What happened

On the afternoon of 17 July 2016, two pilots departed Bridport Aerodrome in Tasmania in an amateur-built, Europa Aircraft Classic registered VH-BWI and operated in the experimental category. The ownership of the aircraft had recently been transferred and the purpose of the flight was a familiarisation flight for the new owner. After flying to the north-east of Tasmania, the aircraft returned to Bridport and completed two touch-and-go circuits. Shortly after take-off on the third circuit the engine spluttered for a short time, before stopping completely. A forced landing was conducted in a nearby paddock. One pilot sustained spinal injuries and the aircraft was moderately damaged.

What the ATSB found

There was inadequate communication between the pilots, which resulted in VH-BWI departing Bridport Aerodrome with no defined flight plan, no pre-flight brief and each pilot believing the other was in command. The lack of a flight plan prevented the pilots from ensuring there was sufficient fuel and reserves available to ensure safe flight. In addition, in-flight fuel monitoring was not sufficient to identify low fuel quantity and ensure fuel supply to the engine was not interrupted.

The ATSB also identified instances of misinterpretation of a number of the regulations concerning the maintenance of amateur-built experimental aircraft. This has the potential to affect the safety of this aircraft and those on board.

Safety message

All flights, even those conducted for private purposes, should be conducted with due consideration of operational needs and requirements, including appropriate experience, training and licencing on type. This accident highlights the importance of pre-flight planning. Pilots should ensure that every flight is appropriately planned for, utilising accurate flight times and fuel calculations. Once airborne, the continual monitoring of time and remaining fuel should be conducted. The Civil Aviation Safety Authority (CASA) published Civil Aviation Advisory Publication (CAAP) 234 Guidelines for aircraft fuel requirements, which recommends private, visual flight rules (VFR) flights plan for 45 minutes of fixed fuel reserves.

Good communication between pilots, observing recommended operating procedures and effective flight planning, will all help to reduce risk and enable safe flying.

Finally, ongoing safety requires aircraft owners and maintainers to operate and maintain the aircraft in accordance with relevant regulations, including those specific to experimental aircraft.

Photograph VH-BWI

Source: Tasmanian Police

Source: Tasmanian Police

On the afternoon of 17 July 2016, two pilots departed Bridport Aerodrome, Tasmania, on a local flight, in an amateur-built Europa Aircraft (Europa) Classic, registered VH-BWI (BWI). The aircraft was operated in the ‘experimental category’.

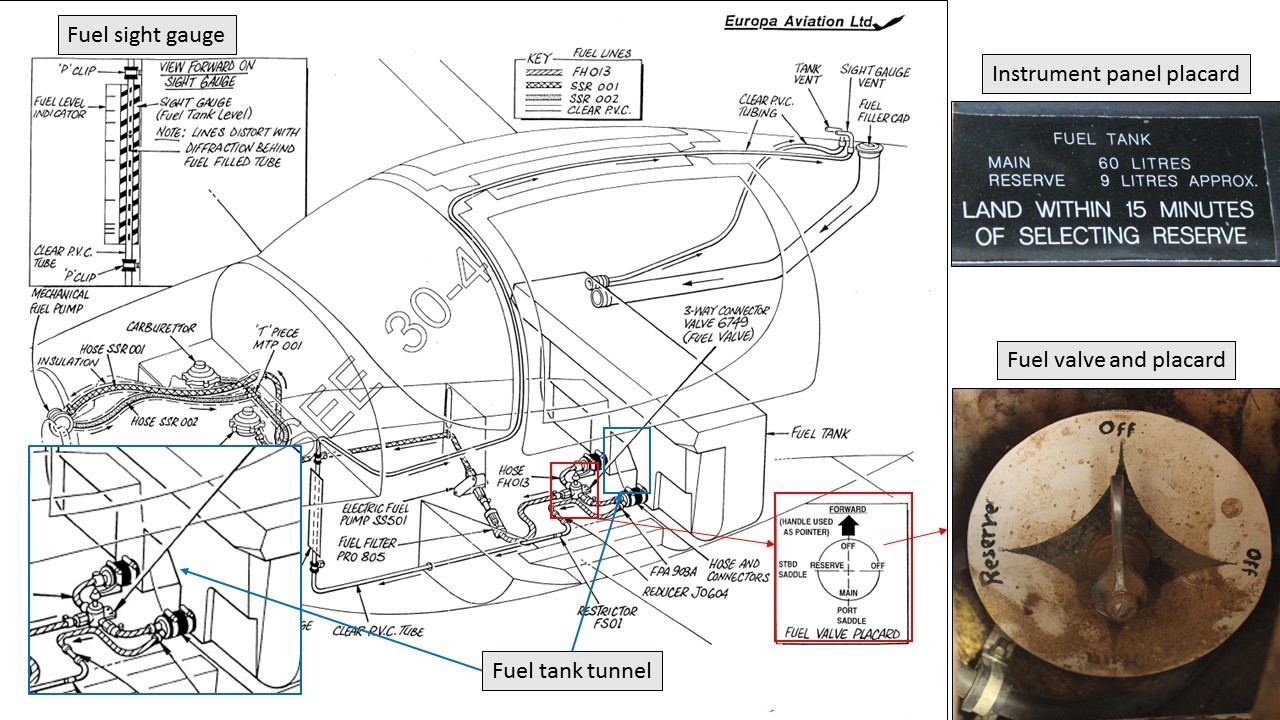

BWI was a two-seat, low-wing, composite kit aircraft. The aircraft could be flown from either seat, however, the fuel sight gauge and instrument panel were oriented primarily for left[1] seat operation (Figure 1). The landing gear consisted of a monowheel and small outrigger castors which were raised or lowered, simultaneously, with operation of the flap lever. A small tailwheel offered directional control on the ground.

Figure 1: VH-BWI and cabin interior showing component locations. Note the instrument panel and fuel sight gauge orientation toward the left pilot. Refer to Appendix A for further detail on the fuel sight gauge.

Source: Used with permission, modified by the ATSB

BWI was first registered in 1998 and was owned by the builder until November 2013. The aircraft had accumulated about 58 hour’s total time when it was purchased by the second owner (pilot B). Pilot B then sold BWI to the current owner (pilot A) on 27 June 2016. However, the transfer of ownership had not yet been completed and therefore pilot B was still the registered owner and operator at the time of the occurrence.

Pilot A flew their Savannah VG from Cranbourn Airport to Bridport in order to conduct a flight in BWI, with pilot B. The two pilots conducted a pre-flight examination of the aircraft together and an engine ground run was conducted, before being shut down. The top engine cowl was fitted and the engine was then started again for the intended flight. Pilot A was in the left seat and pilot B was in the right seat. Engine run-up checks were conducted prior to departure from Bridport Aerodrome, with no anomalies noted by either pilot.

After departure from Bridport, BWI was initially flown toward St Helens,[2] before adverse weather conditions were observed by the pilots. BWI was then flown to the Musselroe Bay area on the north-east tip of Tasmania, about 37 nautical miles (NM) north of St Helens and about 30 NM north-east of Bridport (refer Figure 2 for localities). Upon arrival back in the Bridport area, several circuits involving touch‑and‑gos[3] were conducted by pilot A. The published standard circuit for Bridport is 1,000 ft above ground level, to the north of the aerodrome. However, the circuits in this instance were conducted to the south of the aerodrome, to minimise aircraft noise over Bridport town.

Figure 2: Google Earth map showing Bridport Aerodrome location and other locations mentioned in the report. VH-BWI forced landing location, about 1.5 km west of Bridport Aerodrome.

Source: ATSB and Google Earth, modified by ATSB.

