The ATSB is investigating an occurrence involving a Qantas A380 aircraft that experienced an uncontained engine failure over Batam Island, Indonesia on 4 November 2010. The aircraft landed safely in Singapore having returned with the aircraft's No 2 engine shut down. There were no injuries.

Update 19 January 2012

The investigation team is being led by the Australian Transport Safety Bureau (ATSB). With the assistance of accredited representatives from the Bureau d'Enquêtes et d'Analyses (BEA), the Air Accidents Investigation Branch of the United Kingdom (UK AAIB), the Air Accident Investigation Bureau of Singapore (AAIB Singapore), the National Transportation Safety Committee of Indonesia (NTSC), and advisors to those investigation bodies including Rolls-Royce, Airbus, SAFRAN Sagem, Honeywell (USA and UK), Aerolec UK and Singapore Aero Engine Services Private Limited, the data gathering phase of the investigation is complete and the team has commenced analysing that data.

During the period July to August 2011, accredited representatives from the BEA and UK AAIB and advisors from Airbus met with ATSB investigators in Canberra, Australia to ratify relevant A380 technical data in respect of the structural and systems damage sustained by the aircraft as a result of the uncontained engine failure. The examination of relevant Rolls-Royce Trent 900 engine data and a number of engine manufacturing processes is nearing completion.

The ATSB has met with Rolls-Royce and Qantas Airways to update those parties on the progress of the investigation. In accordance with international protocol and ATSB policy and procedures, those and other relevant stakeholders will be involved in the development of the investigation findings and final report.

In conjunction with the UK AAIB and Rolls-Royce, the ATSB is continuing its examination of the circumstances and missed opportunities with the potential to have detected the reduced wall thickness and offset counter bore of the oil feed pipe prior to, during and after the manufacture of the module 51 assemblies. The ATSB has also reviewed the quality audits undertaken, and quality assurance system affecting the module 51 design and manufacturing process, and their effectiveness in detecting deficiencies in that process.

In the interim, Rolls-Royce has conducted a number of major internal investigations into its processes including the:

- manufacture of oil pipes with reduced wall thickness

- management of retrospective concessions of manufactured components

- failure mode, effects and criticality analysis (FMECA) of previous component failures.

As a result of those investigations, Rolls-Royce has:

- revised procedures for new structures that include feature verification and risk assessment during the design and manufacture process

- introduced a revised, standalone procedure with appropriate supporting training to better manage the application of retrospective manufacturing concessions

- revised its FMECA procedures to provide 'best practice' numerical justification for any assumptions made.

The investigation will monitor the progress of those initiatives.

Aircraft response to the disc failure

The examination of airframe and systems damage that resulted from the engine disc burst has been completed. That examination did not reveal any significant or critical safety issues.

The continuing repair of the aircraft in Singapore has allowed the examination of relevant removed/replaced aircraft components at the ATSB's technical facilities in Canberra. Those components have included a number of wiring looms, elements of the aircraft's airframe and a number of sub-components.

Airbus proactive safety action

As part of its ongoing examination of this event, Airbus has commenced working with a number of airport and rescue and firefighting agencies to develop an agreed safe means for those agencies to externally shut down engines on Airbus aircraft - as became necessary in this case. Any agreed procedures will be incorporated in the Airbus Aircraft Rescue and Fire Fighting Chart and be made available to airports and fire crews on line in document and poster form.

Ongoing investigation activities

The investigation is continuing and has progressed to the analysis of the large amount of complex factual information that has been gathered during the investigation. The drafting of the investigation report has commenced and will include extensive liaison with domestic and international stakeholders. In accordance with international protocol, that will include a 60-day consultation period for international parties to the investigation.

The final report is anticipated for public release in the third quarter of 2012.

The information contained in this web update is released in accordance with section 25 of the Transport Safety Investigation Act 2003 and is derived from the initial investigation of the occurrence. Readers are cautioned that new evidence will become available as the investigation progresses that will enhance the ATSB's understanding of the accident as outlined in this web update. As such, no analysis or findings are included in this update.

Update 3.00pm - 18 May 2011

An interim ATSB investigation report has confirmed the sequence of events that led to the 4 November 2010 uncontained engine failure on board a Qantas A380 aircraft over Batam Island, Indonesia.

