Safety summary

What happened

A coal train MR336 departed for Newcastle after being loaded with coal from Moolarben loading terminal. On route the 25th wagon in the train consist derailed at Antiene and then subsequently collided with another coal train WC915 as it passed in the opposing direction at Ravenan. The collision resulted in the locomotives on WC915 being damaged and derailed and several wagons from both trains were also damaged and derailed.

What the ATSB found

A loading sensor malfunctioned during the loading sequence which stopped coal from being loaded into the 25th wagon. The train loading operator (TLO) was pre-occupied when control alarms sounded and missed viewing the wagon pass under the loading bin. The TLO could not confirm if the wagon was loaded or not in the low light conditions, so instigated a verification check. The TLO unknowingly provided misleading information to check the 28th wagon, rather than the 28th vehicle in the sequence. The empty 25th wagon was not detected by the loading terminal before MR336 departed onto the rail network.

An empty wagon positioned between two loaded wagons was allowed onto the rail network and this known risk materialised in a derailment of the empty wagon. The derailed state of the wagon on MR336 caused the collision with WC915.

The controls for managing loading irregularities, were operational in the Moolarben loading system however, it is likely, the reliability of the alarms to indicate a loading irregularity in the loading system contributed to the TLO questioning their accuracy.

What has been done as a result

Moolarben loading terminal corrected the malfunctioning sensor and implemented more detailed verification processes of the train load out summary. They reviewed their risk assessment for train loading and implemented a number of actions resulting from this review process. The details of these actions is presented in this report.

Safety message

Empty or light loaded wagons positioned between loaded wagons running on the rail network is a known risk that can have severe consequences. Coal loading terminals and rolling stock operators should review their processes to prevent this known risk from materialising.

Train loading

At 0356 on 26 September 2018, coal train MR336 arrived at Moolarben coal loading terminal to load coal and return to Newcastle, New South Wales.

Shortly after, the train driver of MR336 moved the train up to the loading bin in readiness to commence loading. At 0417, loading coal into the wagons of MR336 commenced.

At 0445, the TLO was alerted to a ‘wagon empty detected’ alarm from the loading system.

When this alarm sounded, the TLO was pre-occupied and could not confirm if the wagon was loaded by viewing it as it passed under the loading bin. The TLO then waited for the weighbridge readings for wagons 28 and 29. The TLO received a ‘wagon empty alert’ from the weighbridge but was unable to visually verify if these wagons were empty as the wagons had moved beyond the lit loading area.

Shortly after, the TLO called the Coal Handling Preparation Plant (CHPP) Supervisor to check wagon 28. The CHPP Supervisor confirmed he would check the wagon. The TLO then continued to load the train with the train driver communicating through a combination of telemetry[1] and radio calls.

The CHPP Supervisor and a technician drove up to the front of the loading train then proceeded to count back from the 1st wagon. When they reached the 28th wagon, they checked wagons 27, 28 and 29 and confirmed that all three wagons were loaded.

The TLO continued to load the train, with another three loading interruptions occurring before it was completed at 0645.

Shortly after, the TLO contacted the train driver by radio to advise loading was complete. MR336 then departed the loading terminal on its path to Newcastle where it would unload.

Derailment

MR336 travelled approximately 160 km after departing Moolarben loading terminal before the train derailed on the up main line[2] at Antiene. The leading wheelset of the trailing bogie of the 25th wagon mounted the rail at kilometre mark 274.396 km.[3] The wheelset dropped off the rail in a derailed state at kilometre mark 274.394 km.

Shortly after derailing, a wheelset ejected from its bogie and came to rest at 271.684 kms. The train continued to travel in a derailed state for approximately nine kilometres.

Figure 1: Location of ejected wheelset

Source: ARTC

Collision

As MR336 reached Ravenan, another coal train, WC915 travelling in the opposite direction approached on the down main line.

The second person in WC915 was alerted to something dragging along-side MR336. As WC915 got closer, the second person shouted to the train driver of WC915 to apply full emergency brakes. The train driver applied the emergency brakes as the second person got on the radio to tell the train driver of MR336 to stop immediately.

The trailing bogie on the 25th wagon on MR336 was dragging across the down track fouling the down main line. The lead locomotive of WC915 collided with the dragging bogie that had been partly dislodged from the wagon earlier. The collision between the lead locomotive of WC915 and the dragging bogie caused the wagon it was attached to (25th) and the seven following wagons on MR336 to derail and incur damage to varying degrees.

