At 1110 Eastern Standard Time on 12 May 2005, a Eurocopter EC120B helicopter, registered VH-ADC, departed Canberra for Jindabyne, NSW, with the pilot and two passengers. The pilot reported that about 30 minutes after departure, while in cruise flight at 5,000 ft above mean sea level (AMSL) in smooth flying conditions, the main rotor speed (NR) RPM audio warning sounded1. The pilot reported that a scan of the instrument panel revealed that the NR was exceeding 450 RPM and that he then lowered the collective pitch lever. He reported that after entering an autorotation configuration, it took approximately 5 to 7 seconds to arrest the high NR rate by lifting the collective lever, which then reduce the NR and silenced the audio warning2.

The pilot further reported that he completed a left turn towards a cleared area and lined the helicopter up on a north-easterly heading, while rapidly losing altitude before turning towards the south-east over trees to the clearing. The pilot flared the helicopter for landing, but noted no perception of power from the engine (audible or torque) and the helicopter sank through the flare before it impacted the undulating ground. It then bounced back into the air momentarily, before it impacted the ground once more and slid to a halt. The pilot then applied the rotor brake to stop main rotor rotation and assisted the passengers to exit the helicopter. There were no injuries to the passengers and only minor injuries to the pilot. The elevation at the final resting place of the helicopter was about 4,340 ft AMSL.

The helicopter was determined to be within weight and balance limits and carried sufficient fuel for the flight.

The helicopter sustained damage to the main rotor blade tip caps, front skid landing gear, front bottom canopy and aft upper tail cone/fenstron area. During the landing sequence, the main rotor blades had contacted the aft upper tail cone/fenstron area as a result of the flaring of the helicopter. The initial impact ground scars of the helicopter skid landing gear were reported to have been about 35 m from the final resting place of the wreckage.

At the time of the occurrence, the helicopter had accumulated 195.9 hours total airframe time. The Turbomeca model Arrius 2F engine, serial number 34039, had been installed on 28 February 2005 with 736.8 hours time since new. At the time of the accident, the engine had accumulated 775.0 hours time since new. The engine was a replacement engine that had been provided by the engine manufacturer while the original engine was being repaired.

The original engine had been removed for an unrelated over-torque event. An examination the helicopter's operational and maintenance records conducted by the Civil Aviation Safety Authority (CASA) found that the helicopter had been maintained correctly and satisfactory records maintained.

Following the accident, the engine was removed and shipped to the engine manufacturer for testing, disassembly and examination under the supervision of the Bureau d' Enquetes et d' Analyses of France, on behalf of the Australian Transport Safety Bureau. The engine was placed into a test cell and operated to confirm operating parameters. The engine was tested through all operating parameters without any abnormal vibrations, high temperatures, overspeeding or other anomalies. The fuel control unit was then removed and bench tested with no anomalies found. Testing, disassembly and examination of the engine did not reveal any anomalies that could have contributed to the in-flight shutdown as reported.

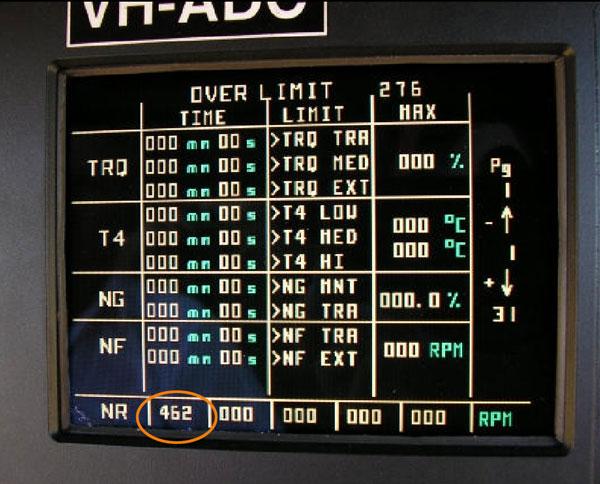

The helicopter's on-board diagnostic equipment was accessed immediately following the event. The maintenance page of the equipment displayed only a fault code indicating that an over limit NR event to 462 RPM had taken place. No other faults were displayed.

The rotorcraft flight manual included a section entitled ENGINE FLAME-OUT, which detailed procedures in the event of an engine flame-out in cruise flight including:

AUTOROTATION PROCEDURES OVERLAND

- Collective pitch…………REDUCE to maintain NR in green arc.

The rotorcraft flight manual also included a section entitled ENGINE GOVERNOR FAILURE which detailed emergency procedures for a rapid increase in NR as follows:

NR INCREASE

Simultaneously to maintain NR in green arc:

- Collective……………….INCREASE

- Twist Grip………………SLIGHTLY REDUCE

NOTE

During the flight, the pilot shall control NR using the twist grip.

The rotorcraft flight manual did not include procedures specifically related to a sudden increase in NR during cruise flight. However, the CASA requirements for the granting of a helicopter licence require a pilot to demonstrate the ability to control NR within rotorcraft flight manual limits. During this training, pilots are taught to control the NR utilising both the collective lever and the throttle twist grip.

- An intermittent tone activated at 420 RPM NR. Normal operating range for NR was 390 to 415 RPM, the caution range was 415 to 447 RPM with 447 RPM the maximum with power off.

- Increasing collective pitch of the main rotor blades using the collective pitch lever reduces the NR by slowing down the rotational speed of the blades for that given engine power setting.