What happened

On 2 January 2017, the pilot of a Van’s RV-6A aircraft, registered VH-TJM, conducted a private local flight from Starke Field aircraft landing area (ALA), Queensland. At about 1029 Eastern Standard Time (EST), after a flight of about 85 minutes, the aircraft approached to land at the ALA on runway 15. The aircraft landed heavily, bounced back into the air, and as it contacted the ground again, the nose landing gear collapsed. The propeller struck the runway and the aircraft nosed over and came to rest inverted. The pilot and passenger were seriously injured, and the aircraft sustained substantial damage (Figure 1).

Figure 1: Accident site showing damage to VH-TJM

Source: Queensland Police

Structures Study

In response to an accident that occurred on 12 August 2005 in Alaska USA, in which a Van’s RV-9A aircraft nosed over during the landing roll and sustained substantial damage, the US National Transportation Safety Board (NTSB) conducted a finite element analysis (FEA) of the nose gear strut and fork from the Van’s Aircraft series RV-6A, -7A, -8A and -9A. The study examined data from 18 previous accidents and one incident in which a Van’s aircraft became inverted during landing. In all cases, the nose gear struts and forks made contact with the ground, initiating the damage sequence. The FEA concluded that the nose gear strut had sufficient strength to perform its intended function.

The report also found that the risk of the fork contacting the runway surface was increased by:

- poor piloting technique

- bounced landings

- low tyre pressure

- heavier engine/propeller weights

- forward centre of gravity

- heavy braking

- runway condition – soft or undulating ground, high grass and depressions of objects on the runway.

The aircraft manufacturer subsequently increased the ground clearance of the nose gear fork by about 2.5 cm (1 inch). The Van’s Aircraft service letter in response to the structures study describes the revisions to the nose gear leg design.

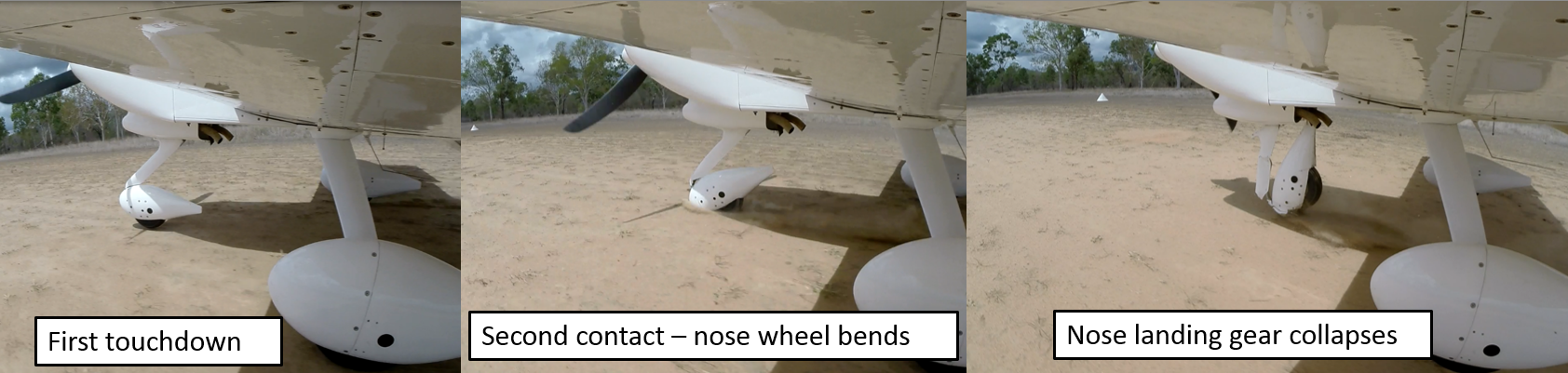

Video footage

Footage from a video recording device, mounted on the underside of the aircraft’s fuselage, showed that the aircraft landed heavily on the initial touchdown. The nose wheel touched very soon after the main wheels and started to vibrate (or shimmy). The aircraft then bounced back into the air and the nose landing gear was still vibrating fore and aft. The nose landing gear was aft of its neutral position when it contacted the ground the second time, just before the main wheels touched again. With that impact, the nose landing gear fork bent and the nose landing gear folded under itself. The aircraft then nosed over.