The 25th, 26th and 27th wagons tipped on their side away from the down main line. The 25th wagon was found without coal.

The locomotives and two wagons on WC915 were derailed and damaged as a result of the collision.

Track infrastructure underneath the derailed rollingstock was damaged and approximately nine kilometres of track and infrastructure between Antiene and Ravenan was damaged to varying degree by the dragging bogie on MR336.

There were no injuries to the train drivers from either train.

Figure 2: Curve and gradient diagram indicating point of derailment and point of collision

Source: ARTC annotated by OTSI

Incident response

The train crew on WC915 contacted Network Control and their organisation’s operations control to inform them of the incident. They checked their locomotives for any fluid loss and confirmed with their operations control that the locomotives were intact.

The rail infrastructure manager sent crews to isolate the site and make it safe. Information was communicated to relevant organisations as required and post incident investigations commenced that afternoon.

__________

- In train coal loading, a telemetry system is used to monitor train speed to ensure an optimum speed is maintained to facilitate coal loading. The train driver is able to observe the desired speed and adjust the power to ensure that speed is maintained.

- In NSW, trains travelling towards Sydney travel in the up direction, trains travelling away from Sydney are travelling in the down direction.

- Kilometre mark in New South Wales is the distance a section of rail is from Platform 1 Central Station, Sydney, New South Wales.

Hunter Valley Coal Chain

Spanning over 450 km the Hunter Valley Coal Chain is made up of coal producers (or mines), rail haulage providers, the Australian Rail Track Corporation (ARTC), three export terminals, port managers and the Hunter Valley Coal Chain Coordinator. Collectively the Hunter Valley Coal Chain facilitates more than 20,000 train trips and the loading of 1,600 vessels annually in order to export more than 80 different types of thermal and coking coal to destinations around the world.

The trains involved in this incident were coal trains.

Australian Rail Track Corporation

The ARTC is the rail infrastructure manager for mainline rail in the Hunter Valley. ARTC was accredited by the Office of the National Rail Safety Regulator (ONRSR) to manage the Hunter Valley rail network.

As the accredited organisation, ARTC is responsible for maintaining the condition of the rail infrastructure to relevant standards and for providing network control for the movements of rollingstock over the network.

The rail track where the derailment and subsequent collision occurred was under the management of the ARTC. The system of safeworking was rail vehicle detection using axle counters to detect the presence of rail traffic in a block section.

Moolarben Coal Complex

The Moolarben Coal Complex is located approximately 40 kilometres north of Mudgee in the Western Coalfields of New South Wales.

Moolarben Coal Operations Pty Ltd (MCO) is the operator of the Moolarben Coal Complex on behalf of the Moolarben Joint Venture (Moolarben Coal Mines Pty Ltd, Yancoal Moolarben Pty Ltd and a consortium of Korean power companies). MCO, Moolarben Coal Mines Pty Ltd and Yancoal Moolarben are wholly owned subsidiaries of Yancoal Australia Limited.

Operating 24 hours a day, the Moolarben Coal Complex comprises four approved open cut mining areas, three approved underground mining areas and other mining related infrastructure (including coal processing and transport facilities).

Moolarben loading terminal

The Moolarben loading terminal is a loading facility built for loading coal trains and forms a significant part of the transport facilities of the Moolarben Coal Complex.

Coal loading process

Train information sent to TLO

Prior to the arrival of the coal train at the loading terminal, the rolling stock operator was responsible for sending Moolarben information relating to train loading. The information which was sent includes but is not limited to wagon and locomotive; type, number, position in consist and loading restrictions (i.e. if some wagons are to remain empty or partially filled).

Information uploading

As the train approaches the loading terminal, the TLO uploads the information provided in preparation to load the train. The data is uploaded into the train load point supervisory control and data acquisition system (SCADA). This system monitors the progress of a train and through the use of algorithms loads the train at a speed and rate so as to optimise the volume of coal loaded on each train against certain customer requirements.

