeller length and showed no evidence

of having failed to fully contain the fractured impeller blades.

Around the blade tip path, the shroud internal surfaces showed

several circumferential wear bands that indicated significant tip

interference (figure 8). These were most clearly defined at the

forward and rear limits of the blade path. Random indentation and

scratching damage was noted around the shroud 'throat' region -

this was consistent with the effect of multiple fragment impacts

produced by the failing impeller blades. No specific evidence of

hard-object impact damage was found across the blade path. Dark,

waxy stains produced by an unidentified liquid draining through the

fan shroud were noted at the low-point of the assembly (figure 9)

and a series of tide-marks were formed on the front face of the

shroud as the liquid had accumulated and later drained away.

|

|

| FIGURE 8: Fan shroud showing prominent evidence of rotational contact. |

FIGURE 9: Fan shroud with stains from liquid draining through the assembly. |

1.3.3. Fan motor and housing

Being a brushless three-phase induction motor, the unit was

comparatively simple in construction, with a star-wound stator

containing a compact cage-type armature. Internal inspection found

evidence of rub and erosion of the iron stator former over the

innermost twenty millimetres of the stator length (figure 10),

however the armature did not reflect this and showed no evidence of

operational damage (figure 11). Several areas where material had

been removed by bevelling the core corners were evidence that the

armature had been re-balanced at some time following original

manufacture (figure 12). Both armature shaft bearings rotated

smoothly by hand and showed no notable indications of distress or

abnormal operation. The rear armature bearing housing (figure 13)

contained particulate debris that appeared to be the fine brown

dust mixed with lubricant lost from the bearing unit. The contact

points of the leaf spring and the housing bottom showed light

fretting damage (figure 14), with some evidence of rotation also

noted.

|

|

| FIGURE 10: Motor stator inside surface showing clear evidence of rotational contact against the armature. |

FIGURE 11: Motor armature showing no evidence of contact with the stator. |

|

|

| FIGURE 12: Motor armature with material removed for balancing purposes. |

FIGURE 13: Motor end bearing housing with contaminants found. |

|

|

| FIGURE 14: Area of fretting damage found between the seating spring and housing base. |

FIGURE 15: Electrical arcing damage and associated metal loss. |

The fan motor electrical supply was routed behind the outlet

guide vanes and terminated in an external housing fitted with an

eight-pole connector. A localised area of heavy electrical arcing

was clearly evident adjacent to the connector and had resulted in

the melting and loss of around ten to fifteen millimetres of

material in a v-shaped notch from both the front and side faces of

the connector housing (figure 15). The metal loss had exposed some

of the internal wiring and had produced an appreciable level of

heating around the contact area, as evident from the tinting of the

surrounding surfaces.

1.4. Dust analysis

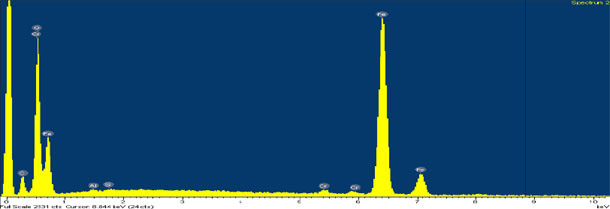

The sample of brown dust recovered from the underside of the

impeller body was qualitatively analysed using energy-dispersive

x-ray spectroscopy techniques under the scanning electron

microscope. The results of this testwork (figure 16) showed the

material to be comprised primarily of an iron-oxide compound, with

traces of chromium, aluminium and silicon.

|

| FIGURE 16: EDS spectra for the brown dust found beneath the impeller. Strong Fe and O peaks. |

2. ANALYSIS

2.1. Impeller failure

All of the failed impeller blades exhibited brittle overload

fractures. No evidence of material flaws, cracks or other

pre-existing damage was shown by the blade stubs, however this was

not conclusive, given the opportunity was not available to examine

all of the blade remnants. Resin materials such as that used to

manufacture the impeller have an inherent lack of ductility and as

such, are prone to cracking and fracture under impact or elevated

stress conditions. While no direct evidence was found to suggest

the ingestion of foreign object/s, the damage sustained was not

unlike that expected from such an event, and thus this possibility

cannot be discounted.

2.2. Motor damage

The abrasion exhibited by the inner sections of the stator

assembly was believed to be evidence of armature contact,

presumably caused by the failure and collapse of the end bearing

unit. The dust under the fan impeller was believed to be an

accumulation of wear products from this contact - both the stator

former and the armature core were ferrous alloys, while the

remainder of the motor and fan assembly was predominantly aluminium

based materials. Given that the installed armature showed no

indication of stator contact and the end bearing was sound, it was

concluded that the stator damage was a product of a previous

failure that had been repaired by replacement of the armature and

the re-use of the remaining components, including the impeller.

The collapse and failure of an armature shaft bearing and the

shaft misalignment that results would be expected to alter the

impeller - shroud clearances, with a risk of contact between the

shroud and the impeller blade tips if the misalignment became

severe enough. Impeller blade tip contact, if it did not produce

immediate blade breakage, may produce latent cracking damage that

could lead to later blade failures if not detected. While there was

no evidence found to suggest that pre-existing damage of this

nature existed, the possibility remained that this damage had been

sustained given the evidence of the rear bearing failure and the

contact marks inside the fan shroud.

2.3. Vibration

Rotary equipment such as the cooling fan relies upon accurate

dynamic balancing to minimise the vibration induced during

operation. Events such as the impeller failure will disrupt the

balance of the assembly and can lead to significantly increased

vibration levels. Wiring or piping that is installed against or in

contact with the vibrating equipment may sustain fretting or

erosion damage if the external protection or insulation has not

safeguarded against this event.

3. CONCLUSIONS

3.1. Findings

- The cooling fan impeller had sustained gross breakage of all

blades at or adjacent to the body of the impeller. - All fractures were brittle in nature and showed no evidence of

pre-existing defects. - No evidence of foreign object damage was found.

- The fracture profiles of some blades suggested preferential tip

breakage before the complete blade failure. - The fan motor showed evidence of a previous rear bearing

failure that had produced contact and wear between the armature and

the stator. The armature had subsequently been replaced, however

the stator and other motor components remained in service. - The previous bearing failure may have allowed operating contact

between the impeller blade tips and the fan shroud. This contact

may have produced blade cracking which predisposed the impeller to

failure in the manner observed. - After failure, the fan impeller would have presented a

significant unbalanced load to the fan.