The investigation team has inspected the damaged engine and components and determined the sequence of events that led to the failure of the engine disc.

The investigation is also examining the airframe and systems damage that resulted from the engine disc burst to understand its effect on those systems and the impact on flight safety. That includes their effect on the aircraft's handling and performance and on crew workload. A flight simulator program was used to conduct a number of tests in a certified A380 flight simulator. Analysis of the flight simulation test data is ongoing.

The investigation is continuing.

Interim-factual report AO-2010-089

Update 3.30pm - 23 December 2010

The ATSB investigation into the in-flight uncontained engine failure that occurred over Batam Island, Indonesia on 4 November 2010 is continuing. Two ATSB investigators have recently returned to Australia from meetings with the European Aviation Safety Agency (EASA), Rolls-Royce plc and Airbus. During these meetings the progress and findings of the investigation to date were reviewed and the scope of the ongoing investigation discussed.

In the United Kingdom (UK), Rolls-Royce plc is continuing the examination of the engine HP/IP structures at their facility in Derby, under the supervision of the UK Air Accident Investigations Branch. Rolls-Royce plc is also working with European airworthiness authorities to facilitate the return to service of all affected A380 aircraft.

Work to characterise the oil feed pipe fracture surfaces has identified that the location of the fatigue fracture appears to be associated with the thinnest pipe wall section, consistent with the previously-identified counter-bore eccentricity.

Since early in the investigation, an inspection regime has been in place to detect any abnormal leakages in key parts of Trent 900 engines. Based on recent engine inspections, manufacturing data and stress analysis work, Rolls-Royce plc has revised the threshold for inspection and the intervals at which inspection should be completed.

These revised inspection requirements were mandated through the 21 December 2010 EASA Airworthiness Directive (AD) 2010-0242R1. A copy of the AD is available at: http://ad.easa.europa.eu/ad/2010-0242R1

The ATSB will continue to report significant progress in the investigation as information comes to hand.

Update 3.30pm - 8 December 2010

Results from safety inspections of engines

On 2 December 2010, the ATSB issued a safety recommendation that identified a potential manufacturing defect with an oil tube connection to the high-pressure (HP)/intermediate pressure (IP) bearing structure of the Trent 900 engine installed in some A380 aircraft.

As a result of the safety recommendation, Rolls-Royce plc immediately issued revision 1 to the non-modification service bulletin (NMSB) 72-G595 incorporating assessment and engine rejection criteria for the measurement of potential oil feed stub pipe counter-bore misalignment, and a tightening of the compliance time frame from 20 to 2 flight cycles.

Since the issue of that bulletin, 45 Trent 900 engines have been inspected, and of those engines:

- 29 engines were installed on operating aircraft

- 8 engines were not installed on aircraft

- 4 engines were due to be delivered on a new aircraft

- 4 engines were on a flight test aircraft.

Three engines failed the inspection and were removed from service for further examination. All Qantas aircraft engines currently flying had no defects recorded and remain in service.

In addition, the European Aviation Safety Agency (EASA) approved software updates to the Rolls-Royce plc change to the engine electronic control system has now been incorporated in all operating aircraft. The software upgrade predicts intermediate turbine overspeed events and shuts the engine down before a turbine disc failure occurs.

Update 10.30am - 3 December 2010

Manufacturing problem potential factor in QF32 engine failure

In a preliminary investigation report released today, the ATSB outlines safety actions that have already been taken in response to an uncontained engine failure on board a Qantas A380 aircraft over Batam Island, Indonesia on 4 November 2010.

"The investigation highlights Australian and international cooperation in the interests of aviation safety," said the ATSB's Chief Commissioner, Martin Dolan. "The ATSB is the lead investigator, but many others are involved and their cooperation has been essential".

"We're still in the early stages of investigation," Mr Dolan added, "but significant action has already been taken to minimise the risk of a recurrence". Full media release more...

Update 1.00pm - 2 December 2010

Manufacturing problem potential factor in QF32 engine failure

The ATSB has issued a safety recommendation about potential engine problems in some Airbus A380 aircraft.

The safety recommendation identifies a potential manufacturing defect with an oil tube connection to the high-pressure (HP)/intermediate-pressure (IP) bearing structure of the Trent 900 engine installed in some A380 aircraft.

The problem relates to the potential for misaligned oil pipe counter-boring, which could lead to fatigue cracking, oil leakage and potential engine failure from an oil fire within the HP/IP bearing buffer space.