Shortly after the third take-off, when pilot A reported to have retracted the flaps and landing gear and switched off the electric fuel ‘boost’ pump, the engine started to splutter and run rough. At the time, the aircraft was reportedly climbing, with an altitude of between 200 and 500 ft.

Pilot A recalled:

- deciding they were too low for a return to the aerodrome, so prepared for a straight ahead forced landing

- choosing to keep the flaps and landing gear retracted

- concentrating on maintaining control of the aircraft

- selecting a nearby paddock, that was relatively clear of trees and fences, for the forced landing.

When the engine started to run rough pilot B reported saying to pilot A that he believed they had run out of fuel, however from the right seat he could not see the fuel sight gauge to confirm this suspicion. Pilot B recalled:

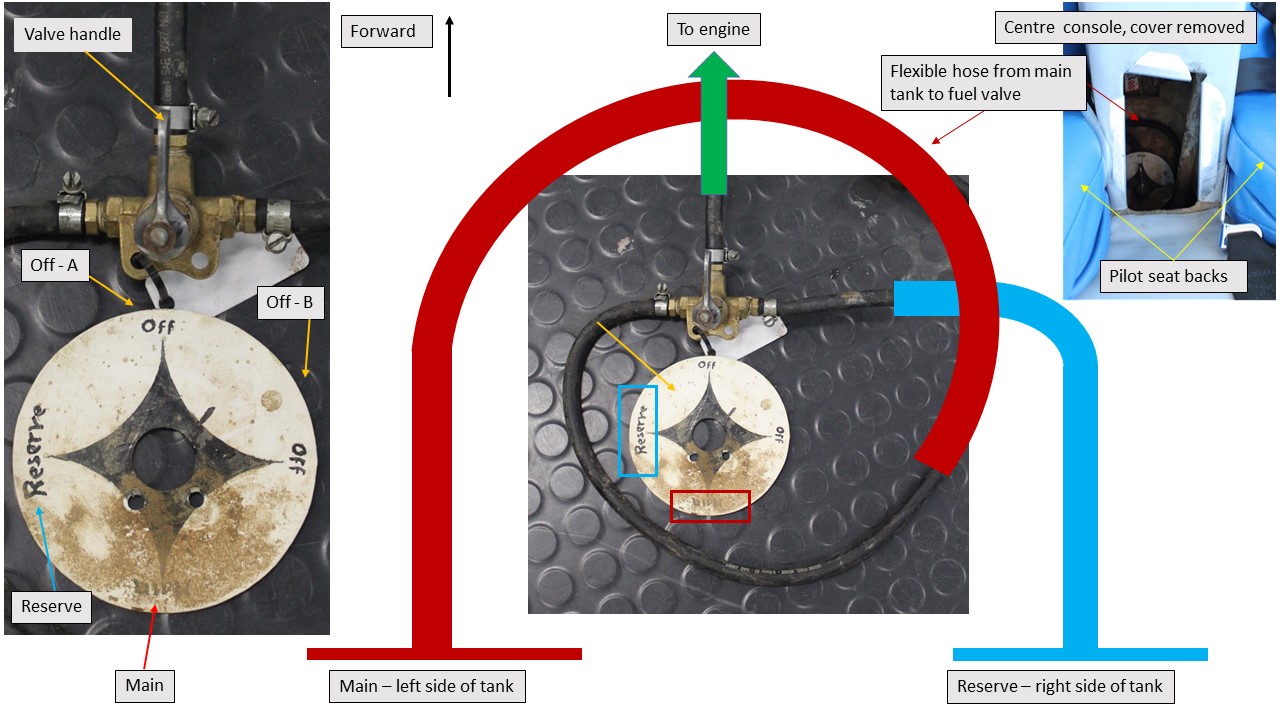

- removing the centre console cover (refer Figure 1) to access the fuel selector valve. Pilot B was in the unfamiliar right seat and was unsure of the direction required to turn the fuel valve to select the other tank. Confirmation was sought from pilot A, before moving the handle through 90˚.

- switching the electric fuel pump on to assist in getting a sufficient fuel flow to the engine

- believing they did not have sufficient height for engine power recovery

- ‘putting in some aileron control’ when suspecting that the current trajectory had them ‘going into the dam’.

The engine initially appeared to recover a little before it and the propeller stopped completely, just prior to the forced landing. The aircraft bounced once, then slid for about 40 m before coming to a stop. BWI landed on an upward sloping paddock, about 1.5 km to the west of Bridport Aerodrome (Figure 2).

Pilot A was uninjured and phoned emergency services, who then transferred pilot B to Hobart by helicopter for suspected spinal injuries. After the landing, pilot A reported moving the fuel valve handle through 180˚, to be pointing forward in the ‘off’ position. When interviewed by the ATSB, pilot A could not recall the in-flight fuel quantity prior to the engine rough running.

During the course of the investigation there were multiple differences identified in the recollections of the involved pilots, which the ATSB was unable to reconcile.

Investigation

Examination of the wreckage identified no pre‑existing mechanical defects that may have contributed to the engine stoppage and hard landing. The three-blade propeller had rearward bending to one blade only, consistent with the propeller not turning at the point of impact.

Conduct of the forced landing

The Europa Owners Manual contained procedures for emergency situations. The engine failure procedures included the following pilot actions:

Trim for 75 kt

Fuel pump on – select reserve

Check ignition on both

Assess height

…

If less than 1,000 feet:

Choose an area straight ahead

Land with gear and flaps down

The manual stated, ‘glide in the clean configuration (gear and flaps up) to achieve best glide range’ and ‘do not try to stretch your glide’. In addition, it was advised ‘only if there is time and you have maintained control of the aircraft should you try to restart the engine’.

The ATSB published Avoidable Accidents No. 3: Managing partial power loss after takeoff in single-engine aircraft[4] to increase awareness about aspects such as the importance of pre-flight decision making and planning for emergencies and abnormal situations for the particular aerodrome. It outlines that:

It may be advantageous to conduct a forced or precautionary landing as if experiencing a total engine failure, as it removes the variability and unknown reliability of some engine power, particularly where there are suitable landing options available. Moreover, all pilots are specifically assessed and trained to deal with a complete engine failure after takeoff.

When the forced or precautionary landing is beyond the aerodrome, the publication advised:

…a pilot faced with an unsuitable area in which to stop should attempt to slow the aircraft as much as possible. Protecting the occupants from injury should be your highest priority, rather than preventing damage to the aircraft.

Using the landing gear…to absorb energy on impact… Avoiding direct contact of the fuselage with solid objects reduces the risk of serious injury.

Pilot A elected to leave the landing gear / flaps retracted for the forced landing, which was not in accordance with the manufacturer’s procedures. However, the off-aerodrome forced landing was conducted almost straight ahead, which was in line with best practice and reduced the risk of a loss of control had a turn back to the runway been attempted.

