On 30 April 2005, the pilot of a Beech Aircraft Corporation V35A Bonanza aircraft, registered VH-FWE, was conducting a private flight from Lilydale, Vic. to Temora, NSW. The pilot reported that while cruising at 7,500 ft, there was a loss of aileron control. Initially the aircraft tended to drift to the right, which he corrected by rolling the aircraft to the left. He then felt something break and the right wing dropped. He turned the aileron control yoke to the left, until it was almost upside down, but the aircraft continued rolling to the right and entered a progressively steeper descent. The pilot broadcast a PAN1advising air traffic control that he had an aileron control problem and that he would attempt to land the aircraft on a local glider field. He reported that he arrested the roll by extending the landing gear, adjusting engine power and applying full left rudder. The pilot subsequently landed the aircraft without the use of wing flaps.

Aircraft

The aircraft was manufactured in 1969 and had recorded 6,154.8 hours in service at the time of the incident. It was maintained in accordance with the applicable maintenance requirements and had a valid Maintenance Release. It had flown approximately 22.9 hours since the last periodic inspection completed in March 2005.

Aileron control examination

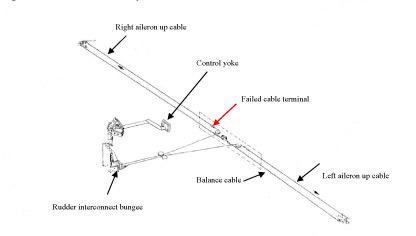

When examined, the aircraft's left aileron was found deflected to the fully down position and the right aileron fully up. To return the ailerons to their neutral position, a force was required to overcome the tension of the rudder interconnect bungee spring. Once the force was removed, both ailerons returned to the fully deflected positions. The examination of the aileron control cables revealed that the right aileron 'up' cable terminal, located in the rear spar carry through structure, had failed.

The aircraft manufacturer advised that since the aileron control cables are connected to the rudder interconnect bungee spring, the separation of the right aileron up cable would result in that spring forcing the left aileron down and the right aileron up (Figure 1).

Figure 1: Aileron control system

Terminal examination

The failed control cable terminal was sent to the Australian Transport Safety Bureau (ATSB) for examination. The terminal shaft that is screwed into the turnbuckle had fractured close to the locking wire attachment point (Figure 2). The examination revealed that the fracture was initiated by stress corrosion cracking2 that had propagated under the surface of the shaft and weakened it to the point of failure.

Figure 2: Failed control cable terminal

The cable terminal was a standard swaged fitting designated AN669. Chemical analysis of the material showed that its composition closely matched that of SAE-AISI 303 stainless steel. A recent US National Transportation Safety Board (NTSB) Safety Recommendation3 identified SAE-AISI 303 stainless steel as being susceptible to stress corrosion cracking when used in a corrosive environment. The Safety Recommendation mentioned that cracking propagates as a function of the time a component is exposed to the corrosive environment rather than its actual time in service and that 'about 18 to 20 years is required for terminals exposed to the most damaging environment to reach their fracture point'.

Terminal inspection

During routine aircraft maintenance inspection of control system cables, corrosion pits on the surface of the cable terminal shaft may be the only visual indication of a potential problem. With the shaft area being typically wrapped with safety wire, the shaft can be difficult to inspect.

In August 2001, The Civil Aviation Safety Authority (CASA) issued Airworthiness Bulletin 27-1 Issue 1, Control Cable Terminal Inspection that was also published on the CASA web site www.casa.gov.au. The Airworthiness Bulletin provided information regarding the susceptibility of control cable terminals made of SAE-AISI 303 stainless steel to failure due to stress corrosion and highlighted the 'importance of meticulous inspection of the terminals'. It recommended that aircraft older than 15 years, and using terminals constructed of SAE-AISI 303 stainless steel, should have their control cable terminals visually inspected on an annual basis.

A review of the aircraft's logbooks found no evidence of the aileron controls having been subjected to any specific inspections to detect corrosion, including the removal of lock wire, within the previous 15 years. Routine maintenance inspections had been conducted during that period.

Both the ATSB and CASA databases contained four reports of similar control cable terminal failures in the period between 1995 and 2004. The NTSB Safety Recommendation mentioned 10 instances of aircraft that were found having fractured or cracked control cable terminals.

- PAN is a radio code indicating uncertainty or alert.

- A cracking process that requires the simultaneous action of a corrosive environment, such as a chlorine-rich atmosphere in moist coastal areas, and sustained tensile stress.

- US National Transportation Safety Board Safety Recommendation A-01-6 through -8 of April 16, 2001.