The Aviation Safety Investigation Report 200402669 on the fatal accident involving a Bell 47G-3-B-1 helicopter registered VH-RTK which occurred 12km west of Wodonga, Vic. on 19 July 2004. The aircraft was on an aerial agriculture mission when it collided with a powerline. There have been related safety actions from CASA, the Aerial Agriculture Association, and the upcoming ATSB research report on wirestrike accidents.

Sequence of events1

On 19 July 2004, the owner-operator pilot of Bell Helicopter Company 47G-3B-1 Soloy2 helicopter, registered VH-RTK, was contracted to spray herbicide on a property near Wodonga, Victoria.

Early in the day, the pilot and the company operations manager met with the property owner to discuss the proposed work. The discussion included the identification of known powerlines, other hazards, and sensitive areas likely to affect the operation. Shortly before the discussion, the operations manager showed the pilot the known primary powerlines in the general area where the spraying and loading was to be conducted.

Later that morning, the loader/driver of the chemical and re-fuelling truck arrived at the proposed replenishment point. The pilot positioned the helicopter at the replenishment point at about midday and commenced the final preparations for the day's spraying operations. The preparations included an aerial survey, in the company of the property manager, of the areas to be sprayed. During that flight, the property manager indicated to the pilot the areas that were free from powerlines, including a valley that he considered a safe transit zone between the replenishment truck and the proposed spray area.

The pilot commenced spraying operations on the occurrence property at about 1458 Eastern Summer Time. Shortly before 1512, the property manager heard the helicopter returning to the replenishment point from an unexpected direction and not from the direction of the identified safe transit zone.

The property manager reported that he observed some 'glitter' emanate from the helicopter, before it then descended and disappeared into heavily timbered terrain. No radio broadcasts were made by the pilot to air traffic services, or to the loader/driver to signify that an emergency had occurred.

The helicopter impacted terrain about 860 m to the south-west of the replenishment point, and was destroyed by impact forces. The pilot, who was the sole occupant, was fatally injured. There was no fire.

The loader/driver notified the company operations manager, then commenced to search for the helicopter. The company operations manager notified emergency services, and they arrived at the accident site about 20 minutes later.

A two-cable electric powerline was found severed at a point approximating that at which the property manager reported seeing 'glitter' come from the helicopter. There was no other property damage.

The powerlines struck by the helicopter during the approach to the replenishment point consisted of two parallel three-strand lightweight high-tensile steel cables, each of 2.75 mm diameter. The powerlines had been erected several years previously, and were located on the north-eastern side of a ridgeline, strung across the direct track from the last treatment area to the replenishment point.

The powerlines were not depicted on the relevant aeronautical or topographical charts. They were not connected to the power supply grid and had developed a dull oxidised finish. No high visibility devices were attached to the powerlines, and nor were they required to be.

Personnel information

The pilot was reported to have been fit, well and adequately rested prior to the flight, and he was appropriately qualified and endorsed for the agricultural operation in the helicopter.

Helicopter information

The investigation found that the helicopter was certified, equipped, and maintained in accordance with existing regulations and approved procedures. It was not, nor could it have been, fitted with a wire-strike protection system, nor was there any regulatory requirement for such a system.

No evidence was found of a defect in the helicopter or its systems that may have influenced the circumstances of the occurrence. The weight and balance of the helicopter were within prescribed limits.

The helicopter's perspex windscreen was clean and there was no pre-existing damage, or any obstruction that might have adversely affected visibility from the cockpit. Based on the available evidence, the aircraft was certified, equipped and maintained in accordance with the regulations and approved procedures.

Meteorological information

No evidence was found to suggest that the weather or environmental conditions influenced the circumstances of the occurrence.

Wreckage and impact information

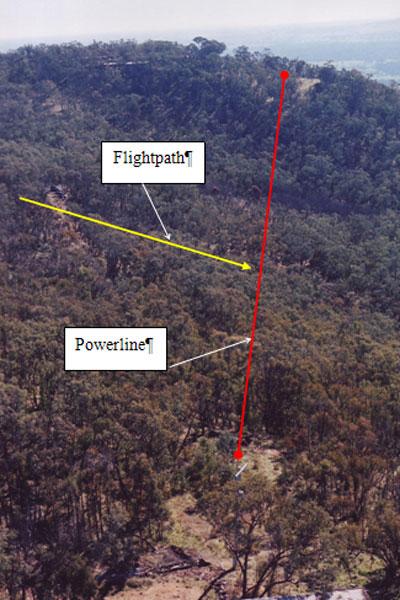

The powerline that was struck lay approximately perpendicular to the helicopter's flightpath from the spray area to the replenishment point (see Figure 1). The powerline was supported by two poles, 669 m apart, which were located on heavily timbered terrain. The point at which the powerline was severed by the helicopter was estimated to be about 34 m above the tree tops, and 54 m above ground level.