Fuel system

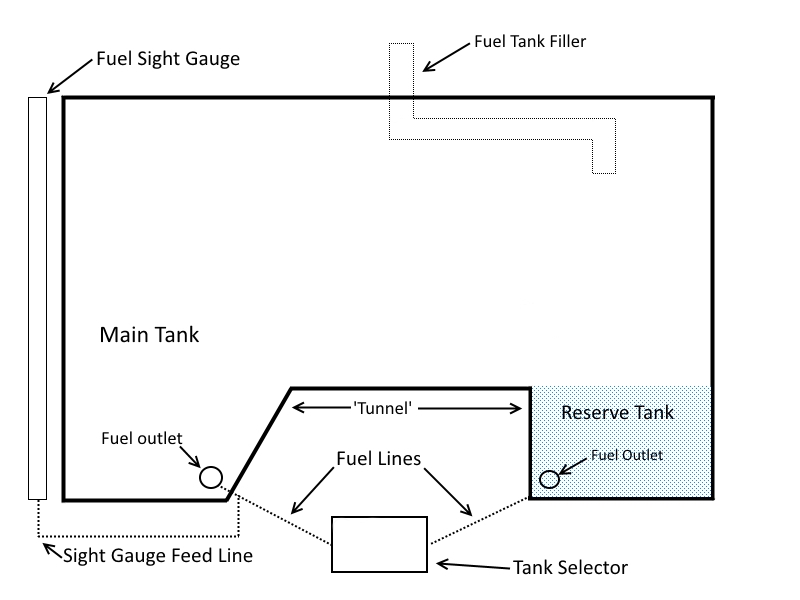

The fuel tank installed in BWI consisted of one large polymer tank located behind the pilots’ seat backs. The lower section of the tank was divided in two by a tunnel to allow for the passage of flight controls to the aircraft’s empennage. The volume on one side of the tunnel was designated as the reserve tank and the volume on the opposite side of the tunnel, plus the volume above the tunnel, was the main tank (although the volume above the tunnel was available to either tank). A detailed examination of the fuel system is covered in Appendix A.

The pertinent findings from the examination were that:

- The fuel sight gauge reflected the fuel quantity available to the engine with the main tank selected. There were no other fuel quantity indicators. In addition, the fuel sight gauge was accurate in flight (level attitude) only.

- The fuel sight gauge scale in BWI included reserve fuel in the indicated quantities, which is not in line with industry best practice.

- An unofficial fuel calibration had been conducted by pilot B to determine fuel quantity when reading the gauge on the ground, with the aircraft in a tail-low attitude. The unofficial calibration resulted in additional marks on the fuel sight gauge that were to be read in conjunction with associated marks on the pilot check card.

- During the unofficial fuel calibration, pilot B reported that 35 litres of fuel was required to be added to the tank to bring the sight gauge to the 5 litre, level (in-flight) mark. This demonstrated that a significant quantity of fuel could be present in the tank, but unavailable to the engine in tail-low attitudes, such as during climb.

- The fuel valve was likely set on the reserve tank for the flight (considering the final position of the valve and both pilot’s recollection regarding movement of the valve).

- The fuel sight gauge (main tank) would not have indicated the reducing fuel levels in the selected reserve tank when the fuel level dropped below the height of the tunnel.

- About 16 litres of fuel was recovered after the forced landing, with approximately equal amounts from each tank drain point. Considering the fuel tank setup and likely movement (sloshing) of the fuel during landing, there was likely to have been about 10 litres on one side of the tunnel and six litres on the other prior to the engine stoppage. The six litres in the selected tank had the potential to allow the fuel to un-port and interrupt fuel flow to the engine.

- Inadequate fuel records for the aircraft had been maintained.

- The aircraft’s log book was incomplete with respect to fuel system maintenance and the aircraft’s fuel filter had been replaced with an unapproved part.

With respect to the aircraft’s electric fuel boost pump, the Europa Owners Manual Normal Operations section stated that following take off, the pump was to be selected to ‘off’ after the aircraft reached 1,000 ft above ground level. The Pilots Check Card and Flight Planner ‘climb’ check differed from the Owner’s Manual, indicating that the electric fuel pump was to be switched off after the flaps and landing gear were selected up and before a cruise climb of 90-100 kt was established. No altitude guidance was provided on the check card for this action. Pilot A reported that they would normally have the electric fuel pump on for standard circuits. In this instance however, pilot A wanted to practice departure and approach procedures. This involved retracting the flaps and landing gear and switching off the pump at about 500 ft as part of the departure climb. This procedure was completed in reverse during the approach.

Weather conditions

The Bureau of Meteorology (BoM) observations from Bridport weather station at about 1500, indicated a temperature of 13 ˚C, relative humidity of 68% and a wind speed of 7 kt from the west. In addition, the BoM area forecast incorporating Bridport indicated isolated showers. The dew point was between 5.1 and 5.6 ˚C at the time of the occurrence.

Both pilots indicated their awareness of carburettor icing conditions and standard mitigating procedures. The recorded temperature, dew point and relative humidity at the time of the occurrence were conducive for serious carburettor icing at any power. However the following conditions indicated that carburettor icing in this occurrence was unlikely:

- In this installation, both carburettors were located on top of the engine, at the rear of the engine compartment. This resulted in air passing through the radiators and over the hot engine before being drawn into the carburettors. The introduction of warm air into the carburettors reduces the likelihood of icing.

- Carburettor icing more commonly occurs at lower engine power settings.[5] In low power settings, the airflow through the carburettor is partially impeded by the throttle valve. This valve provides more area for the ice to form and also increases the partial vacuum downstream of the valve, resulting in further chilling of the air and water droplets. The engine in this occurrence was at a high power setting, prior to the stoppage.

- A search of Australian and several major international aviation databases found that carburettor icing events on Europa aircraft were rare. From more than 120 Europa occurrences worldwide, only one was identified as a possible carburettor icing event.

Regulations

Airworthiness and maintenance

BWI was built in Australia in 1998 from a kit supplied by Europa Aircraft and was issued with a Special Certificate of Airworthiness (SCOA) on 17 August 1999. The log book statement issued at this time required a periodic inspection to be conducted every 12 months, in accordance with the Civil Aviation Safety Authority (CASA) maintenance schedule (Schedule 5).[6] An updated SCOA was issued 27 November 2002 and was subject to the operational and maintenance-related conditions detailed in the associated Annex. The conditions in the Annex included, in part:

...

6. No person shall operate this aircraft unless, within the preceding 12 calendar months, it has had a condition inspection performed in accordance with CASA Maintenance Schedule Number 5, and has been found to be in a condition for safe operation.

7. Condition inspections may be performed by an eligible builder or by a LAME, in accordance with any conditions entered on this special airworthiness certificate.

8. Condition inspections shall be recorded in the aircraft maintenance records showing the following or a similarly worded statement:

-I certify that this aircraft has been inspected on (date) in accordance with the CASA Maintenance Schedule and any conditions on the Experimental Certificate, and has been found to be in a condition for safe operation...

CASA advised the ATSB that, other than a number of specific exemptions, aircraft which are built and operated in the experimental category are to be maintained in accordance with the regulations and any other additional instructions detailed in the SCOA annex. In addition, the regulations document who may carry out maintenance.

The holder of a pilot licence, valid for the aircraft, is authorised to conduct certain maintenance as specified in Civil Aviation Regulation (CAR) Schedule 8 (Schedule 8). In addition, CASA Instrument 15/16 Authorisation of persons to carry out maintenance on certain amateur‑built, kit‑built and light sport aircraft with a special certificate of airworthiness detailed that, in some circumstances, a person who builds or has previously built an amateur‑built aircraft of a similar type (essentially similar),[7] may be authorised to conduct certain maintenance and issue a maintenance release for that aircraft.

Pilot B was the second owner of BWI and had not built it or an essentially similar aircraft and was therefore not authorised to conduct maintenance beyond that permitted under Schedule 8. Pilot B reported that he had sought clarification from representatives of CASA, Recreational Aviation Australia (RAAus) and the Sports Aircraft Association of Australia of the requirements for privileges as per Instrument 15/16, and therefore believed he was authorised, per the essentially similar aircraft clause.[8] The ATSB could not verify the nature of the clarification sought or the response reportedly provided by these organisations. In addition, CASA advised the ATSB that, once an aircraft build has been completed, any task that could affect the continuing airworthiness, (including repairs or reconstruction) is considered to be maintenance.