In response to the recommendation Rolls Royce, affected airlines and safety regulators are taking action to ensure the continued safe operation of A380 aircraft. The action involves the close inspection of affected engines and the removal from service of any engine which displays the suspected counter-boring problem.

The ATSB will hold a media briefing tomorrow (Friday 3 December 2010) at 10.30am to accompany the release of its preliminary factual investigation report into the QF32 occurrence. ATSB Chief Commissioner Mr Martin Dolan will present the known facts gathered from the investigation and highlight the key safety issues that have resulted from the investigation to date.

The full safety recommendation is available via the ATSB website at AO-2010-089.

Update 11.00am - 1 December 2010

Media Briefing

On Friday 3 December 2010, the ATSB will hold a media briefing to accompany the release of its preliminary factual investigation report into the 4 November 2010 engine failure onboard Qantas Flight QF32 over Batam Island, Indonesia.

Update 4.40 pm - 22 November 2010

Engine examination

ATSB investigators examining the engine in Singapore are expected to return to Australia on Wednesday 24 November. The parts of interest from the failed No 2 engine have been removed. This includes the Low Pressure Turbine (Figure 1) module and the Intermediate Turbine module and drive shaft. The Intermediate Pressure components have been photographed and are being shipped to Rolls-Royce in the UK for detailed examination by Rolls-Royce, under the supervision of the UK Air Accidents Investigation Branch.

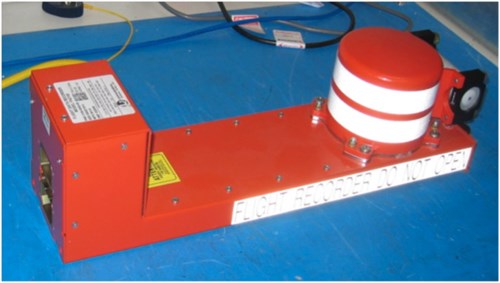

Figure 1: Low Pressure Turbine module removed from the No 2 engine

Aircraft examination

The examination of the aircraft damage is continuing with a focus on the hydraulic, mechanical and electrical systems affected by debris strikes. ATSB investigators involved in this examination are expected to return to Australia on Friday 26 November.

On-going investigation activities

The ATSB is continuing to analyse the recorded data recovered from the aircraft systems.

The next update on this investigation will coincide with the release of the preliminary factual report on 3 December 2010.

Update 4.00 pm - 17 November 2010

Engine examination

The No 2 engine has been successfully removed from the aircraft in Singapore (Figure 1), and is being progressively dismantled in a local engine workshop. The Low Pressure Turbine module has been removed to allow access to the damaged Intermediate Pressure Turbine area for examination. The disassembly and examination of the remainder of the engine should be completed by the end of this week.

The examination of the recovered No 2 engine turbine disk segment at the Rolls-Royce facility in Derby, United Kingdom has been completed. The two ATSB investigators who supervised that examination have returned to Australia. The ongoing examination of relevant No 2 engine components and of any material subsequently recovered from Batam Island, Indonesia will be carried out at the Rolls-Royce, Derby facility. This will be done under the supervision of investigators from the United Kingdom Air Accident Investigation Branch.

ATSB investigators will continue their oversight of activities in the United Kingdom in cooperation with the Rolls-Royce engineering staff in Derby, and with the supervising Air Accident Investigation Branch investigators.

Figure 1: No 2 engine being removed from aircraft

Aircraft examination

The examination of the aircraft in Singapore is also continuing. A number of wing and body fairing panels have been removed from the aircraft to facilitate the examination of the underlying structure and systems affected by the engine failure.

This work is expected to continue for at least the remainder of this week.

Locating aircraft components

The search for the remaining engine debris on Batam Island, Indonesia was concluded by the Indonesian National Transportation Safety Committee and ATSB investigators on Saturday 13 November 2010. A number of small engine components were recovered during the search, including some turbine blades and blade attachments; however, other significant parts of the liberated No 2 turbine disk have not been located.

If anyone on Batam Island finds anything that resembles the remainder of the turbine disk or other engine components, they are requested to contact the local authorities.

On-going investigation activities

ATSB investigators are also reviewing:

- the recorded Singapore Air Traffic Control radio and radar data

- the flight and cabin crew interviews

- the downloaded flight and other data from the aircraft.