Figure 1: Aerial view of powerline and approximate aircraft track

The wreckage distribution and damage to the surrounding trees was consistent with the helicopter impacting the ground with significant vertical, but low forward speed.

A trail of shattered perspex commenced in a position approximately underneath the point at which the powerlines had been severed, and extended for approximately 180 m to the point where the helicopter impacted the ground. The perspex corresponded to that used in the construction of the helicopter windscreen. No other helicopter components were found along the perspex trail.

The ground impact point and wreckage were located on steeply sloping and heavily wooded terrain that was covered with dense vegetation and large rocks (see Figure 2). The area was covered with small to medium sized trees, some approximately 12 to 20 m tall. The ground impact scars indicated that the helicopter was in a relatively level attitude at the time of impact, before it slid approximately 13 to 15 m down the sloping ground and collided with a tree.

Figure 2: Helicopter wreckage

Impact damage to the helicopter was extensive. The helicopter lay on its deformed left side with the cockpit left side panel, the firewall, and the seat assembly compressed in a rearward/inward direction. Damage to the cockpit right side panel was less severe and the panel had retained its shape. A limited amount of the shattered perspex windscreen remained with the main wreckage.

There was severe disruption to the cockpit, and the instrument pedestal had been partially severed from the floor and was pushed towards the pilot's seat. The engine, fuel, hydraulic, and flight control systems' components were dislodged from their installed position and damaged, but remained in their respective locations. The engine was recovered from the accident site and transported to an overhaul facility for technical examination under Australian Transport Safety Bureau (ATSB) supervision. The examination revealed that the engine was capable of normal operation at the time of the accident.

The main rotor blades and mast, main transmission, and the remainder of the helicopter's major components, systems, and controls were also accounted for at the accident site, and in close proximity to the main helicopter wreckage.

Both fuel tanks and their respective firewalls dislodged from their installed position and were damaged. That included impact puncture damage to the fuel tanks. While fuel leakage was evident on the ground around the main wreckage, approximately 20 litres of fuel was recovered from the helicopter's fuel tanks for sampling purposes. A fuel sample was also taken from the re-fuelling truck. The results of independent laboratory tests of both samples were consistent and indicated that the Jet Fuel was bright, free from water and considered suitable for use.

The remains of the tail boom structure was bent slightly upwards, and the tail boom assembly had detached from the rear of the centre fuselage frame about 2 m back from that frame. Sections of the tail boom and the tail rotor drive shaft had separated at impact, but remained oriented in the correct position relative to each other. That was consistent with the helicopter having negligible yaw at impact. A small section of the tail boom structure was located down slope from the main helicopter wreckage.

All major components and extremities of the installed agricultural spray equipment were accounted for with the main helicopter wreckage.

The left and right cockpit door frames were deformed just above the upper door hinge, corresponding to about 15 to 20 cm above the top of the instrument pedestal. That included a deep, circular indentation to the right door frame and a partial tear and bulging of the left door frame. The indentation in the right door frame was 'married' to a length of the severed power cables, and the damage was found to be consistent with the cables having impacted with that door frame (see Figure 3). There were no similar deformations or markings to the instrument pedestal, cyclic or other helicopter controls, or any other part of the helicopter.

Figure 3: The cut into the perspex bubble frame matched with the conductor

Medical and pathological information

Based on the autopsy, toxicology, and medical reports, there was no evidence to indicate that the pilot's performance was degraded by physiological factors.

Survival aspects

A four-point restraint harness, with inertia reel shoulder straps was fitted to the pilot's seat. Video footage of the helicopter departing on the accident flight revealed that the pilot had fastened the harness. Examination of the harness at the accident site revealed that it remained attached to the firewall and that there was no evidence of failure of the locking mechanism.

The pilot was wearing a helmet at the time of the occurrence. That helmet exhibited significant impact damage, but remained intact. The helmet visor was found in the raised position.