Maintenance carried out on an aircraft is required to be certified complete in accordance with the regulations. BWI’s log book had multiple occurrences of maintenance that had incomplete certification or was uncertified in its entirety (refer to Appendix A for additional information). In addition, scheduled and unscheduled maintenance had been conducted by a person who was not authorised to do so.

The engine log book contained an incomplete entry, indicating that a periodic inspection was completed on 25 June 2016. There was no corresponding entry in the aircraft log book, as would be expected for this type of inspection. A new maintenance release had been raised at about this time, however it had no certification by an authorised person and was therefore not valid. In addition, details of the accident flight had been endorsed on the previous similarly invalid, and expired, maintenance release.

Ultimately, per CAR 42CB Experimental aircraft, the certificate of registration holder is responsible for ensuring the aircraft is maintained in accordance with the regulations. In addition, CAR 133 Conditions of flight requires the pilot in command to ensure that all the required maintenance has been completed and is appropriately certified.

Recreational Aviation Australia

CASA oversights several self-administering organisations within the sport and recreational aviation sector. Many self-administering organisations operate under a series of exemptions and delegations. This allows specialised craft such as balloons and aircraft that don’t meet certification standards to operate through exemptions from some of the regulations that apply to broader aviation activities. These exemptions also define how the recreational aircraft may be used and where they can be operated.

RAAus administers ultralight, recreational, weight shift microlight and light sport aircraft. RAAus train and certify pilots, flying instructors and maintainers, register their aircraft fleet and oversee a large number of flight training schools across Australia. The Europa Classic can be registered with either RAAus or CASA. BWI was a CASA registered aircraft, and as such, was required to comply with the published CASA regulations.

Pilot licencing requirements for Australian aircraft

RAAus administers the issuing of certificates to pilots to permit them to act as pilot in command of RAAus registered aircraft. Pilot A held a current RAAus pilot certificate which allowed him to operate his other, RAAus registered aircraft. Pilot B had previously held a RAAus pilot certificate however, it was not current at the time of the occurrence.

As BWI was VH-registered, the regulations required it be operated by the holder of a CASA pilot licence. At the time of the occurrence pilot A did not hold any type of CASA issued pilot licence. CASA issued pilot B with a Recreational Pilot (Aeroplane) Licence[9] (RPL) on 12 February 2015. The licence authorised pilot B to operate manual propeller pitch control and retractable undercarriage, single engine aircraft. The licence did not include a navigation endorsement,[10] which was required for operations in excess of 25 nautical miles from the departure aerodrome. While the pilot held the requisite training and documentation to receive this endorsement, the application documentation was insufficient. Pilot B believed they were authorised for navigational flight and therefore any violation in this instance was likely unintentional. This highlights the importance of careful review of documentation for correctness, particularly when transitioning of licences and authorisations.

Pilot A was preparing to apply for a CASA RPL at the time of the occurrence. CASA will issue a RPL to RAAus pilot certificate holders, on the basis of completion of a medical and English test. However, a flight review must be completed with flight instructor to exercise the privileges of the RPL.

Pilot roles on the occurrence flight

At the time of the occurrence, the Civil Aviation Regulations 1988 (CAR) and Civil Aviation Safety Regulations 1998 (CASR) were in force.

CAR Part 2(1) defined the operator of an aircraft as ‘a person, organisation, or enterprise engaged in, or offering to engage in, an aircraft operation’. The CASR defined the operator of an aircraft as ‘the person, organisation or enterprise that make the aircraft available to the aircraft’s pilot in command for a flight’. When an aircraft is registered on the Australian aircraft register, the details of the registered operator are included to ensure that the legal entity of the operator, as specified in the CAR and CASR, is known.

CAR 224 (1) Pilot in command applied to the flight and stated:

For each flight the operator shall designate one pilot to act as pilot in command.

Once designated, the pilot in command had specific obligations under the regulations that directly related to the safe operation of the aircraft. These included ensuring the amount of fuel on board the aircraft was sufficient to safely conduct the flight. That responsibility for fuel was also shared with the operator of the aircraft under CAR 234.

The transfer of ownership of BWI had not yet been submitted to CASA and as such pilot B was the registered operator of the aircraft at the time of the accident flight. Pilot B was therefore responsible for the nomination of the pilot in command for the flight. Although the nomination of a pilot in command was to meet a regulatory requirement, it was also essential to ensure the safe conduct of the flight.

The two pilots had flown together in BWI on three previous occasions, before the transfer of ownership. Pilot A reported he flew the aircraft from the left seat on the second and third flights. Pilot B reported all three flights were conducted with pilot A in the right seat. Pilot A had no formal training or experience flying either a Europa or similar performing low‑wing aircraft other than during these three flights.

Pilot B reported knowing that pilot A did not hold a pilot licence, yet reported telling pilot A, prior to departure, that they (pilot A) would be the pilot in command for the flight. Pilot B indicated that pilot A accepted the role of pilot in command, but wanted pilot B along for confidence, due to their limited experience in the aircraft. Pilot B advised he was not ‘instructing’ pilot A, but rather, offering ‘reassurance’. Pilot A reported that, as pilot B was the previous owner and held a pilot licence, they had the necessary qualifications to act as pilot in command and therefore pilot B was ‘the pilot in charge’.

During the pre-flight preparation most of the time was taken up with running the engine and conducting an examination of the aircraft. Both pilots reported that the aircraft had 45-50 litres of fuel on board and considered that it would be sufficient for the flight. However, neither pilot reported confirming the exact amount of fuel on board, nor conducting specific planning for the flight in terms of actual endurance and reserve fuel amounts.

As there was no agreed confirmation by either pilot as to who was the pilot in command, neither pilot ensured that any of the actions required by the regulations, to ensure a safe flight, were completed.

Despite the aircraft being equipped with dual controls, BWI’s instrument panel and fuel sight gauge were oriented primarily for left seat command operation. Therefore pilot B, in the right seat, was not in an ideal position to act as pilot in command, or to assist if it were required, during flight.

Related occurrences

AO-2009-026 Fuel starvation event involving Bell 206 helicopter, VH-JTI

The pilot was conducting a 20-minute scenic flight with four passengers, from a helipad at an entertainment facility at Coomera, Queensland. After about 15 minutes flying the fuel boost pump low pressure warning light illuminated briefly. The pilot believed he had sufficient fuel on board and continued the flight. While the helicopter was descending to land at the helipad the engine lost power, resulting in autorotation[11] and a forced landing. Two passengers sustained serious injuries.

The investigation found that the helicopter departed with insufficient fuel to complete the flight. The low fuel quantity approaching the helipad increased the risk that any unusual attitudes or out‑of‑balance may uncover the fuel boost pump(s) and starve the engine of fuel.

AO-2011-138 Fuel exhaustion involving Cessna 172, VH-PHV

The pilot was the sole occupant and departed for a private local flight to inspect a number of paddocks at a nearby property. After about 2 hours and 40 minutes the engine began to run rough. The pilot attempted to regain engine performance however, the engine stopped completely a short time later. A forced landing was conducted resulting in serious damage to the aircraft. The pilot was not injured.

The pilot did not conduct a formal fuel plan prior to the flight and his estimates of the flight’s fuel consumption were not consistent with manufacturer published information. In addition, the pilot had not referred to the fuel gauge at any stage of the flight.

The report included the following safety message:

All flights, even those conducted for private purposes, should be conducted with due consideration of operational needs and requirements. This accident highlights the vital importance of pre-flight planning. Pilots should ensure that every flight is appropriately planned for, using accurate flight times and fuel calculations. Once airborne, the continual monitoring of time and remaining fuel should be conducted.