Train movement into loading terminal

Once the information is uploaded by the TLO, the TLO provides the train driver a verbal authority to proceed through the loading terminal via 2-way radio. The TLO also advises the train driver to maintain a speed which was advised to be around 0.7-0.8 km/h. Beyond the initial verbal communication, the train speed is communicated from the TLO to the train via the train speed indicator (TSI) panel in the locomotive cabin. The speed of the train is monitored by sensors at the loading terminal and warns the TLO of any over speed or under speed.

Train loading display screen

Prior to the occurrence (wagon not being loaded), the train loading display screen did not display the wagon number column.

Figure 3: Train loading display screen

Source: OTSI

There was no clear delineation between the ‘wagon’ position in the train consist and the ‘vehicle’ position in the train consist. That is, vehicle position was the physical count of all vehicles (wagons and/or locos) starting from the first vehicle (in the direction of travel) of the train consist. Whereas wagon position was the physical count from the first wagon in the train consist, not including any locomotives. To be clear, if there were 3 locomotives on the front of a head end powered train, wagon number 25 was the same as vehicle 28. The requirement to distinguish between locomotives and wagons was a recent change as a result of Moolarben’s investigation into this occurrence.

Train loading

Moolarben’s coal loading terminal has a semi-automated coal loading system that uses a number of sensors for wagon detection to start and stop coal loading. The coal loading system is overseen by the TLO. The TLO would normally be seated in the loading cabin which was situated above the wagons so coal loading into the wagons could be easily observed.

How the sensors work

The sensors are known as photo electric (PE) sensors. The sensors work by emitting and receiving electromagnetic radiation. If there is an obstruction, the receiver cannot detect the emitted radiation and hence knows there is an obstruction. If the receiver can receive the emitted radiation, the system knows that there is no obstruction.

Figure 4: PE Sensor operation

Source: OTSI

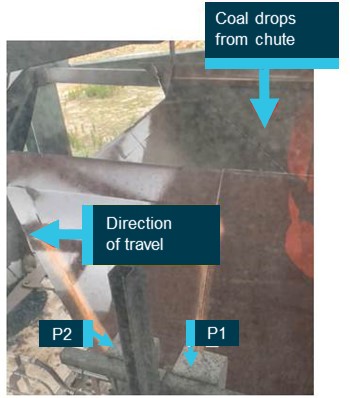

The sensors involved in coal loading were P1, P2, N1, N2, N3 and N3A.

Sensors P1 and P2

Sensors P1 and P2 initiate the loading of coal from the coal bin above the wagons. The coal bin has a capacity of 1000 t and it is continuously monitored and filled by conveyor belts during a typical train loading operation. A typical 93 x 120 t train will carry approximately 9021 t of coal.

The sensors detect a gap between the front of the wagon to be loaded and the rear of the wagon which had just been loaded. Once the front of the wagon to be loaded obstructs P1 and P2, there is a delay and the system instructs the bin gates to open to commence loading.

Figure 5: Sensor P1 and P2 instructing system to drop coal

Source: OTSI

Coal loading then continues as the train progresses at 0.7 to 0.8 km/h.

Sensors N1, N2, N3 and N3A

Sensors N1, N2, N3 and N3A work to instruct the system to stop loading coal. As a gap emerges at N1, it warns the system that it is approaching the end of the wagon and begins to slow the loading of coal. Once a gap emerges at N2, the system instructs the loading to stop completely and by the time there is a gap at N3, the system should have stopped loading coal.

It was advised by Moolarben representatives that a redundant sensor N3A also existed at the time of the occurrence which was used to confirm what the N3 sensor was detecting. This redundant sensor has since been removed.

Figure 6: N1, N2 and N3 sensors

Source: OTSI

Post wagon loading

After the wagons are loaded, they enter a weigh bridge approximately three wagon lengths from the loading terminal in the direction of travel. The weigh bridge measures the weight of the wagons to confirm the wagon has been loaded within tolerances. This weigh data is used as feedback to the SCADA system so as to load more or less coal in the remaining wagons based upon a number of parameters including the speed of the train, the time the load bin chute is open for, etc).

It was advised that if the wagons fall below or above a threshold weight, an alarm is activated to alert the TLO. In this scenario, the wagon may be reversed to load more coal or adjusted to reduce the amount of coal within it.

Safety Interface Agreements

A safety interface agreement is a written agreement for managing the risks to safety at interfaces.