Relevant information from these sources will be included in the ATSB preliminary factual report that is planned for public release by 3 December 2010.

Update: 4.00pm - 13 November 2010

Aircraft examination continuing

In Singapore, the No 2 engine has been successfully removed from the aircraft and is being prepared for transport to a local engineering facility for technical examination under ATSB supervision. The removal of the engine will also facilitate closer examination of the damage to the surrounding wing and other structures and systems.

Locating aircraft components

The search for the remaining engine and debris on Batam Island by the Indonesian National Transportation Safety Committee and ATSB investigators and local authorities is ongoing. After initial success, the search is becoming increasingly difficult as a result of the local terrain, which includes virgin jungle (Figure 1).

Figure 1: Indication of the some of the terrain on Batam Island

On board recorded flight and other data

The retrieval and analysis by ATSB investigators of the recorded flight, cockpit voice, engine monitoring and other data is continuing. The aircraft's 'black box' flight data and cockpit voice recorders were removed from the aircraft and returned to Australia immediately after the occurrence.

The aircraft's flight data recorder provided extensive flight and engine data, including from the entire occurrence flight (Figure 2). That data was forwarded to the aircraft and engine manufacturers through the relevant accredited representatives to allow a full understanding by the various parties of the event as the physical and other examinations were taking place.

Figure 2: Aircraft's flight data recorder

The cockpit voice recorder was transported to the ATSB's technical facilities in Canberra, Australia for download and analysis. Over 2 hours of cockpit audio was recovered. However, due to the failure of the No 1 engine to shutdown in Singapore, and therefore continuing power supply to the recorder, the audio at the time of the engine failure well over 2 hours before the No 1 engine could be shut down, was overwritten. That said, elements of the available audio are expected to be of assistance to the investigation.

Figure 3: Aircraft's cockpit voice recorder

A number of other data recorders, such as the aircraft's wireless quick access recorder have also been recovered by the ATSB for download (Figure 4). Those recorders offer a record of additional engine and other parameters to those recorded by the aircraft's flight data recorder. This information is particularly valuable in gaining a full understanding of this type of event, more specifically during the lead up to and during the engine failure.

Figure 4: Aircraft's wireless quick access recorder

Despite initial difficulties as a result of damage to the aircraft's electrical system, the ATSB, in collaboration with Airbus, Qantas, the Air Accident Investigation Bureau of Singapore and the aircraft condition monitoring system manufacturer, have successfully recovered all pertinent data. That data has been shared with Rolls-Royce and other participants in the investigation.

Conclusion

The integration, examination and analysis of the data from the various recorders is continuing, and will supplement the evidence obtained from the examination of the No 2 engine turbine disk segment at the Rolls-Royce facility in Derby, United Kingdom and the disassembled No 2 engine and damaged aircraft in Singapore.

Update: 6.55pm - 12 November 2010

Engine investigation

The examination under ATSB supervision of the No 2 engine turbine disk segment at the Rolls-Royce facility in Derby, United Kingdom is continuing. Boroscopic and other examination of the engine itself continues in Singapore.

EASA Airworthiness Directive (AD)

On 10 November 2010 (European time), the European Aviation Safety Agency issued EASA AD No: 2010-0236-E in respect of the operation of the Rolls-Royce PLC RB211 Trent 900 series engines. The airworthiness directive introduced a requirement for the periodic inspection of the high pressure/intermediate pressure engine structure for any abnormal oil leakage. If any discrepancy is identified, the further operation of that engine is prohibited.

The action by the European Aviation Safety Agency was based on a preliminary analysis of the circumstances of the engine failure by the European Aviation Safety Agency, which the agency said showed that an oil fire in the high pressure/low pressure structure cavity may have caused the failure of the intermediate pressure turbine disc.

Rolls-Royce announcement

This evening, Rolls-Royce announced that its own investigations had led it to draw two key conclusions:

'First, as previously announced, the issue is specific to the Trent 900. Second, the failure was confined to a specific component in the turbine area of the engine. This caused an oil fire, which led to the release of the intermediate pressure turbine disc.'

At this stage, the ATSB does not have enough information to comment on the first conclusion. The second conclusion is not inconsistent with the ATSB's work to date in Derby and Singapore. The ATSB supports any proactive safety action that is undertaken in response.