Research

Two ATSB research investigations have identified that amateur-built aircraft are overrepresented in aviation accidents and incidents in Australia. The research shows pilots involved in accidents in amateur-built aircraft had significantly less experience on the aircraft type they were flying at the time of the accident than pilots involved in accidents in factory built aircraft, despite having higher overall flying experience.

Twenty per cent of amateur-built accidents had pilots with less than 10 hours experience on the aircraft type. More than half of all amateur-built aircraft accidents occur prior to the pilot accumulating 35 hours on the aircraft type. This included owner-builders and recent purchasers of second-hand, amateur-built aircraft.

The ATSB[12] has also published a series of Avoidable Accidents information booklets. Booklet 3, Managing partial power loss after takeoff in single-engine aircraft, identified that most fatal and serious injury accidents resulting from partial power loss after takeoff are avoidable. The key message in this booklet stated the benefits of:

pre-flight decision making and planning for emergencies and abnormal situations for the particular aerodrome

conducting a thorough pre-flight and engine ground run to reduce the risk of a partial power loss occurring

taking positive action and maintaining aircraft control, either when turning back to the aerodrome or conducting a forced landing, until on the ground.

Booklet 5, Starved and exhausted, discussed the procedures that pilots can use before and during a flight to help them be absolutely sure they will have sufficient fuel to land at their destination aerodrome, with reserve fuel intact. The key messages in this booklet stated:

Accurate fuel management starts with knowing exactly how much fuel is being carried at the commencement of a flight. This is easy to know if the aircraft tanks are full, or filled to tabs. If the tanks are not filled to a known setting, then a different approach is needed to determine an accurate quantity of usable fuel.

Accurate fuel management also relies on a method of knowing how much fuel is being consumed. Many variables can influence the fuel flow, such as changed power settings, the use of non‑standard fuel leaning techniques, or flying at different cruise levels to those planned. If they are not considered and appropriately managed then the pilot’s awareness of the remaining usable fuel may be diminished.

Keeping fuel supplied to the engines during flight relies on the pilot’s knowledge of the aircraft’s fuel supply system and being familiar and proficient in its use. Adhering to procedures, maintaining a record of the fuel selections during flight, and ensuring the appropriate tank selections are made before descending towards your destination will lessen the likelihood of fuel starvation[13] at what may be a critical stage of the flight.

The ATSB research paper Australian Aviation Accidents Involving Fuel Exhaustion and Starvation was published in December 2002. This paper identified that fuel exhaustion[14] and fuel starvation accounted for over 6 per cent of all accidents between 1991 and 2000. The private and agricultural categories were found to have the highest rates of fuel exhaustion and fuel starvation accidents. In addition, pilots with fewer hours on type are more likely to be involved in fuel‑related occurrences. Mismanagement of fuel (including running one tank dry and incorrect positioning of fuel system controls) contributed to 42 per cent of total starvation accidents. Inattention to fuel supply contributed to 16 per cent total starvation accidents.

The Federal Aviation Administration (FAA) published a series of Aviation Safety Program publications which included, Time in Your Tanks.[15] This publication provided general tips on determining and managing the ‘time’ in your aircraft fuel tank. It also identified that fuel gauges are subject to malfunctions and errors and added, ‘…unless restricted by the gross weight or centre of gravity limits, it is considered good judgment to "top off" the tanks at fuel stops’. ATSB weight and balance calculations concluded it was possible for the occurrence flight to be undertaken with full fuel tanks. In addition, the weight of the occupants could be increased by 28.9 kg, before reaching maximum takeoff weight.

The ATSB database identified 41 occurrences involving RAAus and VH registered Europa aircraft. Four notifications involved partial or total engine power loss.

Database research[16] of Europa incidents and accidents identified about 120 events and that most Europa occurrences were related to operational events. The research identified only a few occurrences related to possible technical issues.

__________

- The terms left and right are used multiple times in the report and are taken as viewed from the rear of the aircraft, looking forward.

- St Helens is located on the east coast of Tasmania, about 41 nautical miles south-east of Bridport.

- An aircraft manoeuvre where an aircraft briefly lands on a runway and takes off again before the aircraft comes to a stop.

- ATSB publications can be accessed via www.atsb.gov.au

- ATSB publication Melting Moments: Understanding Carburettor Icing is available via the website – www.atsb.gov.au

- CASA publications can be viewed via the website – www.casa.gov.au

- Two aircraft are not essentially similar if (among other criteria detailed) they are made of different materials, or if one had retractable landing gear and the other had fixed landing gear.

- Pilot B was authorised by RAAus to maintain RAAus registered aircraft. In addition Pilot B reported to having aircraft maintenance experience through repairing ‘accident-damaged’ aircraft. However, pilot B was not the holder of a CASA aircraft engineer licence.

- CASA introduced the recreational pilot licence (RPL) in September 2014. An RPL will only allow the holder to conduct certain operations, in certain types of aircraft. It is more restrictive than a Private Pilot Licence.

- Pilot B did not complete the required paperwork to enable the ‘cross country’ pilot certificate endorsement to transfer a ‘navigation endorsement’ on the CASA RPL.

- Autorotation is a condition of descending flight where, following engine failure or deliberate disengagement, the rotor blades are driven solely by aerodynamic forces resulting from rate of descent airflow through the rotor. The rate of descent is determined mainly by airspeed.

- ATSB publications can be accessed via the website – www.atsb.gov.au

- Fuel starvation: when the fuel supply to the engine is interrupted although there is adequate fuel on board.

- Fuel exhaustion: when all useable fuel has been consumed.

- Time in Your Tanks (P-8740-03) can be accessed via the FAA website – www.faasafety.gov

- Database research included the websites of investigation bureaus and regulators, from Australia, the United Kingdom, United States and France.

While on a local flight, the two pilots on board an amateur-built Europa Classic, registered VH-BWI (BWI) were conducting a series of touch-and-go circuits at Bridport Aerodrome, Tasmania. Shortly after lifting off for the third circuit the engine began to run rough, before stopping completely. A forced landing was conducted in a nearby paddock. One pilot sustained spinal injuries and the aircraft was moderately damaged.

This analysis will examine the operational and maintenance aspects, including associated risk controls, and discuss their role in the occurrence.

Operational

Fuel management

The investigation identified that neither pilot completely understood the operation of the fuel system, as pilot B reported not fully understanding the system, and pilot A had only recently purchased the aircraft. There was no flight plan, either formal or informal, identifying a track, distance, or time intended to be flown, to allow for fuel endurance calculation. This prevented the pilots from being able to ensure they had sufficient fuel, and reserves, for any flight beyond local circuits.

Both pilots reported a pre-flight quantity of about 45-50 litres of fuel on board. However, due to the non-standard scale, unapproved fuel calibration (combining the main and reserve quantities) and lack of other fuel quantity verification methods, the accuracy of this indicated fuel quantity could not be determined.

The RAAus 2015 Clear mind, clear prop safety publication[17] provided guidance on fuel planning, stating that ‘fuel mismanagement, exhaustion and/or starvation continues to be a major factor in serious and fatal accidents’. The advice provided to their pilots included:

have a clear understanding of the fuel system, including fuel tap positions, cross feeding issues, water drains and a realistic fuel use per hour

flights in the local area may give you a false impression about the number of litres per hour the aircraft uses, because different power settings may be used locally than those flying long distances, and

if fuel planning is not based on confirmed amounts of fuel via dipstick or number of litres added, an engine failure from fuel exhaustion may result, with pilots then having to deal with the extra pressure of an emergency landing.