Agricultural spray computer disk

The hard disk unit from the on-board agricultural spraying computer was recovered. The unit was assessed by the manufacturer's distributor and an external independent forensic expert. Those examinations confirmed that the damage to the unit precluded extraction of the data.

Organisation

Company Operations Manual

Section A19.5 of the company Operations Manual (manual) contained the en-route procedures affecting low flying operations by company pilots. In part, those procedures included that:

…due consideration shall be given to the dangers of unseen wires, effects of turbulence and other low flying hazards. Prior to the commencement of low level operations, the pilot in command shall carry out an aerial survey of the area to establish an optimum path and aircraft manoeuvring plan for the safe conduct of the operation.

An overview of those procedures affecting the conduct of aerial agricultural operations by company pilots was included at Section D 6.1 of the manual. That included that:

Normal aircraft operating procedures are detailed in the relevant Pilot Operating Handbooks, the Aeronautical Information Publication, as well as CAO 20.21, and the Agricultural Pilots Manual (AAAA [Aerial Agricultural Association of Australia Limited] Pilot and Operations Manual). And these should be followed unless specified otherwise below.

Section D 6.5 of the manual reinforced the regulated requirement for an agricultural pilot to conduct an aerial inspection of a proposed treatment area prior to commencing aerial agricultural as follows:

It is a CASA requirement that prior to commencing agricultural operations the pilot shall carry out an aerial inspection of the proposed treatment area - where practicable, a ground inspection will also be conducted as per sub-section D 6.4.

The manual continued that the pre-treatment aerial inspection was to include the examination of:

…Wires - their location in relation to the boundaries of the area to be treated, height and position of, and distance between poles and guy wires…

Additional information

Previous wirestrike occurrences

A review of the ATSB's accident and incident database revealed that there were six single-fatality agricultural helicopter accidents in Australia during the period 1 January 1995 to 20 June 2005. Those accidents represented 43% of all fatal helicopter wirestrike accidents during the period.

Regulatory framework

Civil Aviation Regulation (CAR) 206 lists agricultural operations as operations conducted for aerial work purposes. Agricultural operations are defined as:

…the broadcasting of chemicals, seeds, fertilizers and other substances from aircraft for agricultural purposes of pest and disease control.

Civil Aviation Order (CAO) 40.6 defines the requirements of the Agricultural Pilot Rating Grades 1 and 2. Those requirements include completion of a period of ground training and a written exam, before carrying out initial and operational flying training. The operational flying training includes operational planning, such as: ground and aerial inspections of the treatment area; assessment of wires; and route selection to and from the treatment area, including the height to fly during such transit flights. That training is to be followed by a period under supervision, before the newly rated agricultural pilot is able to conduct unrestricted agricultural operations.

Aerial Application Pilots Manual3

Chapter 5 of the Aerial Application Pilots Manual contains information pertaining to the identification of powerlines and other low flying hazards with the potential to affect agricultural operations. Chapter 8 of that manual outlines the information specific to helicopter agricultural operations. Those chapters elaborate on the recommended pre-flight planning and inspections that should be carried out by a pilot prior to the conduct of agricultural operations, including that:

If the pilot is obliged to rely on a farmer briefing regarding wire hazards, a thorough interrogation of the farmer is necessary to establish the position of concealed wires…

They are seldom aware that wires outside the treatment area can be hazardous to aircraft approaching for a spraying run. Farmers may forget that they recently connected a shed to the power, ran a new overhead wire to a pump or accidentally hooked a powerline with a farm implement and pulled it over 'a bit'.

Considerable effort is needed to extract vital information from the client. Remember there are some wires that you may strike unless the farmer makes you aware of their location.

In addition, sometimes the background to the wires - trees, hills etc. - provides a poor contrast, while poles may be concealed by intervening obstacles or by being located so far to the periphery of the pilot's visual field that they are not noticed.

During climb and cruise to and from the treatment area the aircraft should track as directly as possible consistent with avoiding nuisance areas and poor terrain.

Don't come below possible powerline height until you are certain all wires have been safely identified.

The property manager reported that he was aware of the powerlines that were struck by the helicopter, but that he had not passed that knowledge on to the pilot because they were located outside both the area to be treated, and the safe transit route between the replenishment truck and the proposed spray area.

