FACTUAL INFORMATION1

Sequence of events

At about 1512 Western Standard Time on 18 January 2005, a Beech Aircraft Corp B200 (Super King Air) aircraft, registered VH-SGT, sustained damage when its main landing gear collapsed during touchdown on runway 24 at Perth Airport, WA.

The aircraft had earlier departed the aerodrome on a charter flight with one pilot and seven passengers on board. Shortly after take-off, the pilot selected the landing gear up and subsequently observed that the red 'gear-in-transit' warning light remained illuminated. An aerodrome controller noticed that the aircraft's landing gear did not retract and passed that information to the departures controller. The departures controller cleared the pilot to climb to 4,000 ft and provided radar vectors to a suitable area where the pilot could complete troubleshooting of the aircraft systems.

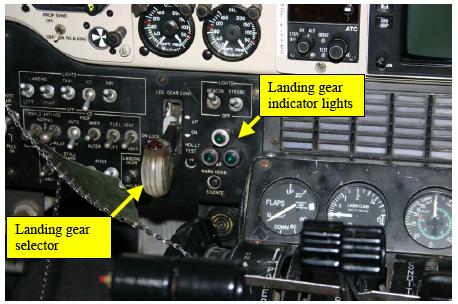

The pilot completed the checklist actions contained in the Aircraft Flight Manual in an attempt to manually extend the landing gear. That included pumping the manual extension lever to its maximum resistance. However, the green 'gear down' indicator lights did not illuminate2 (Figure 1).

Figure 1: Landing gear selector and landing gear indicator lights

The pilot returned to Perth Airport and conducted a flypast of the aerodrome control tower and maintenance facility at an altitude of about 500 ft. Engineer and air traffic control witnesses to that flypast indicated to the pilot that the landing gear appeared to be in the extended position.

During the subsequent landing, the right main landing gear collapsed and retracted into the wheel well. The left main landing gear partially retracted into the wheel well and the nose gear remained extended (Figure 2). The right engine nacelle fuel tank was punctured, requiring removal of the remaining fuel in that tank prior to the aircraft's removal from the runway.

Figure 2: Aircraft on the runway after landing

Abrasive damage was sustained to the rear right side of the lower aircraft fuselage skin and structure, the right-wing flap and gear doors and rear fairing of the right engine nacelle. The extended nose landing gear and partially extended left main landing gear prevented significant damage to other parts of the aircraft's structure. There was no post-impact fire.

Aircraft information

An approved maintenance organisation carried out end play checks on the left and right main landing gear screw jack actuators during routine maintenance on 7 January 2005. Following those checks, each actuator was disassembled for lubrication, reassembled and refitted to the aircraft. That required the removal and reinstallation of each actuator's thrust bearing. The aircraft maintenance manual included a requirement to recheck the actuators' end play following their reassembly, to verify the correct installation of the thrust bearings.

The aircraft was released from maintenance on 11 January 2005 and completed six flights without incident between 11 and 13 January. On the seventh flight following that maintenance, the landing gear failed to retract normally. In that instance, the pilot manually extended the landing gear and landed without incident. Maintenance troubleshooting following that flight revealed that the 60 amp circuit breaker for the landing gear's electric motor had tripped3. The aircraft's maintenance records indicated that the circuit breaker was reset, and the landing gear was re-rigged and functionally tested. The system was certified as being serviceable and the aircraft was returned to service. During the subsequent flight, flown by the same pilot, the landing gear collapsed.

The aircraft operator examined the aircraft's landing gear system following the accident. The examination identified that the landing gear electric motor's 60 amp circuit breaker had again tripped. In addition, disassembly of the screw jack actuator for the left main landing gear revealed:

- an incorrectly installed thrust bearing4

- an unseated upper bearing

- damage to the inner pinion bearing

- displacement of the pinion within its housing

- cracks and shearing of the pinion gears.

That damage significantly increased the torque required to rotate the actuator during either electrical or manual extension of the landing gear.

A component overhaul facility bench tested another screw jack actuator with a similarly incorrectly installed thrust bearing under the supervision of an airworthiness inspector from the Civil Aviation Safety Authority. That actuator displayed abnormal squealing and grinding noises during operation, and an increased amount of torque was required to rotate the screw jack. The test report indicated that the increased operating loads had unseated the incorrectly installed thrust bearing, which allowed the transfer of the load normally carried by the thrust bearing to the pinion gears, causing binding and abnormal operating noise.

Survival information

Either a pilot in command or the responsible Air Traffic Services (ATS) personnel can declare a Local Standby condition in response to a problem, or potential problem affecting the operation of an aircraft. The effect of such a declaration is to activate an airport's Rescue and Fire Fighting (RFF) services and other relevant agencies in accordance with the airport's Aerodrome Emergency Plan.

In this occurrence, neither the pilot in command nor ATS personnel declared a Local Standby condition. However, because the pilot was returning for an unplanned landing, and had requested a visual check of the landing gear, the aerodrome controller advised the RFF personnel of the developing situation. The RFF personnel responded by boarding their vehicles in preparation for a possible emergency response.

- Only those investigation areas identified by the headings and subheadings were considered to be relevant to the circumstances of the occurrence.

- The illumination of those lights would have confirmed the successful extension of the landing gear.

- During normal operations, the landing gear's electric motor provided the torque to rotate the landing gears' screw jack actuators to extend the aircraft's landing gear.

- It is essential to correctly install the thrust bearing to ensure that the bearing resists axial loads along the actuator's shaft. The bearing is appropriately marked to assist with correct installation.