The fuel valve was likely selected to the reserve tank for the duration of the flight. Due to the design of the tank, the fuel sight gauge would have continued to indicate (in level flight) the remaining 10 litres of fuel in the main tank as the reserve tank was depleted. A casual observation of the fuel gauge while in this condition would not have led to any significant concern about the fuel quantity remaining (10 litres in the main tank and about 10 litres in reserve provided over an hour’s endurance). If the fuel selector was on the main tank for the flight, the same amount of usable fuel would have been available, however the fuel sight gauge would have correctly reflected the depletion of fuel from that tank.

The amount of fuel that could be in the main tank in a nose-up attitude and not available to the fuel outlets was significant and was demonstrated by the unofficial on-ground fuel calibration. Immediately prior to the engine stoppage, the fuel remaining in the selected tank was likely to have been about 6 litres, including up to 4 or 5 litres of unusable fuel. This amount of fuel in the climb attitude of the third circuit, would have likely resulted in the forward-facing fuel outlet being uncovered. This would have introduced air to the fuel lines and engine, leading to the rough running of the engine, as reported by the pilots.

Switching off the electric fuel pump below 1,000 ft, at a height lower than recommended and during a period of increased engine power, may have also introduced low fuel flow to the engine, resulting in the observed rough running. That scenario could not be discounted during the investigation.

Pilot risk assessment

The RAAus 2016 safety publication provides a definition of normalisation of deviance as ‘the gradual process through which unacceptable practice or standards become acceptable. As the deviant behaviour is repeated without catastrophic results, it becomes the social norm for the pilot’. Normalisation of deviance is a known phenomenon in aviation accidents and incidents, where known risks are taken by pilots before and during flight which have no adverse outcome, and eventually become a standard practice.

The normalisation of deviance is not necessarily an intentional violation, but rather part of a series of factors which affect decision making. Orasanu and Martin (1998) discuss the underestimation of risk as ‘if somewhat similar risky situations have been encountered in the past and the crew has successfully taken a particular course of action, they will expect also to succeed this time with the same course of action’.

The two pilots involved in this incident demonstrated the underestimation of risk and associated normalisation of deviance, in many of the risks they accepted in operating the flight, compared to RAAus and CASA best-practice guidance and flight training standards.

Neither pilot was authorised by CASA to operate as pilot in command on the flight in this instance, due to pilot A only holding a RAAus pilot certificate and pilot B not holding a navigational endorsement on their CASA RPL that was required for flights greater than 25 nautical miles from the aerodrome. In addition, pilot B could not be an effective pilot in command from the right seat, nor act as a flight instructor. The two pilots had not communicated effectively about the nature of the flight, their roles in the aircraft, or the roles they were to take in emergency situations. This inadequate communication increased the risk of an unintended outcome of the flight.

Pilot A had limited experience on, and no formal training on, the Europa, which increased his workload during the flight and increased the risk of certain procedures being overlooked. Pilot B had operational knowledge and experience flying BWI but the location of the fuel sight gauge meant that only pilot A could monitor the fuel quantity during the flight. When the engine started to run rough, pilot B believed they had run out of fuel. Pilot A could not recall the fuel quantity remaining prior to the engine trouble, which was consistent with insufficient fuel monitoring practices. Checking that the fuel is selected to ‘MAIN’ is a check listed item in the owner’s manual and on the pilot’s check card. It is possible that, since the fuel lever was reportedly never moved, that this check was overlooked by the pilots.

Meteorological conditions present at the time of the occurrence were conducive to formation of carburettor ice. The extent to which either pilot considered this risk could not be determined. However, the location of the carburettors, at the rear of a warm engine compartment and the high power setting at take-off reduced the risk of carburettor ice formation. Therefore, while the formation of ice in the carburettors and its associated effect on engine performance remains a possibility, it was found to be unlikely in this occurrence. In any event, pre-flight assessment of the conditions and alertness to early indication, combined with a prompt and effective response can reduce the risk of carburettor ice affecting engine operation.

It is likely that both pilots were experienced in flying local flights in their own aircraft during benign weather conditions, without a lot of abnormal challenges to the flight. The ATSB Avoidable Accidents Booklet 6: Experience won’t always save you provided the guidance to pilots that:

A pilot’s total flying experience is not necessarily an indication of good decision-making ability. In some instances, that experience and familiarity can persuade a pilot to take greater risks in the belief that it will enable them to achieve an objective, despite the improbability, that a less experience pilot would not event contemplate.

In addition, the ATSB recommends that owners of amateur-built aircraft should ensure they have adequate training on type before operating newly built or purchased aircraft.

Maintenance

The ATSB has identified instances of misinterpretation and misuse of regulations concerning the maintenance of amateur-built experimental aircraft in a number of occurrence investigations. In several instances, the regulation breaches were identified as contributing to those occurrences.

This investigation identified multiple occurrences of uncertified and unauthorised maintenance having been conducted on BWI. In addition, the flight was conducted on an uncertified and unauthorised maintenance release and details of the flight were endorsed on an invalid maintenance release that had also expired.

It is the responsibility of the person conducting maintenance to ensure it is within the scope and privileges of their authorisation. It is also the responsibility of the aircraft owner and/or pilot in command, prior to each flight, to ensure that all required maintenance has been completed and correctly certified. Undocumented maintenance reduces the information available for others to make informed decisions regarding serviceability of the aircraft. In addition, the use of up-to-date manufacturer documentation is in line with industry best practice to ensure aircraft serviceability and safety of its occupants.

There was insufficient evidence to indicate that the uncertified and unauthorised maintenance directly contributed to this occurrence. However, adhering to regulations and best practice minimises associated risk and increases the likelihood of continued safe operation.

__________

From the evidence available, the following findings are made with respect to the loss of engine power and forced landing involving an amateur-built Europa Classic, registered VH-BWI that occurred near Bridport Aerodrome on 17 July 2016. These findings should not be read as apportioning blame or liability to any particular organisation or individual.

Contributing factors

- Inadequate flight and fuel planning, limited understanding of the fuel system and in-flight management issues led to an unrealised low fuel condition.

- The loss of engine power and forced landing likely occurred as a result of a fuel starvation event.

Other factors that increased risk

- A non-standard fuel gauge scale, combined with an unapproved fuel quantity calibration, increased the likelihood of a misinterpretation of available fuel.

- Uncertified and unauthorised maintenance carried out on VH-BWI increased the risk to flight safety.

Sources of information

The sources of information during the investigation included the:

- Civil Aviation Safety Authority

- Tasmanian Police

- Airservices Australia

- Bureau of Meteorology

- Light Aircraft Association, United Kingdom

- aircraft kit manufacturer

- pilots of VH-BWI

References

Orasanu and Martin, L, 1998, Errors in Aviation Decision Making: A Factor in Accidents and Incidents, Human Error, Safety and Systems Development Workshop 1998

Submissions

Under Part 4, Division 2 (Investigation Reports), Section 26 of the Transport Safety Investigation Act 2003 (the Act), the Australian Transport Safety Bureau (ATSB) may provide a draft report, on a confidential basis, to any person whom the ATSB considers appropriate. Section 26 (1) (a) of the Act allows a person receiving a draft report to make submissions to the ATSB about the draft report.

A draft of this report was provided to the Civil Aviation Safety Authority, the Air Accidents Investigation Branch (UK), the Light Aircraft Association (UK), the aircraft kit manufacturer and the pilots of VH-BWI.

Submissions were received from the Air Accidents Investigation Branch (UK), the Light Aircraft Association (UK) and the pilots of VH-BWI. The submissions were reviewed and where considered appropriate, the text of the report was amended accordingly.