Ongoing ATSB investigation

The effort by the ATSB and investigation team to fully understand the nature and implications of the engine failure and its consequences is ongoing. The search for additional engine and other components on Batam Island, Indonesia enjoyed initial success, with the recovery of a small engine part. The search continues and it is hoped that additional large portions of the No 2 engine turbine disk will be located.

Preparations for the removal of the No 2 engine from the aircraft are nearing completion and it appears that the engine may be able to be removed from the aircraft somewhat earlier than initially planned. Once safely removed from the aircraft, the engine will be transported to a local engine repair facility for disassembly and technical examination under ATSB supervision.

In Australia, the flight crew interviews have been finalised and collated. Qantas has invited ATSB investigators to attend the cabin crew post-incident de-brief.

Update: 12.55pm - 12 November 2010

Locating aircraft components

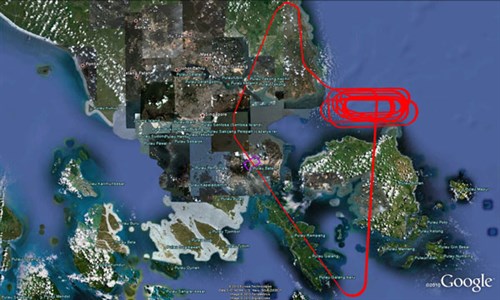

ATSB investigators will arrive in Batam Island this morning to assist Indonesian National Transportation Safety Committee investigators search for the remaining engine and debris on Batam Island. The mapping of the damage to the aircraft is complete and has meant that the search will concentrate to the right of the aircraft's track (Figure 1). Assistance from the local authorities on Batam Island and a number of Rolls Royce staff is being coordinated by National Transportation Safety Committee investigators. Any recovered engine components will be forwarded to the Rolls Royce facility in Derby, United Kingdom for technical examination under ATSB supervision.

Figure 1: Search area of interest (aircraft tracking from top to bottom)

click photo for larger version

Cabin crew interviews

ATSB investigators are gaining an understanding of how the cabin crew managed the cabin safety during the recovery of the engine failure as well as during the landing and exit of passengers at Singapore. Initial planning is to interview the cabin manager and relevant cabin services staff. A survey of the remaining cabin services staff is also being planned.

Figure 2: Aircraft track showing the departure from Singapore, the holding pattern as the crew managed the emergency and reduced the aircraft's landing weight and the recovery to Singapore

click photo for larger version

Aircraft examination continuing

Internal examination of the on-wing No 2 engine has been carried out via borescope and a specialist lifting cradle is en route to Singapore from Germany to facilitate the removal of the engine from the aircraft. That removal is planned for this weekend.

A number of electronic engine control and other components have been removed from the engine and sent to the Rolls Royce facility in Derby, United Kingdom for examination and possible recovery of recorded data.

Turbine disk examination

Technical examination of the sectioned No 2 engine turbine disk at the Rolls Royce facility in Derby, United Kingdom is ongoing. Additional areas of the disk are being sectioned before cleaning for closer examination. If located on Batam Island, the remainder of the turbine disk and other engine components will be subjected to similar examination.

Update: 2.50pm - 11 November 2010

Safety action in response to the engine failure

On 10 November 2010 (European time), the European Aviation Safety Agency issued airworthiness directive EASA AD No: 2010-0236-E in respect of the operation of the Rolls-Royce PLC RB211 Trent 900 series engines. The airworthiness directive introduces a requirement for the periodic inspection of the high pressure/intermediate pressure engine structure for any abnormal oil leakage. If any discrepancy is identified, the further operation of that engine is prohibited.

This action is based on a preliminary analysis of the circumstances of the engine failure by the European Aviation Safety Agency, which the agency says shows that an oil fire in the high pressure/low pressure structure cavity may have caused the failure of the intermediate pressure turbine disc.

While the investigation is ongoing, and may take some time to fully understand the nature and implications of the engine failure, the action by the European Aviation Safety Agency to issue AD No: 2010-0236-E represents proactive safety action to minimise risk. That safety action will be reflected in the ATSB preliminary factual report that will be released to the public no later than 3 December 2010.