Risk management

Australian/New Zealand Standard AS/NZS 4360:2004 Risk Management (the Standard) defined risk as:

the chance of something happening that will have an impact upon objectives.

NOTE 1: A risk is often specified in terms of an event or circumstance and the consequences that may flow from it.

NOTE 2: Risk is measured in terms of a combination of the consequences of an event … and their likelihood…

NOTE 3: Risk may have a positive or negative impact.

The Standard described risk management as 'the culture, processes and structures that are directed towards realizing potential opportunities, while managing adverse [or negative] effects'. The risk management method described by the Standard includes that initially the basic parameters or context affecting the assessment of risk should be identified. That can include 'defining the extent of the project activity or function in terms of time and location'. Residual risk is that 'risk remaining after implementation of risk treatment'. Options for modifying or treating identified risks with negative outcomes included:

- influencing the likelihood of a risk, in order to reduce the probability of a negative outcome

- changing the consequence(s) of an event to minimise the extent of any losses.

Detection of powerlines

The requirements for the mapping and marking of power cables and their supporting structures are published in Australian Standards AS 3891.1 1991 Part 1: Permanent marking of overhead cables and their supporting structures, and AS 3891.2 - 1992 Part 2: Marking of overhead cables for low level flying. The general requirements of those standards were discussed in ATSB investigation report 200404286 and include that, in general, there is no requirement for the marking of power cables with a height above terrain, or obstacles of less than 90 m. The power cable that was struck by the helicopter did not require marking in accordance with either standard.

Technical committees are formed by Standards Australia to develop and review relevant standards, and comprise a balance of interested and affected parties that are nominated by generally national organisations. The aim is that the standards should include consideration of the views of large, common interest groups. Organisations that consider they represent a valid, previously unrepresented interest group are able to nominate for consideration for inclusion in a committee.

A number of aviation industry associations and other bodies were involved in the development of the Australian Standards affecting the marking of overhead power cables and their supporting structures. That did not include some of the groups and associations normally associated with a number of agricultural and other low-level operations.

There are currently a number of engineering solutions available, with the potential to assist pilots identify overhead powerlines. While their suitability or cost-effectiveness may not prove acceptable for all helicopter types or operations, those engineering solutions include, but are not limited to:

- laser-based systems that alert a pilot of approaching electrified powerlines, or that scan the environment for wires and other obstacles

- enhanced ground proximity-based warning systems that include relevant software and an onboard powerline database in order to identify approaching powerlines.

1 Only those investigation areas identified by the headings and subheadings were considered to be relevant to the circumstances of the occurrence.

2 The designation 'Soloy' indicates that the helicopter had been modified and fitted with a turboshaft engine.

3 Version 6 prepared by the AAAA. A significant upgrade of the Aerial Application Pilots Manual was sponsored by the Civil Aviation Safety Authority (CASA).

The damage to the right door frame corroborated the nature and distribution of the damaged perspex windscreen fragments along the wreckage trail and indicated that the helicopter struck the powerlines. The wirestrike was at a position consistent with that at which the property manager estimated he observed ‘glitter’ emanate from the helicopter.

It was likely that following the initial contact with the powerlines, the cockpit windscreen deformed sufficiently to capture the powerlines around the cockpit door hinge area. That would have prevented the powerlines from sliding up the windscreen towards the mast, or down towards the landing gear skids, before severing, and would explain the lack of any powerline damage or markings to the remainder of the helicopter.

The investigation considered whether a helicopter or associated system fault might have been implicated in the circumstances leading to the wirestrike. In that regard, there was no evidence of any technical or other failure of the helicopter or its associated systems prior to the ground impact, and the engine performed normally under test throughout the normal power range. That and the quality and quantity of the fuel remaining onboard the helicopter indicated that it was unlikely that any airframe, engine or system fault had contributed to the accident.

Risk management options for application during an aerial application task include reducing the consequence and/or likelihood of adverse events, such as the helicopter striking a powerline. Those options having the potential to decrease the adverse consequences of a wirestrike include:

- the use of helmets, as worn by the pilot

- if appropriate to the helicopter structure, the installation of wire strike protection systems

- the installation of advanced safety harnesses, such as that in the accident helicopter

- appropriate flight following and search and rescue procedures, as in this case due to the ongoing interaction between the pilot and loader/driver at the replenishment point.