Purpose of safety investigationsThe objective of a safety investigation is to enhance transport safety. This is done through:

It is not a function of the ATSB to apportion blame or provide a means for determining liability. At the same time, an investigation report must include factual material of sufficient weight to support the analysis and findings. At all times the ATSB endeavours to balance the use of material that could imply adverse comment with the need to properly explain what happened, and why, in a fair and unbiased manner. The ATSB does not investigate for the purpose of taking administrative, regulatory or criminal action. TerminologyAn explanation of terminology used in ATSB investigation reports is available here. This includes terms such as occurrence, contributing factor, other factor that increased risk, and safety issue. Publishing informationReleased in accordance with section 25 of the Transport Safety Investigation Act 2003 Published by: Australian Transport Safety Bureau © Commonwealth of Australia 2017

Ownership of intellectual property rights in this publication Unless otherwise noted, copyright (and any other intellectual property rights, if any) in this report publication is owned by the Commonwealth of Australia. Creative Commons licence With the exception of the Coat of Arms, ATSB logo, and photos and graphics in which a third party holds copyright, this publication is licensed under a Creative Commons Attribution 3.0 Australia licence. Creative Commons Attribution 3.0 Australia Licence is a standard form licence agreement that allows you to copy, distribute, transmit and adapt this publication provided that you attribute the work. The ATSB’s preference is that you attribute this publication (and any material sourced from it) using the following wording: Source: Australian Transport Safety Bureau Copyright in material obtained from other agencies, private individuals or organisations, belongs to those agencies, individuals or organisations. Where you wish to use their material, you will need to contact them directly. |

Appendix A – Fuel system additional information

Fuel Tank

The fuel tank installed in BWI consisted of one large polymer tank located behind the pilots’ seat backs. The lower section of the tank had a tunnel in the middle to allow for the passage of flight controls to the aircraft’s empennage. The fuel system components and their locations are shown in Figure A1.

Figure A1: Fuel system components

Source: Manufacturer, modified by the ATSB

The Europa Owner’s Manual stated the aircraft had a fuel capacity of 68 litres.[18] The left side of the tunnel was identified by Europa as the main tank and the right side of the tunnel was identified as the reserve tank. The amount of fuel contained in the main tank side of the tunnel was about 10 litres and the reserve side about 9 litres, depending on aircraft build.

Fuel was drawn from each tank separately and flow to the engine was controlled by the tank selector valve. Fuel flow was provided by the engine driven ‘mechanical’ pump and an ‘electric’ fuel boost pump, which was located in the centre console, downstream of the fuel selector valve (Figure A1). The fuel tank outlets were located on the forward face of the tank, on each side of the tunnel, approximately near the tank base. The holes for the outlets are moulded-in bosses that are drilled open by the builder before the tank is fitted to the airframe. The height of the outlets above the fuel tank base determined the unusable fuel quantity.

Europa reported that when the fuel level was below the tunnel it was possible for fuel to ‘slosh around’ between the main and reserve, as there were no tank baffles. Additionally, the fuel tank outlets were oriented high during take-off and other ‘nose up’ aircraft attitudes. These conditions could result in 4 or 5 litres per tank being unavailable to the fuel outlets. The unusable fuel quantity could vary between aircraft, depending on the differences in each build, turbulence and aircraft attitude.

The fuel system included a fuel sight gauge, located forward of the fuel tank, on the left side of the centre console, under the instrument panel. That sight gauge was a clear polyurethane tube that was directly connected to the main tank outlet. There were no other fuel quantity indicators installed on the fuel system of BWI. A schematic of the fuel tank and associated fuel sight gauge is shown at Figure A2.

Figure A2: VH-BWI fuel tank schematic (not to scale), as viewed from the rear of the aircraft. The reserve tank is shown shaded and the remainder is the main tank.

Source: ATSB

The fuel system was designed so that the fuel level in the sight gauge was a direct reflection of the fuel available in the main tank, when the aircraft was in a level attitude. If the fuel selector was moved to the reserve tank position, the fuel sight gauge would only indicate correctly until the fuel level reached the level of the top of the tunnel, where the gauge would continue to indicate the amount of fuel remaining in the main tank only. A placard located on the instrument panel advised the pilot to land the aircraft within 15 minutes of selecting the reserve tank (Figure A1).

The placement of the fuel filler was such that it ensured the reserve tank was completely filled before fuel became available to the main tank. The fuel filler line had a number of turns in it, preventing a visual or dipstick determination of the fuel level. The fuel sight gauge was therefore the only means to determine fuel quantity, unless the tank was filled to capacity.

Manufacturer’s fuel calibration instructions

When the Europa kit was first introduced, the fuel sight gauge feed line was located downstream of the fuel tank selector valve. Following kit modifications in 1997, the sight gauge feed line was moved to a single location, coincident with the outlet port on the main tank only. Onsite examination of the fuel system of BWI indicated that it had been constructed to the post-1997 configuration. The modifications to the fuel system introduced a modified fuel sight gauge calibration procedure. That procedure accounted for the inability of the fuel sight gauge to indicate available fuel in the reserve tank. The procedure was as follows:

Fuel sight gauge calibration

When the time comes to calibrate the fuel sight gauge, ensure that the valve is positioned to take fuel from the port side of the tank, which is the ‘Main’ side. Set the aircraft level to simulate level flight then pour in sufficient fuel to fill both sides of the tank, 25 litres minimum will be required to do this.

Now empty the port side of the tank only, so that you can calibrate the gauge without the effect of the reserve side filling up causing anomalies. Next, pour in fuel in equal quantities, 5 litres at a time for example. Mark off the gauge after each 5 litres has been added, bearing in mind that due to the tunnel in the tank and the variations in cross-section, the marks will not be equally spaced.

Another point to consider is that, after the fuel has been used down below the top of the tunnel, the sight gauge will indicate the level of the port side of the tank (main) only.

The fuel tank is designed to hold approximately 9 litres of reserve fuel. However, this amount may be reduced in turbulent conditions. There will be a small quantity of unusable fuel.

There was no fuel quantity calibration procedure provided by Europa that would allow fuel quantity indications to be determined for the aircraft while it was in the ground configuration (tail low).

Initial fuel quantity calibration

A fuel calibration was conducted during the aircraft build and was certified by a Licenced Aircraft Maintenance Engineer (LAME). That calibration was recorded in the aircraft logbook and indicated that the usable fuel quantities were 60 litres main tank and 9 litres reserve tank. Following this calibration, a fuel quantity scale was manufactured by the builder and installed behind the fuel sight gauge (Figure A3).

Figure A3: Fuel quantity scale located behind the fuel sight gauge. Four black marks correspond with the Pilot Check Card marks and figures that were developed following pilot B’s fuel calibration.

The scale showed fuel quantity available in 5 litre increments up to 60 litres. Towards the bottom of the sight gauge, the quantities of 20 and 10, and 15 and 5 were displayed in pairs against the same mark on the scale (refer right sections of Figure A3). The figures 5 and 10 represented the quantity of fuel in the main tank. The figures 15 and 20, and the remaining figures on the scale, included the reserve and therefore represented the total fuel on board. For example, when the scale indicated 30 litres, only 20 litres was available in the main tank and the fuel valve would need to be selected to access the remaining approximately 10 litres from the reserve.[19] The ATSB was advised that Europa intended the fuel quantity scale show fuel in the main tank only. There was no advice on or near the scale qualifying this non-standard method of indicating fuel quantity. In addition, there was no method of monitoring fuel level in the reserve, and this was highlighted by the instrument panel placard advising to land with 15 minutes of selecting reserve (Figure A1).

