|

Key points:

|

The ATSB has released a Safety Advisory Notice to Yakovlev Yak-52 aircraft owners and maintainers highlighting the potential for fatigue cracking in Yak-52 aluminium alloy elevator bellcranks.

The Safety Advisory Notice comes as a result of the ATSB’s ongoing investigation into the collision with water of a Yak-52 aircraft during a private aerobatic flight near South Stradbroke Island, Queensland, on 5 June 2019, in which the pilot and passenger were fatally injured.

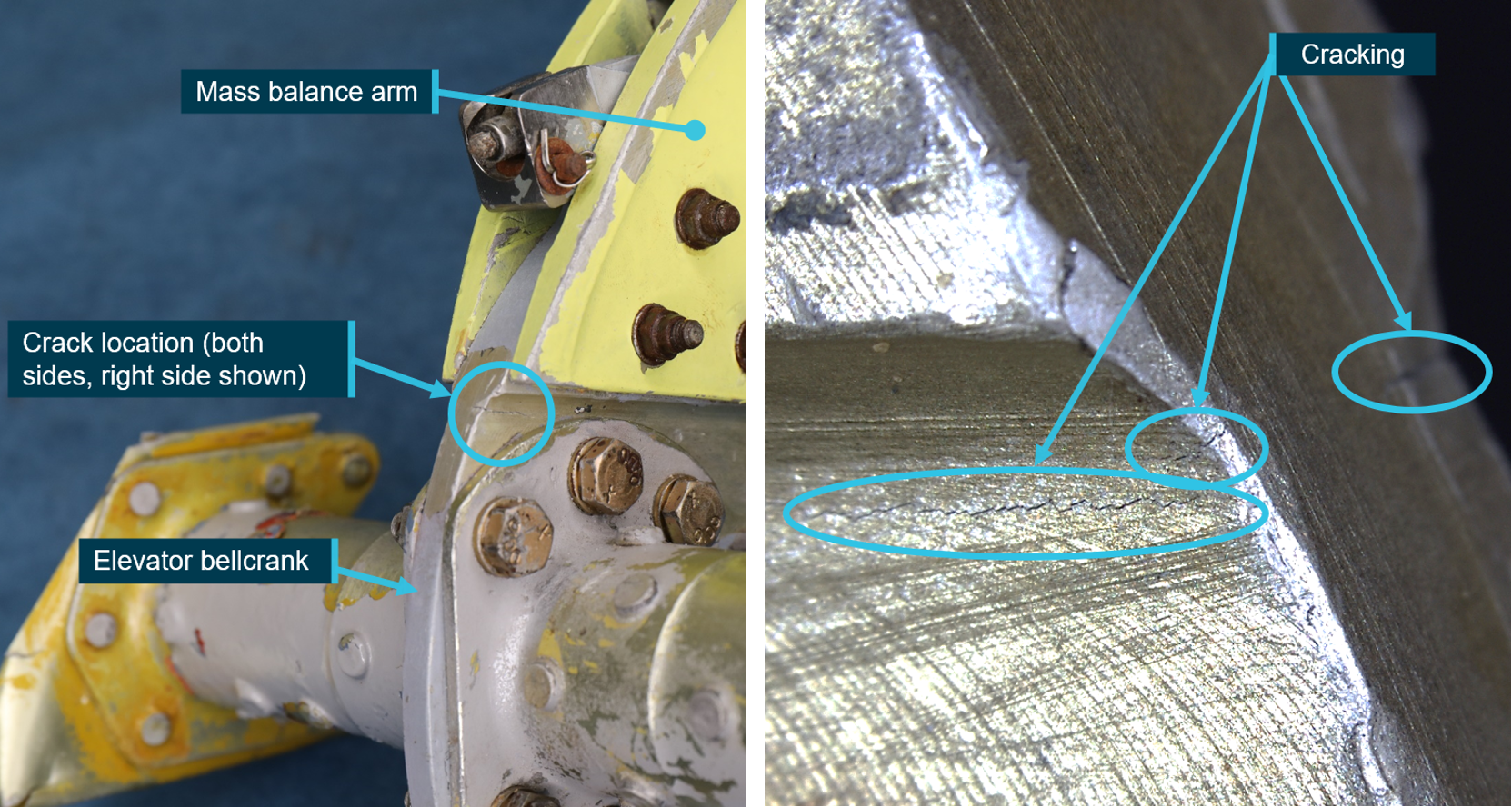

“During the course of the investigation, the ATSB detected two small cracks in the aircraft’s aluminium elevator bellcrank, one of which was established to be a pre-existing fatigue crack,” said Acting ATSB Director Transport Safety, Kerri Hughes.

“The ATSB stresses that the crack did not contribute to the South Stradbroke Island accident. However, cracking in this area can result in the failure of the bellcrank and a subsequent loss of control of the aircraft,” said Ms Hughes.

A review of the available Yak-52 maintenance documentation identified a difference in the requirements for inspecting the bellcrank, Ms Hughes noted.

In 2009, Yakovlev amended the aircraft’s scheduled maintenance program to require a dye penetrant inspection of the elevator bellcrank every 25 flying hours (plus or minus 5 hours). In 2012, as a result of a fatal Yak-52 accident in 2010, where the elevator bellcrank had failed in-flight, Yakovlev directed that all aluminium bellcranks be replaced with steel.

However, the Yak-52 is an ex-military ‘warbird’ aircraft that was not designed to western civil certification standards and is flown in Australia under a Limited category special certificate of airworthiness.* Consequently, neither the 2009 requirement to use dye penetrant inspections every 25 flying hours, nor the 2012 requirement to replace aluminium bellcranks with steel bellcranks, had been incorporated into maintenance schedules for the aircraft in Australia, and nor was there a requirement to do so.

In Australia, Yak-52 elevator bellcranks were required to be dye penetrant inspected every 100 flying hours or 12 months.

“Given the known fatigue cracking and potential failure of Yak‑52 elevator bellcranks manufactured from aluminium alloy, the ATSB reminds maintainers and operators of the importance of dye penetrant inspections to detect and remove defective bellcranks from service,” Ms Hughes said.

“The ATSB would also like to ensure that operators and maintainers of Yak‑52 aircraft are aware that Russia, the aircraft’s state of design, increased the inspection frequency for the bellcranks to 25 plus or minus 5 flying hours. Further, aluminium alloy bellcranks are no longer approved for use on Yak-52s operating in Russia.”

The ATSB’s investigation into the South Stradbroke Island accident is continuing, with a final reported anticipated to be released in the first half of 2021. Pending the publication of an investigation’s final report, the ATSB may issue Safety Advisory Notices to raise awareness of safety critical concerns determined during the course of an investigation without waiting for the conclusion of the investigation.

Read the Safety Advisory Notice AO-2019-027-SAN-024: Elevator bellcrank inspections

* Under the Civil Aviation Safety Authority’s Limited category, operators can fly warbird ex-military and replica aircraft in Australia on an ‘informed participation’ basis where they are willing to accept the risk of the aircraft not meeting international airworthiness certification standards.