A full copy of EASA AD: 2010-0236-E is available at: http://ad.easa.europa.eu/ad/2010-0236-E

Update: 10.15am - 11 November 2010

Flight crew interviews

ATSB investigators have completed their interviews of the flight crew, which began in Sydney yesterday, assisted by a senior Airbus A380 test pilot. The flight crew interviews have provided an understanding of the aircraft's performance during the emergency, the effect on the aircraft's systems during that time, and of the flight crew's actions to recover from the emergency. It is anticipated that the examination of the management of the emergency will identify valuable insights into the handling of future emergencies in the A380.

Aircraft examination continuing

Qantas engineers have developed a number of technical orders and work sheets to prepare for the removal of the No 2 engine from the aircraft. It is anticipated that the removal of the engine for disassembly and further examination will occur later in the week.The examination will take place in a Singapore engineering facility under ATSB supervision.

Locating aircraft components

The mapping of the damage to the aircraft is complete. It has been integrated with the relevant recorded flight data to localise the search for the remaining engine and other debris on Batam Island. The results of that integration are encouraging, markedly reducing the potential search area. Investigators from the Indonesian National Transportation Safety Committee are presently returning to Batam Island to coordinate the search with the authorities on the island. ATSB and Singapore Air Accident Investigation Bureau investigators will travel from Singapore to Batam Island to assist with the search.

Turbine disk examination

The initial technical examination of the recovered portion of the No 2 engine turbine disk at the Rolls Royce facility in Derby, United Kingdom has concluded. The disk will be sectioned into more manageable parts. The relevant surfaces and areas will be forensically 'cleaned' before anadditional, more detailed examination.

Failure of the No 1 engine to shut down after landing at Singapore

The ATSB is working with engineering advisors from Airbus, Rolls Royce, the European Aviation Safety Agency and other members of the investigation team to understand the nature and implications of the failure of the No 1 engine to shut down after landing.

Timeframe

The ATSB has begun planning for the release of a preliminary factual report via the ATSB website at www.atsb.gov.au by 3 December 2010. The investigation is anticipated to be completed within 1 year of the occurrence. However, should any critical safety issues emerge, the ATSB will immediately bring those issues to the attention of the relevant authorities or organisations and publish them as required.

Update: 4.50pm - 9 November 2010

Flight crew interviews

The ATSB today commenced interviews in Sydney with the flight crew, and are being assisted by an Airbus A380 test pilot. The flight crew interviews will provide an understanding of the aircraft's performance during the emergency, and of the flight crew's actions to recover from that emergency. The flight crew will also be able to advise what went well during their management of the emergency. This will provide highly useful safety lessons for managing similar incidents in the future.

Aircraft examination continuing

The aircraft has now been moved to a hangar at Changi Aerodrome. An initial internal examination of the No 2 engine has been carried out using a slender optical periscope (borescope). The engine is expected to be removed from the aircraft's wing for technical examination during the next few days.

Locating aircraft components

The ATSB has mapped the damage to the aircraft. This map is being used with relevant recorded flight data to localise the search on Batam Island for the remaining engine and other debris. The ATSB is working with the Indonesian Transportation Safety Committee and Batam Island authorities to recover those components. ATSB investigators are particularly interested in recovering the remainder of the fractured turbine disk. The ATSB advises Batam island residents to avoid handling any of the aircraft components due to potential health risks.

Turbine disk examination

ATSB investigators have arrived at the Rolls Royce facility in Derby, the United Kingdom to examine the recovered portion of the No 2 engine turbine disk. A copy of the recorded flight data has been provided to the engine and aircraft manufacturers by the respective accredited representatives. This will allow the manufacturers to assist with a full understanding of the data and its implications for the investigation.

An investigation of this complexity can take up to a year to complete. However, should any critical safety issues emerge, the ATSB will immediately bring those issues to the attention of the relevant authorities.

Update: 12.15pm - 8 November 2010

The portion of the recovered engine component has arrived in the United Kingdom under the ATSB's custody. The component is being transported to the engine manufacturer's premises in Derby for a detailed technical examination under ATSB supervision. That examination is planned to commence when additional ATSB technical expertise arrives in Derby on Tuesday 9 November 2010.

The examination of the aircraft in Singapore is continuing. This involves mapping the damage to the aircraft as a result of the uncontained engine failure. Once finalized, that damage map may assist the investigation, the Indonesian National Transportation Safety Committee and Batam Island authorities to localize the search for the remainder of the engine component on the island.