The Rail Safety National Law (RSNL) requires that rail transport operators (i.e. rail infrastructure managers and rolling stock operators) and road managers must enter into interface agreements to manage the risks to safety at interfaces.

Pacific National Pty Ltd and Moolarben Coal Operations Pty Ltd entered into a safety interface agreement between the two parties from the 14 March 2016.

In part 31.2 of the safety interface agreement;

Moolarben Coal Operations Pty limited is responsible for train (wagon) loading operations to ensure wagons are loaded safely and evenly without causing damage to Pacific national property and notification to Pacific National of any wagon loading irregularity, including overloading, underloading (wagons to be loaded within maximum and minimum gross load limit) empty or part loaded wagons, coal spillages, and will ensure wagon loading is carried out, so far as reasonably practicable, as detailed in Pacific National Procedure NSWC005 – Coal Train Loading Process.

Introduction

A number of potential contributing factors were considered in this investigation, including the condition and maintenance history of the rolling stock and the rail infrastructure.

Rolling stock maintenance history was provided by the rollingstock operators and the investigation concluded maintenance did not contribute to the incident. Post incident inspections of the damaged wagons, draw gear, bogies and wheelsets found the damage to be consistent with the derailment and collision and therefore unlikely any pre-existing condition in the rollingstock contributed to the incident.

Track measurements (top, gauge and twist)[4] were taken of the Up Main line from the point of mount (274.396 km)[5] to 100 m in the down direction. Track measurements were also taken up to 25 m after the point of mount in the up direction The track measurements were all within the ARTC’s track geometry standards. Maintenance data for the section of track was provided by the ARTC and the investigation concluded track maintenance and the condition of the track did not contribute to the incident.

The focus of the analysis is on the conditions that led to the derailment of the 25th wagon in the train consist and the awareness of this risk in the industry.

Wagon empty and undetected

There were a number of controls in place at the Moolarben loading terminal to detect when a wagon had not been loaded as required. At the time, Moolarben loading terminal was in process of commissioning various parts of the loading system so that it could be a fully automated loading process without the need for intervention by a TLO.

The loading system was set up with sensors to detect wagons and automatically load each wagon as it passed underneath the coal loading chute. As loading progressed on the morning of the incident, there was a fault in the system which stopped coal from being loaded into the 25th wagon. Moolarben’s post incident analysis of the loading system found the stop loading sensor N3A had malfunctioned. Moolarben loading terminal decommissioned the N3A sensor shortly after.

When loading faults such as this occurred there was the ‘wagon empty detected’ alarm which formed part of the check system that was being commissioned and would form part of the system for automatic loading. In the commissioning phase, this alarm had false triggered on a number of occasions and the confidence level of the TLO in the alarm was not high.

The wagon empty detected alarm sounded as required but was reliant on an action from the TLO to intervene and check that the alarm was indicating an actual event and then set the train back so the wagon could be loaded if required.

At the time the alarm sounded, the TLO was pre-occupied with other non-work related activity which kept his attention long enough to miss being able to confirm if the wagon had been loaded by viewing it as it passed under the loading bin.

When the TLO eventually returned his attention to the train loading, he attempted to confirm whether there was coal in the wagon, however the wagon had moved beyond the lit loading area and in the low light of pre sunrise the TLO could not visually confirm whether there was coal in the wagon or not. The TLO was aware the wagon would be passing over the weighbridge which was also fitted with an alarm for detecting empty wagons.

When the weighbridge alarm sounded indicating there was an empty wagon, the TLO waited for the next wagon to go over the weighbridge to confirm whether the weighbridge was reading correctly. When the following wagon passed over without sounding the weighbridge alarm, the TLO contacted the CHPP Supervisor to check the wagon.

Prior to the incident the train loading display screen for the TLO only had the Seq. No. column. When the TLO contacted the CHPP Supervisor to check the wagon, the TLO called the wagon – wagon 28, when it was in fact the 25th wagon, as there were 3 locomotives at the front of the train.

The CHPP Supervisor and a technician drove up to the position of the 28th wagon by counting back from the first wagon after the locomotives. They checked the 27th, 28th and 29th wagons to confirm all were loaded. As the 25th wagon (28th vehicle in the sequence) was the unloaded wagon, it was missed by this check.

The CHPP Supervisor confirmed the 28th wagon was loaded and the TLO continued to load the train.