Figure 2: Landing sequence with collapse of nose landing gear

Source: Video footage supplied by Queensland Police

Safety analysis

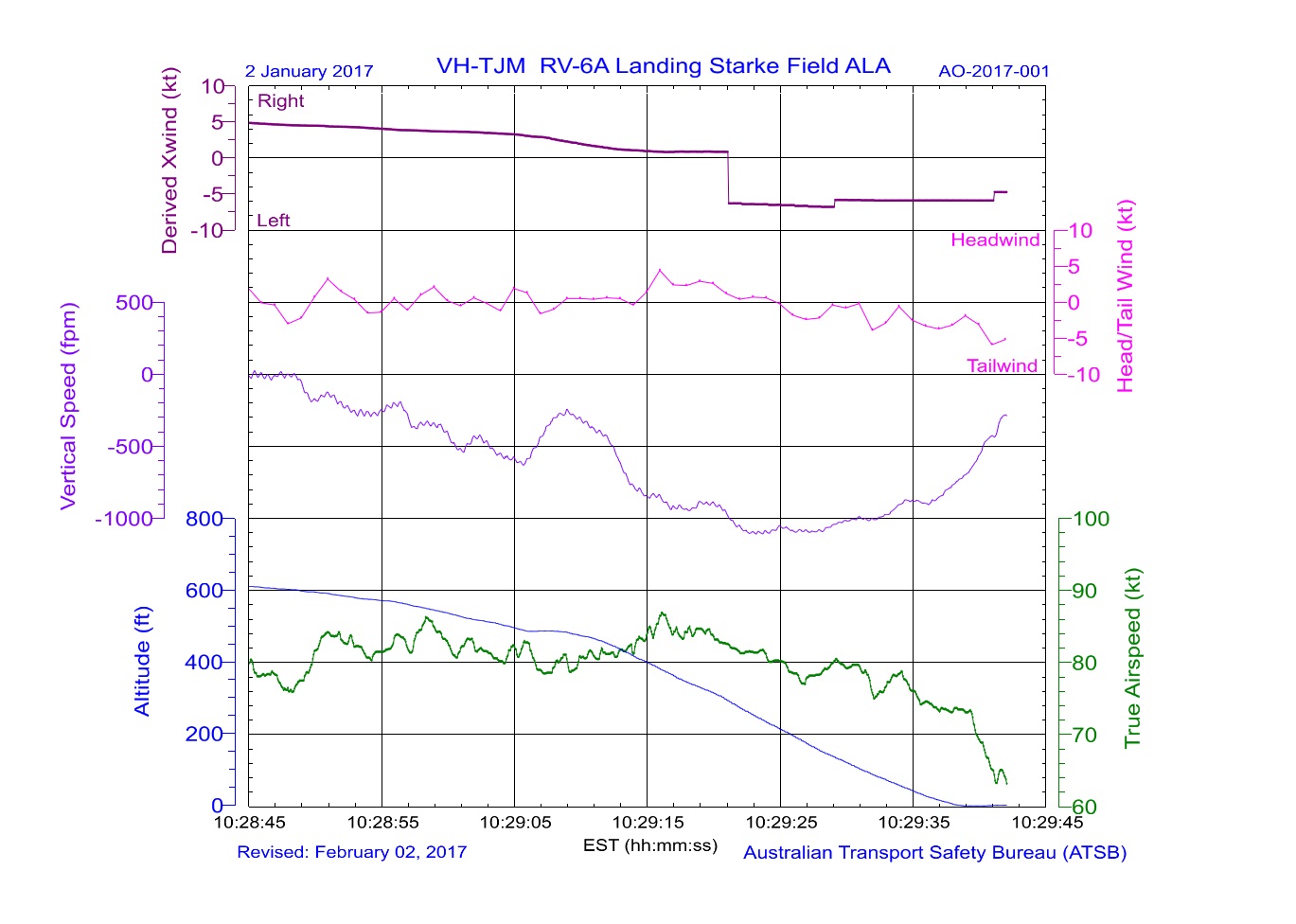

Flight data

The ATSB analysed the recorded flight data from the aircraft’s avionics system for the incident flight. Figure 3 shows the final minute of the flight as the aircraft descended from about 600 ft above ground level. At 1029:21, the wind changed from 335° at 5 kt to 098° at 7 kt, the aircraft encountered a crosswind of 6 kt and the tailwind, which had been about 4 kt reduced to about 1 kt. The vertical speed at that time was about 1,100 ft per minute.

At 1029:38, the aircraft first contacted the ground, at an airspeed of about 75 kt, with a tailwind of 2 kt and descending at about 700 ft per minute.

Figure 3: Flight data extract

Source: Aircraft owner

The aircraft had a stall speed[1] of 48 kt without flaps and 43 kt with 40 degrees of flap, therefore the aircraft landed at about 1.6 times the published stall speed. The normal approach speed for an aircraft is about 1.3 times the stall speed in the landing configuration. The high rate of descent and speed relative to the ground at landing probably contributed to the nose landing gear collapse.

The airstrip operator commented that the preferred landing direction was to the south-east (runway 15) particularly in crosswind conditions, due to trees and a road at the southern end of the runway. This may have contributed to the pilot’s decision to land on runway 15, albeit with a light tailwind.

The pilot had flown the aircraft to be hangered at that airfield about two weeks prior to the incident, so had limited experience landing on the runway.

The NTSB Structures Study found the nose landing gear strut had sufficient strength for its intended function. The study also identified a number of operational factors and local conditions that may contribute to Van’s RV nose-over occurrences. While the ATSB did not perform a detailed analysis into the nose gear failure, factors such as the bounced landing and runway condition were probably relevant to this occurrence.

Findings

These findings should not be read as apportioning blame or liability to any particular organisation or individual.