In addition, the No 2 engine and surrounds were prepared for the engine's removal from the aircraft. A comprehensive plan for that removal was developed with expert assistance from the engine and aircraft manufacturer members of the investigation team.

An Airbus A380 test pilot will arrive in Canberra today to assist Operations Group investigators. The Operations Group will examine the cockpit indications leading up to the engine failure, and the aircraft operational aspects of the failure and subsequent recovery to Singapore.

It is anticipated that interviews will take place with the flight crew in the next few days.

Update: 9.15am - 7 November 2010

The ATSB has requested any residents of Batam Island that might have recovered additional aircraft items, in particular similar to the portion of what looks like a geared disk at Figure 1, to forward those items to the local police for retention. The recovery of that disk could be crucial to a full understanding of the nature of the engine failure, and may have implications for the prevention of future similar occurrences.

The Indonesian Transportation Safety Committee has assisted the ATSB with the recovery of a number of items of debris from the QANTAS A380 aircraft that sustained an engine failure overhead Batam Island, Indonesia on Thursday, 4 November 2010. The recovered items arrived in Singapore on 6 November, and a portion of a recovered engine component has been prepared for on forwarding to the United Kingdom in the custody of the ATSB. On arrival in the United Kingdom, that item will be examined by the engine manufacturer and other expert parties under the supervision of ATSB investigators.

Additional ATSB investigators will depart Australia on 7 November 2010 for the United Kingdom to oversight the examination of the recovered engine component, and to Singapore to assist the in-place investigation team with the ongoing examination of the aircraft, and of the remaining debris that was recovered from Batam Island.

Figure 1: Portion of recovered turbine disk

At Changi International Airport, Singapore the damage to the aircraft as a result of the engine failure is being mapped by investigators in order to understand the nature of the uncontained engine failure, and the failed number two engine and surrounds is being readied for removal from the aircraft. Once removed from the aircraft, the engine will be transported to an appropriate engineering facility for disassembly and technical examination.

A highly-experienced and technically-qualified international team of accredited representatives and advisors has assembled in Singapore to assist the ATSB investigation. Those representatives and advisors are being overseen by the ATSB and include personnel from the aircraft and engine manufacturers, the aircraft operator, the United Kingdom Air Accident Investigation Branch, the Indonesian National Transportation Safety Committee, the Singapore Aircraft Accident Investigation Bureau and the French Bureau d'Enquêtes et d'Analyses pour la sécurité de l'aviation civile (BEA). Personnel from those organizations and agencies can also be expected to partake in the examination of the recovered engine component in the United Kingdom.

Update: 3.00pm - 5 November 2010

General Manager, Aviation Safety Investigations, Mr Ian Sangston conducted a media briefing today on known factual aspects of the investigation. • Media Release

Update: 11.30am - 5 November 2010

ATSB investigators arrived in Singapore last night to examine the Qantas A380 aircraft. Flight data recorders have arrived in Australia and are currently being downloaded in Sydney. The Australian Transport Safety Bureau is working with international counterparts, including the UK AAIB, Rolls Royce, the French BEA, Airbus, Singapore AAIB and the Indonesian NTSC.

Update: 5:55pm - 4 November 2010

The ATSB has confirmed, following consultation with Singaporean and Indonesian officials that the ATSB will lead the investigation into the incident. Singaporean and Indonesian investigation officials can expect to be invited to be involved in the ATSB investigation in accordance with international protocols.

Indonesian representatives are currently supervising the collection and preservation of physical evidence on Indonesian territory. The ATSB has quarantined a number of aircraft components for later technical examination.

A team of four ATSB investigators are expected to arrive in Singapore early Friday, 5 November.

Update: 4:30pm - 4 November 2010

The ATSB is investigating the incident involving Airbus A380 aircraft operating as flight QF32 near Singapore today and is dispatching a team of four investigators to Singapore tonight. The ATSB is already working closely with its Indonesian and Singaporean colleagues and anticipates commencing its examination of the aircraft tomorrow, Friday 5 November.

Further investigation updates from on-site will be promulgated as they come to hand.

A preliminary factual report is anticipated for public release on the ATSB web site www.atsb.gov.au no later than 3 December 2010. Readers can ensure advice of the release of that report by subscribing to the ATSB web site.