‘Less than safely loaded’ wagons

In June 2010, the Independent Transport Safety and Reliability Regulator (ITSRR), the then rail safety regulator in New South Wales, released a rail industry safety notice (RISN No.32) on the ‘Operation of less than safely loaded wagons’.

The safety notice was published following instances of one or more wagons in a coal train consist being left unloaded or lightly loaded and positioned between loaded wagons at a coal loading point on a railway balloon loop off the main line.

The safety notice was directed to coal loading operators and rolling stock operators who were responsible for loading coal into wagons of a coal train to a safe level.

In the 20 months leading to the release of the safety notice, a freight operator in NSW had experienced three incidents most likely attributed to an empty or lightly loaded vehicle entering service undetected post loading, within the train consist. In each case, the empty or lightly loaded wagon had been positioned between two fully loaded wagons resulting in the trailing in-train longitudinal forces either lifting the wagon off its bogie(s), lifting the wagon and bogie(s) off the rail or, the precursor, the forces creating a diminished wheel loading on wheelsets of the affected wagon, which heightens the risk of derailment.

On each of the above occasions, the wagon was retained in the train consist by the solid drawbar connection which prevented the train consist from uncoupling, however, two of the incidents resulted in derailments.

As a result ITSRR provided some key points to consider which included:

- Rolling stock operators to check that suitable and sufficient information has been provided to the loading points regarding appropriate wagon loading configurations (ie. less than safely loaded thresholds) for safe operations.

- Existing controls for the majority of coal loading facilities are predominantly procedural based ie. reliance on the competency and fitness for duty (ie. drug and alcohol, fatigue management, etc) of their coal load personnel and their vulnerability to human error (or performance variability).

- Attention of coal load personnel can also be subject to distraction from other train management, mining and stockpile duties.

- A number of incidents of less than safely loaded wagons have either gone undetected and/or the train crew involved have not been informed prior to completion of the loading activity.

Refer to Appendix A for the full rail industry safety notice.

In July 2019, the ONRSR released a safety message titled; ‘Unsafe Loading of Coal Wagons’. It was an updated safety message with the same safety related content released in response to this occurrence.

Refer to Appendix B for the full safety message.

Derailment

The train travelled approximately 160 km without incident. As the train approached Antiene, it is likely a combination of train handling (train braking was being applied), track geometry (a falling grade of 1:59 and a left hand 690m curve radius[6] into a turnout on tangent track), and the trailing in-train longitudinal forces lifting the 25th wagon and its trailing bogie resulting in the leading wheelset of the trailing bogie mounting the rail at kilometre mark 274.396 km. The wheelset then dismounted the rail in a derailed state at kilometre mark 274.394 km.

The 25th wagon was positioned between two loaded wagons, the front of the wagon was coupled to the 24th wagon and was attached to the 26th wagon by the solid drawbar connection.

Figure 7: Point of Mount (POM) and Point of Dismount (POD) – Antiene Up direction

Source: OTSI

Following the derailment the leading wheelset of the trailing bogie was ejected from the bogie and left on the track at kilometre mark 271.684 km. As the driver remained unaware of the derailment, the train continued with the bogie dragging on the down rail of the up main line within the six foot and foul of the down main line.

Figure 8: WC915 front locomotive footage just prior to collision

Source: Aurizon annotated by OTSI

The derailed wagon and dragging bogie caused damage to multiple parts of the rail infrastructure network. As the train travelled in a derailed state, the NCO received information that may have alerted the NCO to a possible problem however it was received and interpreted in the following manner (see Table 1).

Table 1: NCO log of incident events

Source: ARTC annotated by OTSI to de-identify parties

The responses by the NCO to the track failures as they occurred are likely standard responses taken by any NCO when faced with track irregularities.

At 1202 when the NCO was alerted to an irregularity on the down main line, the NCO’s response was to make contact with the signals team and request they investigate a possible track failure.

This is an immediate action taken by the NCO that attends to a potential problem and would allow the NCO to continue working on other issues while waiting for further information.

When the second track failure occurred at 1209, the NCO’s response was to reset the axle counters which appeared to rectify the situation, although the original track failure remained. The NCO had already taken action on the original track failure and it is reasonable to see he would continue to wait to hear back from the signal team.

