On 17 February 2005, a Boeing Company 737-838 aircraft, registered VH-VXN, with seven crew and 150 passengers, was being operated on a scheduled passenger flight from Adelaide, SA to Sydney, NSW. The crew reported that, as the aircraft was climbing through flight level (FL) 180 (18,000 ft), they noticed the stabiliser trim wheel moving opposite to the direction of the control column (elevator) movement.

The pilot in command was the handling pilot for the sector and was manually flying the aircraft when the movement was observed. The crew considered that the trim movement was uncommanded and consequently completed the non-normal procedure for a runaway stabiliser. As the non-normal checklist did not contain the words 'Plan to land at the nearest available airport', the crew levelled the aircraft at FL270 and continued the flight to Sydney.

Following the occurrence, a built in test equipment check was carried out on the flight control system and no faults were found. The two flight control computers were subsequently removed from the aircraft and tested at the operator's avionics workshop with no faults being found in either unit.

Previous flight

A different flight crew operated the aircraft on the preceding flight to Adelaide. That crew reported uncommanded stabiliser trim wheel movement while the aircraft was being taxied to the terminal, after landing at Adelaide. The crew also reported that when the aircraft was shutdown, the autopilot warning horn sounded. They did not notice any autoflight flight director system status annunciations on their respective Electronic Attitude Director Indicator (EADI), nor did they observe the illumination of the autopilot disengage indicator lights on the pilot and copilot instrument panels when the warning horn sounded. The operator's engineering personnel were advised about the apparent uncommanded movement of trim. A built-in test equipment check was subsequently carried out prior to the flight to Sydney but no fault was detected in the flight control system.

Stabiliser trim

The horizontal stabiliser is positioned by the main electric trim motor and is controlled through either of the stabiliser trim switches on each pilot's control column, or by the autopilot trim servo motor. The stabiliser may also be positioned by manually rotating the stabiliser trim wheels located on the control stand between the two pilots.

Pitch control of the aircraft includes a speed trim system. This system is used to improve flight handling characteristics during operations with low gross weight, rearward centre of gravity and high thrust when the autopilot is not engaged. The system provides positive speed stability characteristics to the pilot by adjusting the control column force so that the pilot must provide a significant amount of 'pull' force to reduce airspeed, or a significant amount of 'push' force to increase airspeed. The system trims the stabiliser in the direction calculated to provide the pilot positive speed stability characteristics. Since pilots typically attempt to trim control column force to zero and the speed trim system attempts to trim to positive stick force, the speed trim system operation may be opposite to the direction the pilot is trimming.

Autopilot flight director system

The autopilot flight director system is a dual system consisting of two individual flight control computers and a single mode control panel. The two flight control computers are identified as 'A' and 'B'. For autopilot operation, the computers send control commands to their respective pitch and roll hydraulic servos, which operate the flight controls through two separate hydraulic systems. For flight director operation, each computer positions the flight director command bars on the respective EADI located on the instrument panel for each pilot.

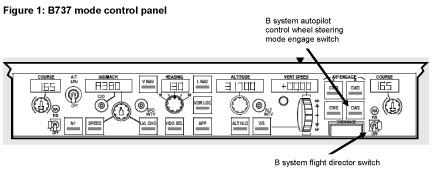

Either autopilot can be engaged in command mode or control wheel steering mode by pushing the appropriate engage switch on the mode control panel, which is located on the glare shield in front of each pilot (Figure 1).

If the autopilot flight director system is engaged in control wheel steering mode, the following system status annunciations will appear above the attitude indications on each pilot's EADI:

| FD |

(the flight director is ON and the autopilot is either OFF or engaged in control wheel steering mode) |

| CWS P |

(the autopilot is engaged in control wheel steering pitch mode) |

| CWS R |

(the autopilot is engaged in control wheel steering roll mode) |

Flight data recorder information

Following the occurrence, data from the aircraft's flight data recorder (FDR) was downloaded and analysed by the aircraft manufacturer and the Australian Transport Safety Bureau (ATSB). The data indicated that during the previous flight the autopilot was engaged after landing at Adelaide. The autopilot was engaged by pushing the control wheel steering mode autopilot engage switch for the 'B' autopilot flight director system. The autopilot engagement occurred when the 'B' system flight director switch was selected to the OFF position while the aircraft was taxiing to the terminal. The flight director switches are usually selected to the OFF position by the crew while carrying out the 'taxi in' normal procedures when the aircraft has vacated the runway after landing.

The 'B' system flight director switch and the control wheel steering engage switch are in close proximity to each other on the glare shield mode control panel, above the centre instrument panel (Figure 1).

The data showed that various up and down trim movements were commanded by the autoflight flight director system following engagement of the control wheel steering mode after landing at Adelaide. The data also showed that the 'B' autopilot flight director system remained engaged when the FDR recording ended for that flight. The aircraft manufacturer advised that 'it is expected that it [the autopilot] disengaged later on (with warning horn) when additional power switching or configuration changes occurred.' The aircraft operator advised that the autopilot would have disengaged when the engines were shutdown and the electrical power source to the autoflight flight director system transferred from the engine driven generators to the auxiliary power unit driven generator.

The aircraft manufacturer also advised that, from their review of the FDR data, 'no trim anomalies could be seen on the following climb out [the occurrence flight]'.