Fuel system modification and recalibration

Pilot B reported to not fully understanding the fuel system on BWI. In addition, pilot B noted that there was no method of determining the amount of fuel in the tank while the aircraft was on the ground in a tail‑low attitude. Pilot B therefore conducted another fuel calibration, shortly after purchasing the aircraft. However, that calibration was not in accordance with the Europa documented procedure. It was also not recorded in the aircraft logbook and the calibration figures noted within the aircraft. Pilot B’s method of calibration involved draining both sides of the fuel tank and then adding fuel in five litre increments. They reported that it took the addition of about 35 litres of fuel to the tank before the sight gauge displayed a fuel quantity.

Marks equal to the incremental fuel amounts were drawn on the bottom of the fuel sight gauge tubing. There were no quantities of fuel recorded on either the tube or scale, however corresponding marks were annotated ‘35’, ‘40’, ‘45’ and ‘50’ on the back of the aircraft checklist card. The intent was to align the card with the black marks on the sight gauge tubing, which would then indicate the on-ground fuel quantity in litres. It was also noted that the words ‘ON GROUND’ were included next to the marks on the card (Figure A3).

The lowest mark of ‘35’ was adjacent to the original 5 litre (main tank) scale indication. This clearly demonstrated the significant quantity of fuel that could move toward the rear of the tank in nose up (tail-low) attitudes. As both sides of the tank were drained prior to the calibration, the 35 litres also included the reserve tank volume, however it was unclear if this was taken into consideration, based on the on-ground marks.

Fuel tank selection

The fuel valve was located inside the central console, between the two pilot seats. It was accessible via an easy to remove cover. It was a manually operated valve with the handle also representing the pointer. A schematic of the fuel valve, placard and associated hoses in VH-BWI is detailed below in Figure A4.

Figure A4: Schematic of fuel valve, placard and associated flexible hoses.

Source: ATSB

There were two positions marked OFF, either of which would stop fuel flow to the engine. These are marked ‘Off – A’ & ‘Off – B’ in Figure A4. To access all usable fuel on board, a positive change of tank from main to reserve, or vice-versa was required. Post-accident examination of the fuel selector valve by the ATSB revealed no abnormalities with the system and that the placard correctly depicted the valve positions.

It was noted that the hose from the main tank to fuel valve was looped around the valve. This was not a Europa-defined arrangement and the reason for it was not determined. It was also noted that if using only the valve handle and hose orientation as a guide, it would be possible to misinterpret the system. This was because the handle orientation was unrelated to the hose supplying fuel.

Pilot B had a copy of the Engine Installation Manual (1995), which he subsequently passed to the new owner. The fuel system diagram in the manual indicated that the main tank was on the right side. This could have further contributed to any confusion around the fuel system and fuel valve. Up to date technical publications were freely available on the Europa Aircraft website.

Pilot B reported that the only time they moved the fuel valve was to conduct the unapproved fuel calibration. Neither pilot reported moving the fuel tank selector during the flight or could positively recall which fuel tank had been selected prior to the engine issue. Pilot B reported that he moved the fuel selector 90 degrees from one tank to the other, following the engine issue. Pilot A reported that he moved the fuel tank selector 180 degrees, to the OFF position, following the accident, as directed by emergency services to isolate the fuel system and render the aircraft safe. Post‑accident examination of the fuel tank selector found it in the ‘Off – A’ position (Figure A4). Based on this, the fuel selector was likely to have been in the reserve tank position for the flight.

Fuel records

Pilot B reported that they did not keep fuel records versus flight times as a method of determining fuel consumption rates. They indicated that they always flew with more fuel than was required for the flight and added fuel to the aircraft as required. The fuel quantity on board was generally reported to be a maximum of 50 litres, using the on-ground calibration marks.

Many of the flights undertaken were about an hour or less and generally did not involve cross country flying. Pilot B reported their normal planned fuel consumption for the aircraft was about 13 litres per hour. The owner’s manual advised that an indicated cruise speed of 120 kt would result in a typical fuel burn of about 18-20 litres per hour. The manual also stated an ‘economy cruise’ of about 100 kt could result in a fuel burn of 11-12 litres per hour. The pilot’s logbook and aircraft maintenance release did not record a significant flight, near the maximum endurance of the aircraft (about 4.4 hours before needing to access reserve fuel). It was therefore likely that pilot B had never operated BWI with flight times and fuel quantities that would have revealed any issues with interpretation of the unapproved fuel calibration.

When the aircraft was sold, pilot B reported that they stopped adding fuel to the aircraft as it was no longer their aircraft. As refuelling records were not kept, the investigation was unable to determine when the aircraft tank was last filled to full. The last reported fuel addition was about 20 litres (after the last flight, about a month before the accident). That amount was reported to not have filled the tank.

Accident flight fuel usage

Both pilots reported that the pre-flight fuel quantity on board was between 45-50 litres, using the on-ground fuel calibration marks, and that fuel was not added to the aircraft during pre-flight preparation. The pilots also indicated that the engine had been run on the ground for about 10‑15 minutes before the flight commenced. Pilot A reported that the engine hour meter indicated 100.8 hours when they commenced the flight. The maintenance release recorded the hour meter as 100.4 at the completion of the previous flight. This indicated that the engine had been operated on the ground for at least 0.4 hour (24 minutes) since the last flight. The power settings during this time could not be recalled by either of the pilots, however as the engine was operating it did indicate that fuel was being used.

The engine hour meter read 102.35 following the accident. Therefore, the aircraft had been flying for about 1.55 hours (1 hour 33 minutes). The longer than normal flight time, combined with touch‑and-go induced varying engine power settings and an extra person on board, increased the difficulty of calculating likely fuel burn and flight time remaining.

Additional fuel system maintenance

In 2008 Europa published a ‘highly recommended’ modification to introduce a fuel filter to each tank outlet, before the fuel selector valve. This modification would allow the selection of the alternate tank in the event of a filter blockage, to enable continued fuel flow to the engine. BWI did not have this modification incorporated.

Pilot B reported to replacing the sole fuel filter, with a locally purchased automotive type. This maintenance was not certified in the aircraft logbook. The Europa recommended PRO 805 filter was cleanable and encased in transparent toughened glass. It reportedly filtered to 52 micron and had a maximum pressure of 7 psi. The automotive Ryco Z200 filter was reported to filter at a nominal 6-7 micron. Use of a non-standard filter could inadvertently affect fuel system operation. The filter element was examined by the ATSB and found to contain debris in the form of fine dust. The amount of debris in this instance was not considered to be sufficient for filter blockage. However, if left unchecked, accumulation of debris in the original single filter installation, had the potential to interrupt fuel flow to the engine.

Pilot B also reported to conducting a ‘five year’ replacement of rubber hoses and fitment of heat resistant sheathing to fuel and oil flexible hoses.[20] This maintenance could not be verified due to the absence of corresponding logbook certification.

__________

- ATSB verification of fuel tank quantities was not within the scope of this investigation.

- The scale indication of 10 litres in the reserve was not consistent with the fuel calibration figure of 9 litres and Owners Manual statement of 8 litres. In this instance however, as the ‘in use’ reserve fuel quantity is not indicated and there is a placard advising to land within 15 minutes of selecting reserve, this difference is considered acceptable.

- All flexible hoses have a finite life. CASA Airworthiness Bulletin (AWB) 02-006 recommends replacing engine compartment hoses at 5 year intervals and airframe hoses every 10 years, unless otherwise indicated by the manufacturer. AWBs can be viewed at www.casa.gov.au