At 1216 when there were multiple track failures, the NCO assumed a possible power issue caused by lightning strike or storm which was occurring further north on the rail network and therefore took action by advising the signals team of these other failures.

Between this time and the emergency call made by the crew on WC915, the NCO had an opportunity to make contact with the train crew on MR336 if he suspected there was a problem. Had the NCO made the enquiry, it is likely the crew of MR336 would not have been able to provide any other information that would help the NCO identify the source of the problem.

As at 1225 when the NCO heard the emergency call from WC915, the NCO made contact with the driver of MR336 and made enquiries. MR336 had come to a stand and the crew reported they were not injured. They were also not aware of any issue other than a minor air issue which they deemed not a problem.

It is possible the air issue was a leak in the trains pneumatic braking system[7] as a result of the derailed 25th wagon however such a situation where air is being lost but not significantly so as to automatically apply the brakes, the train crew would remain unaware of there being a problem with the train.

Management of known risk

The risk associated with releasing an empty or lightly loaded wagon positioned between a loaded wagon onto the rail network was known by the rollingstock operator and the loading terminal. The requirement to load wagons safely and evenly was detailed in the safety interface agreement between the two parties.

Moolarben loading terminal had a number of controls in place to ensure wagons were loaded in accordance with the rollingstock operator’s procedure for loading coal trains. This indicated both parties understood the risk and reasonable mitigating controls had been implemented to prevent the risk from arising.

A summary of the risk controls that were ineffective which lead to the unwanted event of an empty wagon positioned between loaded wagons is depicted below (see Figure 9).

Figure 9: Bow tie risk diagram depicting ineffective risk controls in this incident

Source: OTSI

The layers of control (defences) in place failed to prevent and detect the loading irregularity. As a result, the loading terminal reviewed its risk assessment and controls to confirm the systems level of effectiveness. The outcomes from the review included implementation of additional controls, such as extra lighting on the outbound side of the loading chute, two independent mechanisms for detection of empty wagons and a process of verification of the train load out summary between the TLO and the Control Room Operators to ensure each train is loaded within required specification prior to advising the train operator that loading is complete.

__________

- Top – is vertical alignment or rail level; Gauge - is the distance between points on the inside face of the rails; Twist - is the difference in level of the two rails over a defined length, short twist (2 m), long twist (14 m).

- Kilometre mark in New South Wales is the distance a section of rail is from Platform 1 Central Station, Sydney, New South Wales.

- Track curvature is referenced when facing the up direction

- The pneumatic braking system or air braking system is a fail-safe train braking system that uses compressed air for the release and application of brakes across the train

|

ATSB investigation report findings focus on safety factors (that is, events and conditions that increase risk). Safety factors include ‘contributing factors’ and ‘other factors that increased risk’ (that is, factors that did not meet the definition of a contributing factor for this occurrence but were still considered important to include in the report for the purpose of increasing awareness and enhancing safety). In addition ‘other findings’ may be included to provide important information about topics other than safety factors. These findings should not be read as apportioning blame or liability to any particular organisation or individual. |

From the evidence available, the following findings are made with respect to the derailment of MR336 at Antiene and subsequent collision between MR336 and WC915 at Ravenan New South Wales on 26 September 2018.

Contributing factors

- An empty wagon positioned between two loaded wagons on MR336 was allowed onto the network and this known risk materialised in a derailment of the empty wagon.

- The derailed state of MR336 caused the collision with WC915.

- Sensor N3A malfunctioned during the loading sequence which stopped coal from being loaded into the 25th wagon.

- The TLO was pre-occupied when control alarms sounded and missed viewing the wagon passing under the loading bin.

- The TLO instigated a verification check however the TLO unknowingly provided misleading information to check the 28th wagon, rather than the 28th vehicle in the sequence.

- The 25th wagon in the train consist was not loaded and was not detected by the loading terminal.

Other factors that increased risk

- It is likely, the reliability of the alarms to indicate a loading irregularity in the loading system contributed to the TLO questioning their accuracy.

- The TLO could not see if the wagon was loaded or not in the low light of pre sunrise when the wagon had already passed through the loading area.