- The aircraft landed heavily at a high rate of descent and groundspeed, with the nose wheel touching down very soon after the main wheels. This probably led to the nose landing gear collapsing.

Aviation Short Investigations Bulletin - Issue 59

Purpose of safety investigationsThe objective of a safety investigation is to enhance transport safety. This is done through:

It is not a function of the ATSB to apportion blame or provide a means for determining liability. At the same time, an investigation report must include factual material of sufficient weight to support the analysis and findings. At all times the ATSB endeavours to balance the use of material that could imply adverse comment with the need to properly explain what happened, and why, in a fair and unbiased manner. The ATSB does not investigate for the purpose of taking administrative, regulatory or criminal action. TerminologyAn explanation of terminology used in ATSB investigation reports is available here. This includes terms such as occurrence, contributing factor, other factor that increased risk, and safety issue. Publishing informationReleased in accordance with section 25 of the Transport Safety Investigation Act 2003 Published by: Australian Transport Safety Bureau © Commonwealth of Australia 2017

Ownership of intellectual property rights in this publication Unless otherwise noted, copyright (and any other intellectual property rights, if any) in this report publication is owned by the Commonwealth of Australia. Creative Commons licence With the exception of the Coat of Arms, ATSB logo, and photos and graphics in which a third party holds copyright, this publication is licensed under a Creative Commons Attribution 3.0 Australia licence. Creative Commons Attribution 3.0 Australia Licence is a standard form licence agreement that allows you to copy, distribute, transmit and adapt this publication provided that you attribute the work. The ATSB’s preference is that you attribute this publication (and any material sourced from it) using the following wording: Source: Australian Transport Safety Bureau Copyright in material obtained from other agencies, private individuals or organisations, belongs to those agencies, individuals or organisations. Where you wish to use their material, you will need to contact them directly. |

__________