However, as was the case in this accident, the consequence of a helicopter striking a powerline can generally be expected to be severe to catastrophic. As a result, a large investment is generally made by involved parties in order to decrease the likelihood, and therefore risk of a wirestrike. In this instance, that included adherence by the pilot, company operations manager and property manager to those regulatory and company requirements affecting the operation, and application by that group of the relevant content of the Aerial Application Pilot’s Manual to the task.

However, by electing to return to the replenishment point via a direct track, and not via the safe transit zone, the pilot unwittingly altered the context or parameters on which his pre-spray application risk assessment was based. The result was that none of the risk treatments applied to the spray operation and safe transit route were applied to the pilot’s approach to the replenishment point.

In that case, the pilot’s return transit was via an unsurveyed route. The dull surface of the powerlines, the nature of the vegetation and topographical background, the location of the supporting poles and long span of the powerlines would have reduced the likelihood that the pilot might have visually acquired the powerlines in sufficient time to have allowed him to avoid striking them.

The investigation was unable to quantify the effect that the installation of high visibility devices on the powerlines, which were not mandated in this case, might have had in preventing this accident. Similarly, the investigation was unable to assess the potential risk reduction capability of the possible installation in the helicopter of an advanced technology wire detection system.

While the reason for the pilot returning to the replenishment point via a direct track could not be determined, the investigation considered it most likely that the pilot had sought to optimise the efficiency of his operation. For example, if the pilot had exhausted the chemical supply at a position where he could observe the location of the replenishment point on the onboard global positioning system equipment, it might have been natural to ‘pop up’ the hill and fly direct to the truck, rather than conduct a long right turn and fly back through the valley. Had the pilot followed the pre-planned safe transit route, or included the direct route from the treatment area to the replenishment point in his risk assessment, he may not have collided with the powerlines.

CONCLUSIONS

Findings

- The pilot was licensed and qualified for the flight in accordance with existing regulations.

- The maintenance records indicated that the helicopter was equipped and maintained in accordance with existing regulations and approved procedures.

- There was no evidence that engine or airframe failure or system malfunction influenced the circumstances of the occurrence.

- The helicopter’s weight and balance were within prescribed limits.

- There was no evidence that meteorological conditions influenced the circumstances of the occurrence.

- The location of the powerlines was outside the safe transit zone between the designated spray area and the replenishment point

- The powerlines were not marked, nor were they required by the relevant Australian Standards to be marked, with high visibility devices.

- The position of the powerlines was not depicted on the relevant aeronautical or topographical charts.

- The company Operations Manual and Aerial Application Pilot’s Manual included advice on the pre-flight planning, briefings and survey necessary before commencing aerial agricultural operations.

- The pilot conducted a low-level return transit to the replenishment point that was outside the pre-planned safe transit route.

- The pilot did not see the powerline, or did not see the powerline in time to avoid a collision.

Previous relevant safety action

As a result of previous wirestrike occurrence BO/200404285, the following relevant safety actions have been implemented:

Civil Aviation Safety Authority

On 31 January 2005, the Civil Aviation Safety Authority (CASA) convened a round table discussion to consider potential safety activities relating to the conduct of aerial work in proximity to power cables. The participants in that discussion included representatives from relevant industry associations and other bodies and affected Government departments and agencies.

CASA had commenced planning to facilitate a conference in September 2005 involving relevant industry associations and other bodies and affected Government departments and agencies to further progress those safety issues confronting aerial work operations that were identified during the 31 January 2005 round table discussions. However, on 14 July 2005, CASA advised the Australian Transport Safety Bureau that due to funding constraints and minimal financial support from those organisations approached to support the conference, the conference would not go ahead. CASA advised further that the Authority would continue to work with the Aerial Agricultural Association of Australia and other relevant organisations in order to progress the safety issues affecting the potential for wire strikes to occur in the aerial work industry.

Aerial Agricultural Association of Australia Limited

The Aerial Agricultural Association of Australia Limited has nominated to be included in the Standards Australia committee responsible for the development of the standards affecting the mapping and marking of power cables and their supporting structures.

Australian Transport Safety Bureau action

As a result of recent helicopter wirestrike accidents, the Australian Transport Safety Bureau has commenced a research project that is examining wire strikes in the Australian aviation industry. The report is expected to be complete before the end October 2005 and will be published on the ATSB website or be available from the Bureau on request.