Sources of information

The sources of information during the investigation included the:

- Moolarben

- Australian Rail Track Corporation

- Aurizon

- Pacific National

- Office of the National Rail Safety Regulator (ONRSR)

- Interviews with directly involved parties

- Video footage of the incident and other photographs and videos taken on the day of the incident and in the days after

References

ARTC curve and gradient

ITSRR

Safety interface agreement

Rail Safety National Law (RSNL)

Submissions

Under section 26 of the Transport Safety Investigation Act 2003, the ATSB may provide a draft report, on a confidential basis, to any person whom the ATSB considers appropriate. That section allows a person receiving a draft report to make submissions to the ATSB about the draft report.

A draft of this report was provided to the following directly involved parties:

- Moolarben

- Australian Rail Track Corporation

- Aurizon

- Pacific National

- ONRSR

- Transport for NSW

Submissions were received from:

- Moolarben

- Australian Rail Track Corporation

- Pacific National

- Transport for NSW

- ONRSR

The submissions were reviewed and, where considered appropriate, the text of the report was amended accordingly.

Appendix A – Rail Industry Safety Notice (RISN No. 32)

Appendix B – Safety Message: Unsafe Loading of Coal Wagons

This safety message is directed to coal loading operators and any other rolling stock operators responsible for loading coal into wagons.

Recently a coal train consist at a coal loading point on a railway balloon loop off the main line in New South Wales was allowed to depart with an unloaded wagon. The unloaded wagon subsequently derailed on the main line whilst the train was braking to negotiate a curve.

The empty wagon had been sandwiched between two fully loaded wagons resulting in the trailing in-train longitudinal forces either; lifting the wagon off one of its bogies, lifting the wagon and one of its bogies off the rail or, as a precursor, the forces created a diminished wheel loading on wheelsets of the affected wagon - subsequently heightening the risk of derailment.

Further the wagon was retained in the train consist by a solid drawbar connection which prevented uncoupling and resulted in a derailment. One bogie dislodged from the centre casting and rotated under the vehicle before fouling the adjacent track. The derailed bogie was subsequently struck by another coal train traveling on the adjacent track causing that train to derail.

In view of the above, it is imperative that the actual load in each wagon is ascertained at the loading points prior to the consist entering a rail transport operator’s network.

Points to consider

- Rolling stock operators should check that suitable and sufficient information has been provided to the loading points regarding appropriate wagon loading configurations (i.e. less than safely loaded thresholds) for safe operations.

- Existing controls for the majority of coal loading facilities are predominantly procedural based i.e. reliance on the competency and fitness for duty (i.e. drug and alcohol, fatigue management, etc.) of their coal load personnel and their vulnerability to human error (or performance variability).

- Attention of coal loading personnel can also be subject to distraction from other train management, mining and stockpile duties.

The following actions should be taken by rail transport operators

ONRSR requires coal loading operators and rolling stock operators to carry out their respective railway operations in relation to loading coal into wagons of a coal train in a safe manner, to do so in a way that does not threaten safety. Coal loading operators and rolling stock operators should:

- Review the risks associated with operations and loading of coal trains, in particular ensuring correct and known loading configurations are met for the subsequent movement of the train away from the coal loading facility.

- In the context of this safety message review the current standards, procedures, rules and control measures including safety interface agreements to ensure:

- clear delineation of roles and responsibilities;

- Ongoing effectiveness of existing controls; and

- Opportunities to implement additional controls including engineering controls such as ultrasonic load profile detectors, track based load cells, etc.)

This advice is effective immediately

Purpose of safety investigationsThe objective of a safety investigation is to enhance transport safety. This is done through:

It is not a function of the ATSB to apportion blame or provide a means for determining liability. At the same time, an investigation report must include factual material of sufficient weight to support the analysis and findings. At all times the ATSB endeavours to balance the use of material that could imply adverse comment with the need to properly explain what happened, and why, in a fair and unbiased manner. The ATSB does not investigate for the purpose of taking administrative, regulatory or criminal action. TerminologyAn explanation of terminology used in ATSB investigation reports is available here. This includes terms such as occurrence, contributing factor, other factor that increased risk, and safety issue. Publishing informationReleased in accordance with section 25 of the Transport Safety Investigation Act 2003 Published by: Australian Transport Safety Bureau © Commonwealth of Australia 2020

Ownership of intellectual property rights in this publication Unless otherwise noted, copyright (and any other intellectual property rights, if any) in this report publication is owned by the Commonwealth of Australia. Creative Commons licence With the exception of the Coat of Arms, ATSB logo, and photos and graphics in which a third party holds copyright, this publication is licensed under a Creative Commons Attribution 3.0 Australia licence. Creative Commons Attribution 3.0 Australia Licence is a standard form licence agreement that allows you to copy, distribute, transmit and adapt this publication provided that you attribute the work. The ATSB’s preference is that you attribute this publication (and any material sourced from it) using the following wording: Source: Australian Transport Safety Bureau Copyright in material obtained from other agencies, private individuals or organisations, belongs to those agencies, individuals or organisations. Where you wish to use their material, you will need to contact them directly. |

Train 1 details

|

Track operator: |

Australian Rail Track Corporation |

|

|

Train operator: |

Pacific National |

|

|

Train number: |

MR336 |

|

|

Type of operation: |

Freight |

|

|

Consist: |

Coal |

|

|

Departure: |

Moolarben loading terminal |

|

|

Destination: |

Newcastle |

|

|

Persons on board: |

Crew – 2 |

Passengers – N/A |

|

Injuries: |

Crew – 0 |

Passengers – N/A |

|

Damage: |

Substantial [7 wagons damaged] and nine kilometres of track |

Train 2 details

|

Train operator: |

Aurizon |

|

|

Train number: |

WC915 |

|

|

Type of operation: |

Freight |

|

|

Consist: |

Coal (empty) |

|

|

Departure: |

Newcastle |

|

|

Destination: |

Werris Creek |

|

|

Persons on board: |

Crew – 2 |

Passengers – N/A |

|

Injuries: |

Crew – 2 (minor) |

Passengers – N/A |

|

Damage: |

Substantial [2 locomotives and 2 wagons damaged] |

|

Central to the ATSB’s investigation of transport safety matters is the early identification of safety issues. The ATSB expects relevant organisations will address all safety issues an investigation identifies. Depending on the level of risk of a safety issue, the extent of corrective action taken by the relevant organisation(s), or the desirability of directing a broad safety message to the rail industry, the ATSB may issue a formal safety recommendation or safety advisory notice as part of the final report. All of the directly involved parties were provided with a draft report and invited to provide submissions. As part of that process, each organisation was asked to communicate what safety actions, if any, they had carried out or were planning to carry out in relation to each safety issue relevant to their organisation. The initial public version of these safety issues and actions are provided separately on the ATSB website, to facilitate monitoring by interested parties. Where relevant, the safety issues and actions will be updated on the ATSB website as further information about safety action comes to hand. |

Safety action not associated with an identified safety issue

|

Whether or not the ATSB identifies safety issues in the course of an investigation, relevant organisations may proactively initiate safety action in order to reduce their safety risk. The ATSB has been advised of the following proactive safety action in response to this occurrence. |

Moolarben loading terminal

Following the occurrence Moolarben conducted an internal investigation and developed a number of safety actions in their corrective action plan. During the DIP process Moolarben provided an update on the status of the actions listed below.

Malfunctioning Sensors

Sensor N3A was determined to be faulty and for this reason has been removed from service.

Empty wagon detection sensors have been re-commissioned and are functional.

Verification of train load out summary

Communicate requirement for verification of train load out summary at end of loading by both the TLO and Control Room Operators to ensure train is loaded within required specification prior to advising train operator that loading is complete. Completed.

Review risk assessment for additional train loading requirements

Review of the train load out risk assessment has been completed. Outcomes of this review included the following items;

- Train loading sequence stop and alarms raised if wagon overloaded, underloaded or empty.

- Empty wagon detection via two independent methods, being radar profiling and weighbridge.

- Sequence number, wagon number and unique wagon identifier to appear on train summary page.

- Improve lighting on outbound side of train load out.

- Use of radar for train speed detection.

- Increased monitoring of weighbridge performance.

- Enable recording of train load out CCTV cameras.

- Install scraper blade for removal of coal from the top of a wagon if an overload occurs.

- Upgrade and reprogram the train loading control system to incorporate all of the above requirements.

Complete change management for additional train loading requirements

Complete Change Management for additional train loading functionality requirements as identified by the risk assessment review. The additional requirements listed above have been implemented since the incident occurred.

Review and update train loading manual and training package

Review and update train loading manual and training package including additional train loading functionality requirements and actions to be taken if a wagon is outside of acceptable loading specifications. Completed.